A kind of method adopting microchannel reaction device to prepare dovitinib intermediate

A technology of microchannel reaction and dovitinib, applied in the direction of organic chemistry, can solve the problem of low product yield, achieve the effect of reducing consumption and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

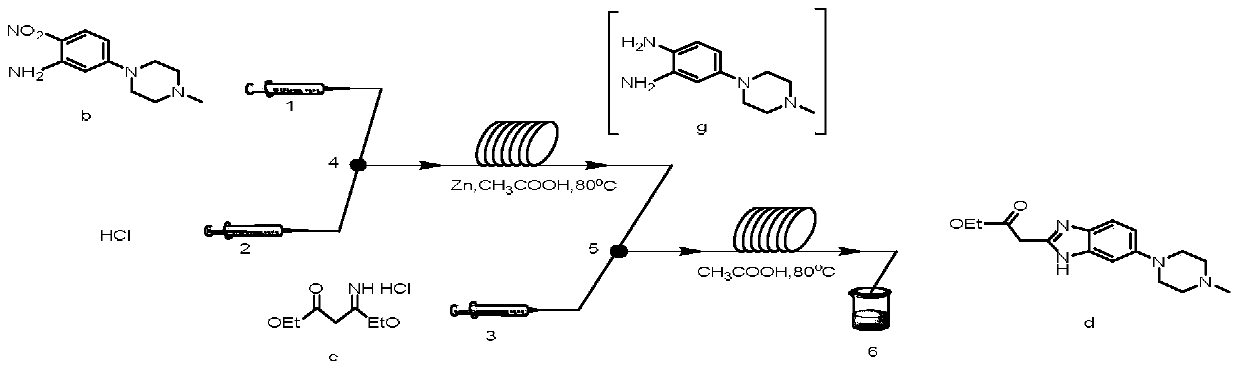

Method used

Image

Examples

Embodiment 1

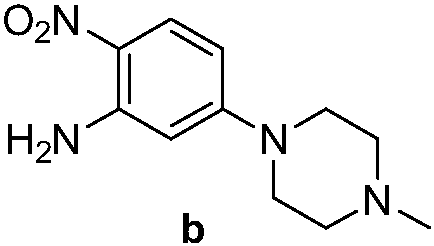

[0033] (1) Synthesis of 5-(4-methylpiperazinyl-1-yl)-2-nitroaniline (compound b)

[0034]

[0035] a, adding ethanol to the reaction solution for reaction

[0036]Under nitrogen protection, add compound a (20g, 0.12mol) and N-methylpiperazine (50g, 0.50mol) into a 100mL three-necked flask, then add 75mL of ethanol, stir, heat the oil bath to reflux, and react for 24h , use thin layer chromatography to track whether a is completely reacted, if not, continue to react until a is completely reacted. Pour the reaction solution into a 1L beaker containing 400mL of water while it was hot. A yellow substance precipitated out. The suspension was mechanically stirred for half an hour, filtered with suction, and the filter cake was washed 2 to 3 times with ice-cold ethanol. The filtrate was discarded, and the obtained filter cake was dried in an oven at 60° C. to obtain the product compound b with a yield of 65%.

[0037] b. Do not add ethanol to the reaction solution

[0038] Unde...

Embodiment 2

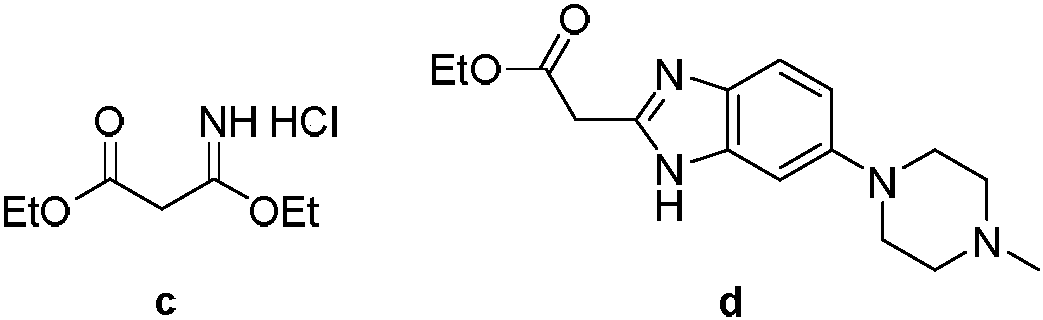

[0049] The preparation method is the same as in Example 1, and step (1) adopts the b method of step (1) in Example (1), but the mol ratio of 5-chloro-2-nitroaniline to N-methylpiperazine is 1 : 2, the productive rate of 5-(4-methylpiperazinyl-1-yl)-2-nitroaniline is 79%;

[0050] Step (2) adopts the b method of step (2) in the embodiment (1), but 5-(4-methylpiperazinyl-1-yl)-2-nitroaniline and β-ethoxyl-β The molar ratio of ethyl iminopropionate hydrochloride is 1:1.2 to obtain ethyl-2-(6-(4-methylpiperazin-1-yl)benzimidazol-2-yl)ethyl acetate The yield was 82%;

[0051] Moles of ethyl-2-(6-(4-methylpiperazin-1-yl)benzimidazol-2-yl)ethyl acetate, 2-amino-6-fluorobenzonitrile, KHMDS in step (3) The ratio was 1:1.2:3, and the yield of dovitinib was 69%.

Embodiment 3

[0053] The preparation method is the same as in Example 1, and step (1) adopts the b method of step (1) in Example (1), but the mol ratio of 5-chloro-2-nitroaniline to N-methylpiperazine is 1 : 6, the productive rate of 5-(4-methylpiperazinyl-1-yl)-2-nitroaniline is 85%;

[0054] Step (2) adopts the b method of step (2) in the embodiment (1), but 5-(4-methylpiperazinyl-1-yl)-2-nitroaniline and β-ethoxyl-β The molar ratio of ethyl iminopropionate hydrochloride is 1:3 to obtain ethyl-2-(6-(4-methylpiperazin-1-yl)benzimidazol-2-yl)ethyl acetate The yield was 87%;

[0055] Moles of ethyl-2-(6-(4-methylpiperazin-1-yl)benzimidazol-2-yl)ethyl acetate, 2-amino-6-fluorobenzonitrile, KHMDS in step (3) The ratio was 1:1.5:4, and the yield of dovitinib was 73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com