Patents

Literature

55results about How to "Improve the wear resistance coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

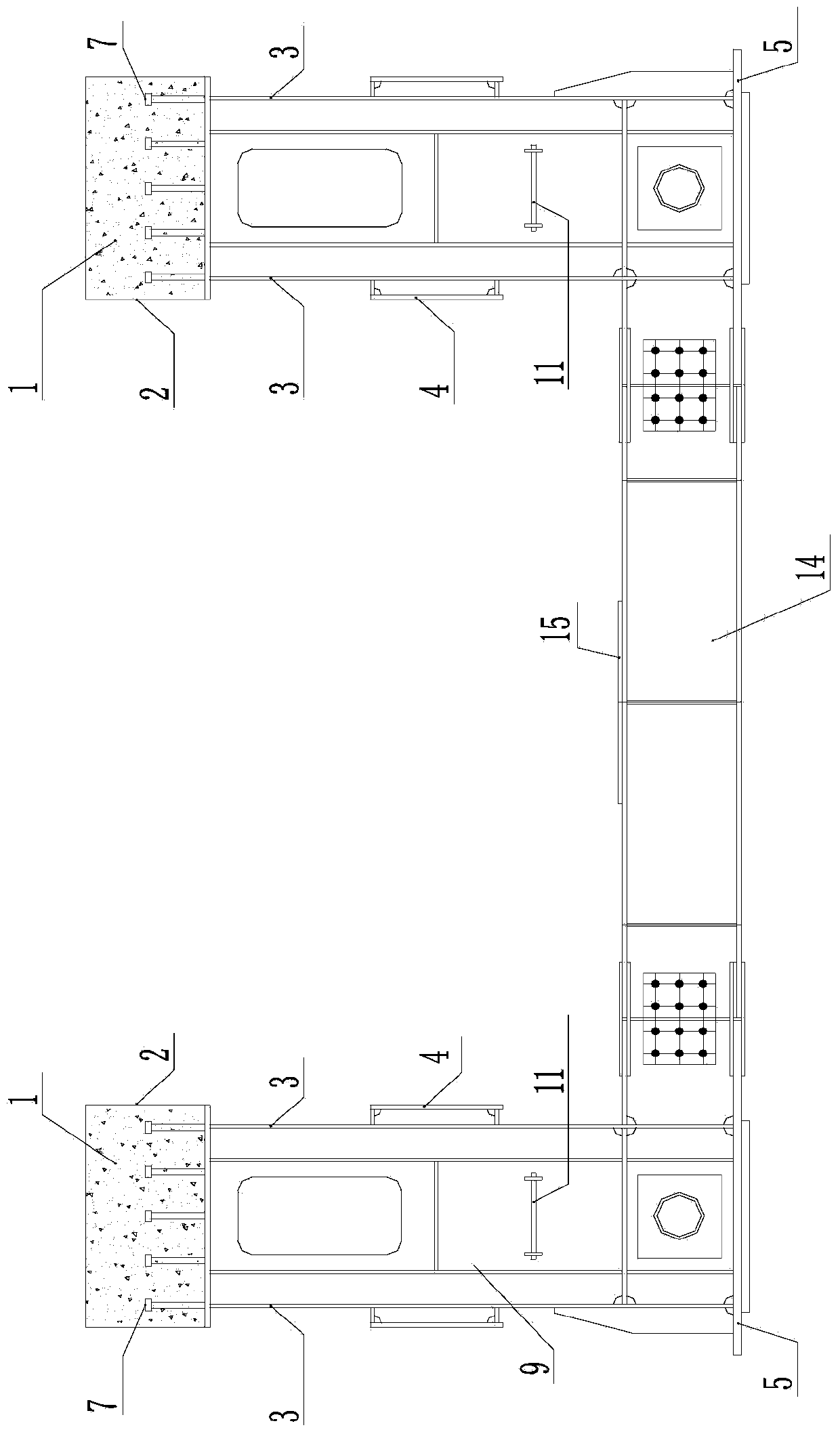

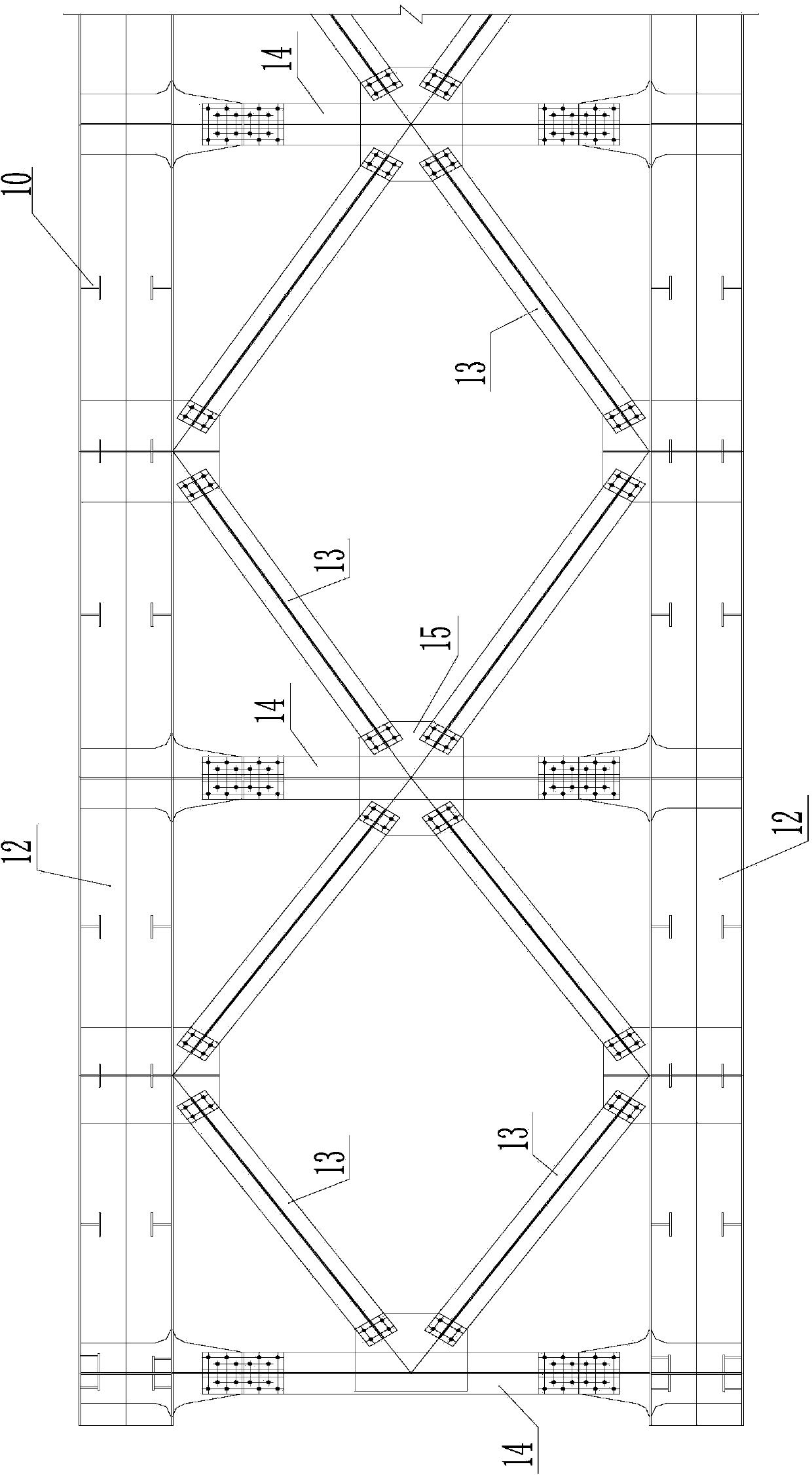

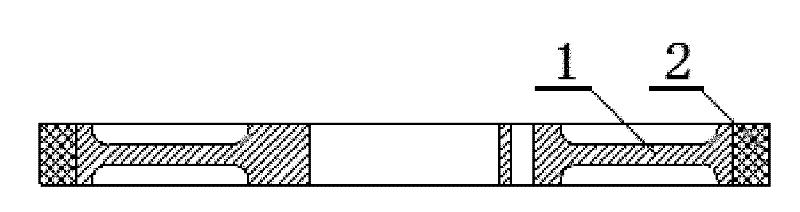

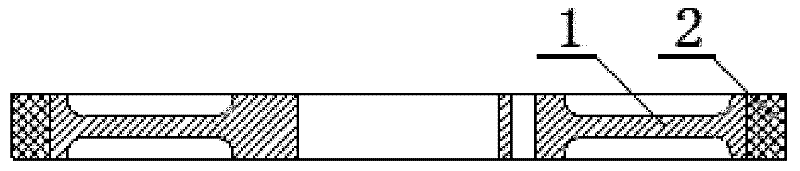

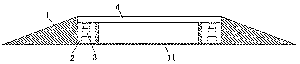

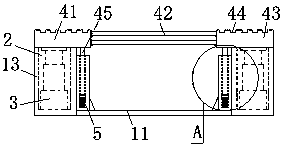

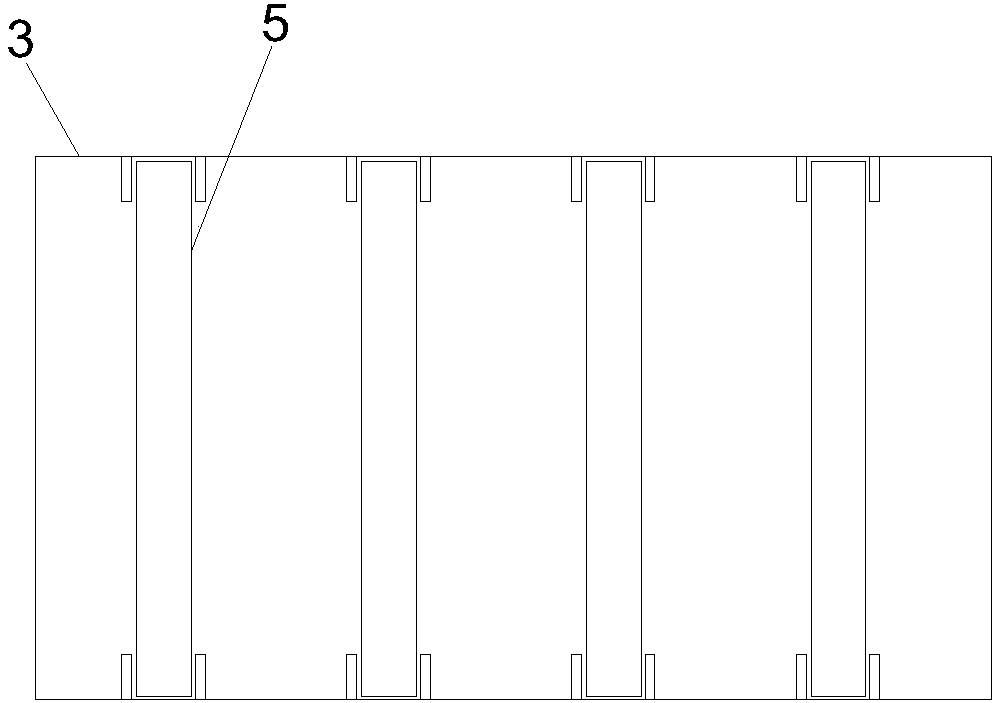

Straddle type single-track double-box rectangular steel-concrete composite track beam structure

InactiveCN104213477AImprove carrying capacityIncrease lateral stiffnessRailway tracksBridgesEngineeringSpandrel

The invention relates to the field of track beams, in particular to a straddle type single-track double-box rectangular steel-concrete composite track beam structure. The straddle type single-track double-box rectangular steel-concrete composite track beam structure comprises two steel-concrete track main beams parallel to each other; the two steel-concrete track main beams are connected through crossbeams below and a low plain longitudinal; each steel-concrete track main beam comprises a steel beam structure with a box-type cross section and a concrete cuboid structure with a rectangular cross section; each concrete cuboid structure is positioned above the corresponding steel beam structure and is connected with the steel beam structure through shear nails; the span of each steel-concrete track main beam is 30-80 meters; the cross beams are I beams and are in bolt connection with cross beam connecting plates of the steel-concrete track main beams; the low plain longitudinal is a diamond truss, and plain main rod piece parts are respectively connected with the steel-concrete track main beams and the cross beams. The straddle type single-track double-box rectangular steel-concrete composite track beam structure can be suitable for building double-line large-span track beams, and the double-line large-span track beams are large in span, high in transverse stiffness and high in transverse stress performance structurally.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

