Barite crushing components and production equipment

A barite and component technology, applied in the field of barite crushing components and production devices, can solve the problems of high product impurity content, excessive product particle size, low grinding efficiency, etc., and achieves small product particle size, concentrated product particle size, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

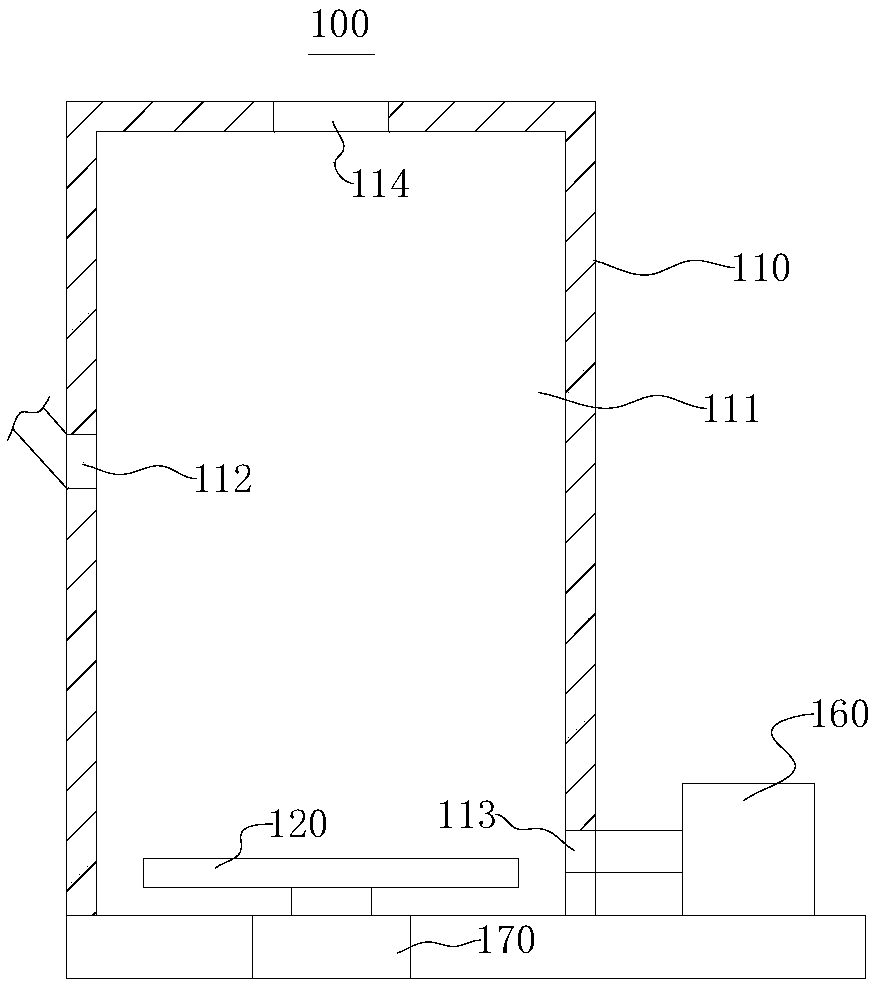

[0036] see figure 1 , the present embodiment provides a barite crushing assembly 100 , including a crushing chamber 110 , a rotating disk 120 , an air compressor 160 and a driving device 170 .

[0037] Specifically, the crushing chamber 110 has a crushing chamber 111 , and the crushing chamber 110 is provided with a feed port 112 , an air inlet 113 and a discharge port 114 respectively communicating with the crushing chamber 111 .

[0038] The air inlet 113 is arranged at the bottom of the side wall of the crushing chamber 110 , and the air compressor 160 communicates with the air inlet 113 , and the air compressor 160 passes the compressed gas into the bottom of the crushing chamber 111 through the air inlet 113 .

