Method for extracting polyhydroxyalkanoates from active sludge

A technology for polyhydroxyalkanoates and activated sludge, which is applied in the field of extracting polyhydroxyalkanoates and can solve problems such as ultrasonic-assisted extraction of PHA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

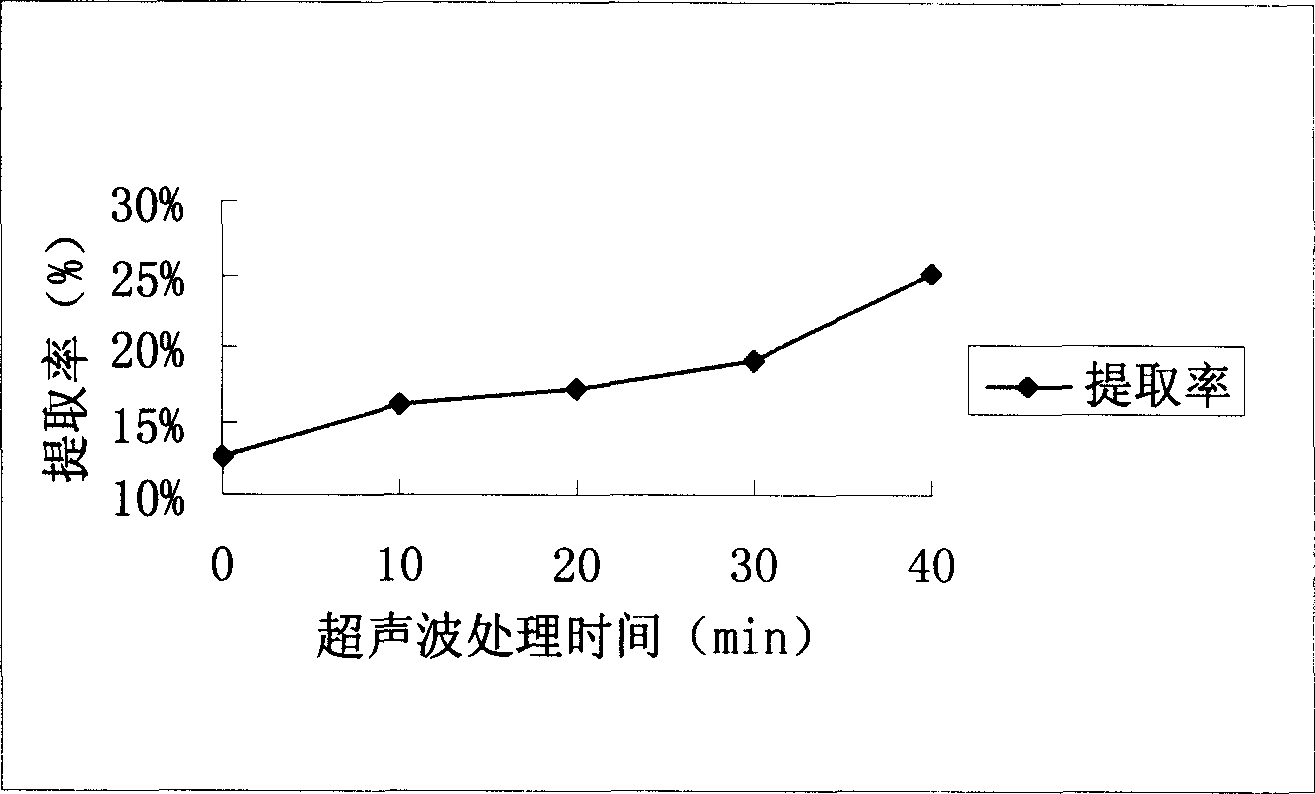

Image

Examples

Embodiment 1

[0012] Experimental Drugs:

[0013] Activated sludge is taken from Tianjin TEDA Municipal Wastewater Treatment Plant

[0014] Chloroform Analytical Pure Tianjin North Chemical Glass Purchase and Sales Center

[0015] Methanol Analytical Pure Tianjin Fuyu Fine Chemical Co., Ltd.

[0016] Antifomin Analytical Pure Tianjin Chemical Reagent No. 3 Factory

[0017] Glucose, ammonium chloride, potassium dihydrogen phosphate, ZnSO 4 ·7H 2 O, NiCl 2 ·H 2 O, CuSO 4 ·5H 2 O Sudan black, saffron, xylene (all are analytically pure)

[0018] 1. Test steps

[0019] 1. Activated sludge taken from Tianjin Taida Municipal Sewage Treatment Plant, using glucose, ammonia nitrogen and sodium phosphate according to the culture medium prepared under the condition of C: N: P = 100: 1: 1 (weight ratio) to cultivate activated sludge , using aerobic and anoxic alternate domestication sludge, the cycle is 4 hours, the time ratio of aerobic and anoxic state is 1:1.

[0020] 2. Take 3.0L of activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com