Patents

Literature

156results about How to "Enhanced elastic cushioning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

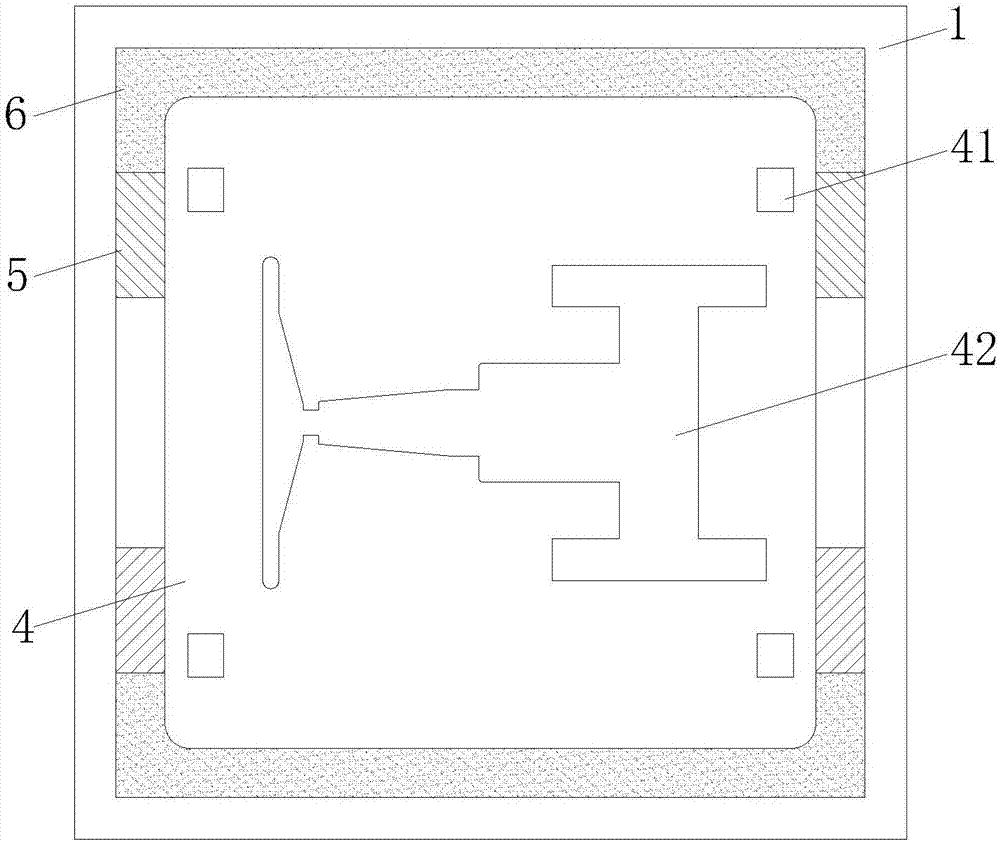

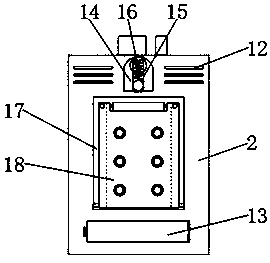

Folding screen, manufacturing method thereof, and mobile terminal

InactiveCN110211499AStrong scratch resistanceGood elastic cushioning effectIdentification meansElastic modulusEngineering

The invention relates to a folding screen, a manufacturing method thereof, and a mobile terminal. The folding screen comprises a flexible display panel and a flexible protective film; the flexible display panel is provided with a display face, and the flexible protective film comprises flexible glass and a protective layer; the flexible glass covers the side, where the display face is located, ofthe flexible display panel, and the elastic modulus of the flexible glass is smaller than or equal to 72 Gpa; and the protective layer covers the side, back on to the display face, of the flexible glass, and the elastic modulus of the protective layer is smaller than or equal to 10 Gpa. According to the folding screen, the manufacturing method thereof, and the mobile terminal, the flexible glass provides good scratch-resisting performance, and thus when the flexible glass covers the display face of the flexible display panel of the folding screen, the side, where the display face is located, of the flexible display panel can be effectively prevented from being scratched; and the flexible glass is protected through the protective layer, and thus the flexible glass is not prone to being broken so as to guarantee that the flexible glass stably protects the flexible display panel.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

Substrate for artificial leathers, artificial leathers and production method of substrate for artificial leathers

ActiveCN1637187AImprove water absorptionImprove oil absorption capacityNon-woven fabricsFiber bundlePolyamide

The artificial leather base of the present invention includes an elastic polymer in the gap between the tangled non -woven fabric made of polyamine microfiber beam and a gap in a non -woven fabric.The single fiber fiber of the polyamide microfiber bundle is 0.2dtex or smaller.The polyamide micro fiber bundle has a 3.5cn / dtex or a larger average toughness and 60 % or smaller average elongation.Although its apparent proportion is as low as 0.30 or smaller, the base of the artificial revolution shows high mechanical properties, such as 50N / mm or larger tear intensity.As a result, the base of the artificial revolution has a good balance between mechanical performance, feeling, and especially in the application of sneakers, and its degree is not achieved by tradition.