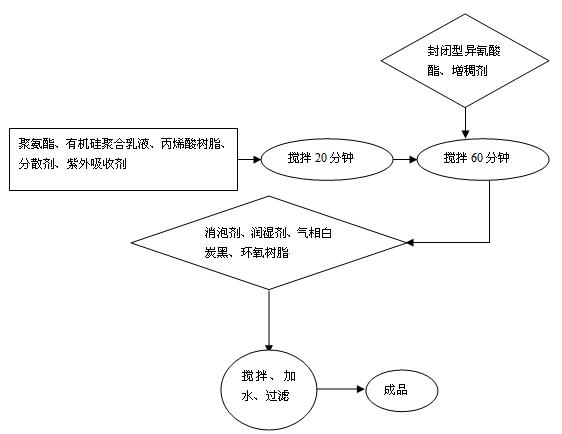

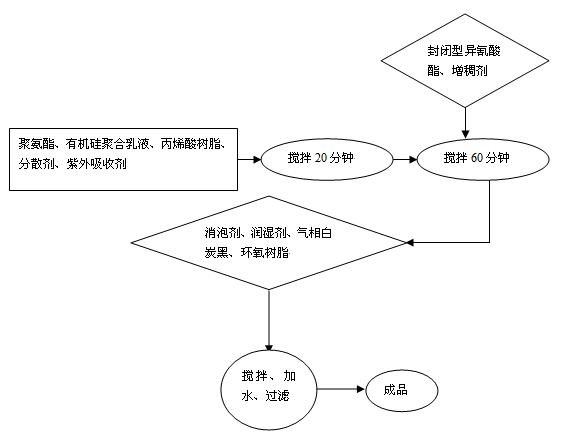

Coating for automobile sealing strip and preparation method thereof

ActiveCN102585681AGood flexibilityImprove aging resistanceAntifouling/underwater paintsPaints with biocidesEpoxySolvent

The invention discloses coating for an automobile sealing strip and a preparation method thereof. The coating comprises a film forming material, at least one curing agent, a plurality of auxiliaries, at least one packing and solvent. The film forming material comprises organic silicon polymer emulsion, epoxy resin and polyurethane. The curing agent is closed isocyanate. The auxiliaries include a dispersing agent, a wetting agent, a thickening agent, an antifoaming agent and an ultraviolet absorber, and the solvent is water. The coating for the automobile sealing strip has excellent abrasion-resistance, yellow degeneration resistance at high temperature, flexibility, pollution resistance, environmental friendliness, and is convenient to transport and use and easy to store.

Owner:云南三恩汽车新材料有限公司

Wear-resistant nano ceramic sealing ring

InactiveCN104482203AImprove mechanical propertiesGood physical propertiesEngine sealsVulcanizationWear resistant

The invention discloses a wear-resistant nano ceramic sealing ring, by means of taking nanoscale raw material white corundum, silicon dioxide, silicon carbide, boron carbide, zinc oxide, titanium oxide and the like as green body materials, and taking chloroprene rubber, silicone rubber, brominated butyl rubber, N660 carbon black, glass fiber, activating agent and PEG20000 as rubber components, the sealing ring is obtained through heat vulcanization process, the preparation process is simple and easy to industrialize, and the sealing ring prepared has excellent physical and chemical properties.

Owner:QINGDAO R & D INST XIAN JIAOTONG UNIV

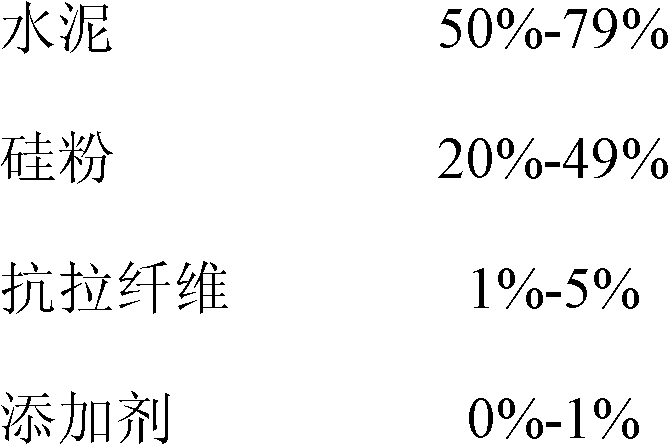

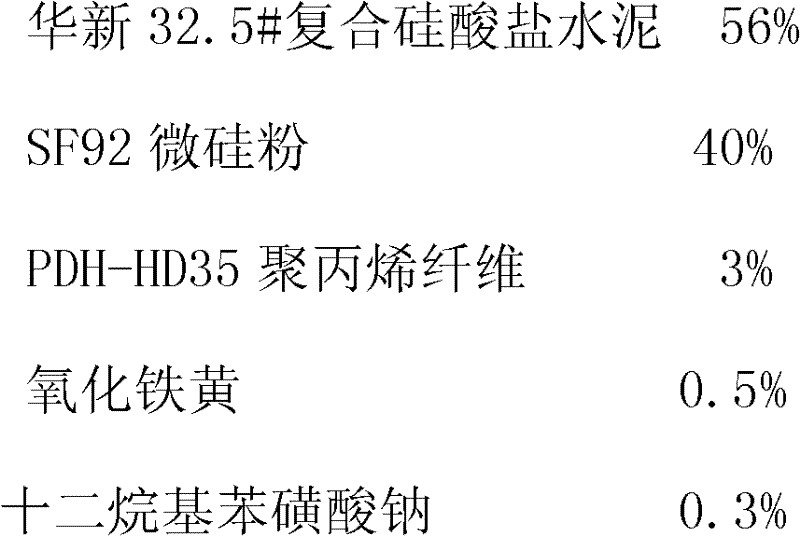

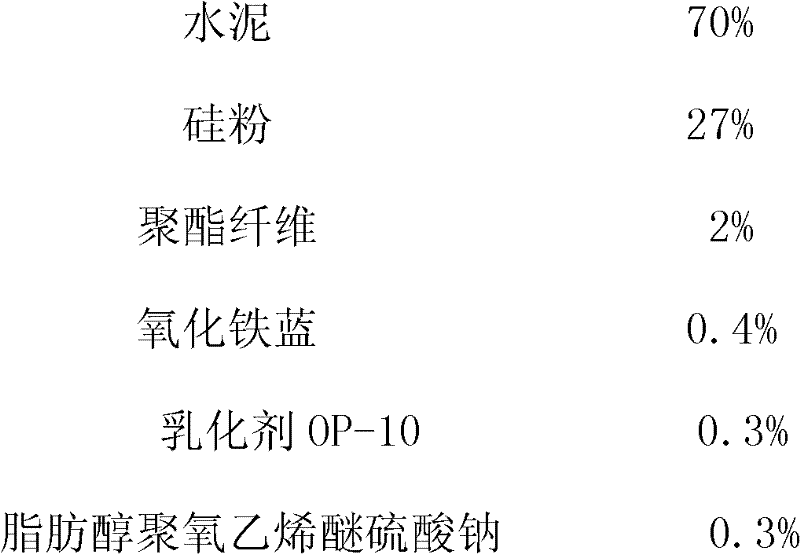

On-site molded waterproof and heat-insulating material and construction method thereof

InactiveCN102442805ASimplify the construction processLow costBuilding constructionsFiberPolymer science

The invention provides an on-site molded waterproof and heat-insulating material and a construction method thereof. The waterproof and heat-insulating material is formed by quantitatively mixing and packaging 50-70% of cement, 20-49% of silica powder, 1-5% of anti-tensile fiber and 0-1% of additive into dry powder components, quantitatively packaging polymer emulsion into a liquid component, and mixing and agitating the dry powder and the polymer emulsion on site according to the ratio of (1-2.5): (0.5-2.5), wherein the polymer emulsion is one or a mixture of more of ethylene-vinyl acetate copolymerized emulsion, pure acrylic emulsion, styrene-acrylic emulsion, silicone acrylic emulsion and aqueous polyurethane emulsion. According to the on-site molded waterproof and heat-insulating material and the construction method thereof, provided by the invention, the waterproof function and the heat-insulating function are combined into one and the construction is carried out by utilizing a continuous coating way; the system is intact and a seamless connection is used, so that the reliability of the heat-insulating and waterproof performance is high, the construction is simple and convenient, and the cost is low; and the on-site molded waterproof and heat-insulating material with a certain thickness and good ageing resistance and wear resistance can be formed.

Owner:WUHAN YOUBANG NEW MATERIAL CHEM

Novel high-wear-resistant driving wheel

InactiveCN102476406AIncrease the number of reusesLow costPortable liftingWorking accessoriesDrive wheelWear resistant

The invention discloses a novel high-wear-resistant driving wheel used on a single crystal silicon cutting squaring machine. The novel high-wear-resistant driving wheel comprises an aluminum embedding element, wherein a polyurethane layer is formed on the aluminum embedding element through injection molding, the polyurethane layer is in a double-layer structure, the inner layer is made of TPU359X materials, the outer layer is made of a mixture obtained through mixing TPUTK95A materials and 3M polytetrafluoroethylene wear-resistant agents according to a weight ratio of 1:(80-100). On one hand, the cost of products is reduced, the wear-resistant performance and the smooth finish are enhanced, and the wear-resistant coefficient is increased by more than 1.7 after the addition of the wear-resistant agents; and on the other hand, the recovery and the reutilization can be realized, and the recovery cost is further reduced.

Owner:汤子仁

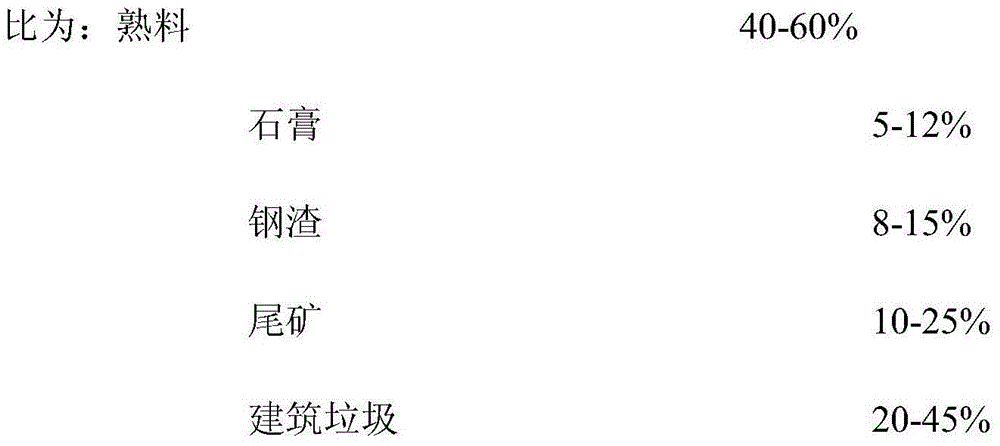

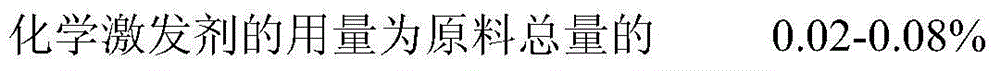

Silicate cement prepared from solid wastes and preparation method of silicate cement

The invention discloses silicate cement prepared from solid wastes and a preparation method of the silicate cement and belongs to the technical field of building materials. The silicate cement is prepared from the raw materials: clinkers, gypsum, slag, tailings and building wastes by adding a chemical excitant. The silicate cement is prepared from the following raw materials in percentage by weight: 40-60% of clinkers, 5-12% of gypsum, 8-15% of slag, 10-25% of tailings and 20-45% of building wastes, wherein the use level of the chemical excitant is 0.02-0.08% of the total weight of the raw materials; the slag is slag without metallic iron; the tailings are wastes left by exploiting a mine; the building wastes are building waste bricks or concrete plate blocks without metals or other impurities. The silicate cement disclosed by the invention is widely applied to concrete and cement products, relieves increasingly deficient clinker firing resources and reduces discharge of carbon dioxide of cement, thereby facilitating reduction of severe haze in atmosphere. primary resources are saved and replaced, so that the circular economy development is promoted and the pollution is reduced to protect the ecological environment. In the production process, further pollution on the environment is not generated.

Owner:XUZHOU YUXIN ENVIRONMENTAL PROTECTION BUILDING MATERIALS CO LTD +1

Temperature stage type calendaring film forming method of nonwoven filter cloth

InactiveCN103469514AClosely arrangedImprove the finishFiltration separationTextile shapingPolymer scienceNonwoven fabric

The invention discloses a temperature stage type calendaring film forming method of a nonwoven filter cloth. The method has the beneficial effects of stable finish of a formed film, high wearing coefficient, good regeneration effect and high filter precision. The method comprises the following steps in sequence: carrying out first calendaring treatment, with the melting temperature T1 of surface fibers of a non-woven as the temperature of calendaring rolls; carrying out second calendaring treatment, with the transition point temperature T2 as the temperature of the calendaring rolls; carrying out third calendaring treatment, with the softening point temperature T3 of the surface fibers of the non-woven as the temperature of the calendaring rolls, wherein the transition point temperature T2 is equal to (T1+T3) / 2+ / -5 DEG C.

