Method for improving component uniformity of W elements in GH4720Li alloy

A technology of element composition and uniformity, which is applied in the field of improving the uniformity of W element composition of GH4720Li alloy, can solve problems such as uneven distribution of W elements, and achieve the effects of solving performance uniformity, uniform distribution of W elements, and solving composition differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

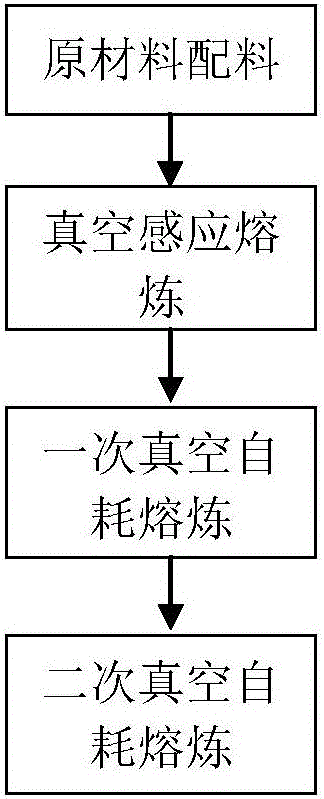

Method used

Image

Examples

Embodiment 1

[0041] Melting GH4720Li superalloy ingots with a diameter of Φ510mm.

[0042] 1. Raw material processing:

[0043] Electrolytic Ni and electrolytic cobalt are subjected to surface sandblasting, and after treatment, they are dried with nickel-tungsten alloy, nickel-molybdenum alloy, pure titanium, pure aluminum, and pure chromium at 100°C for 10 hours.

[0044] 2. Ingredients:

[0045] Determine the alloy ratio, and feed according to the ratio. The alloy ratio and the raw materials and amounts used are shown in Tables 2 and 3.

[0046] Table 2 Alloy chemical composition ratio, wt%

[0047]

[0048] Table 3 raw materials and dosage

[0049]

[0050] 3. Vacuum induction melting:

[0051] The ingot mold of Φ350mm is used for vacuum induction melting, the melting speed is 700kg / h, the refining temperature is 1480℃, and the refining time is 60min; the pouring temperature is 1480℃. Grinding is done after smelting.

[0052] 4. Vacuum consumable melting:

[0053] The electro...

Embodiment 2

[0058] Melting GH4720Li superalloy ingots with a diameter of Φ440mm.

[0059] 1. Raw material processing:

[0060] Electrolytic Ni and electrolytic cobalt are subjected to surface sandblasting, and after treatment, they are dried with nickel-tungsten alloy, nickel-molybdenum alloy, pure titanium, pure aluminum, and pure chromium at 100°C for 10 hours.

[0061] 2. Ingredients:

[0062] Determine the alloy ratio, and feed according to the ratio. The alloy ratio, raw materials and amounts used are shown in Tables 5 and 6.

[0063] Table 5 Alloy chemical composition ratio, wt%

[0064]

[0065] Table 6 raw materials and dosage

[0066]

[0067] 3. Vacuum induction melting:

[0068] Vacuum induction melting uses Φ280mm ingot mold, melting speed is 300kg / h, refining temperature is 1450℃, refining time is 30min; pouring temperature is 1450℃. Grinding is done after smelting.

[0069] 4. Vacuum consumable melting:

[0070] The electrode is turned around for welding and sme...

Embodiment 3

[0075] Melting GH4720Li superalloy ingots with a diameter of Φ560mm.

[0076] 1. Raw material processing:

[0077] Electrolytic Ni and electrolytic cobalt are subjected to surface sandblasting, and after treatment, they are dried with nickel-tungsten alloy, nickel-molybdenum alloy, pure titanium, pure aluminum, and pure chromium at 100°C for 10 hours.

[0078] 2. Ingredients:

[0079] Determine the alloy ratio, and feed according to the ratio. The alloy ratio, raw materials and consumption are shown in Tables 8 and 9.

[0080] Table 8 Alloy chemical composition ratio, wt%

[0081]

[0082] Table 9 Materials and dosage

[0083]

[0084] 3. Vacuum induction melting:

[0085] Vacuum induction melting uses a Φ400mm ingot mold, the melting speed is 700kg / h, the refining temperature is 1550°C, and the refining time is 90min; the pouring temperature is 1550°C. Grinding is done after smelting.

[0086] 4. Vacuum consumable melting:

[0087] The electrode is turned around ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com