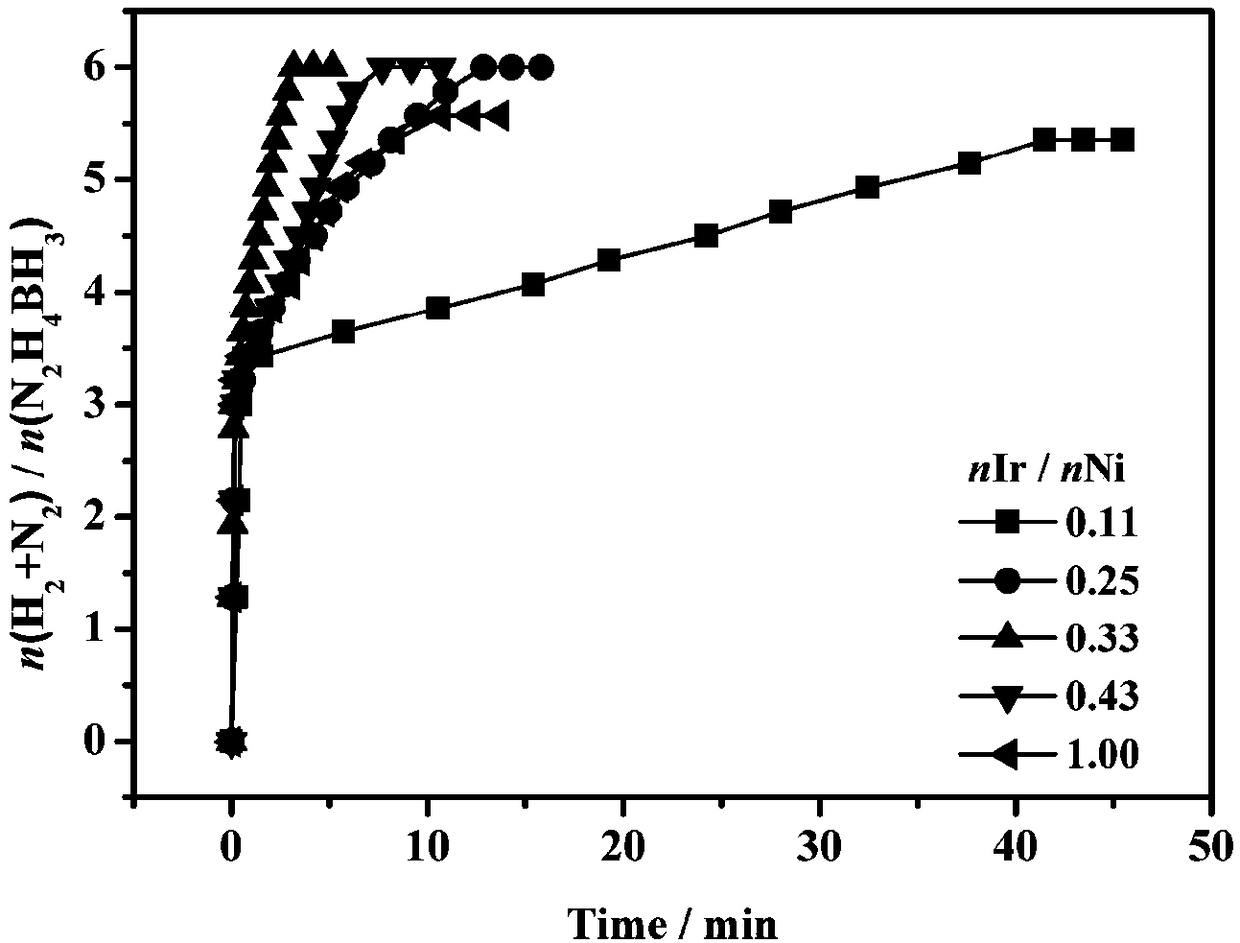

IrNi composite nano catalyst for catalyzing hydrazine borane to produce hydrogen and preparation method thereof

A nano-catalyst and catalytic hydrazine technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problems of low conversion frequency, low catalyst activity and cycle stability, etc., and achieve excellent catalytic effect. , good catalytic activity and cycle stability, the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