Owner:LIAONING XUANYUAN FILTRATION TECH

Composite material for carbon brush used for electric machine and preparation method thereof

The invention discloses a composite material for a carbon brush used for an electric machine and a preparation method thereof. The composite material is composed of modified tungsten dioxide, nanometer graphite powder, epoxy resin and a filler in a weight ratio of (20-32): (12-18): (5-14): (2-9), wherein the modified tungsten dioxide comprises, by weight, 5-8 parts of tungsten dioxide, 18-24 partsof a dopamine solution, 2-8 parts of foamy copper and 1-3 parts of steel fibers. Compared with the prior art, the composite material and the preparation method thereof in the invention have the following advantages: through the modification treatment of tungsten dioxide, the usage amount of tungsten dioxide and the cost of materials used for the carbon brush are reduced; the modified tungsten dioxide is loaded with the steel fibers and carbon fibers, so the wear resistance of tungsten dioxide is improved, and the weight of tungsten dioxide is reduced; and since the carbon brush is prepared from the modified tungsten dioxide, the wear resistance coefficient of the carbon brush is improved and the service life of the carbon brush is prolonged.

Owner:JIANGSU HUAYU CARBON

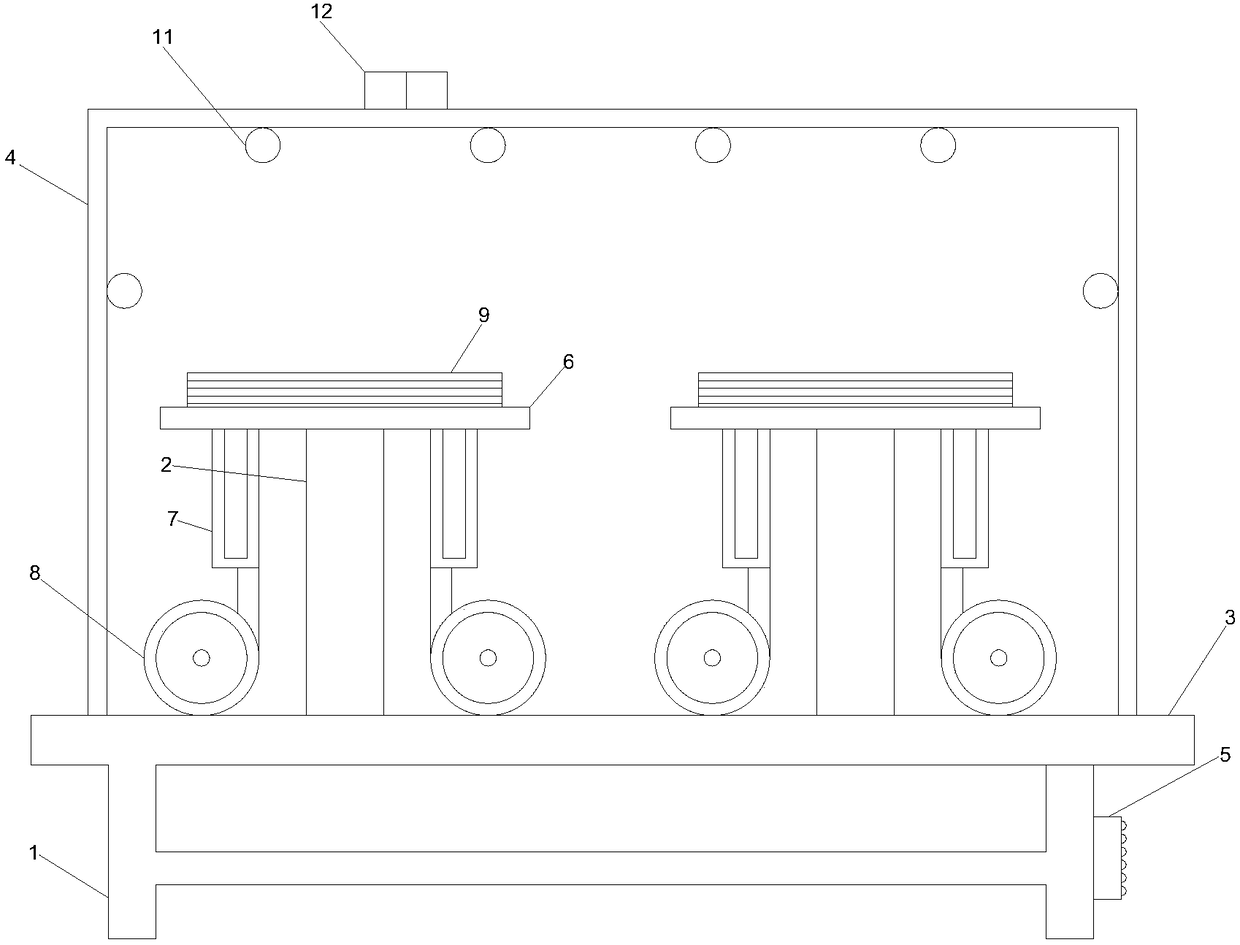

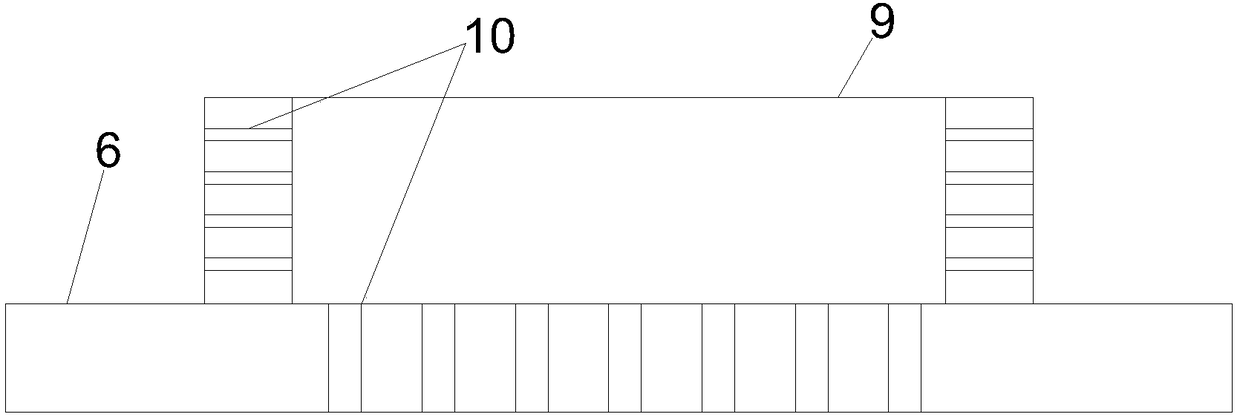

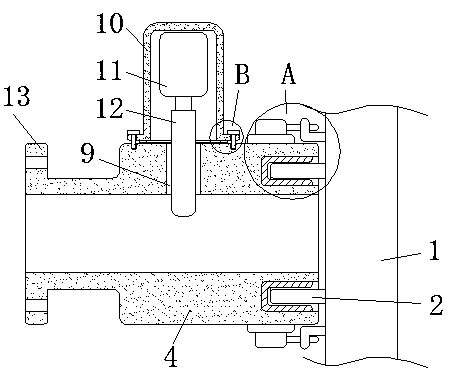

Lifting platform for automobile repair

InactiveCN107720619ASimple internal structureSimple structureLifting framesVehicle servicing/repairingStable stateSurface roughness

The invention discloses a lifting platform for automobile repair. The lifting platform comprises two sloping benches arranged in a mirroring manner, a lifting plate located in the middles of the topsof the sloping benches, and hydraulic jacks for impelling the lifting plate to lift. The structural strength of the lifting plate can be improved, the situation that the lifting plate is broken duringuse due to continuous pressing and clamping force generated by the automobile weight on the lifting plate is prevented, by the action of U-shaped ribs, the surface roughness of the lifting plate is increased, the wearing coefficients of the lifting plate is raised, the abrasion to the lifting plate by vehicle movement when the lifting plate is in use is lowered, the lifting plate can be kept in abalanced and stable state all the time during lifting, and the rock abrasion borne by the lifting plate is reduced, thus the service life of the lifting plate is prolonged, and the service life of the lifting platform for the automobile repair is further prolonged.

Owner:东莞产权投资有限公司

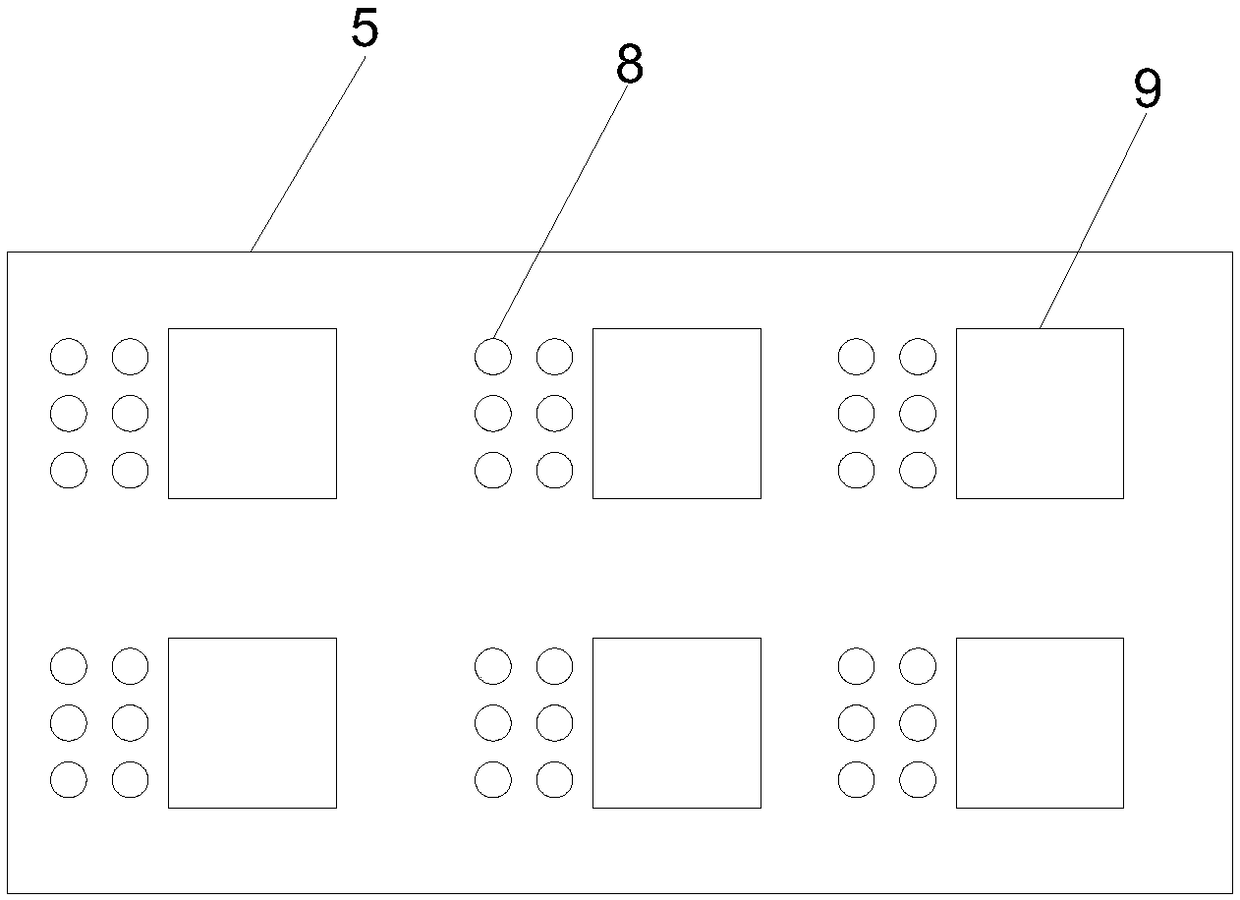

Inspection device of medical breathing bags

InactiveCN108344716ADetect light transmittanceDetect and removeFluid-tightness measurement by detecting dimension changeTransmissivity measurementsBreatherBiochemical engineering

The invention discloses an inspection device of medical breathing bags, and belongs to the technical field of medical supply processing and producing. The inspection device comprises a support frame;a bottom plate is arranged on the support frame; connecting rods are arranged on the bottom plate; a viewing hood is arranged on the bottom plate; the connecting rods are arranged in the viewing hood;a controller is arranged on the support frame; each connecting rod is provided with a fixed plate; breather pipes are arranged on the lower part of each fixed plate; one end of each breather pipe isconnected with a blower fan; a support ring is arranged on each fixed plate; each support ring is provided with rubber bands; viewing lamps are arranged on the viewing hood; the viewing lamps are connected with a switch; the switch is arranged on the upper part of the viewing hood. The inspection device is reasonable in structure; operation is convenient; and detection is more convenient.

