Method for preparing room-temperature self-crosslinking water-based polyurethane emulsion

A water-based polyurethane and self-crosslinking emulsion technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve the effects of high elasticity, high hardness, and scratch resistance physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

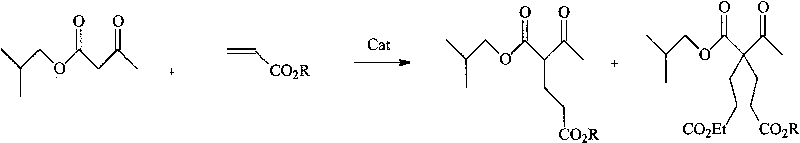

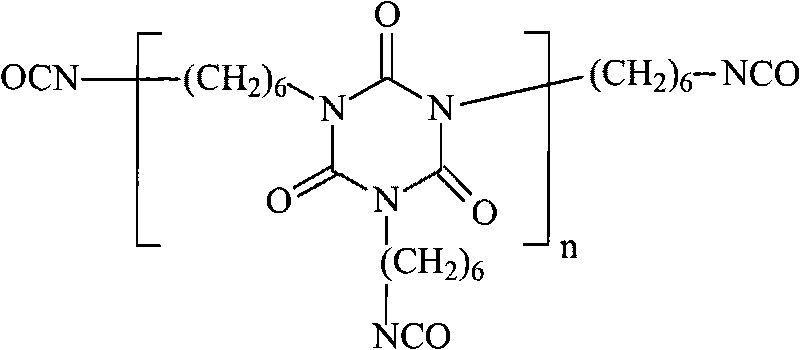

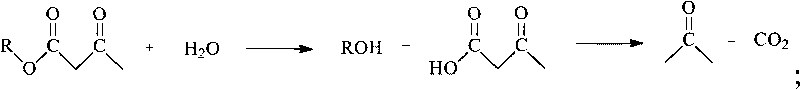

Method used

Image

Examples

Embodiment 1

[0056] 115 grams of Wannate MDI-50 (Yantai Wanhua Polyurethane Co., Ltd., 2,4'-MDI content 45-55%, 2,2'-MDI content is less than 0.5%, the rest is 4,4'-MDI, the same below ) and 150 grams of polypropylene oxide ether glycol PPG1000 with a molecular weight of 1000 were added to a four-necked flask, fed into dry nitrogen, started to stir and gradually warmed up to 70°C, and after 2 hours, the reactant was cooled to 50°C, and 15 grams of 2,2-dimethylolpropionic acid, 10 grams of 1,4-butanediol and 16 grams of pentaerythritol diacetoacetate were kept at a reaction temperature of 60° C. for 2 hours, and 140 grams of acetone was added to reduce the viscosity. Lower the temperature of the prepolymer below 30°C, add 11.5 grams of triethylamine and mix well, use a high-shear disperser to disperse by adding deionized water under rapid stirring conditions, and then add 6.1 grams of ethylenediamine dissolved in water . Finally, the acetone was distilled off under reduced pressure to obta...

Embodiment 2

[0058] Add 115 grams of Wannate MDI-50 and 150 grams of polytetrahydrofuran ether glycol PTMEG1000 with a molecular weight of 1000 into a four-necked flask, pass through dry nitrogen, start stirring and gradually raise the temperature to 70°C, and after 2 hours, cool the reactant to 50°C, divide Add 23 grams of 1,4-butanediol-2-sodium sulfonate, 12 grams of neopentyl glycol and 16 grams of trimethylolpropane monoacetoacetate in batches, keep the reaction temperature at 60°C and continue the reaction for 2 hours, add 140 grams of Acetone reduces viscosity. Lower the temperature of the prepolymer below 30°C, add 16 grams of 25% ammonia water and mix evenly, use a high-shear disperser to disperse by adding deionized water under rapid stirring conditions, and then add 10.9 grams of acetonitrile dissolved in water diamine. Finally, the acetone was distilled off under reduced pressure to obtain a stable room temperature self-crosslinking aqueous polyurethane emulsion.

Embodiment 3

[0060] 115 grams of TDI-80, 120 grams of polybutylene adipate PBA1000 with a molecular weight of 1000 and 30 grams of sodium sulfonate-based glycol (by isophthalic acid-5-sodium sulfonate, adipic acid and 1,4 -Butanediol is produced by condensation reaction, the hydroxyl value is 112mgKOH / g) into the four-necked flask, blown into dry nitrogen, start stirring and gradually raise the temperature to 70°C, after 2 hours, cool the reactant to 50°C, and add 12 gram of neopentyl glycol and 16 grams of pentaerythritol triacetoacetate, kept the reaction temperature at 60° C. to continue the reaction for 2 hours, and added 100 grams of acetone to reduce the viscosity. Lower the temperature of the prepolymer below 30°C, add 16 grams of ammonia water with a concentration of 25% and mix well, use a high-shear disperser to disperse by adding deionized water under rapid stirring conditions, and then add 4.6 grams of bismuth dissolved in water Ethylene triamine. Finally, the acetone was dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com