Silicate cement prepared from solid wastes and preparation method of silicate cement

A Portland cement and solid waste technology, applied in cement production, etc., can solve problems such as low activity, achieve the effects of reducing severe smog in the atmosphere, saving and replacing primary resources, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

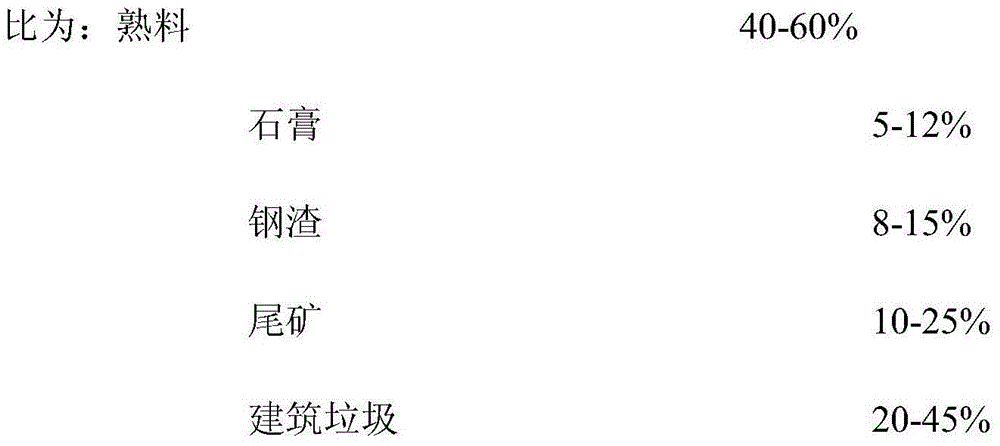

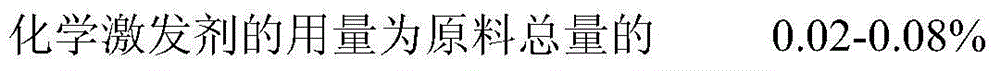

Method used

Image

Examples

Embodiment 1

[0027] Weigh 20kg of raw material construction waste, 10kg of steel slag, 10kg of tailings, 52kg of clinker, 8kg of gypsum, and 60mg of external activator according to the weight ratio. First crush 20kg of construction waste and 8kg of gypsum with a crusher to particles with an average particle size of ≤10mm, dry them until the moisture content is less than 2%, grind 10kg of steel slag and 10kg of tailings with a roller mill for 50min, and mix them with chemical The activator will continue to grind for 25 minutes through the ball mill until the specific surface area is ≥ 500m 2 / ㎏, ready-made product.

Embodiment 2

[0029] Weigh 35kg of raw construction waste, 10kg of steel slag, 13kg of tailings, 45kg of clinker, 7kg of gypsum, and 40mg of external activator according to the weight ratio. First crush 20kg of construction waste and 8kg of gypsum with a crusher to particles with an average particle size of ≤10mm, dry them until the moisture content is less than 2%, grind 10kg of steel slag and 10kg of tailings with a roller mill for 50min, and mix them with chemical The activator will continue to grind for 25 minutes through the ball mill until the specific surface area is ≥ 500m 2 / ㎏, ready-made product.

[0030] The products made in the above two examples are superior to GB175-2007 Portland Slag Cement P·S·A, "Pozzolanic Portland Cement" and "Fly Ash Portland Cement" through testing performance and technical requirements , "Composite Portland Cement" standard. See Table 1 and Table 2 for specific results.

[0031] Example 1: Loss on ignition 2.26, sulfur trioxide 2.74, magnesium oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com