Owner:TIANCHANG JIARUI PACKAGING MATERIAL CO LTD

Lead screw-nut wear-resistant special material

InactiveCN102586671AImprove the wear resistance coefficientLow manufacturing costAlloy elementWear resistant

The invention relates to the field of forging material, in particular to a lead screw-nut wear-resistant special material. The invention provides the lead screw-nut wear-resistant special material which takes common grey cast iron as base material; then, before pouring, alloying elements and non-ferrous metal (including 10% of Cu element, 10% of ductile iron element, 6% of Cr steel element and 2% of Ni element) are added into the base material; and the original pouring technology is adjusted, the proportional alloy is added into cast iron after the cast iron is melted, and pouring is carried out after the cast iron is fully melted.

Owner:大连佐佐木专用设备制造有限公司

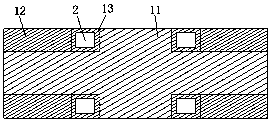

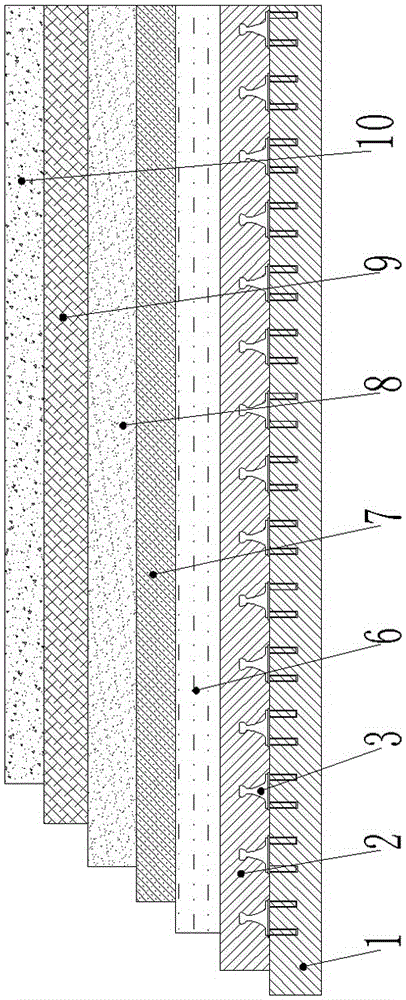

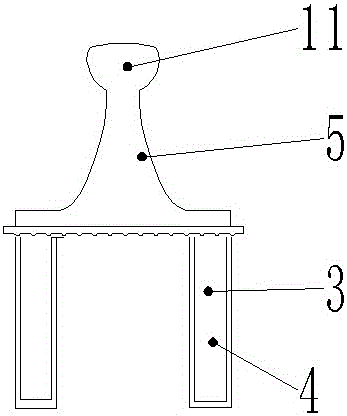

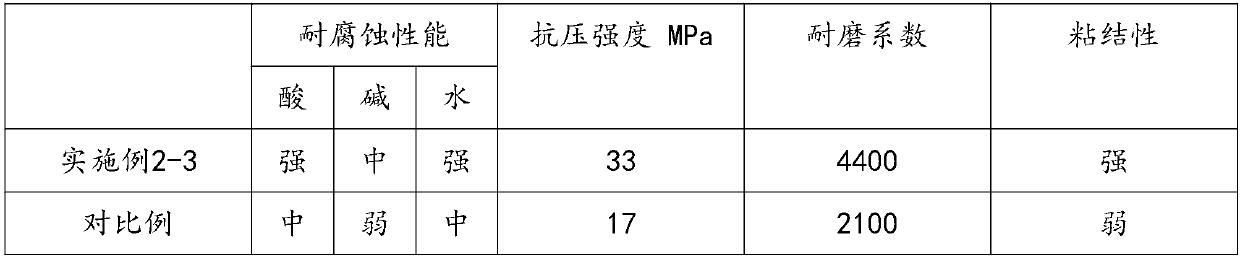

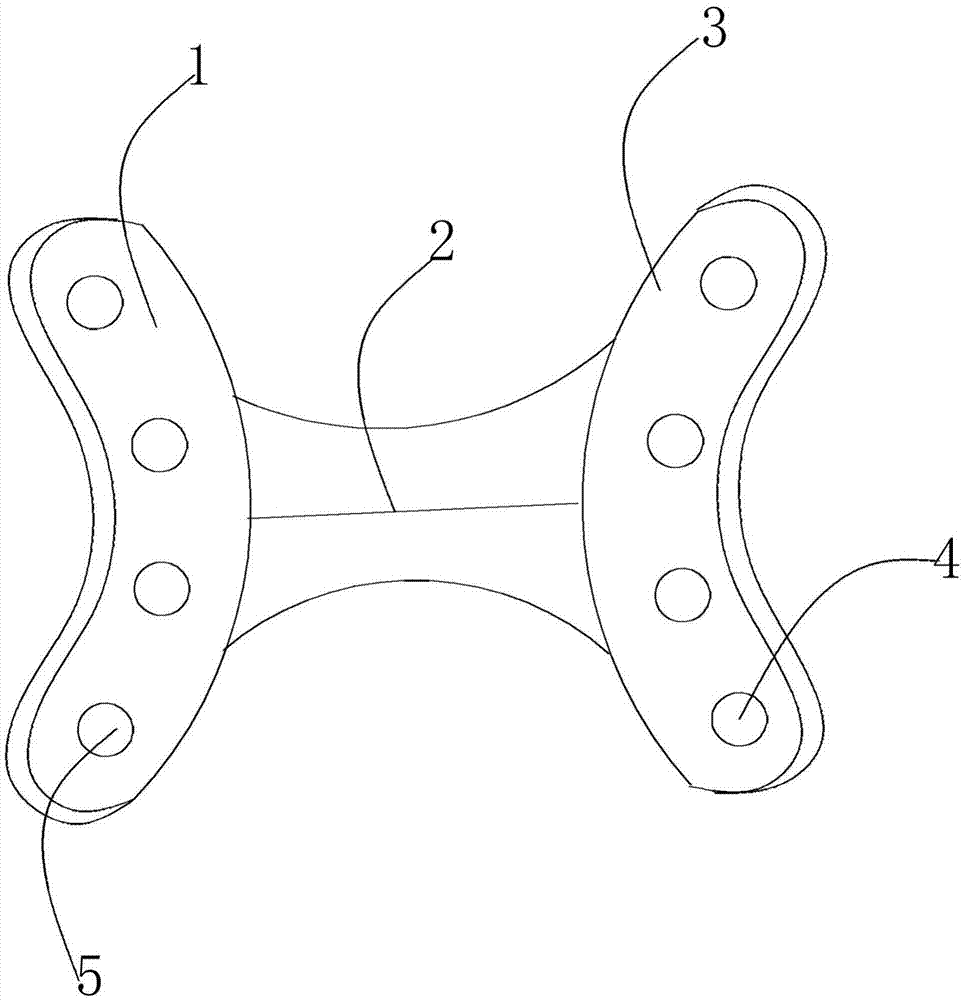

Anti-static wear-resistant floor

InactiveCN105863214AImprove the wear resistance coefficientExtended service lifeFlooringWear resistantEngineering

The invention belongs to the field of floor technology, and specifically relates to an antistatic epoxy resin floor; the specific technical solution is: an antistatic wear-resistant floor, including a concrete layer placed at the bottom and an epoxy resin layer laid on the top of the concrete layer High-permeability primer layer, multiple embedded parts are arranged in the concrete layer, the bottom of the embedded part is provided with two feet, and the top of the embedded part is provided with a lock. The parts are fixed in the epoxy high-permeability primer layer, the top of the epoxy high-permeability primer layer is laid with an oily conductive putty layer, the top of the oily conductive putty layer is coated with an antistatic primer layer, and the top of the antistatic primer layer Coated with an antistatic intermediate coating, the top of the antistatic intermediate coating is coated with an antistatic top coating, and the top of the antistatic top coating is coated with an aggregate wear-resistant layer. The surface of the present invention is worn to a certain extent, It will not damage the conductive tape, and it can be repaired only by recoating the surface of the floor to realize repeated use.

Owner:SHANGHAI FENGBANF BUILDING MATERIAL TECH CO LTD

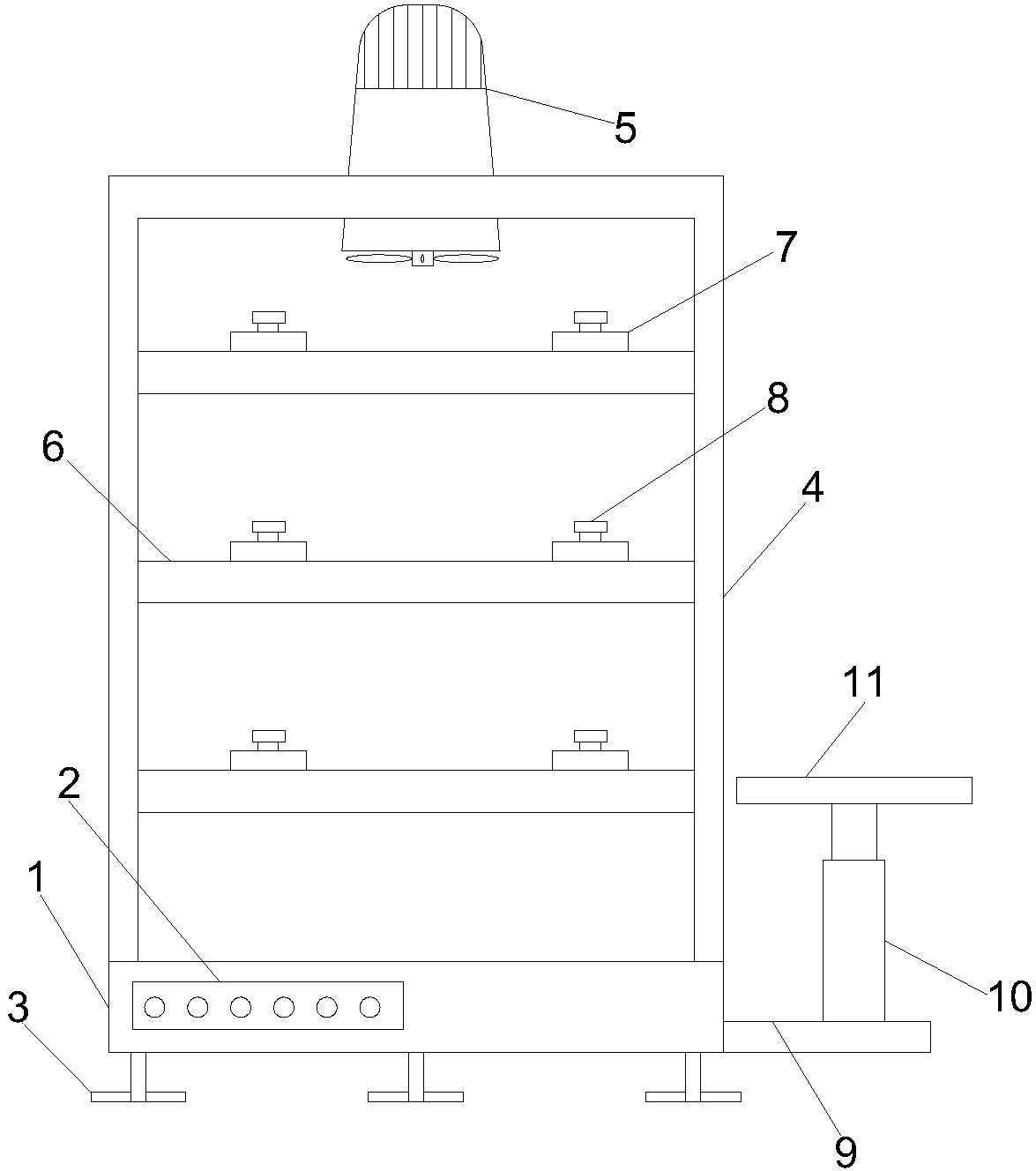

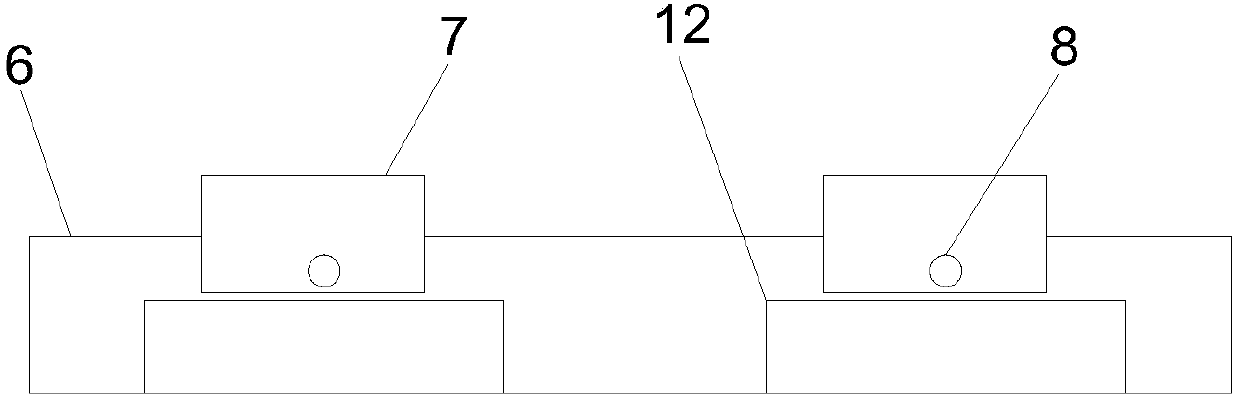

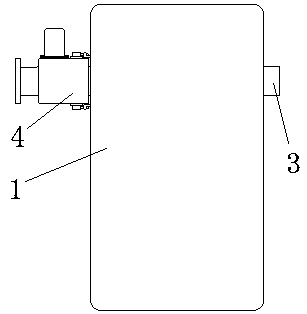

Placing equipment for mold for graphite polystyrene board

InactiveCN108032271AImprove toughnessEasy to operateAnti-corrosive paintsWork tools storageMarine engineeringPolystyrene

