Coating liquid for formation of positive electrode for lithium rechargeable battery, positive electrode for lithium rechargeable battery, and lithium rechargeable battery

A lithium secondary battery, coating liquid technology, applied in secondary batteries, battery electrodes, lithium storage batteries, etc., can solve the problem of incapable of high-density filling, and achieve high practicability, excellent coating properties, and high energy density. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] (1) Preparation of coating solution for positive electrode formation

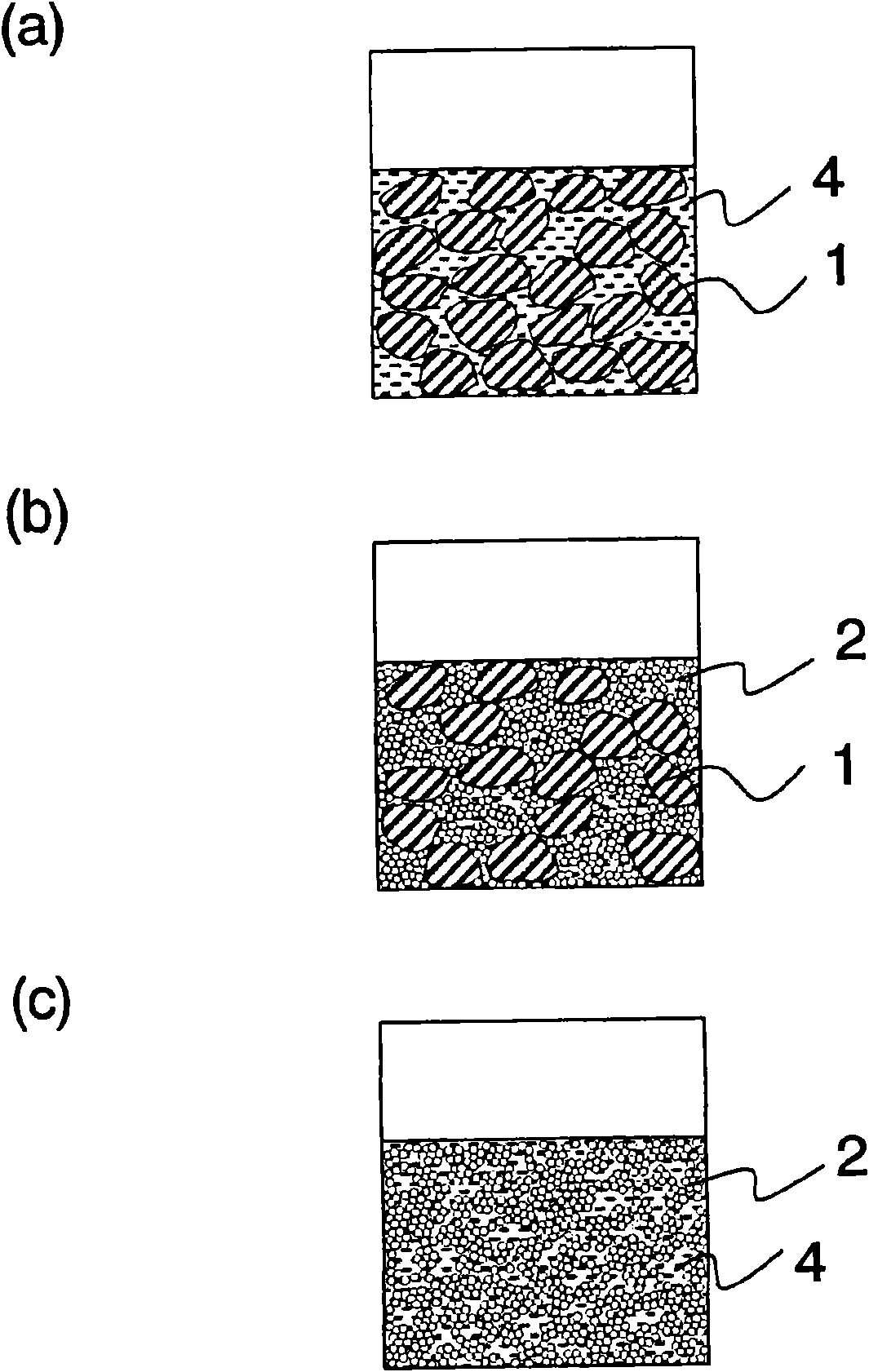

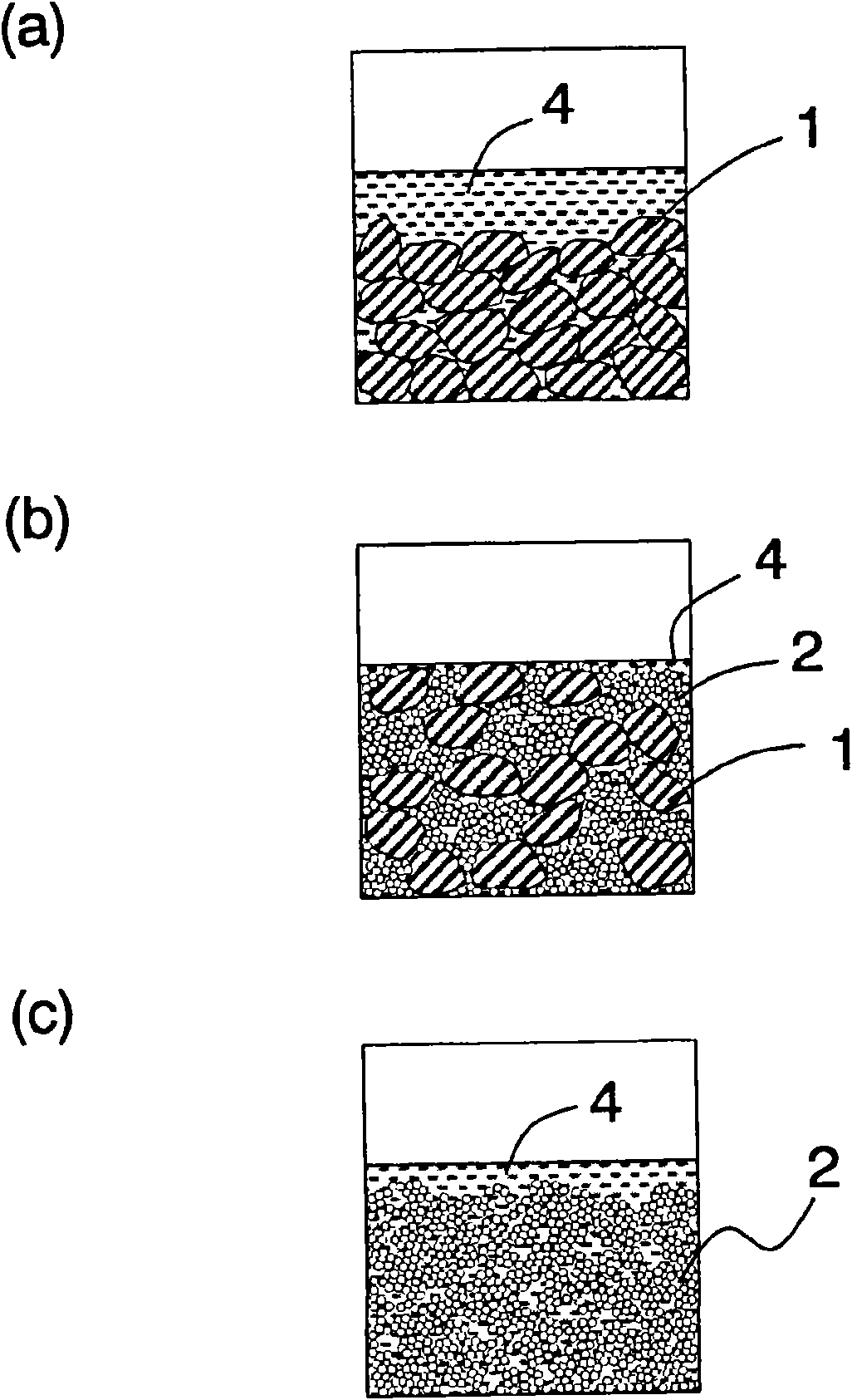

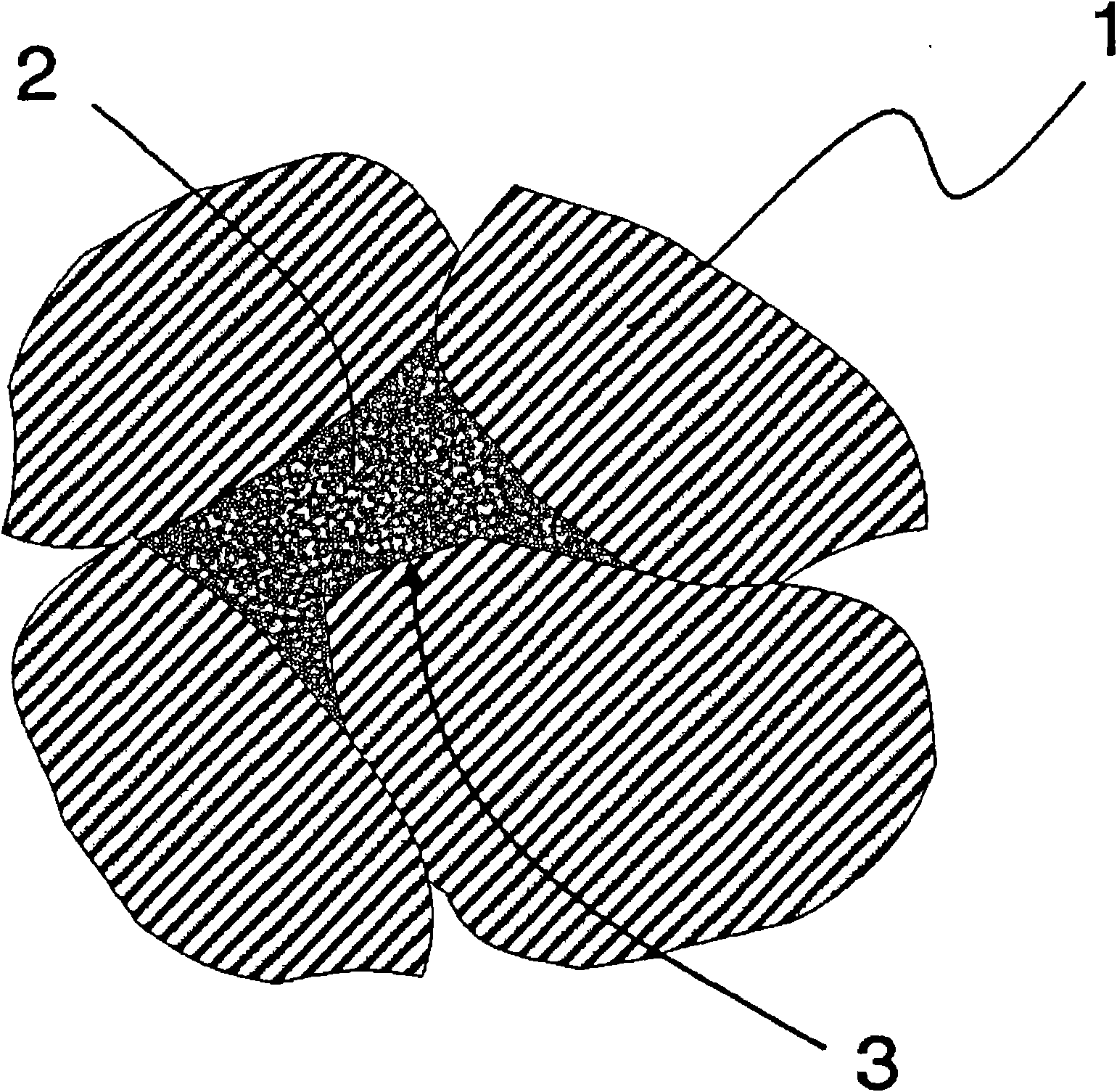

[0109] As the large particle size active material, lithium cobaltate having an average particle size of 7 μm was used. As the small particle size active material, lithium cobaltate with an average particle size of 70 nm was used. In addition, the compounding ratio (active material with large particle diameter:active material with small particle diameter)=70:30 (weight ratio). In addition, since both the active material with a large particle size and the active material with a small particle size