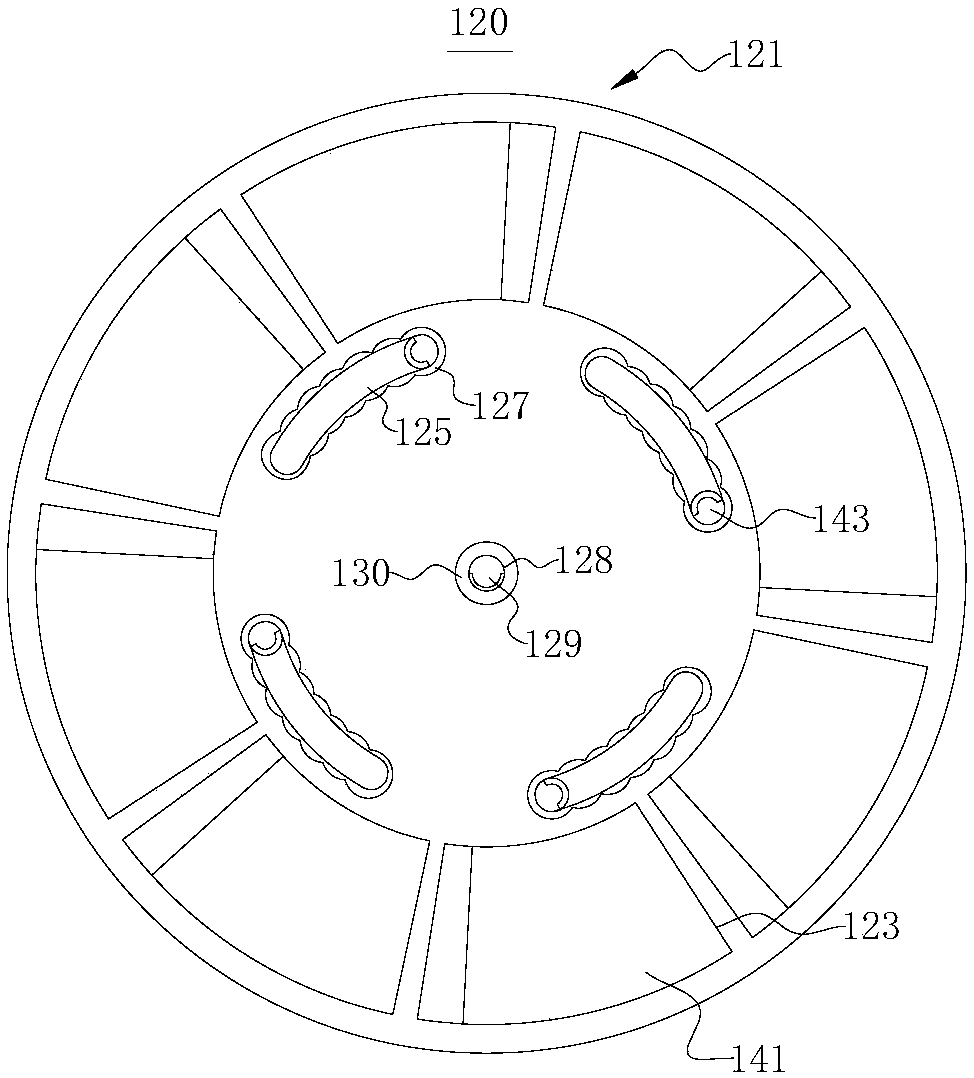

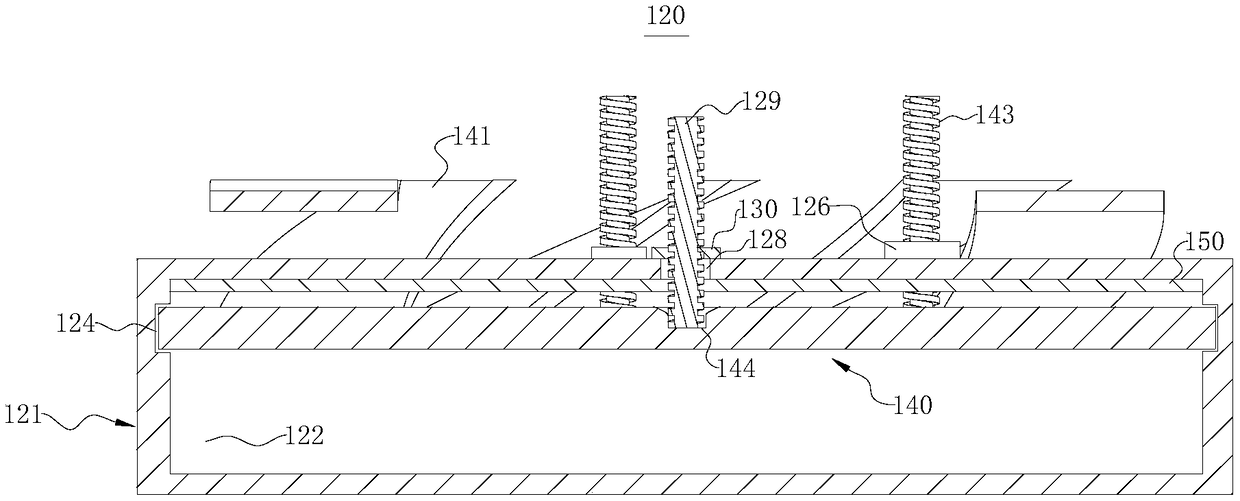

[0039] The rotating disk 120 is arranged at the bottom of the crushing chamber 111, and the rotating disk 120 is substantially parallel to the bottom wall of the crushing chamber 110, that is, the rotating disk 120 is arranged substantially horizontally when insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com