The invention discloses placing equipment for a mold for a graphite polystyrene board and relates to the technical field of transformation of decorative material production equipment. The placing equipment is characterized by comprising a supporting plate; a controller is arranged on the supporting plate; lifting devices are arranged below the supporting plate; a supporting frame is connected above the supporting plate; an air blowing device is arranged above the supporting frame; connecting frames are mounted on the supporting frame; baffles are arranged on the connecting frames; a connectingrod is arranged beside the supporting plate; a hoist is arranged on the connecting rod; and a standing platform is fixed to the upper end of the hoist. The placing equipment is reasonable in structure and convenient to operate and use.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

Wear-resistant coated wire with stable structure and preparation method thereof

InactiveCN106243787AImprove the wear resistance coefficientStrong adhesionCoatingsFiberWear resistant

The invention discloses a wear-resistant coated wire with stable structure and a preparation method thereof. The wear-resistant coated wire comprises a wire matrix and a coating. The coating comprises nanometer silica, nanometer calcium carbonate, vinyl acetate, vinyl butyl acetate, polyvinyl alcohol, epoxypropane, polyethylene wax, cellulose ether, fatty alcohol polyoxyethylene ether, acrylate, polydimethylsiloxane, polyethylether, rare earth, attapulgite, montmorillonite, silicon carbide, polyamide, high-carbon ferro-chrome powder and PAN-based carbon fiber. The wear-resistant coated wire with stable structure disclosed in the invention has the advantages of good wear resistance, adhesion, etc.

Owner:安徽飞弧焊业股份有限公司

Novel polymer composite material and preparation method thereof

The invention relates to a novel polymer composite material and a preparation method thereof. The raw materials of the novel polymer composite material comprise, by weight, 6-8 parts of calcium stearate, 5-7 parts of zinc stearate, 3-6 parts of TBHQ, 4-8 parts of octadecanoic acid, 2-6 parts of papain, 6-10 parts of silicone oil, 5-9 parts of cocoanut fatty acid diethanolamide, 2-5 parts of PPD, 3-10 parts of fatty alcohol polyoxyethylene ether and 8-10 parts of deionized water. The novel polymer composite material has the advantages of easiness in obtaining, low cost, environmental protection, greenness, reduced frictional performance, reduced resistance, easiness in absorption, acceleration of the lubrication speed, improvement of the wear resistance, increased wetness, increase of the surface tension, improved toughness, fast emulsification speed and good anti-oxidation effect and prolongation of the service life.

Owner:伊婕

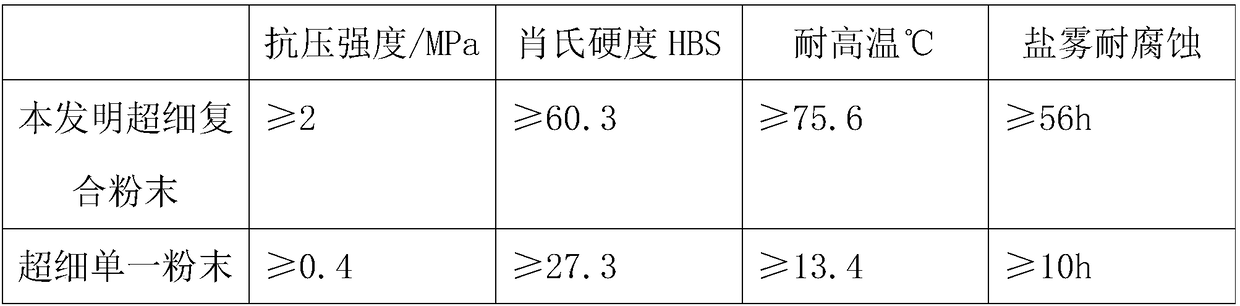

Production method of novel composite powder material containing superfine components

InactiveCN109047777AImprove scalabilityHigh degree of moldingTransportation and packagingMetal-working apparatusHigh energyFatty acid

The invention discloses a production method of a novel composite powder material containing superfine components. The production method of the novel composite powder material containing superfine components comprises the following concrete steps of (1) mixing glycerinum, fatty acid, ethylene oxide, hexadecanol, triethylamine alcohol and water, feeding into a high-temperature stirrer after preliminary mixing, heating for stirring, and obtaining a grinding agent; (2) feeding cobalt, titanium, tungsten carbide, chromium, copper and steel into a high-energy ball-milling machine for grinding, adding a dispersing agent and the grinding agent obtained in the step 1 during the grinding process, preventing the agglomeration of particles, changing the grinding environment, utilizing a cloth dust collector for recovering after finishing grinding, and obtaining metal composite powder; and (3) feeding the metal composite powder obtained in the step 2 into a reaction stirring tank, and stirring at high temperature. The hardness of superfine powder during use is increased, the crushing resistance is improved, the smoothness of the appearance is further improved due to heavy grinding and the use of the dispersing agent, and the occurrence of the phenomena of breakage and cracks after forming is reduced.

Owner:王玉环

Binder with strong high-temperature resistance

InactiveCN109694674ARaise the initial decomposition temperatureHigh maximum thermogravimetric rate temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolystyreneTemperature resistance

The invention discloses a binder with strong high-temperature resistance, and belongs to the field of binders, wherein the binder comprises, by weight, 250-300 parts of aluminum hydroxide, 100-250 parts of an ethylene-vinyl acetate-acrylate copolymer, 100-200 parts of polyethylene powder, 100-150 parts of an ethylene-vinyl chloride copolymer, 90-100 parts of a polyester resin, 70-80 parts of a polyamide resin, 60-70 parts of a polystyrene resin, 30-40 parts of a xylene resin, 30-35 parts of talc powder, 20-35 parts of dibutyl phthalate, 20-30 parts of a bisphenol A type epoxy resin, 10-20 parts of N-phenyl-N'-isopropyl-p-phenylenediamine, 10-20 parts of 2,6-di-tert-butyl-p-cresol, 10-15 parts of a rosin resin, 5-10 parts of bis(2-ethylhexyl) phthalate, and 1-5 parts of a Tween type emulsifier. According to the present invention, with the binder of the present invention, the problems of low high-temperature tolerance and easy shedding at a high temperature of the common binder can be effectively solved.