are lithium cobaltate, the compounding ratio (volume ratio=volume ratio) is replaced by a weight ratio. Hereinafter, even when the active material with a large particle size and the active material with a small particle size are the same compound, the compounding ratio will be replaced by a weight ratio.

[0110] Dissolve 3 parts by weight of polyvinylidene fluoride (binder, weight-average molecular weight:...

Embodiment 2

[0129] In addition to using lithium cobalt oxide with an average particle size of 20 μm as the large particle size active material, using lithium cobalt oxide with an average particle size of 100 nm as the small particle size active material, and setting the compounding ratio (weight ratio) as the large particle size active material The coating liquid for forming a positive electrode and the positive electrode of the present invention were produced in the same manner as in Example 1 except for the small particle size active material = 50:50. Even when the obtained coating liquid of the present invention was stored for 3 weeks, no sedimentation, aggregation, separation of the dispersion medium, etc. were observed. In addition, the coating liquid of the present invention maintained its initial liquid properties even after being stored for 3 weeks, and deterioration in film-forming properties, leveling properties, and the like was not observed.

Embodiment 3

[0131] In addition to using lithium cobalt oxide with an average particle size of 20 μm as the large particle size active material, using lithium cobalt oxide with an average particle size of 100 nm as the small particle size active material, and setting the compounding ratio (weight ratio) as the large particle size active material The coating liquid for forming a positive electrode and the positive electrode of the present invention were produced in the same manner as in Example 1 except that the active material with small particle diameter was 90:10. Even when the obtained coating liquid of the present invention was stored for 3 weeks, no sedimentation, aggregation, separation of the dispersion medium, etc. were observed. In addition, the coating liquid of the present invention maintained its initial liquid properties even after being stored for 3 weeks, and deterioration in film-forming properties, leveling properties, and the like was not observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com