Target shooting system and method capable of achieving automatic target scoring and changing

An automatic, target paper technology, applied in the field of target shooting, can solve the problems of easy damage, danger and difficult control of sensors, and achieve the effect of easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

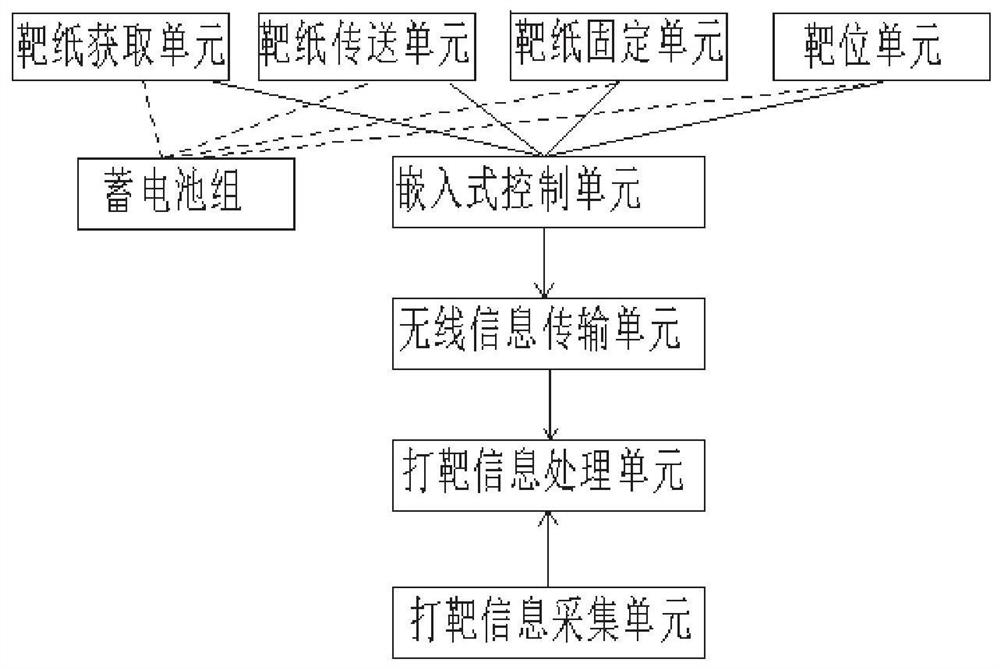

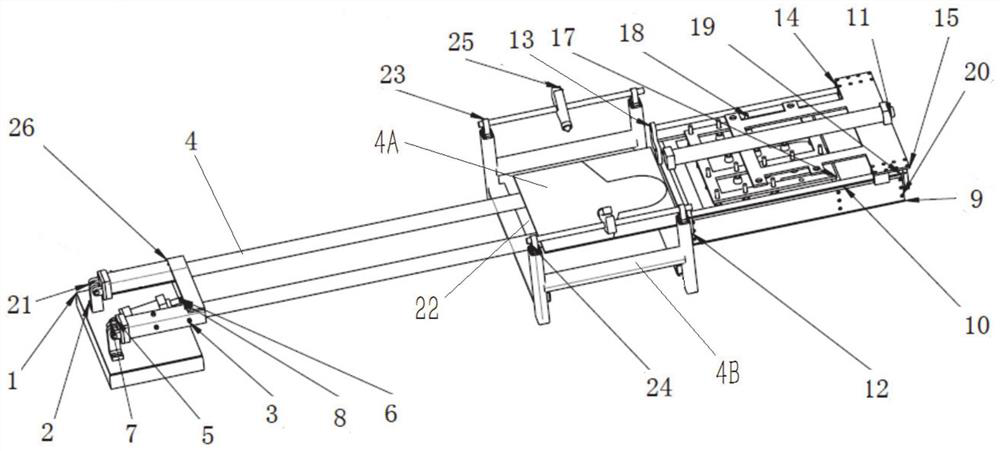

[0042] Such as Figure 1-Figure 4 As shown, this embodiment provides a target shooting system capable of automatic target reporting and target replacement, including a target carton 9 with an open upper end, a target paper acquisition unit, a target paper delivery unit, a target paper fixing unit, a target position unit, and target information collection unit, the target paper box 9 is vertically stacked with multiple layers of target paper 10; state; the target paper transfer unit can transfer the target paper acquisition unit and the adsorbed target paper 10 directly above the target paper fixing unit; the target paper fixing unit can support the target plate in a horizontal state, and the target paper fixing unit includes a glue spraying mechanism. The glue mechanism can spray glue to the surface of the target plate to bond and fix the target plate and the target paper 10 released by the vacuum suction cup 18 assembly; Toggle between horizontal orientations.

[0043] The ...

Embodiment 2

[0081] This embodiment provides a method for automatic target reporting and target replacement, utilizing the target shooting system described in Embodiment 1 that can realize automatic target reporting and target replacement, including the following steps:

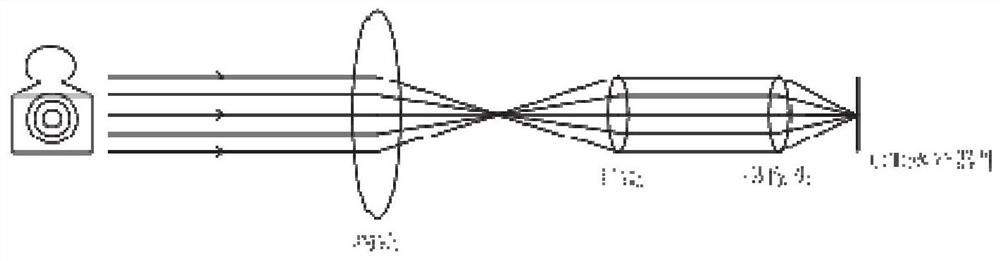

[0082] After the installation of the shooting system capable of automatic target reporting and changing, the targets are arranged vertically, and the shooting personnel shoot towards the target at a set distance; after each shooting, use the telescope set on the shooting personnel's side to collect distant target boards The high-definition camera can capture the image from the telescope and transmit it to the shooting information processing unit for image analysis to judge the shooting information.

[0083] Using image recognition to judge the shooting performance, the operator judges whether the target paper 10 needs to be replaced, when necessary, the target in the target unit is rotated to a horizontal state, and the ta...

Embodiment 3

[0090] A target image processing algorithm proposed in this embodiment consists of Image 6 As shown, it specifically includes the following steps:

[0091] 1. Targeting image preprocessing: After shooting the shooting image, first convert the image into a grayscale image, then perform Gaussian filtering to remove the noise generated during image transmission, and then perform histogram equalization to overcome the interference of light intensity changes , save the preprocessed image (gray_Image).

[0092] 2. Judging whether it was shot or not: make a difference with the last saved image to obtain a frame difference image. (difference_Image), binarize and sum the frame difference images, because the size and area of the actual bullet holes are relatively fixed, so a threshold interval is artificially set according to the area of the bullet holes, and the summed image is compared with the set threshold , if it is within the threshold interval, it is considered that the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com