Owner:朱岳丹

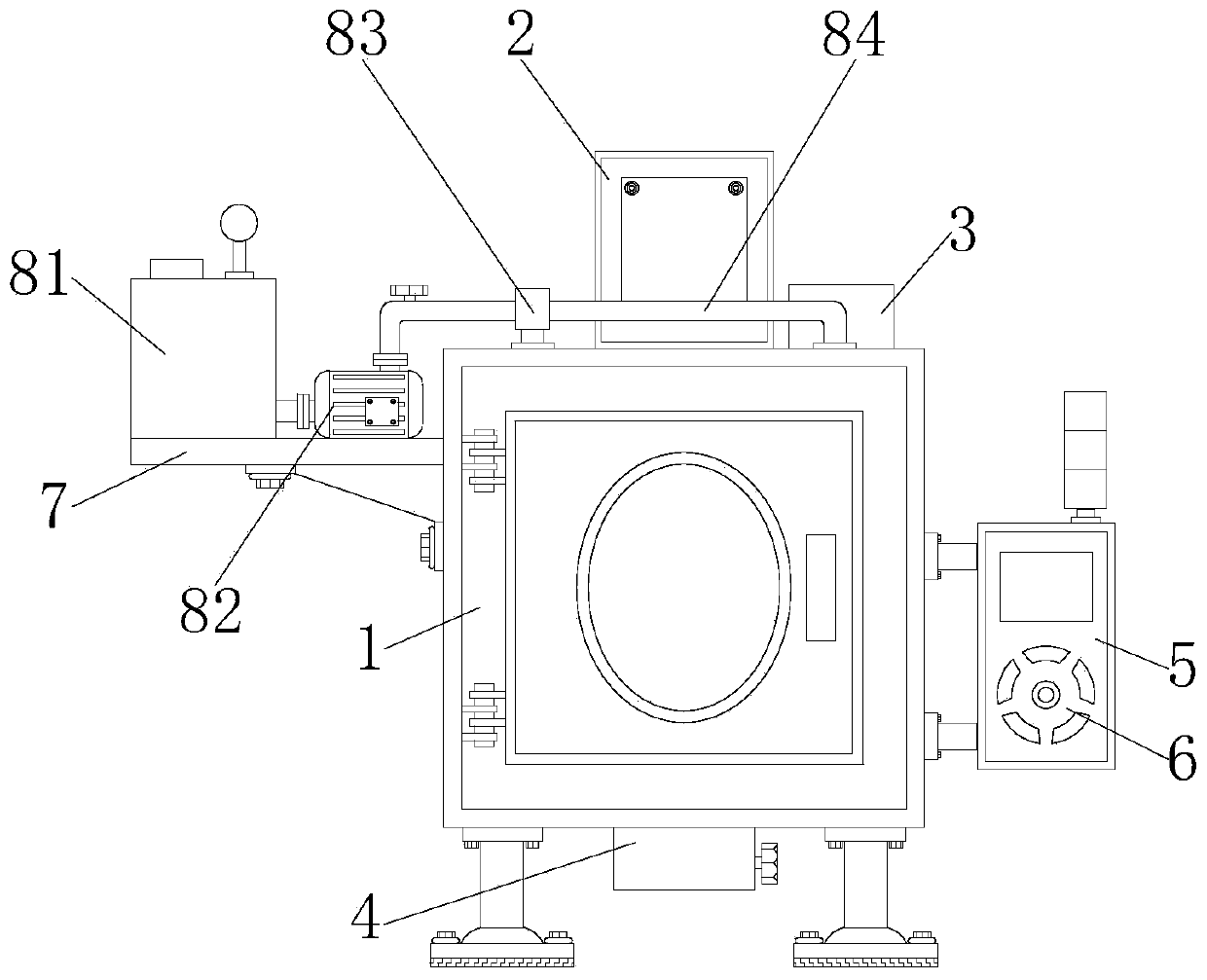

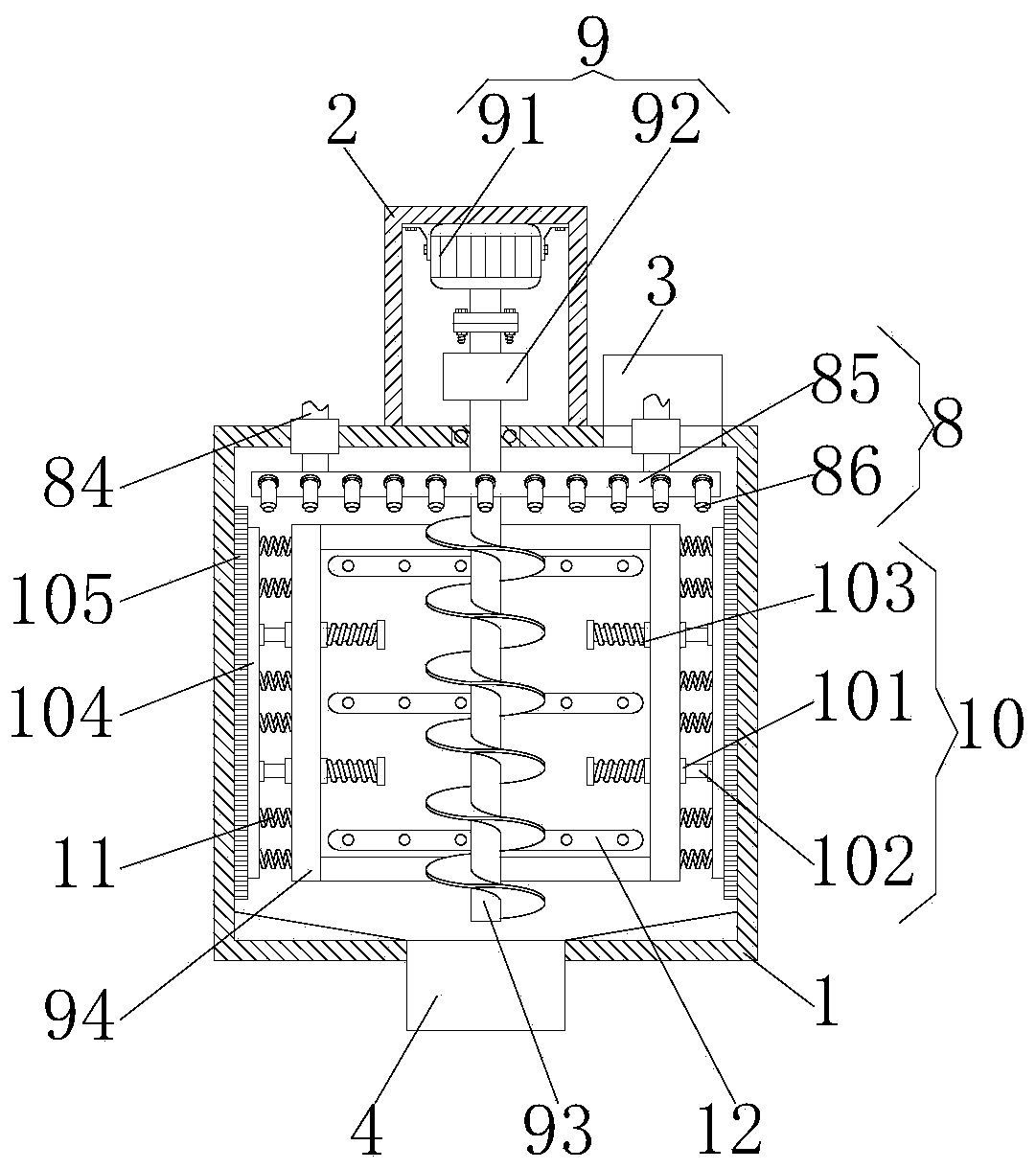

Textile printing and dyeing dye stirring structure with scraper mechanism

InactiveCN111282484AEnhanced spray lubrication effectEnhanced elastic cushioning effectRotary stirring mixersTransportation and packagingTextile printerElectric machinery

The invention provides a textile printing and dyeing dye stirring structure with a scraper mechanism. The stirring structure comprises a tank body, wherein a fixed frame is bolted to the center of thetop of the tank body; a feeding pipe communicates with the right side of the top of an inner cavity of the tank body, a discharging pipe communicates with the center of the bottom of the inner cavityof the tank body, a controller is bolted to the bottom of the right side of the tank body, a speed adjusting button is movably connected to the bottom of the front face of the controller, and a supporting plate is transversely bolted to the top of the left side of the tank body. A driving source is provided through a booster water pump; then a three-way pipe, a manifold, an annular communicatingframe and a high-pressure spray head are matched in structure; cleaning liquid in a water tank is evenly sprayed to the inner wall of the tank body, then the spraying lubricating effect between a scraper and the tank body is enhanced, a driving source is provided through a high-speed motor, then through structural cooperation of a gear motor, a stirring shaft and a stirring frame, printing and dyeing dye in the tank body can be fully mixed, and meanwhile the scraper is driven to rotate circumferentially.

Owner:WUJIANG FUAILIANG TEXTILE

Unconventional-structure pipeline and manufacturing method thereof

ActiveCN106352167ASimple methodReduce difficultyFlanged jointsRigid pipesEngineeringShock resistance

The invention discloses an unconventional-structure pipeline and a manufacturing method thereof. The unconventional-structure pipeline comprises a pipeline body. The pipeline body is composed of an outer wall and an inner pipe. The outer wall is in a quadrangular frustum pyramid shape, a hoop is arranged in the middle of the outer wall, a pair of lifting lugs are arranged on the left side and the right side of the upper portion of the outer wall, and a reinforcing plate is arranged between the lifting lugs. A first lining plate is arranged in the inner pipe of the pipeline body, a bolt hole is formed in the first lining plate, an annular groove is formed in the position, at the edge of the bolt hole, of the first lining plate, an installation hole is formed in the corresponding position, below the bolt hole in the first lining plate, of the pipeline body, the pipeline body and the first lining plate are connected by installing a bolt in the bolt hole and the installation hole, the first lining plate is formed by splicing lining plate blocks, a second lining plate is connected to the first lining plate on the pipeline body through an adhesive layer, and grooves are formed in the second lining plate. The unconventional-structure pipeline has the advantages of being stable in structure, high in safety coefficient, convenient to carry, assemble and disassemble, convenient to replace at a later stage, resistant to wear and good in anti-impact effect.

Owner:NANTONG HONGBO MACHINERY

Abrasion-resistant environment-friendly corrugated paper

InactiveCN110528330AImprove firmnessImprove surface propertiesFlexible coversWrappersEnvironmental resistanceCross-link

The invention discloses abrasion-resistant environment-friendly corrugated paper, and belongs to the technical field of papermaking. The abrasion-resistant environment-friendly corrugated paper is prepared from the components in parts by weight: 50-60 parts of plant straw, 80-100 parts of waste paper, 10-20 parts of polyvinyl alcohol fibers, 10-15 parts of adipic acid cross-linked starch, 5-8 parts of sodium carbonate, 2-5 parts of a penetrant, 20-30 parts of shell powder, 10-15 parts of a styrene-acrylate copolymer, and 5-10 parts of polyacrylamide. The abrasion-resistant environment-friendlycorrugated paper is corrugated raw paper which is high in abrasion resistance, low in production cost, environmentally friendly and capable of realizing resource utilization of solid waste.

Owner:枣阳宏飞纸箱包装厂

A method for preparing ceramic sealing rings from waste materials

ActiveCN104482205BGood physical propertiesImprove mechanical propertiesEngine sealsSolid waste disposalVulcanizationBoron carbide

The invention discloses a method for preparing a ceramic sealing ring by using waste materials, by means of taking industrial waste ceramic materials, silicon dioxide, silicon carbide, boron carbide, zinc oxide, titanium oxide and the like as green body materials, and taking waste silicone rubber, brominated butyl rubber, N660 carbon black, glass fiber, activating agent and PEG20000 as rubber components, the sealing ring is obtained through heat vulcanization process, the preparation process is simple and easy to industrialize, and the sealing ring prepared has excellent physical and chemical properties.

