On-site molded waterproof and heat-insulating material and construction method thereof

A thermal insulation, on-site technology, applied in buildings, building structures, etc., can solve problems such as complex shapes, watertightness of the waterproof layer must not have the slightest defect, and it is difficult to find leakage points, etc., to achieve bond strength and tensile strength. High, high thermal insulation and waterproof reliability, and the effect of meeting the requirements of waterproof life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

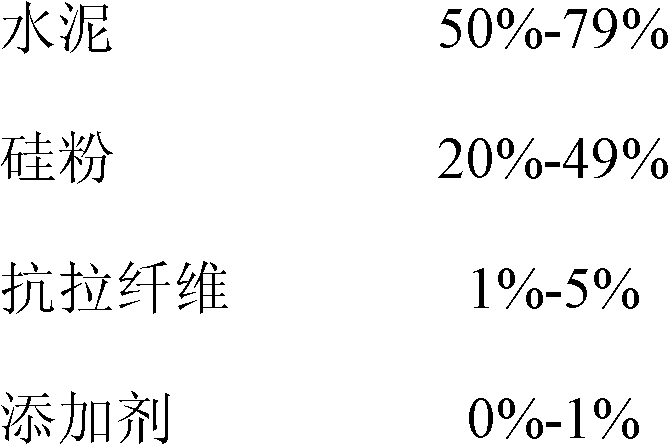

[0030] Example 1: An on-site forming waterproof and thermal insulation material is formed by mixing and stirring mixed dry powder and ethylene-vinyl acetate copolymer emulsion at a ratio of 1:1.5, wherein the mixed dry powder includes Huaxin 32.5# composite Portland cement (Huaxin Cement Co., Ltd. Co., Ltd.), SF92 micro-silica fume (produced by Gansu Lixinyuan Micro-silica Co., Ltd.), PDH-HD35 polypropylene fiber (produced by Shenzhen Pengdahui Building Materials Co., Ltd.), the weight percentage of each component is as follows:

[0031] Huaxin 32.5# Composite Portland Cement 56%

[0032] SF92 Microsilica 41%

[0033] PDH-HD35 polypropylene fiber 3%

[0034] A method for using the above-mentioned waterproof material construction, the specific steps are as follows:

[0035] (1) Mix Huaxin 32.5# composite Portland cement, SF92 silica fume, PDH-HD35 polypropylene fiber, iron oxide yellow and sodium dodecylbenzene sulfonate and quantitatively pack them into dry powder components...

Embodiment 2

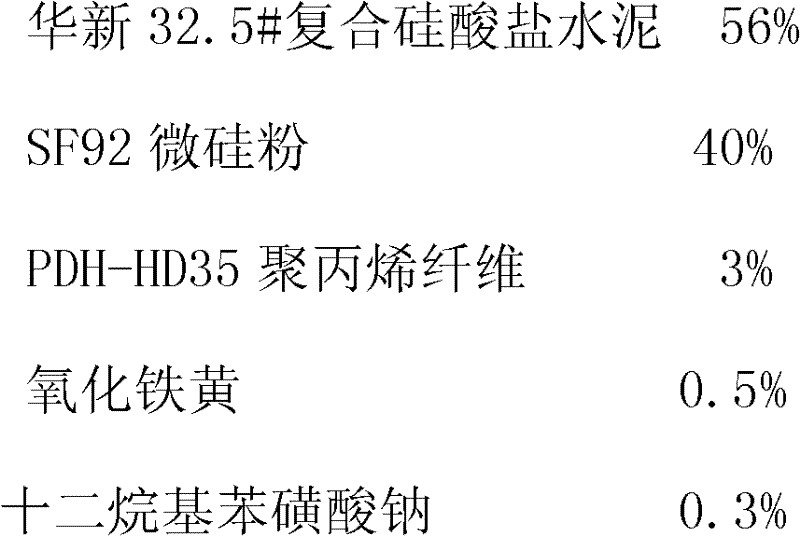

[0040] Embodiment 2: A kind of on-site forming waterproof and thermal insulation material is formed by mixing and stirring mixed dry powder and styrene-acrylic emulsion according to 1.5:2, wherein the mixed dry powder includes Huaxin 32.5# composite Portland cement (produced by Huaxin Cement Co., Ltd. of China), SF92 microsilica fume (produced by Gansu Lixinyuan microsilica fume Co., Ltd.), PDH-HD35 polypropylene fiber (produced by Shenzhen Pengdahui Building Materials Co., Ltd.), iron oxide yellow (produced by Shanghai Xinyan Pigment Co., Ltd.) and twelve Sodium alkylbenzene sulfonate (Jiangsu Qingting washing product Co., Ltd.), the weight percentage of each component is as follows:

[0041]

[0042] A method for using the above-mentioned waterproof material construction, the specific steps are as follows:

[0043] (1) Mix and quantitatively pack Huaxin 32.5# composite Portland cement, SF92 micro silica fume, PDH-HD35 polypropylene fiber, iron oxide yellow and sodium dodecy...

Embodiment 3

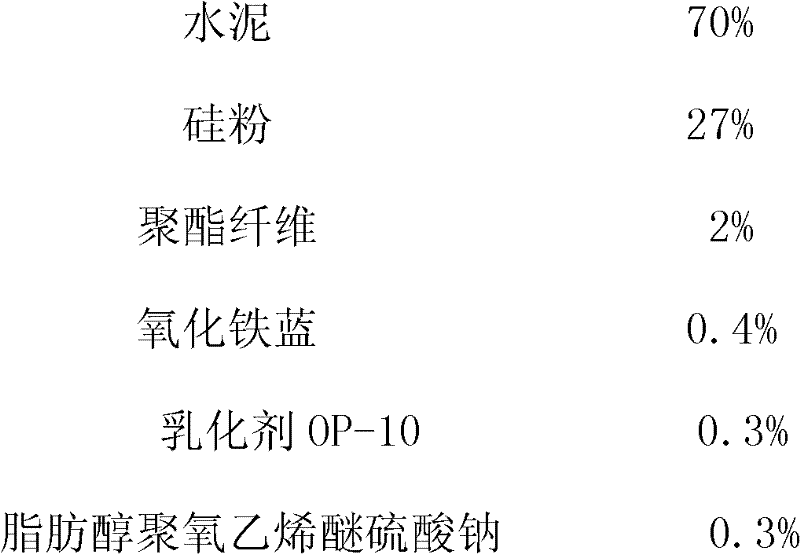

[0048] Embodiment 3: A kind of on-site molding waterproof material is formed by mixing dry powder and pure acrylic emulsion according to the ratio of 2.5:2.5 on site, wherein the mixed dry powder includes Portland cement, silica fume (silicon content is more than 50%), polyester fiber , iron oxide blue (produced by Shanghai Xinyan Pigment Co., Ltd.), emulsifier OP-10 and fatty alcohol polyoxyethylene ether sodium sulfate, the weight percentage of each component is as follows:

[0049]

[0050] A method for using the above-mentioned waterproof material construction, the specific steps are as follows:

[0051] (1) Portland cement, silicon powder (silicon content is more than 50%), polyester fiber, iron oxide blue (produced by Shanghai Xinyan Pigment Co., Ltd.), emulsifier OP-10 and fatty alcohol polyoxyethylene ether sulfuric acid Sodium is mixed and quantitatively packaged into dry powder components, and pure acrylic emulsion is quantitatively filled into liquid components; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com