Textile printing and dyeing dye stirring structure with scraper mechanism

A scraper and textile technology, which is applied in the field of textile processing, can solve the problems of spraying and scraping cleaning of particles and impurities attached to the inner wall of the non-stirrable box, and achieve the effects of enhancing the scraping effect, enhancing the elastic buffering effect, and enhancing the wear resistance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

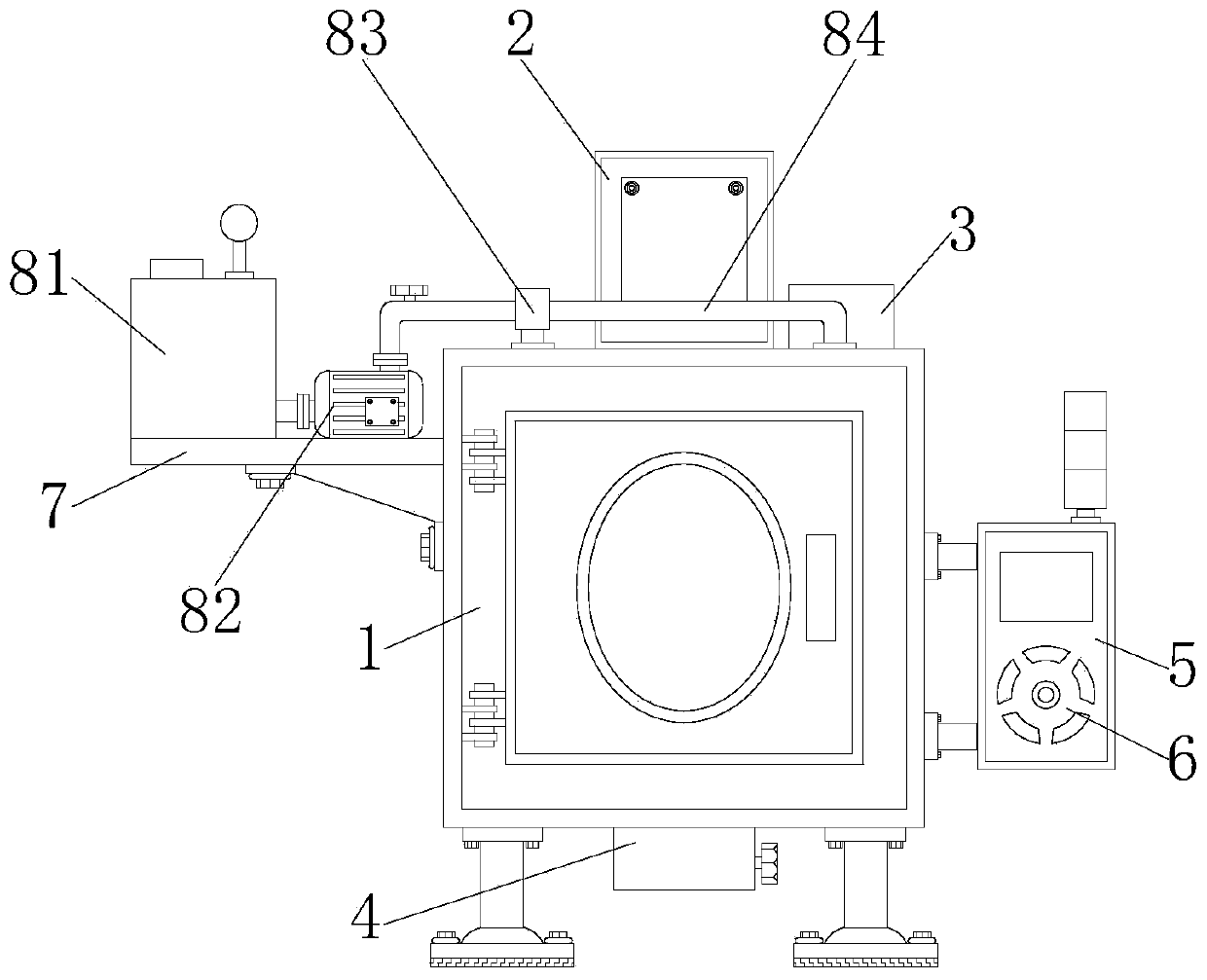

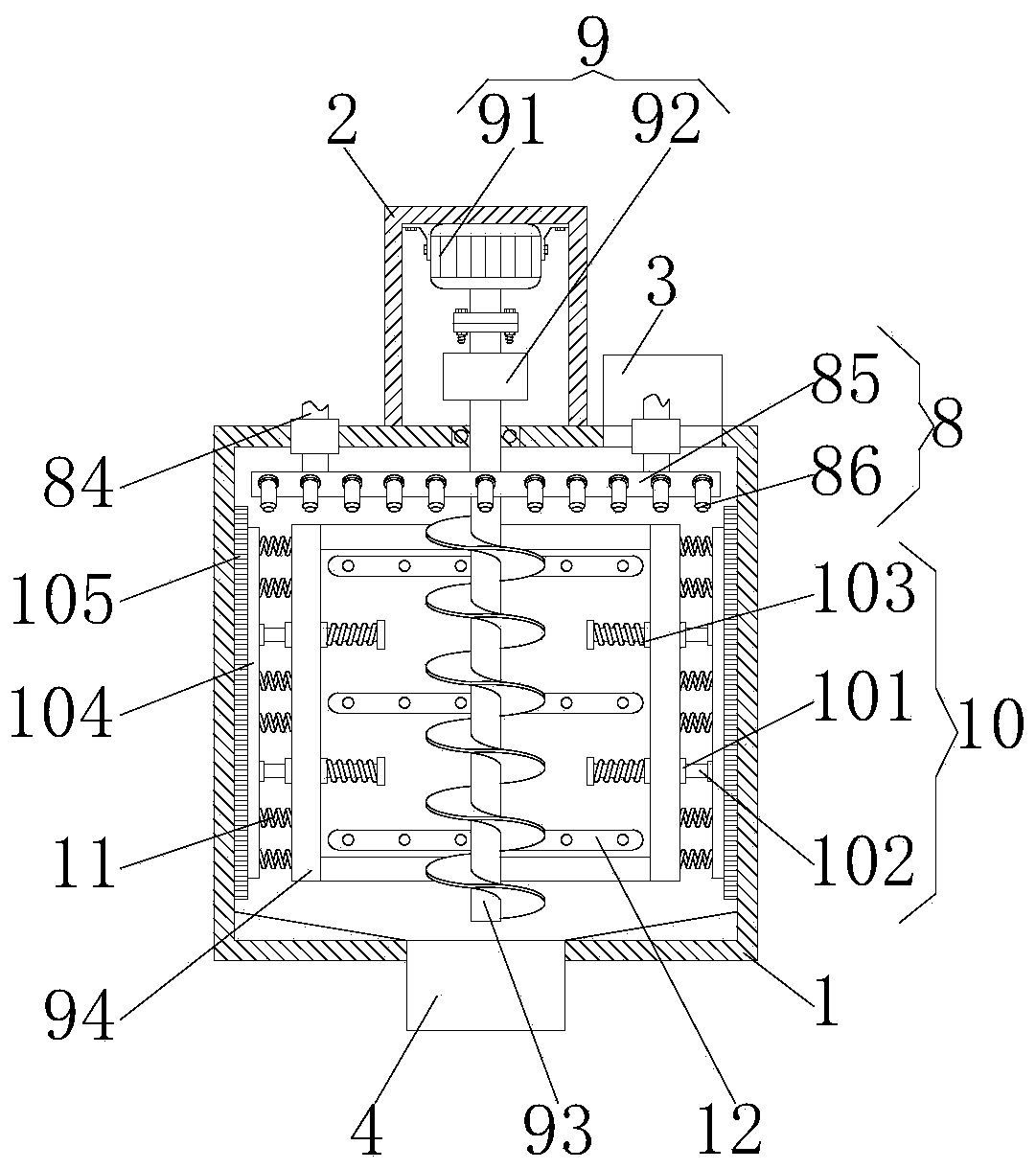

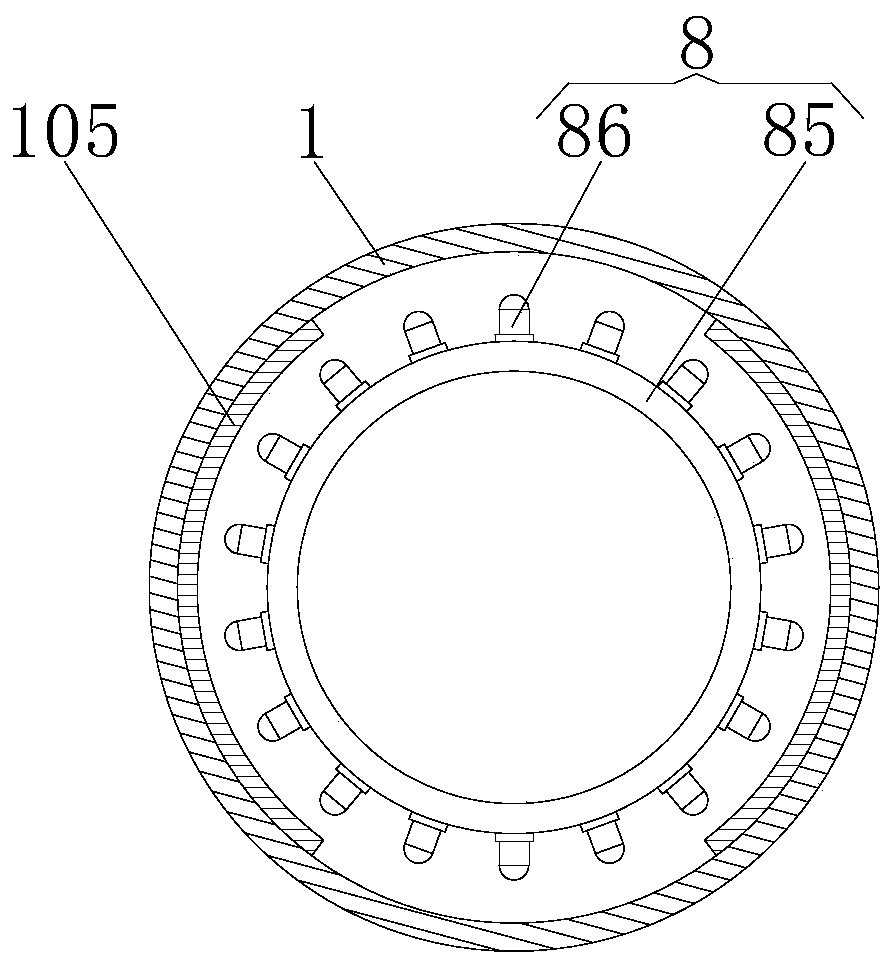

[0023] Please refer to figure 1 , figure 2 and image 3 ,in figure 1 A structural schematic diagram of a preferred embodiment of the textile printing and dyeing dye stirring structure with a scraper mechanism provided by the present invention, figure 2 for figure 1 The structural sectional view of the box body and the fixing frame shown, image 3 for figure 1 The top sectional view of the structure of the box shown. A stirring structure for textile printing and dyeing dyes with a scraper mechanism, comprising: a box body 1, a fixed frame 2 is bolted to the center of the top of the box body 1, and a feeding material is connected to the right side of the top of the inner cavity of the box body 1 Pipe 3, the center of the bottom of the inner cavity of the box body 1 is connected with a discharge pipe 4, the bottom of the right side of the box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com