Unconventional-structure pipeline and manufacturing method thereof

An unconventional, pipeline technology, used in pipeline protection, pipeline damage/wear prevention, and pipes, etc., can solve the problems of long production cycle, high cost of wear-resistant castings, and difficulty in forming wear-resistant materials, and achieves convenient later replacement and improvement. Wear coefficient, the effect of reducing procurement cycle and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following specific examples illustrate the implementation of the present invention. Those familiar with the technology can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

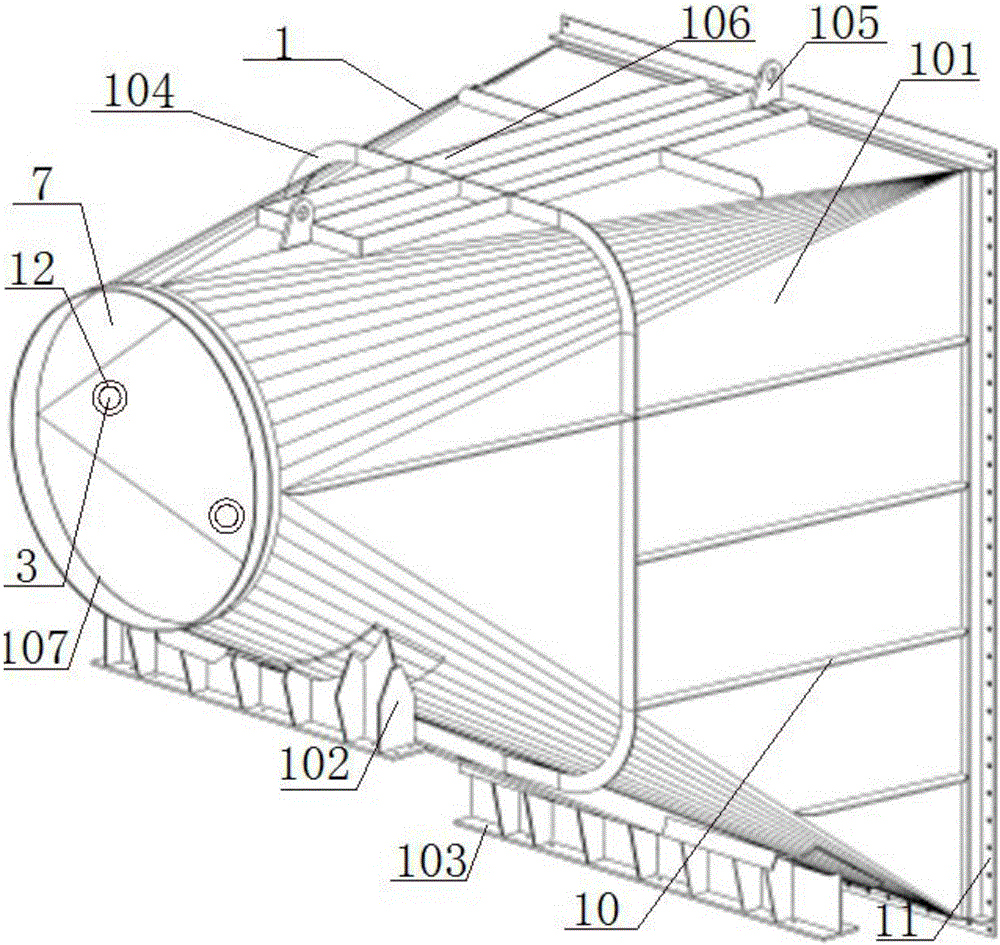

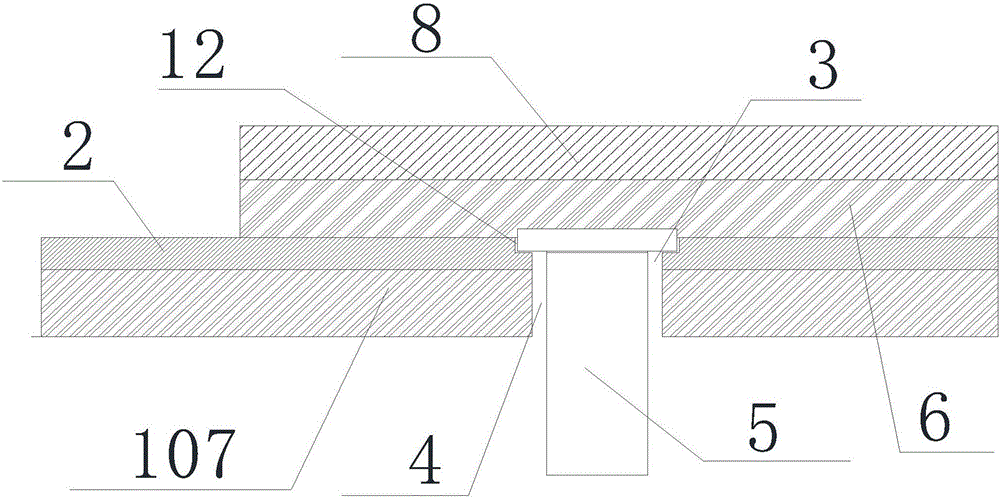

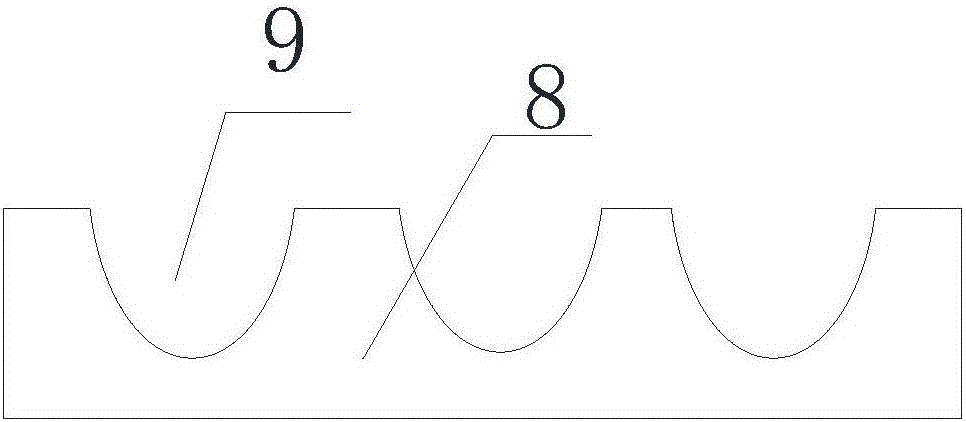

[0024] Such as Figure 1-3 As shown, a pipeline with an unconventional structure includes a pipeline 1. The pipeline 1 is composed of an outer wall 101 and an inner tube 107. The diameter of the inner tube 107 of the pipeline 1 gradually decreases from the right opening to the bottom end. The outer wall 101 is on the outer wall There are reinforcing ribs 10, multiple sets of parallel vertical support plates 102 are provided under the outer wall 101, and a bottom plate 103 is connected under the support plates 102 of the same height, which increases the overall stability and facilitates installation and fixation, especially during hauling , To prevent rolling; the right opening of the pipe 1 is provided with a flange 11 for eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com