Owner:黎清弟

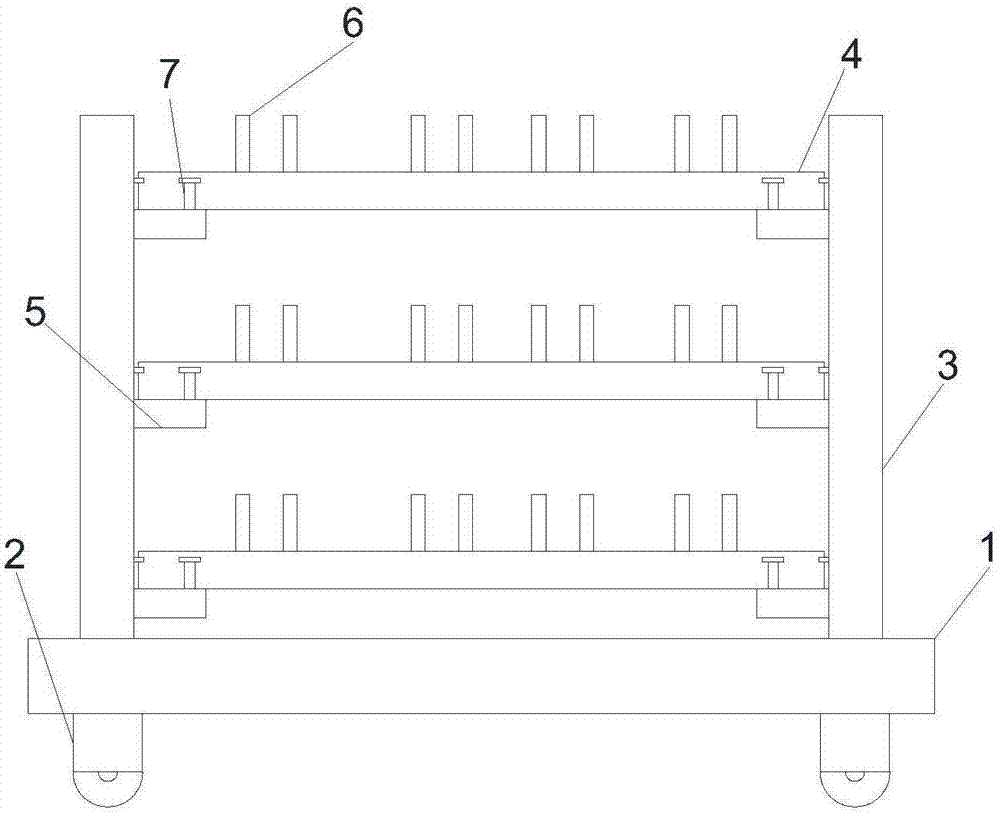

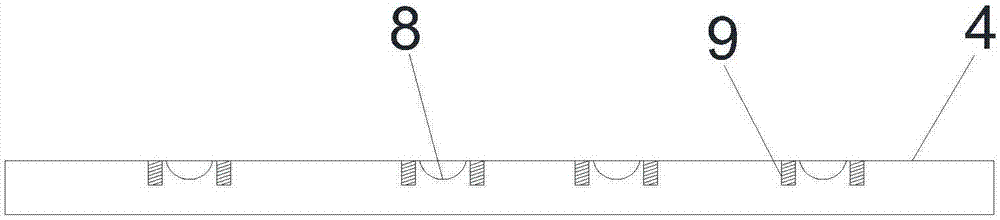

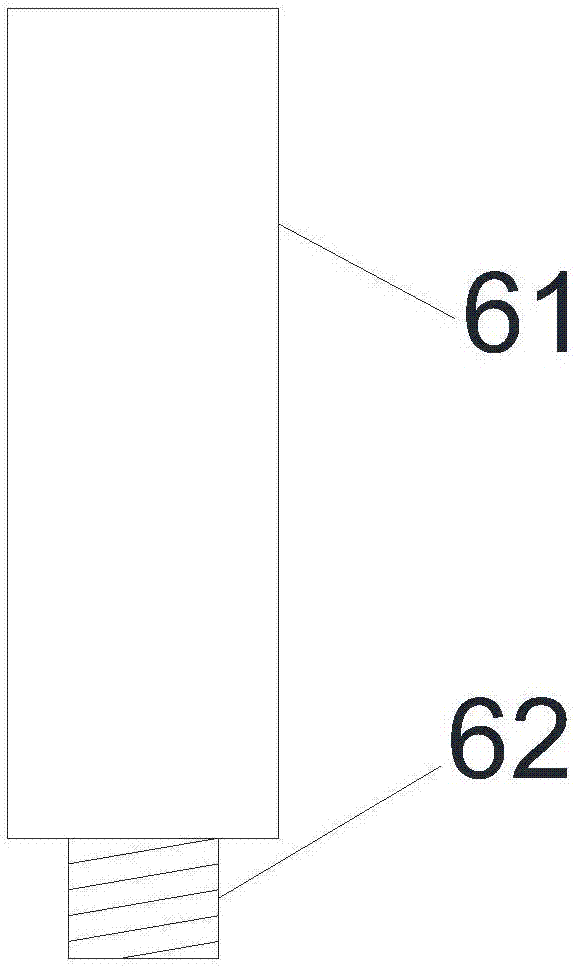

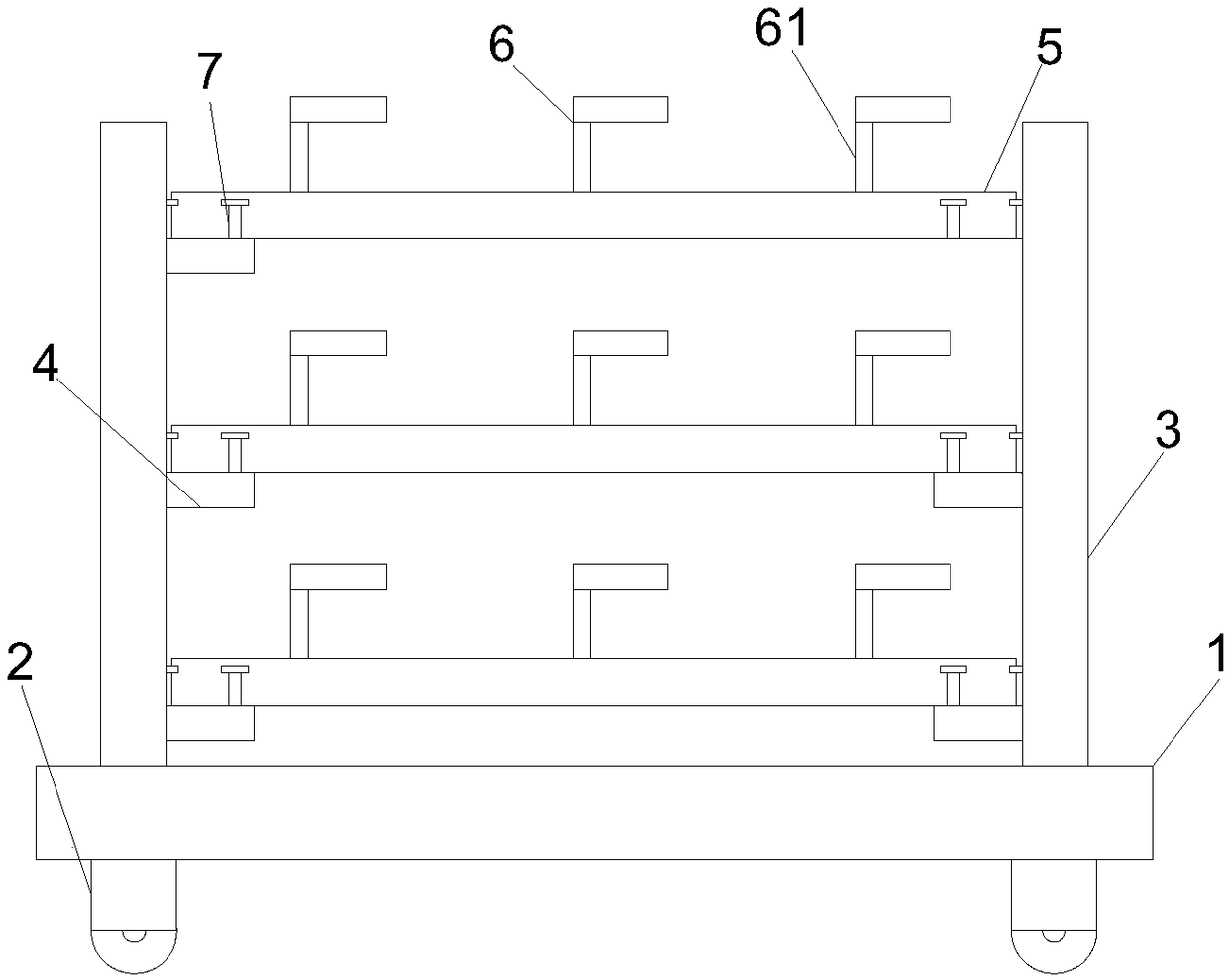

Motor cover accommodating equipment

InactiveCN107955430AImprove toughnessImprove the wear resistance coefficientAnti-corrosive paintsPolyester coatingsAgricultural engineeringIdler-wheel

The invention discloses motor cover accommodating equipment and relates to the technical field of motor processing and production. The motor cover accommodating equipment is characterized by comprising a bottom plate, wherein idler wheels are connected to low part of the bottom plate, an accommodating frame is arranged above the bottom plate, an accommodating plate is arranged in the accommodatingframe, the accommodating plate is connected to the accommodating frame through a fixing bench, an accommodating groove is formed in the accommodating plate, a locating rod is arranged beside the accommodating groove, and a through hole is formed in the accommodating plate. The motor cover accommodating equipment disclosed by the invention has the advantages of reasonable structure, convenience inoperation and convenience in use.

Owner:安徽省锦艺农业科技开发有限公司

A wear-resistant nano-ceramic sealing ring

InactiveCN104482203BImprove mechanical propertiesGood physical propertiesEngine sealsVulcanizationWear resistant

Owner:QINGDAO R & D INST XIAN JIAOTONG UNIV

Storage device for interphone shell

InactiveCN108044584AEasy to take outEasy to useWork tools storageCoatingsElectronic communicationEngineering

The invention relates to the technical field of machining and production of electronic communication equipment, in particular to a storage device for an interphone shell. The storage device for the interphone shell is characterized in that the storage device comprises a supporting frame, a supporting table is installed on the supporting frame and provided with a storage box, a sealing cover is arranged at the bottom of the storage box, partition plates are arranged in the storage box, the storage box is provided with through holes and further provided with a vibration motor, and a switch is arranged beside the vibration motor. The storage device for the interphone shell is reasonable in structure and convenient to operate and use.

Owner:孟凡志

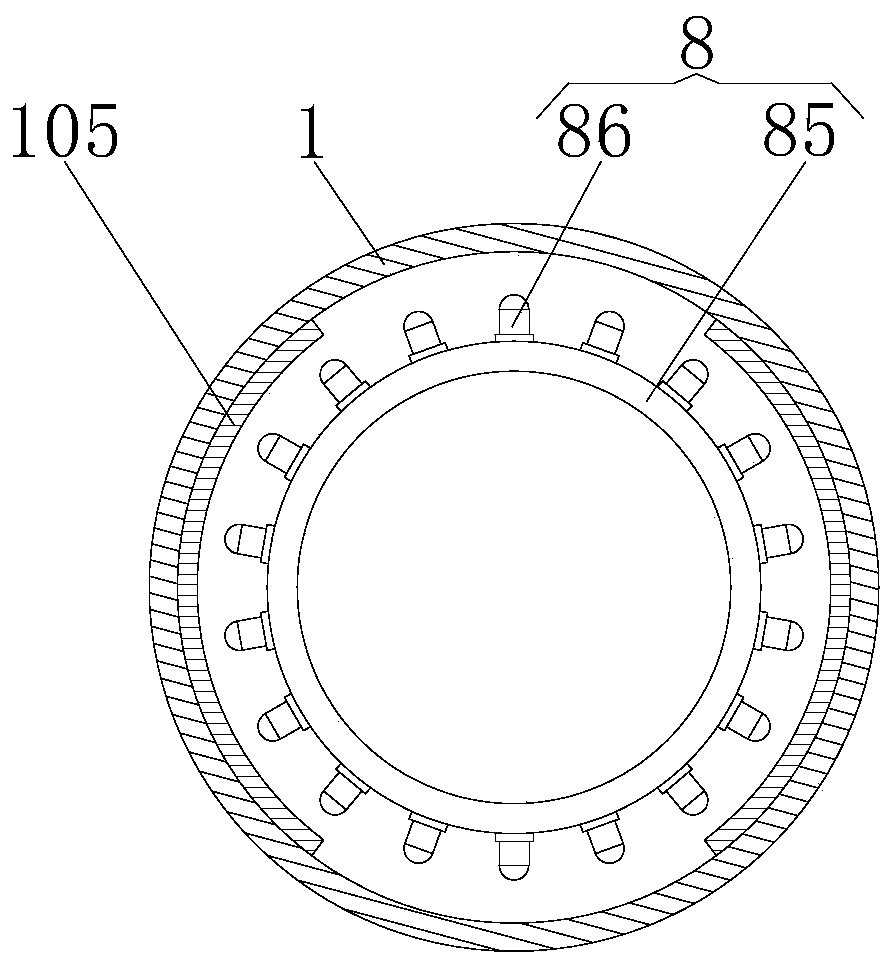

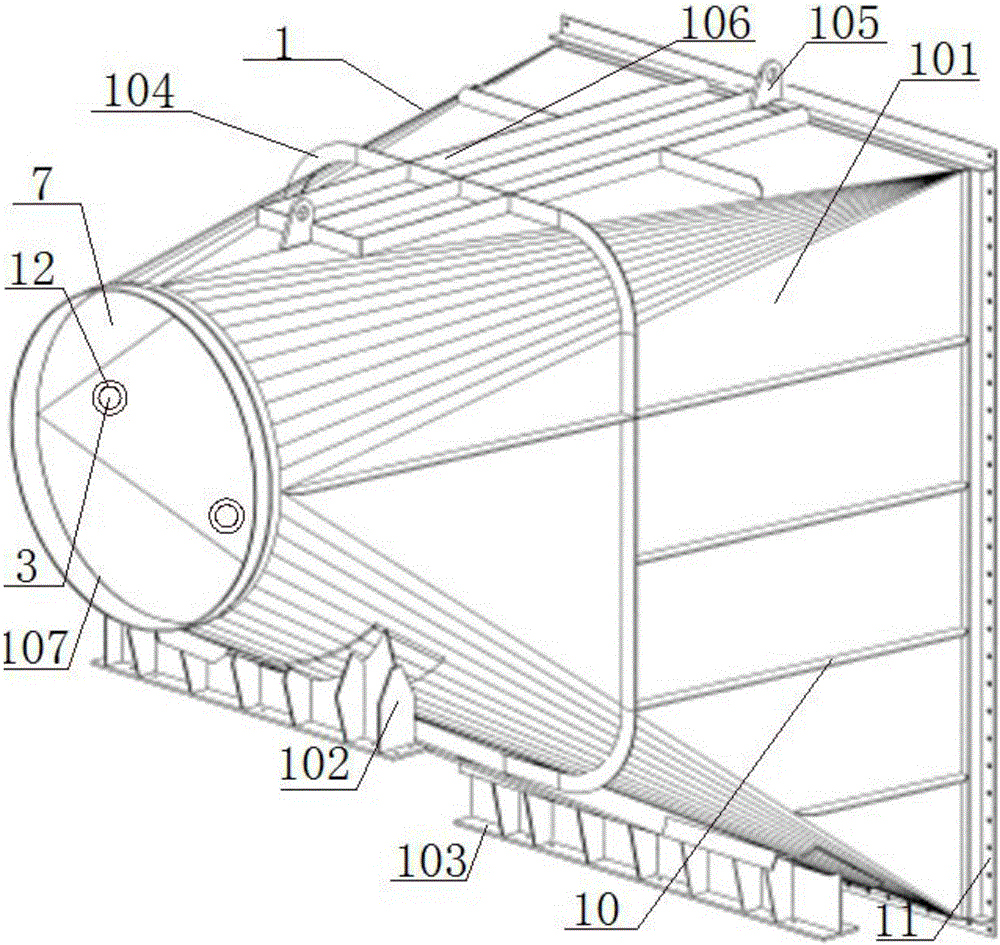

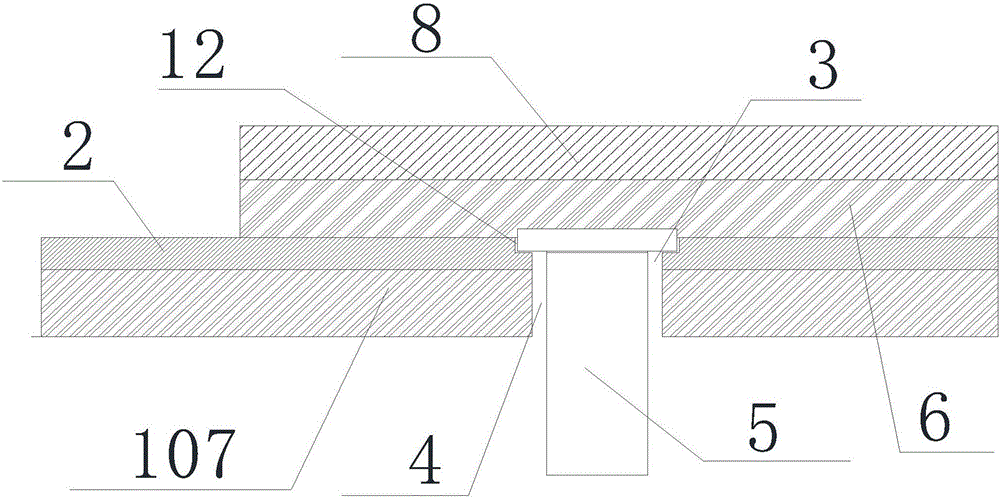

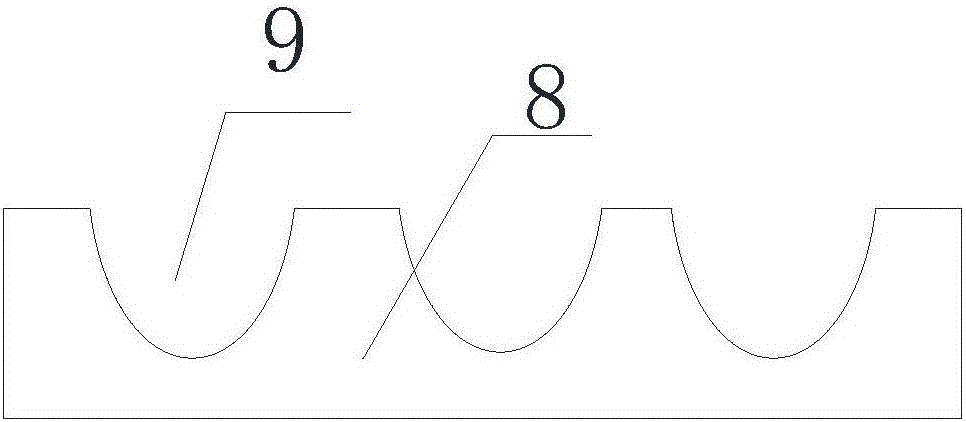

Improved boiler separator

InactiveCN109631026AIncreasing the thicknessImprove separation efficiencyFluidized bed combustionDispersed particle filtrationHydraulic pumpEngineering

The invention discloses an improved boiler separator which comprises a main body, wherein the main body is provided with an inlet and an outlet; a cylinder is coaxially arranged outside the inlet andmade of an abrasion-resistant material; a ring-shaped groove is coaxially formed in the end, close to the inlet, of the cylinder; the inlet is clamped into the ring-shaped groove in a clamping manner;a guiding hole is formed in the side wall of the cylinder; a shell is arranged at the opening of the guiding hole and fixed on the side wall of the cylinder; a hydraulic pump is fixed on the inner top wall of the shell; and a limiting plate is fixed at the extending end of the hydraulic pump and movably inserted into the guiding hole. By the adoption of the improved boiler separator disclosed bythe invention, the feed flow rate can be effectively improved, and then the separating efficiency can be improved.

