Roller brush equipment for medical package bag labels and using method thereof

A packaging bag and label technology, applied in the field of medical supplies processing and production, can solve the problems of unclear printing, change, loss, etc., achieve fast and convenient operation, non-toxic and harmless cost, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

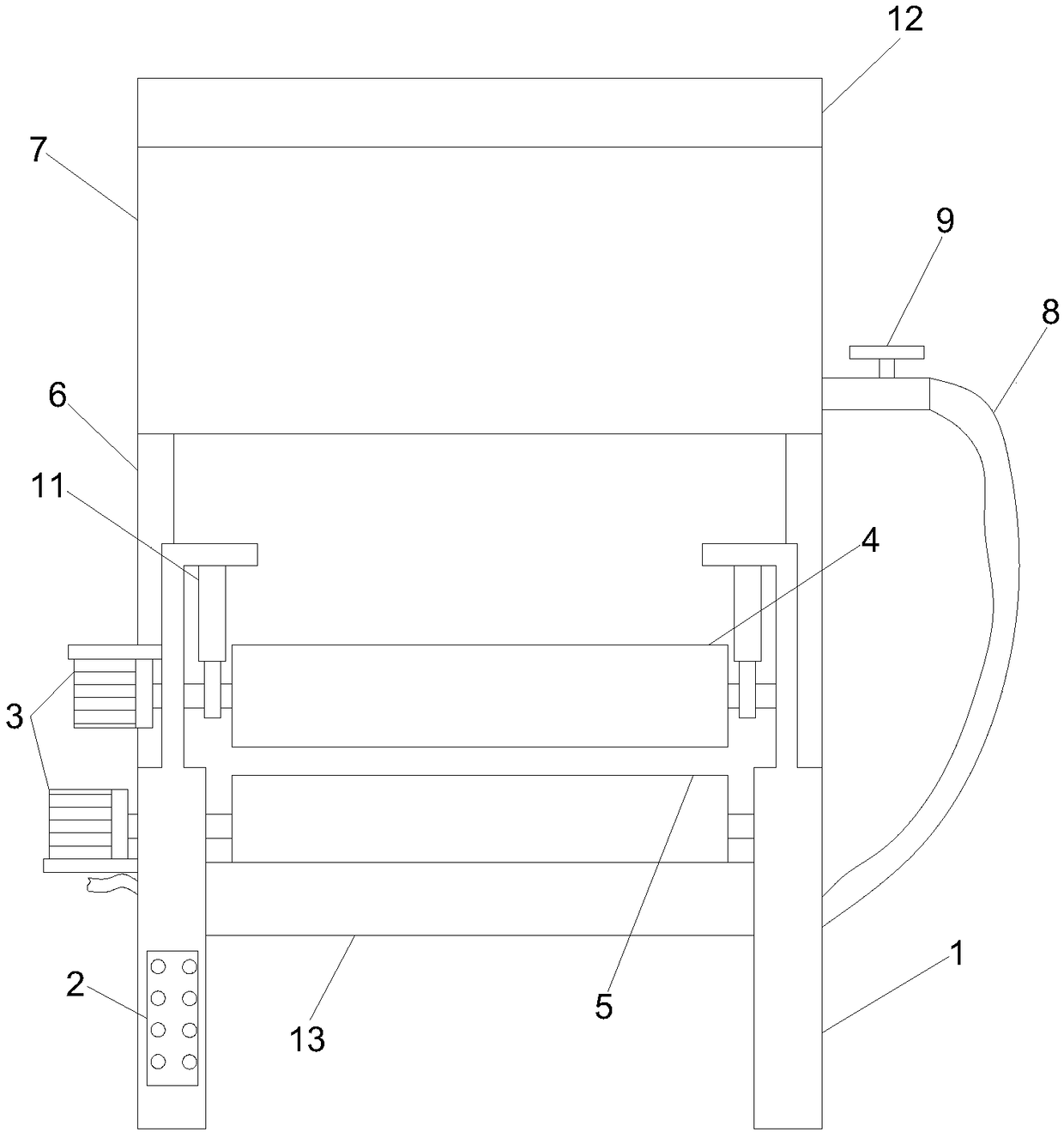

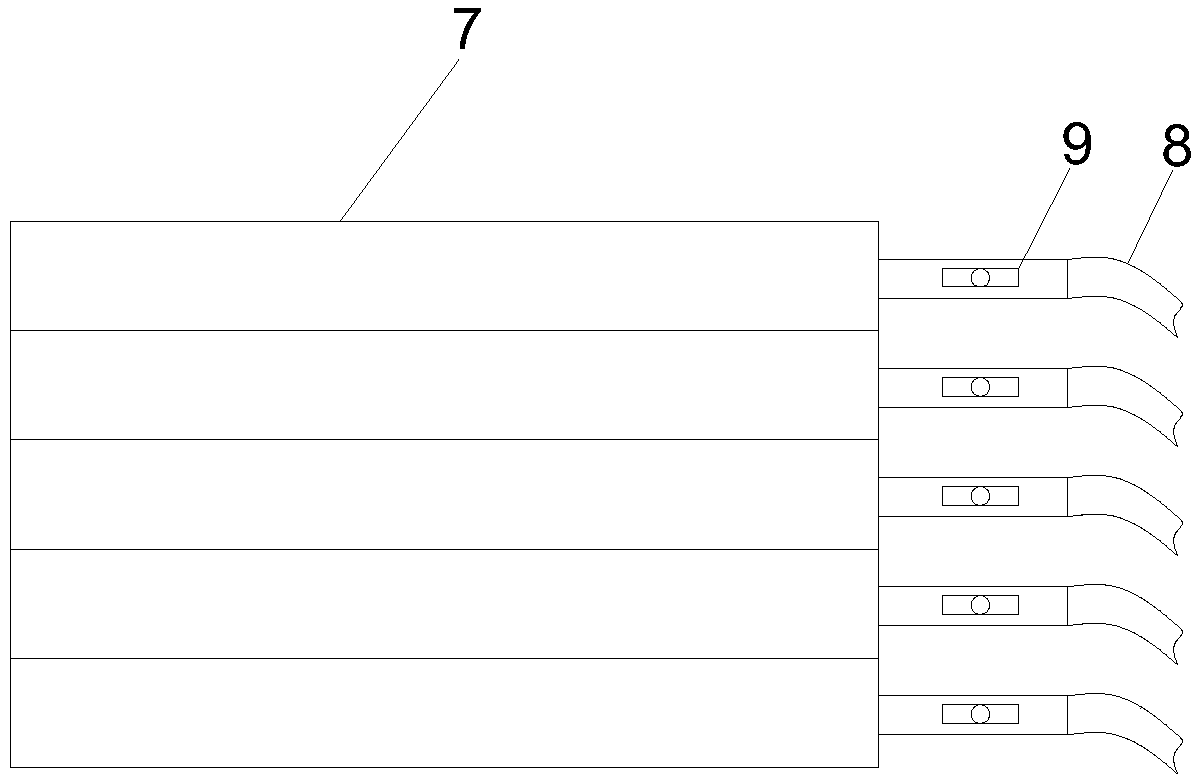

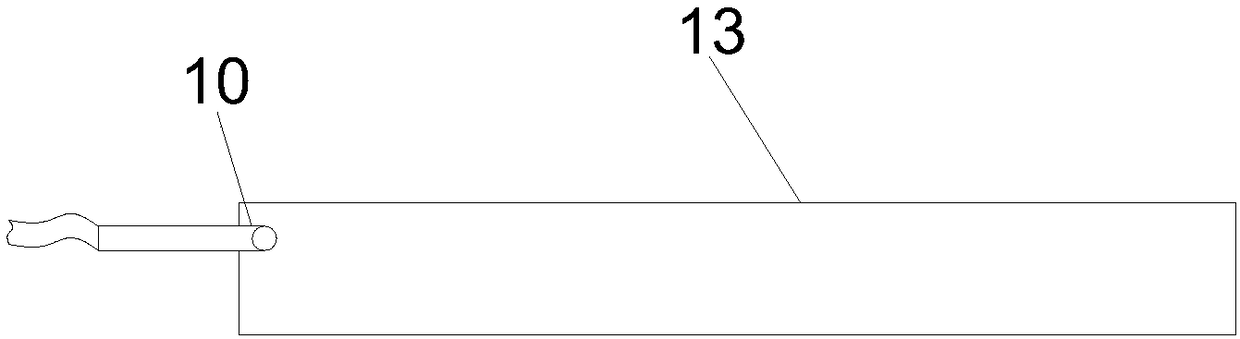

[0039] Such as figure 1 , figure 2 as well as image 3 As shown, a roller brush equipment for medical packaging bag labels includes a support frame 1, a control switch 2 is provided on the support frame 1, a motor 3 is provided on the support frame 1, and the motor 3 is connected to the transmission roller 4, and the transmission roller 4 is provided below. Printing roller 5 is arranged, and printing roller 5 is also connected on the motor 3, and described support frame 1 is provided with connecting rod 6, and storage box 7 is installed on connecting rod 6, is connected with supply pipe 8 on the storage box 7, and supply pipe 8 An electronic valve 9 is provided at the connection with the storage box 7, and one end of the supply pipe 8 is connected in a placement groove 13, and an inductor 10 is arranged in the placement groove 13;

[0040] The sensor 10 is a liquid level sensor;

[0041] The conveying roller 4 is connected with an adjusting rod 11, and the conveying roller...

Embodiment 2

[0048] A method for using a roller brush equipment for medical packaging bag labels, comprising the following steps:

[0049] ⅠSet the number of conveying rollers on the support frame to be 3-8, and there is a printing roller under each conveying roller, and each printing roller is equipped with a placement slot, and the placement slots are equipped with Supply pipe, electronic valve;

