Sludge resourceful treatment method and application

A technology of recycling and sludge, applied in the field of comprehensive utilization of sewage resources, can solve the problems of high cost and low efficiency, and achieve the effect of convenient operation, convenient use and satisfying industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

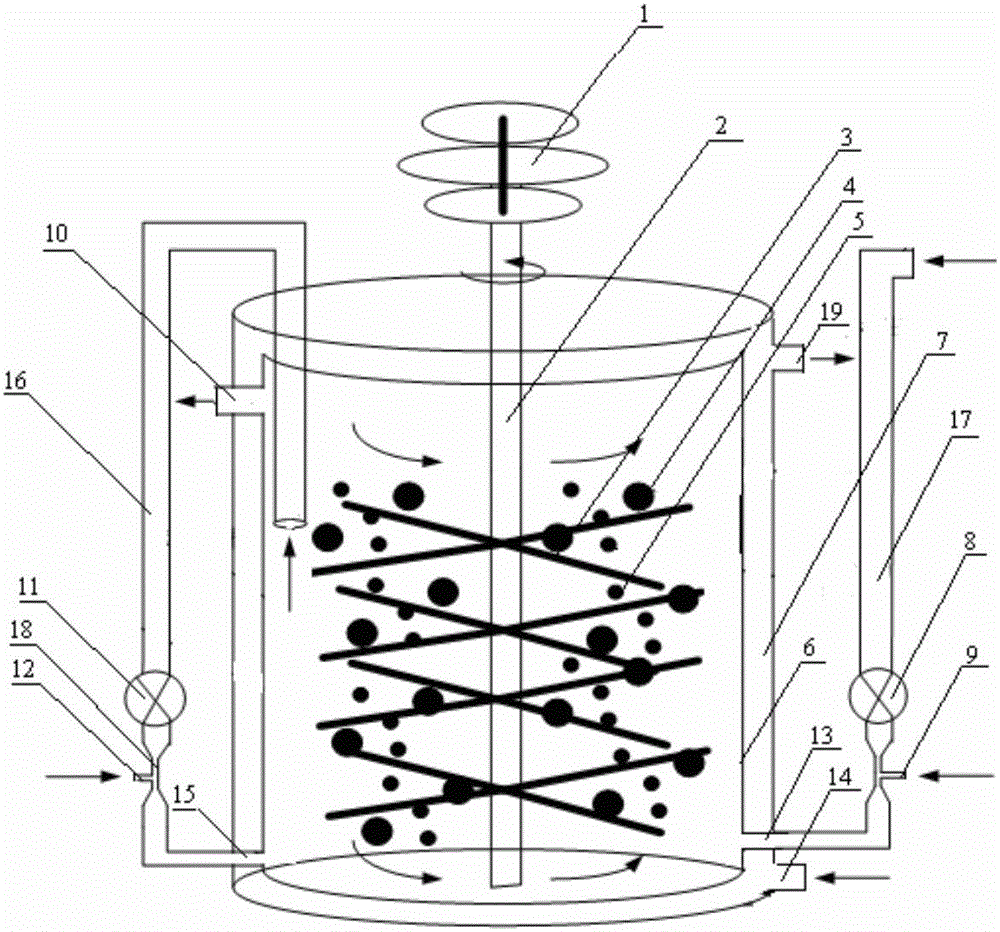

Image

Examples

Embodiment 1

[0045] The process method is used to treat the municipal sludge of the municipal sewage treatment plant, the water content of which is about 81%. Add compound enzyme 200g / t in sludge (complex enzyme is made of α-glucanase, β-glucanase, pectinase, protease, mannase and helicase in mass ratio 10:10:2:1 :1:1 composition), adjust the pH to 7.5 with sodium hydroxide, maintain the temperature at 20-25°C, stir at a speed of 500r / min for 2h, and carry out the sludge biological cell wall pretreatment; The magnetic medium (magnetite) 1000g / t is transferred to a stirring high-speed pulverizer with a steel ball filling rate of 50% for high-speed (rotational speed is about 6000r / min) grinding for 10min to carry out deep wall breaking; After the completion, use a magnetic separator with a magnetic field strength of 800GS to recover the magnetic medium and reuse it. The sludge is centrifuged in a centrifuge for solid-liquid separation. Enter into a carbonization furnace at a temperature of ...

Embodiment 2

[0051] The process method is used to treat the activated sludge of the sewage treatment plant in the industrial park, the water content of which is about 72%. Add compound enzyme 300g / t (composite enzyme is made of α-glucanase, β-glucanase, pectinase, protease, mannase and helicase by mass ratio 10:12:1:1.5 in sludge) :0.8:0.8 composition), adjust the pH to 7.8 with sodium hydroxide, maintain the temperature at 20-25°C, stir at a speed of 300r / min for 1h, and carry out the sludge biological cell wall pretreatment; then add the sludge with a fineness of less than 37μm The magnetic medium (pyrhotite) 1000g / t is transferred to the agitating high-speed pulverizer with a steel ball filling rate of 30% for high-speed (rotational speed is about 6000r / min) grinding for 15min to carry out deep wall breaking; After the wall is completed, use a magnetic separator with a magnetic field strength of 500GS to recover the magnetic medium and reuse it. The sludge is separated from the solid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com