Low-silicon SAPO-34 molecular sieve as well as preparation method and application thereof

A molecular sieve and seed crystal technology, applied in molecular sieve catalysts, chemical instruments and methods, and hydrocarbon production from oxygen-containing organic compounds, can solve problems such as poor economy, environmental pollution, toxicity, etc., achieve high raw material utilization, and facilitate production and application , the effect of obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

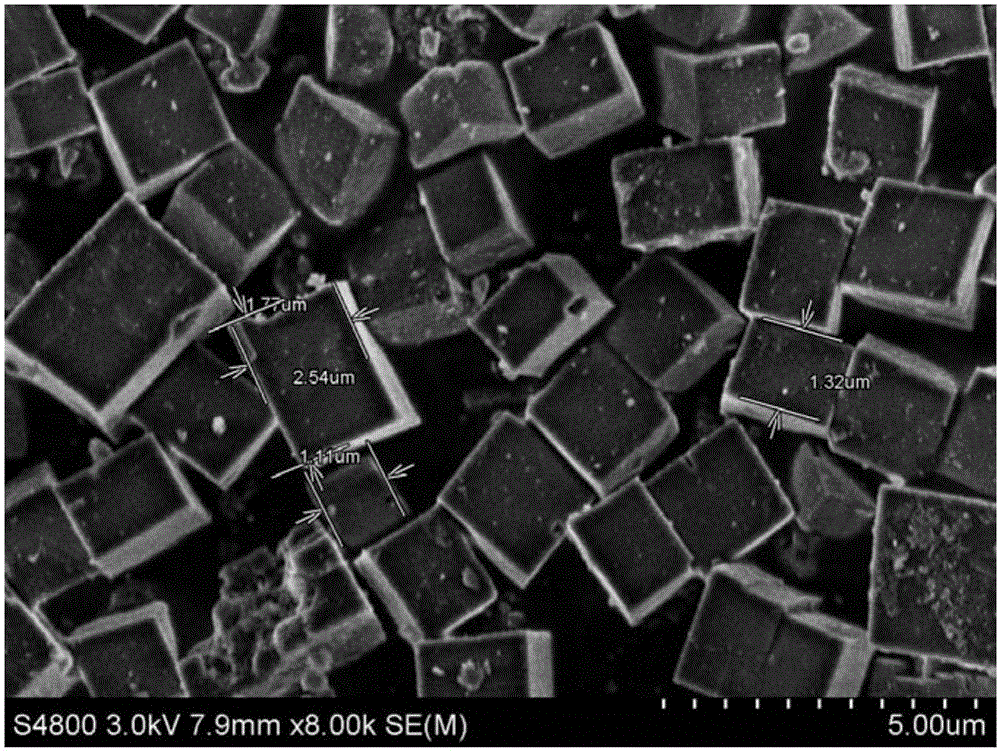

[0044] This embodiment provides a kind of low silicon SAPO-34 molecular sieve, the specific preparation process of this molecular sieve is:

[0045] (1) Preparation of seed crystal guide liquid

[0046] The molar ratio of the feed for the synthesis of the seed crystal guide liquid: 1.2SiO 2 : 1Al 2 o 3 : 0.8P 2 o 5 :2TEA:50H 2 O;

[0047] The specific steps are:

[0048] Mix pseudo-boehmite (68wt%), seed crystal (grain size 6 μm), and 1 / 3 deionized water, the seed crystal is 0.1wt% of the total material, stir at 0°C for 0.2h to dissolve and mix evenly; then Slowly and evenly add phosphoric acid (85wt%) dropwise, keep stirring vigorously for 1h to form a gel, add 1 / 3 deionized water dropwise, and stir for 0.2h; slowly add silica sol (40wt%) dropwise, continue stirring for 0.5h; drop evenly Add triethylamine (99wt%), keep stirring, drop the remaining deionized water, and stir vigorously for 4 hours to obtain the guide liquid gel. In the process of preparing the guide liq...

Embodiment 2

[0055] This embodiment provides a kind of low silicon SAPO-34 molecular sieve, the specific preparation process of this molecular sieve is:

[0056] (1) Preparation of seed crystal guide liquid

[0057] The molar ratio of the feed for the synthesis of the seed crystal guiding liquid: 0.9SiO 2 : 1Al 2 o 3 : 0.8P 2 o 5 :2R:50H 2 O, template R is composed of TEAOH (tetraethylammonium hydroxide) and TEA (triethylamine), the molar ratio of the two is 0.08:1;

[0058] The specific steps are:

[0059] Mix aluminum isopropoxide (99wt%), seed crystals (average grain size 8 μm), and 1 / 3 deionized water, the seed crystals are 0.1wt% of the total material, stir at 15°C for 0.2h to dissolve and mix evenly; then slowly Add phosphoric acid (85wt%) evenly dropwise, keep stirring vigorously for 1h to form a gel, add 1 / 3 deionized water dropwise, and stir for 0.2h; slowly add silica sol (40wt%), continue stirring for 0.5h; TEA (99wt%), kept stirring, added dropwise the remaining deioniz...

Embodiment 3

[0066]This embodiment provides a kind of low silicon SAPO-34 molecular sieve, the specific preparation process of this molecular sieve is:

[0067] (1) Preparation of seed crystal guide liquid

[0068] The molar ratio of the feed for the synthesis of the seed crystal guide liquid: 0.5SiO 2 : 1Al 2 o 3 : 0.8P 2 o 5 :2R:60H 2 O, the template agent R is composed of TEAOH (tetraethylammonium hydroxide) and Mor (morpholine), the molar ratio of the two is 0.15:1, the phosphorus source is composed of phosphoric acid and phosphorous acid, and the molar ratio of the two is 4: 1;

[0069] The specific steps are:

[0070] Mix pseudo-boehmite (68wt%), seed crystals (average grain size 4 μm), and 1 / 3 deionized water, the seed crystals are 0.1wt% of the total material, stir at 10°C for 0.2h to dissolve and mix evenly; then Slowly and evenly add phosphoric acid (85wt%) and phosphorous acid (80wt%) dropwise, keep stirring vigorously for 1h to form a gel, add 1 / 3 deionized water dropwi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com