Placing equipment for mold for graphite polystyrene board

A polystyrene board and mold technology, which is applied to workshop equipment, tool storage devices, manufacturing tools, etc., can solve problems such as mold damage, mold life loss, and no guarantee of safety, so as to achieve improved service life, convenient operation, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

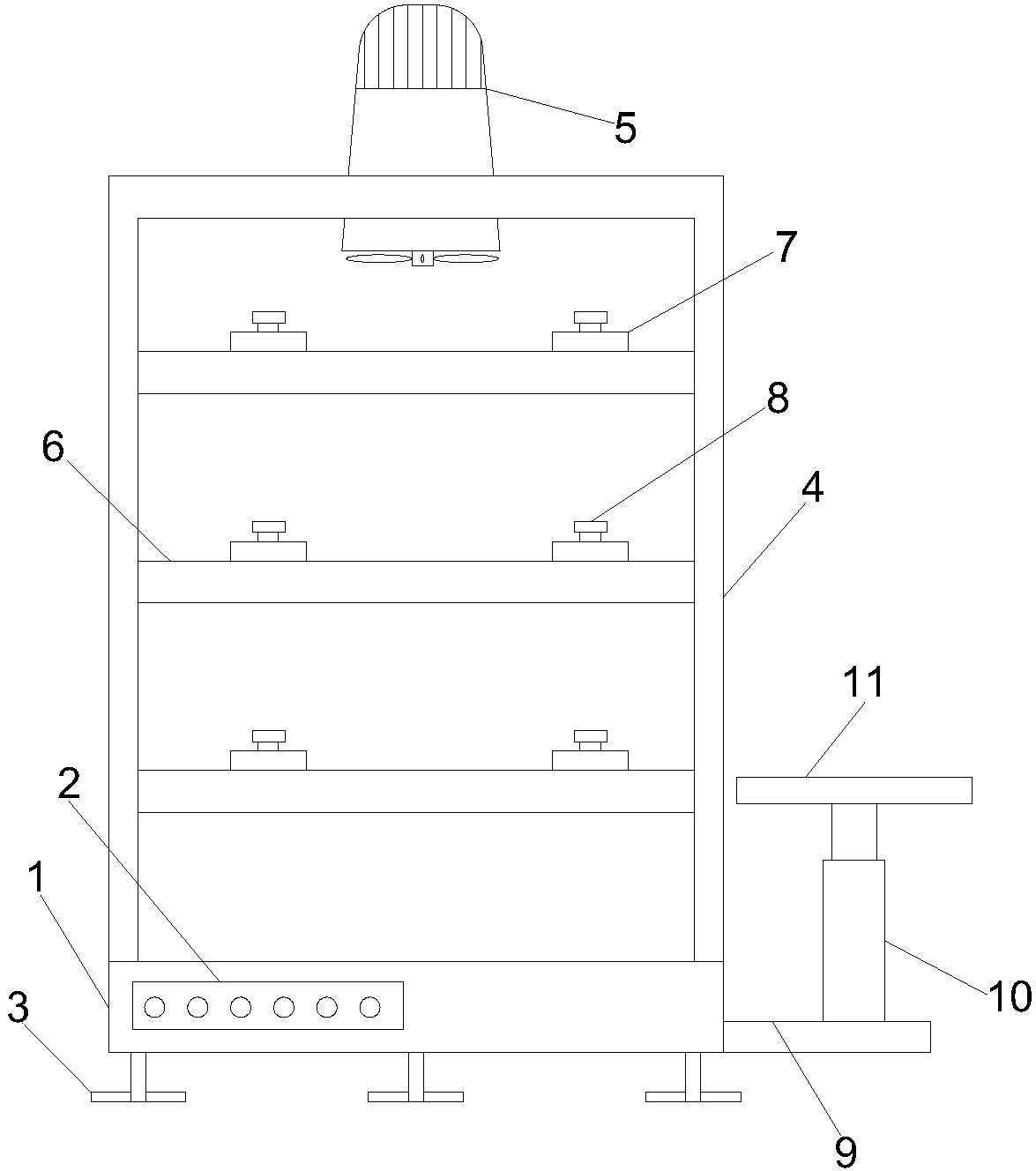

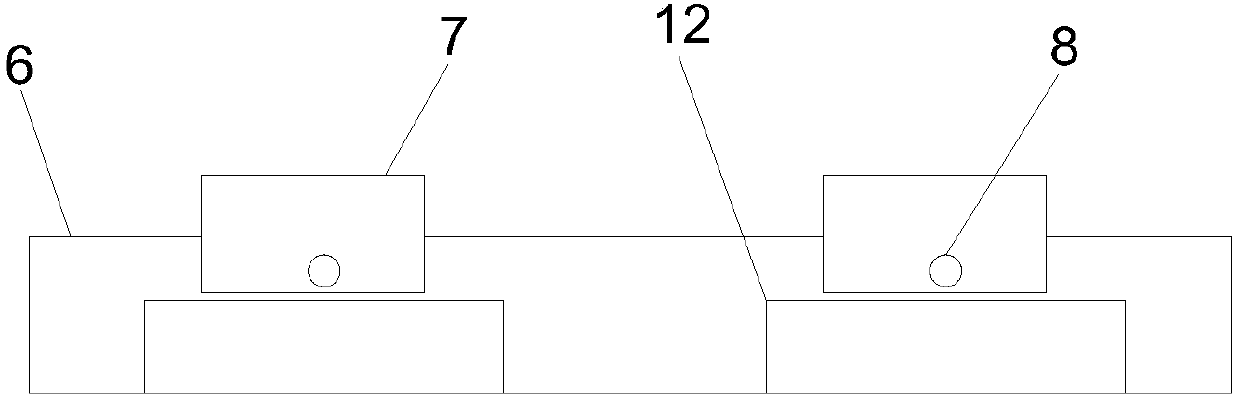

[0031] Such as figure 1 as well as figure 2 As shown, a mold placement device for a graphite polystyrene board includes a support plate 1, a controller 2 is provided on the support plate 1, a lifter 3 is provided below the support plate 1, and a support is connected above the support plate 1 Frame 4, a blower device 5 is arranged above the support frame, a connecting frame 6 is installed on the supporting frame 4, a baffle plate 7 is provided on the connecting frame 6, a connecting rod 9 is provided beside the supporting plate 1, and a connecting rod 9 There is a lifter 10 on the top, and a standing platform 11 is fixed on the upper end of the lifter 10;

[0032] The supporting frame 4 is respectively connected to the supporting plate 1 and the connecting frame 5 by means of welding or screw fastening;

[0033] The connecting frame 5 is provided with a rectangular notch 12, the baffle plate 7 is located beside the notch 12, the baffle plate 7 is connected to the connecting ...

Embodiment 2

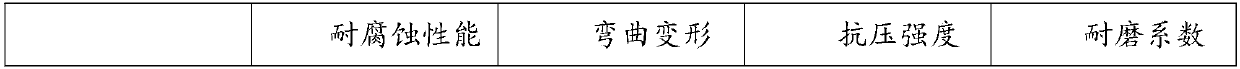

[0038] The protective coating used on the outside of the baffle is made of the following materials in parts by weight,