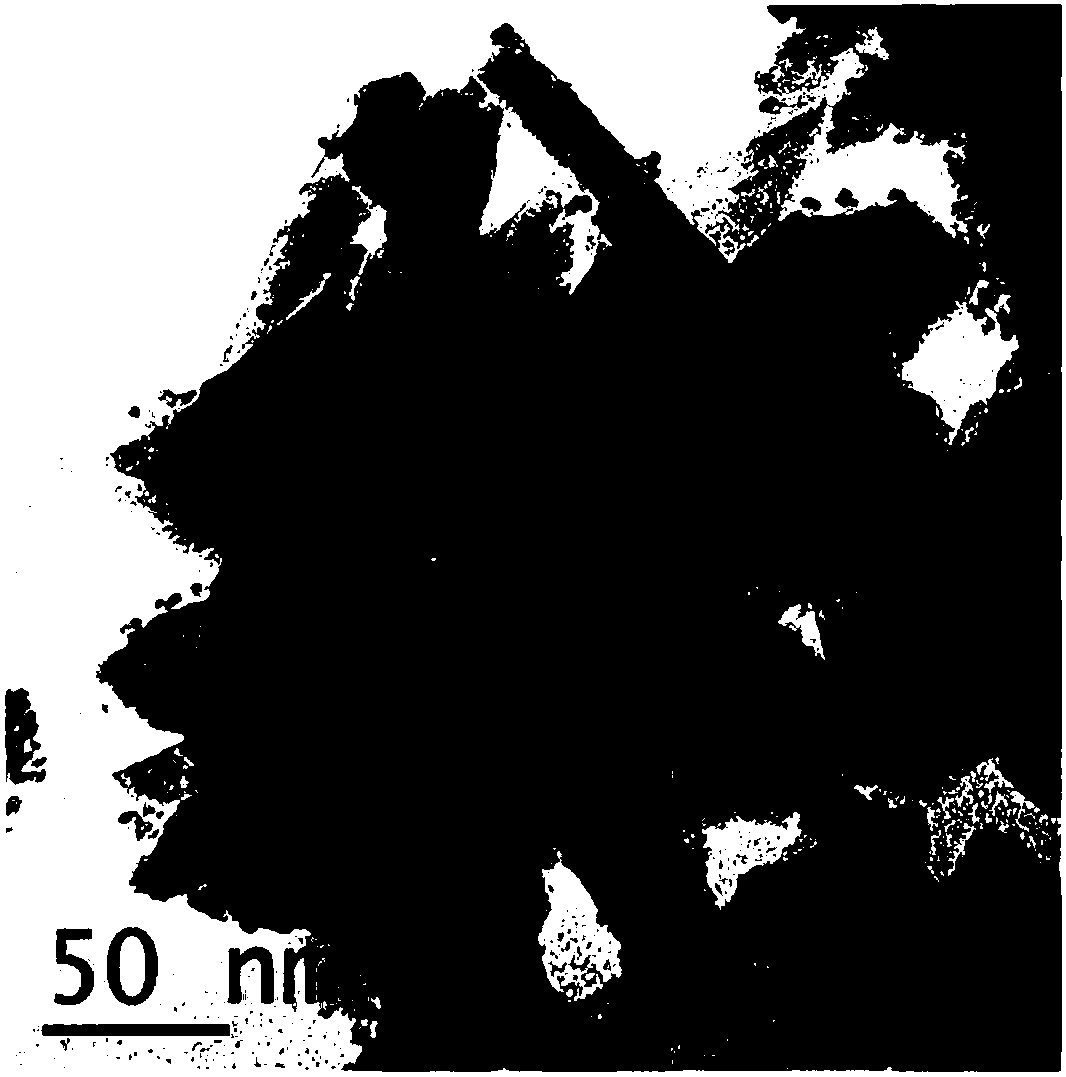

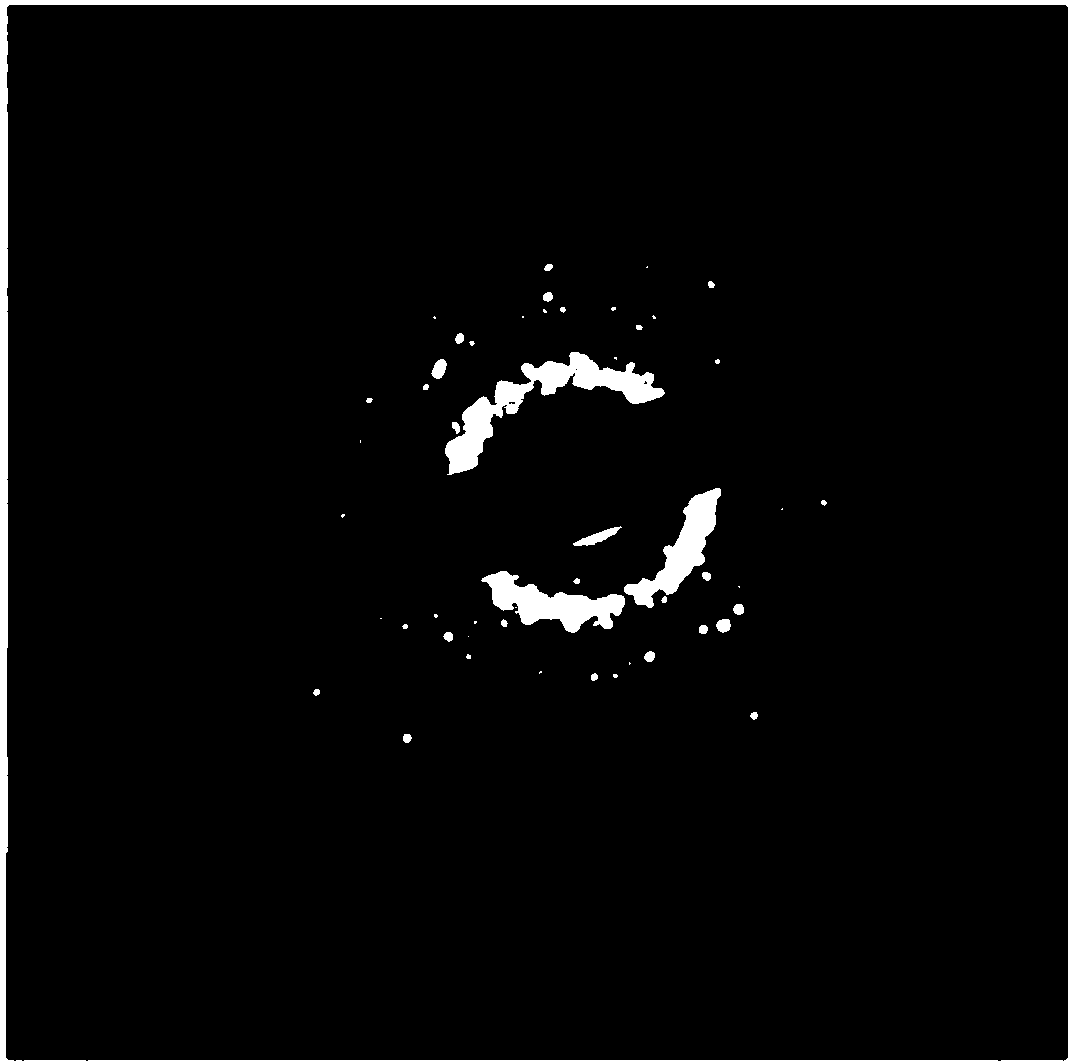

Image

Examples

Embodiment 1

[0035] (1) Add 50mg carrier La in 5ml ultrapure water 2 o 2 CO 3 , stirring for 30 minutes;

[0036] (2) Adding 1 mL of iridium chloride solution with a concentration of 0.025 mol / L to step (1), stirred for 10 minutes;

[0037] (3) Adding 1 mL of nickel chloride solution with a concentration of 0.075 mol / L to step (2), stirred for 10 minutes;

[0038](4) Adding 3mL concentration to step (3) is the mixed solution of 0.2mol / L sodium borohydride and 2.0mol / L sodium hydroxide, vigorously stirred and reacted for 30 minutes at 298K, and obtained metal loading is 15.5wt% and Ir IrNi composite nanocatalyst with a molar ratio of 0.33 to Ni.

Embodiment 2

[0040] Step (1) carrier La in embodiment 1 2 o 2 CO 3 The consumption of the compound was changed to 10mg, and other steps were the same as in Example 1 to obtain an IrNi composite nanocatalyst with a metal loading of 47.9wt% and a molar ratio of Ir and Ni of 0.33.

Embodiment 3

[0042] Step (1) carrier La in embodiment 1 2 o 2 CO 3 The consumption of the compound was changed to 30 mg, and other steps were the same as in Example 1 to obtain an IrNi composite nanocatalyst with a metal loading of 23.5 wt % and a molar ratio of Ir and Ni of 0.33.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com