Camera lens and preparation method thereof, camera assembly and electronic equipment

A camera and lens technology, applied in the field of electronic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

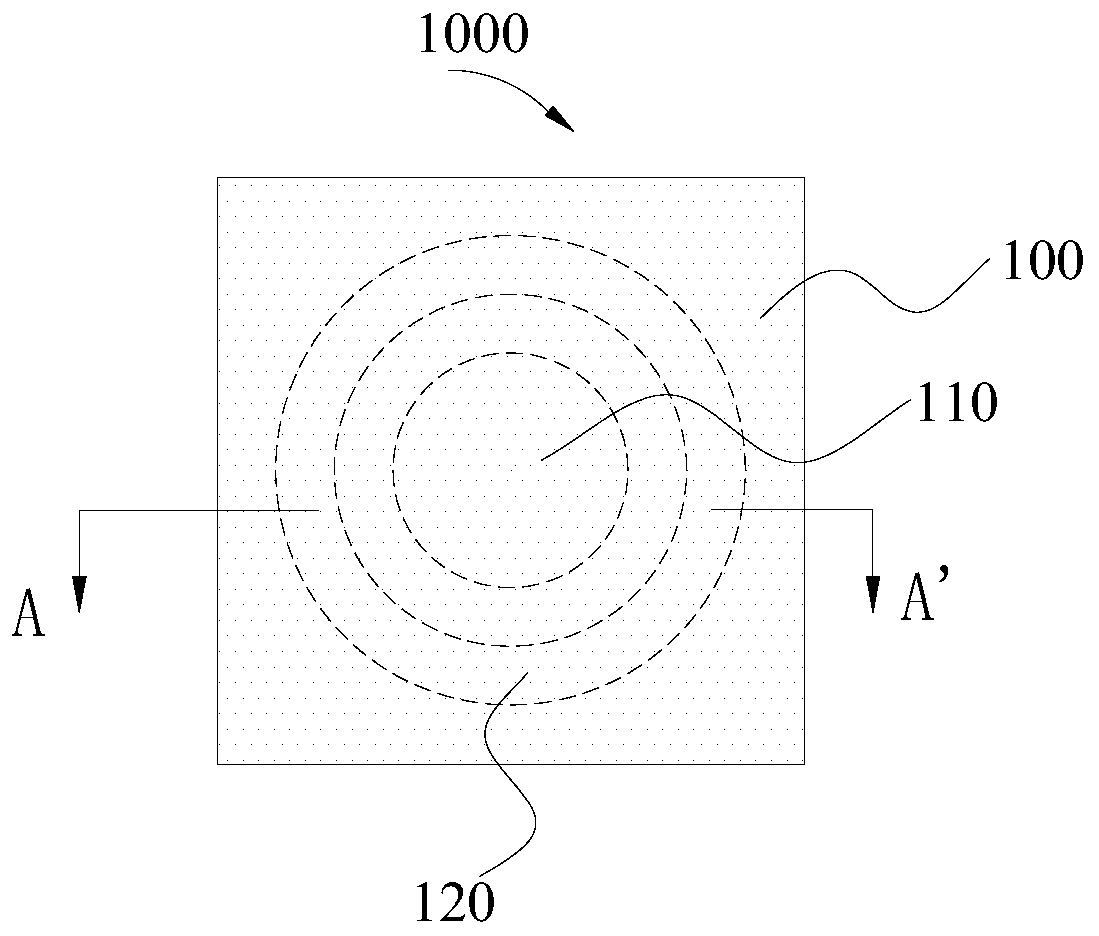

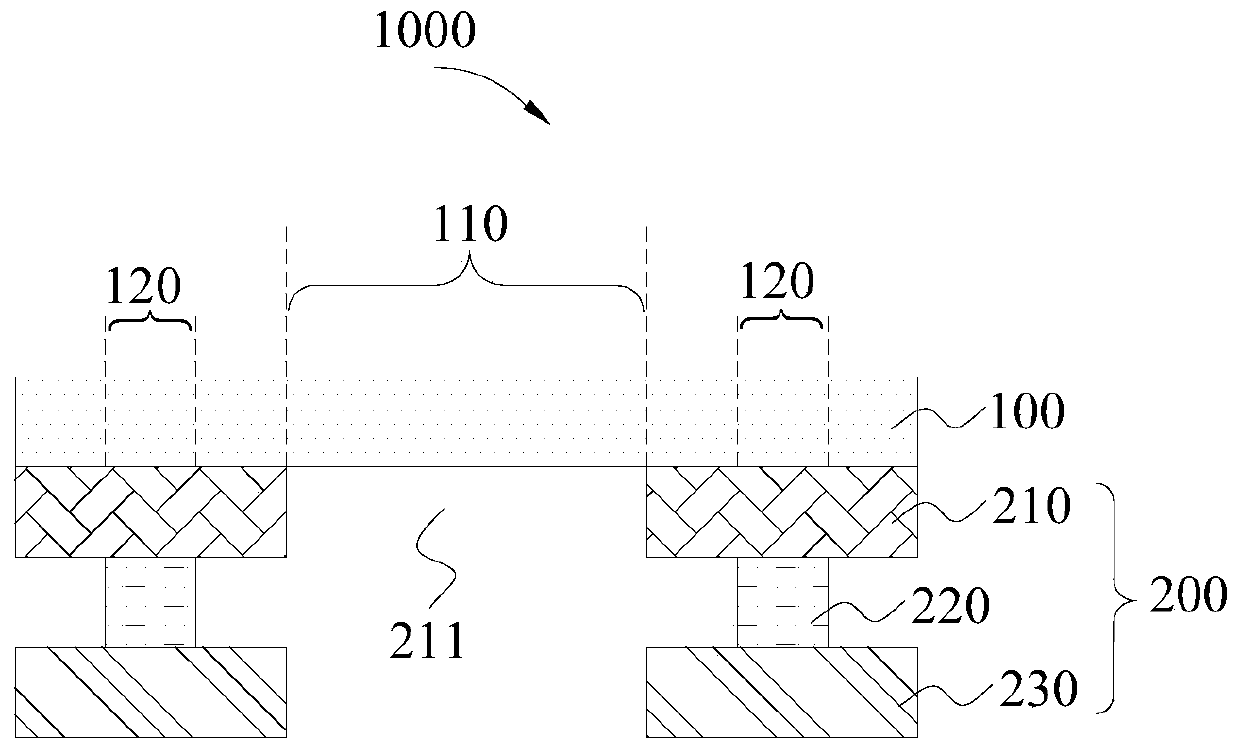

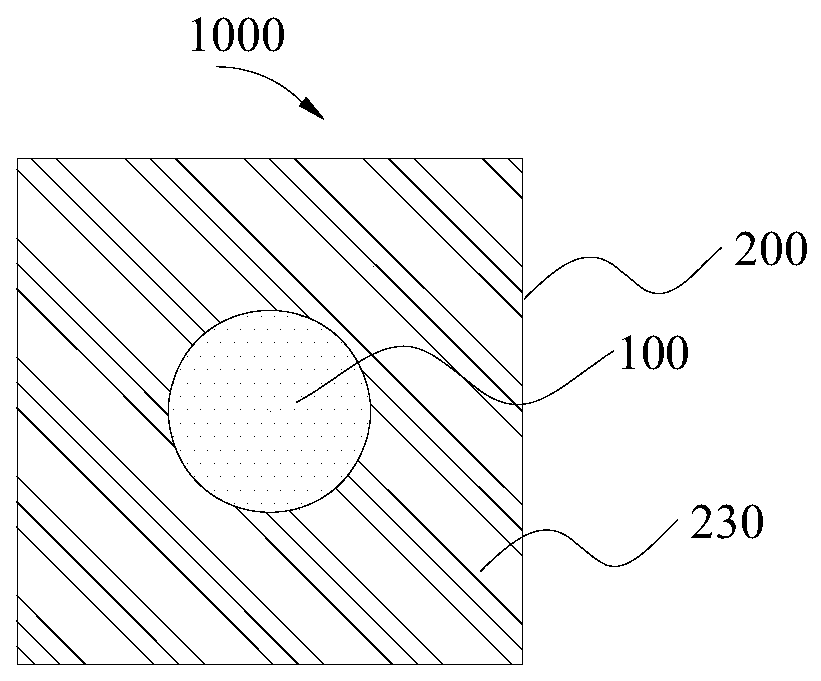

[0078] Prepare camera lens A.

[0079] (1) Provide a glass substrate with a window area and a texture area set around the window area on the glass substrate;

[0080] (2) Preparation of the appearance film: provide a substrate base (PET film), one side of the substrate base has an optical adhesive layer and a release film layer covering the optical adhesive layer, and the substrate base is away from the optical adhesive layer The texture layer is formed by UV transfer on one side, and the texture layer is plated on the side away from the substrate base to form a prefabricated coating layer. The substrate substrate on which the prefabricated coating layer is formed is cut to form on the substrate substrate The first hollowed-out area (the first hollowed-out area corresponds to the window area on the glass substrate), forming an appearance diaphragm;

[0081] (3) Remove the release film layer, and bond the appearance film and the glass substrate through the optical glue layer to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com