[0050] Ⅱ Divide the placement slot, and each partition is equipped with inks of different colors or materials, which are placed according to actual printing needs;

[0051]Ⅲ After adding the ink into the storage tank, turn on the electronic valve and the sensor through the control switch, and turn on the rotation of the conveying roller and the printing roller, and then send the ink into the storage tank through the supply pipe;

[0052] ⅣPut the material to be printed between the conveying roller and the printing roller for conveying, and then adjust the position of the printing roller throug...

Embodiment 3

[0055] The protective coating used on the outside of the printing roller is made of the following materials in parts by weight,

[0056] 17 parts of bisphenol A epoxy resin, 7 parts of modified perlite, 3 parts of 2-methylimidazole, 4 parts of nano-attapulgite, 4 parts of itaconate, 4 parts of lignosulfonic acid, 1 part of carbon black , 3 parts of sodium carboxymethyl cellulose, 1 part of 2-amino-2-methyl-1-propanol, 6 parts of anti-aging agent AW, 8 parts of auxiliary agent, 24 parts of clear water;

[0057] The preparation method of the modified perlite is as follows: grind the perlite and pass through a 400-500 mesh sieve, then bake it at a temperature of 45°C for 30 minutes, and then add 0.8 times its mass of pure water at 60°C, Stir and mix at a constant temperature of 60°C for 1 hour, then add dioctyl azelate, lower the temperature to 40°C, continue stirring and mixing for 1.5 hours, then dry and regrind to obtain modified perlite;

[0058] The mass ratio of the diocty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com