Silicone composition and lubricating grease

A technology of silicone composition and polysiloxane, applied in lubricating compositions, heat exchange materials, petroleum industry, etc., can solve problems such as resistance to scratches that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Examples and comparative examples are shown below to describe the present invention in more detail, but the present invention is not limited to the following examples. In the following, the average particle diameter of the powder is a volume-based cumulative average particle diameter measured using a particle size analyzer Microtrac MT3300EX manufactured by Nikkiso Co., Ltd.

[0071] Each component used in an Example and a comparative example is described below.

[0072] (A) Ingredients

[0073] (A-1)

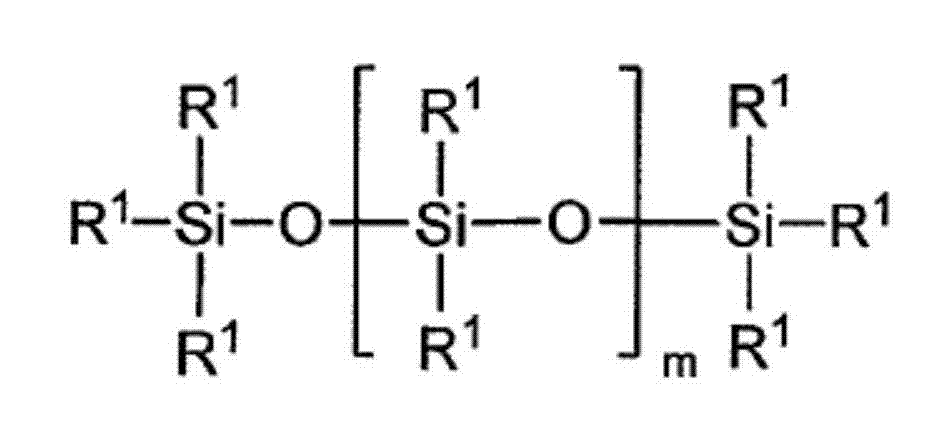

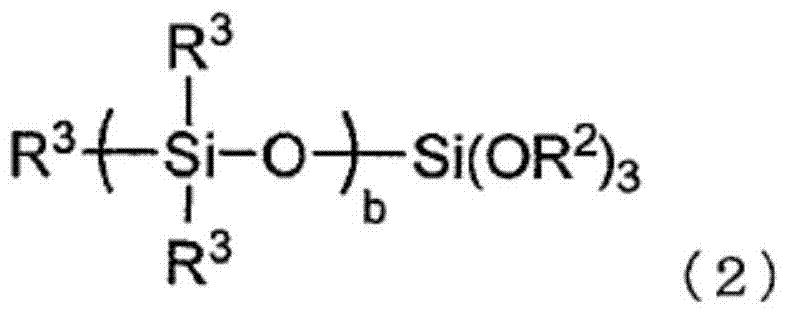

[0074] [Chem 3]

[0075] Dynamic viscosity 5,000mm 2 / s

[0076] (A-2)

[0077] [chemical 4]

[0078] Dynamic viscosity 390mm 2 / s

[0079] (B) Component: thermally conductive filler

[0080] (a) Calcium carbonate powder

[0081] (a-1) Average particle size 1.0 μm

[0082] (a-2) Average particle size 20.5μm

Embodiment 1~ Embodiment 6 and comparative example 1~ comparative example 7

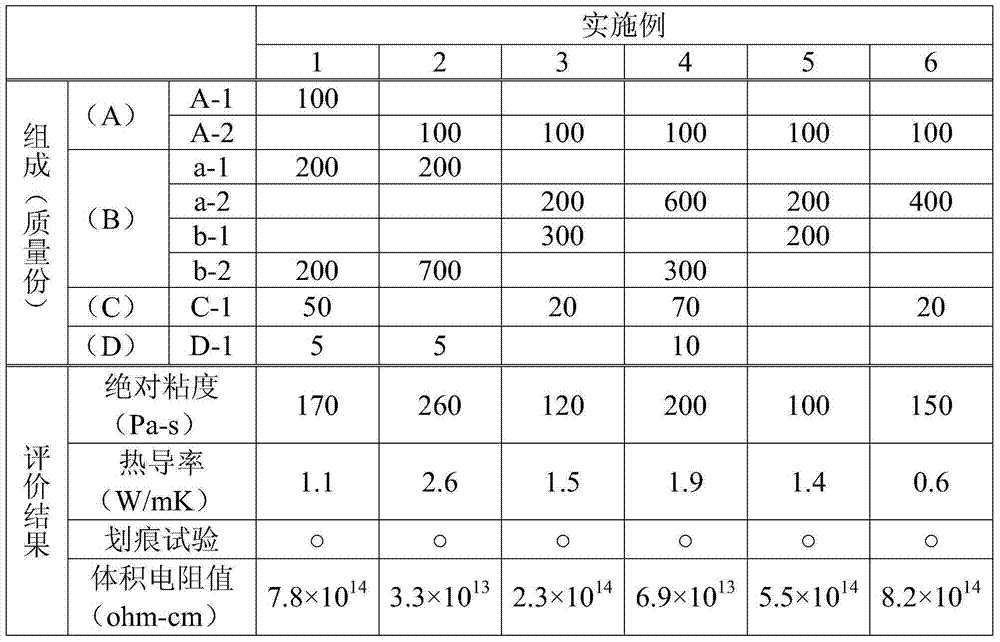

[0102] Preparation of silicone composition

[0103] According to the formulation amounts shown in Table 1 and Table 2, the ingredients were put into a 5-liter planetary mixer (registered trademark of a mixer manufactured by Inoue Seisakusho Co., Ltd.), and stirred at 150°C for 1 hours to manufacture silicone compositions.

[0104] For each composition obtained by the method described above, the viscosity, thermal conductivity, scratch test, and volume resistance value were measured according to the following methods. The results are shown in Table 1 and Table 2.

[0105] [viscosity]

[0106] The absolute viscosity of each composition was measured at 25 degreeC using the model PC-1TL (10 rpm) manufactured by Macon Co., Ltd.

[0107] [Thermal conductivity]

[0108] The thermal conductivity of each composition was measured at 25° C. using TPA-501 manufactured by Kyoto Denshi Kogyo Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com