Owner:JIANGSU LEE & MAN PAPER MFG

A ceramic sealing ring prepared from waste raw materials

ActiveCN104482204BGood physical propertiesImprove mechanical propertiesEngine sealsVulcanizationBoron carbide

The invention discloses a ceramic sealing ring prepared by using waste materials, by means of taking industrial waste ceramic materials, silicon dioxide, silicon carbide, boron carbide, zinc oxide, titanium oxide and the like as green body materials, and taking waste silicone rubber, brominated butyl rubber, N660 carbon black, glass fiber, activating agent and PEG20000 as rubber components, the sealing ring is obtained through heat vulcanization process, the preparation process of the sealing ring is simple and is easy to industrialize, and the sealing ring prepared has excellent physical and chemical properties.

Owner:江苏久日数控机床有限公司

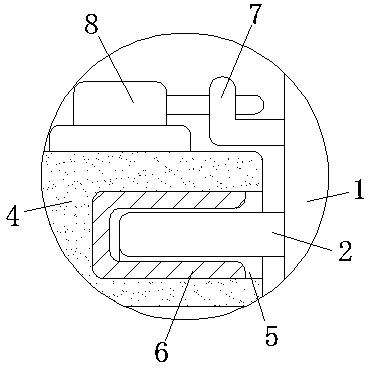

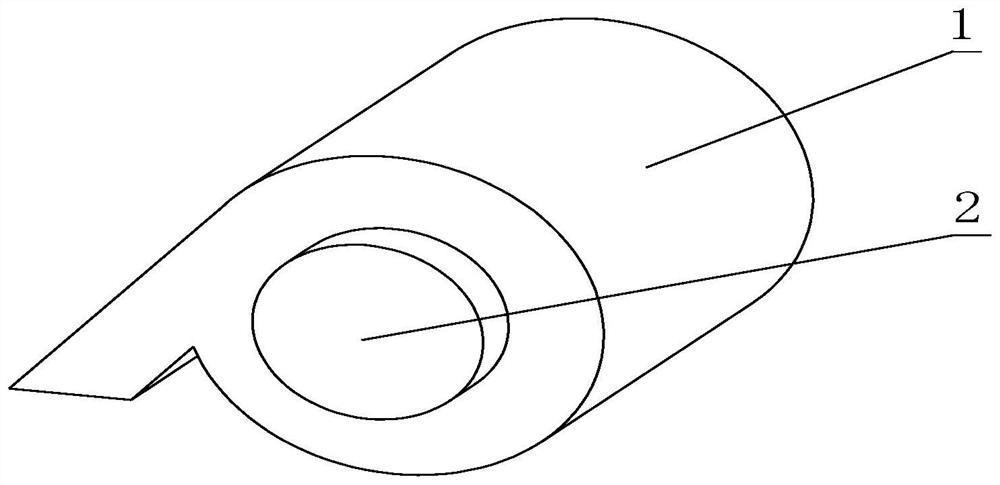

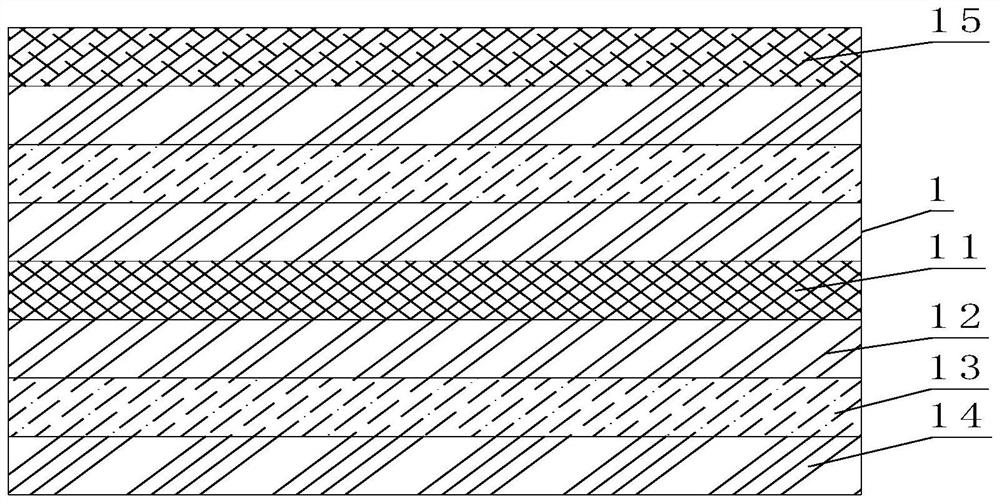

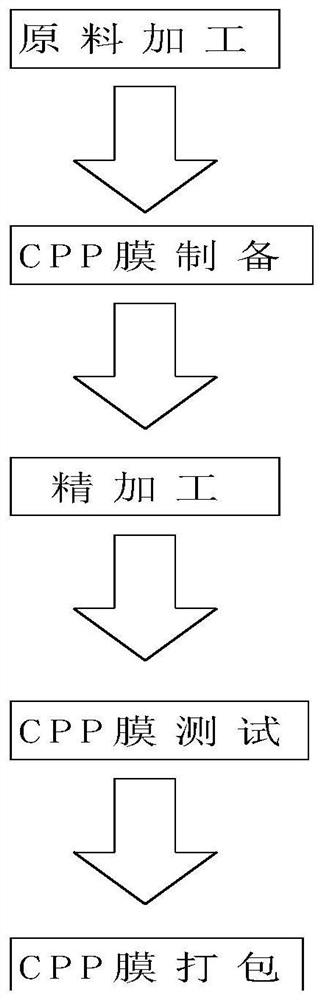

High-performance CPP film and preparation process thereof

PendingCN114274633AImprove the wear resistance coefficientExtended service lifeSynthetic resin layered productsGlass fiberPolymer science

The invention discloses a high-performance CPP film and a preparation process thereof, and relates to the technical field of CPP films, the high-performance CPP film comprises a CPP film, the surface of the CPP film is provided with a film winding roller, the CPP film comprises a CPP film body, the surface of the CPP film body is fixedly connected with a glass fiber film, the surface of the glass fiber film is fixedly connected with an aramid fiber film, and the surface of the aramid fiber film is fixedly connected with a film winding roller. The surface of the aramid fiber membrane is fixedly connected with a wear-resistant coating. Through cooperation of the CPP film body, the wear-resistant coating and the self-adhesive protective film, the CPP film body can be protected in the transportation process through the arrangement of the self-adhesive protective film, meanwhile, the wear-resistant coating is coated to improve the wear-resistant coefficient of the CPP film body, and the problems that the CPP film is often used as a product package, the wear-resistant coefficient of a traditional CPP film is low, and the service life of the CPP film is prolonged are solved. The problem that the service life of the CPP film may be directly affected due to the fact that the CPP film cannot be protected in the transportation process is solved, and the effect of prolonging the service life of the CPP film is achieved.

Owner:徐州宏恩包装新材料有限公司

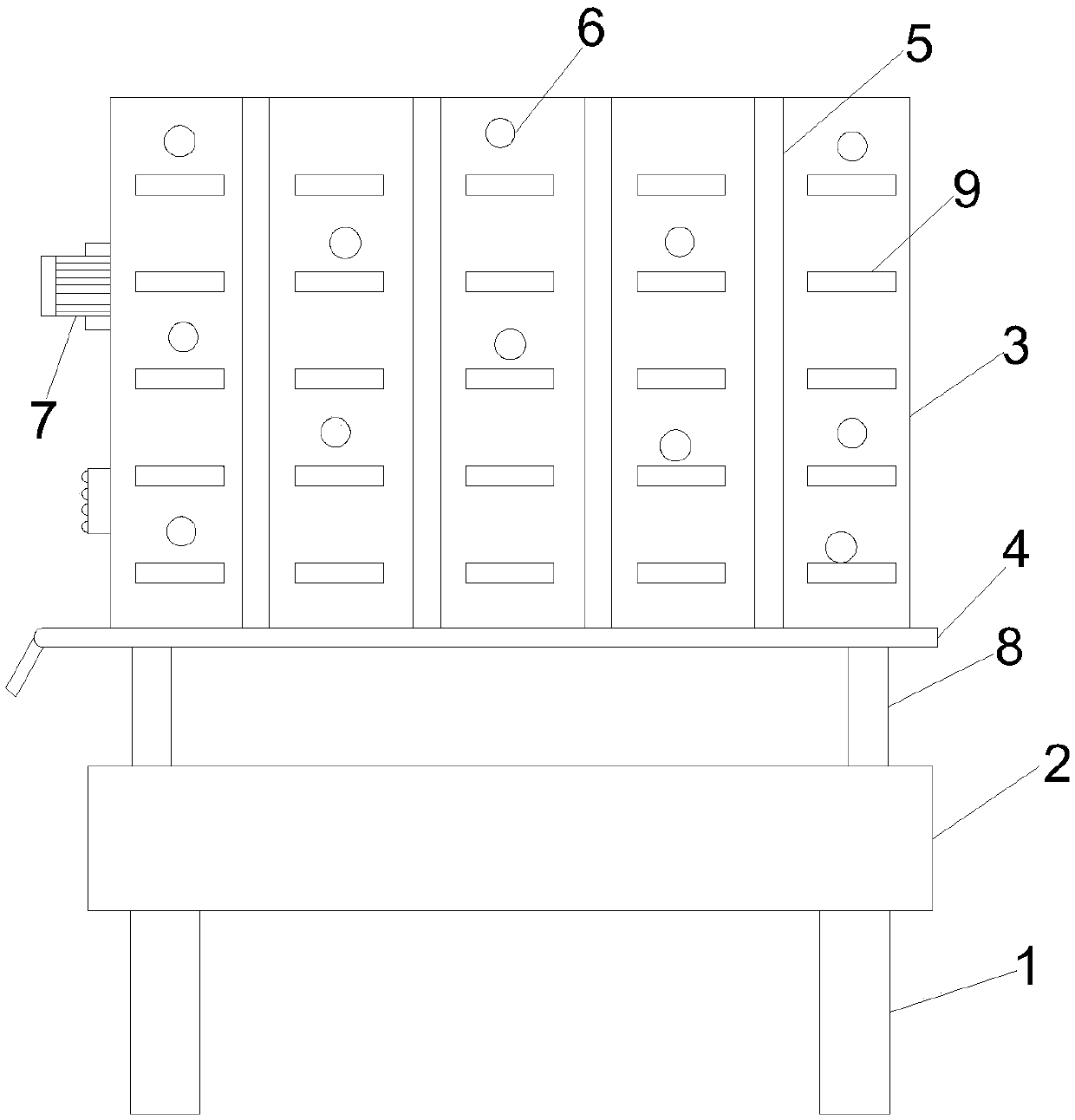

Wooden bench leg transport equipment

InactiveCN108082667AEnvironmental performanceEasy to operateRigid containersExternal fittingsEngineeringHome improvement

The invention provides wooden bench leg transport equipment, and relates to the technical field of processing and production of home improvement products. The wooden bench leg transport equipment is characterized by comprising a baseplate, and moving wheels are arranged under the baseplate; the baseplate is provided with support rods, and each support rod is provided with a placement rod which isprovided with a placement plate which is provided with a locating rod; the baseplate is provided with grooves, and each placement plate is provided with a through hole; and the locating rods are arranged in the through holes. The wooden bench leg transport equipment has the advantages of rational structure, easy operation and convenient use.

Owner:金继善

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com