[0039] 10-16 parts of resin, 9 parts of silane coupling agent KH-5303, 4-9 parts of trimellitic anhydride, 6-11 parts of modified olivine, 1-5 parts of dimethyl terephthalate, 2 parts of dibutyltin dilaurate -7 parts, 1-6 parts of diethylenetriamine, 4-9 parts of xylene, 1-4 parts of talcum powder, 2-8 parts of antioxidant, 3-6 parts of biomass additive, 27-33 parts of clear water;

[0040] Described resin is the one that epoxy resin, phenolic resin, polyethylene resin, alkyd resin are used;

[0041] The anti-aging agent is one of anti-aging agent AW, anti-aging agent RD, anti-aging agent A, anti-aging agent D, and anti-aging agent CPPD;

[0042] The preparation method of the modified olivine is as follows: grind the olivine and pass it through a 500-600 mesh sieve, then bake it in an oven at 45°C for 30 minutes, then add water 0.7 times its weight, and the...

Embodiment 3

[0052] Such as figure 1 as well as figure 2 As shown, a mold placement device for a graphite polystyrene board includes a support plate 1, a controller 2 is provided on the support plate 1, a lifter 3 is provided below the support plate 1, and a support is connected above the support plate 1 Frame 4, a blower device 5 is arranged above the support frame, a connecting frame 6 is installed on the supporting frame 4, a baffle plate 7 is provided on the connecting frame 6, a connecting rod 9 is provided beside the supporting plate 1, and a connecting rod 9 There is a lifter 10 on the top, and a standing platform 11 is fixed on the upper end of the lifter 10;

[0053] The supporting frame 4 is respectively connected to the supporting plate 1 and the connecting frame 5 by means of welding or screw fastening;

[0054] The connecting frame 5 is provided with a rectangular notch 12, the baffle plate 7 is located beside the notch 12, the baffle plate 7 is connected to the connecting fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com