Owner:KURARAY CO LTD

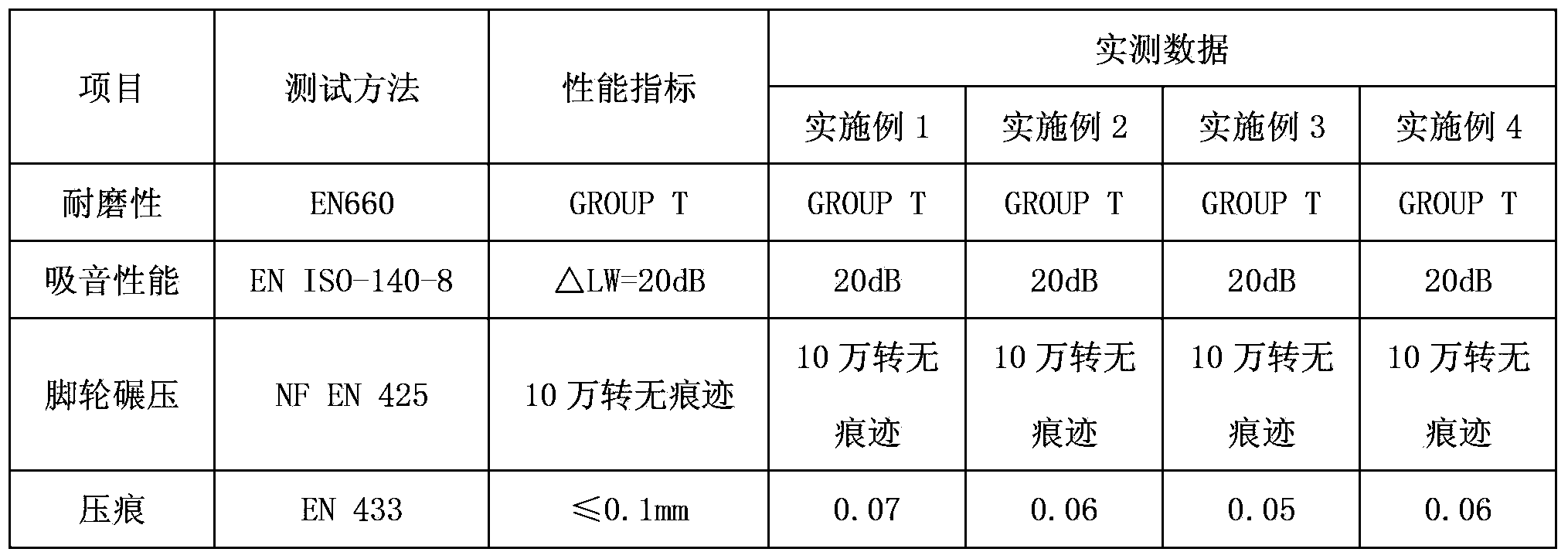

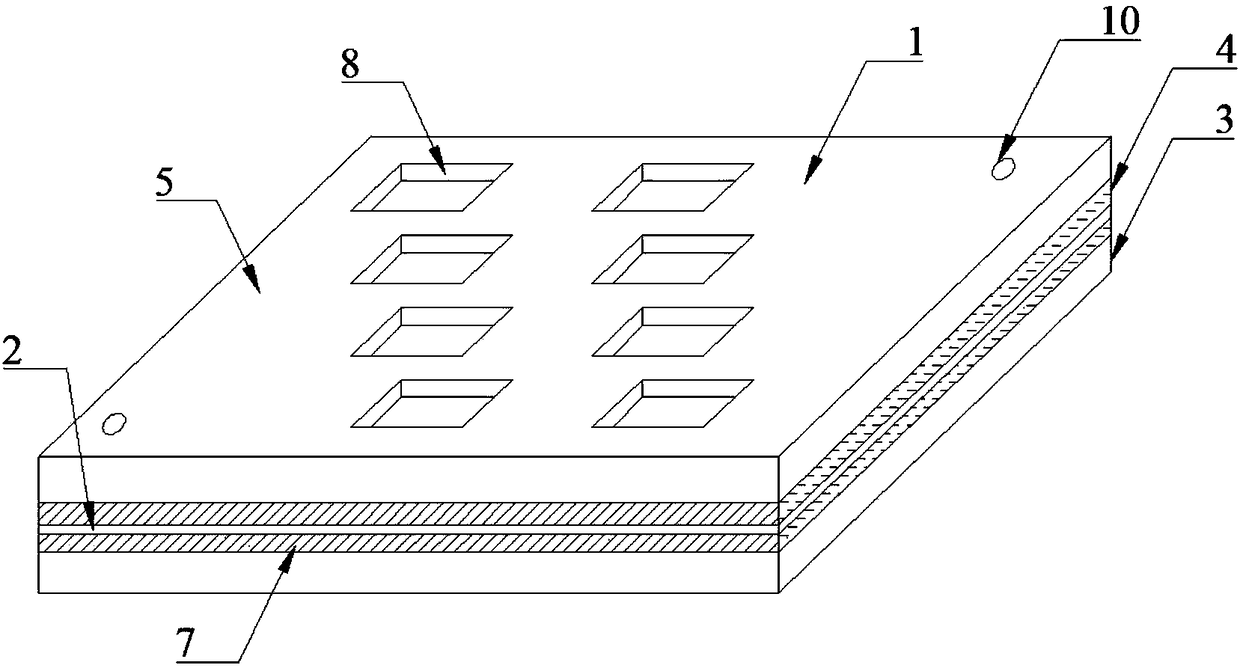

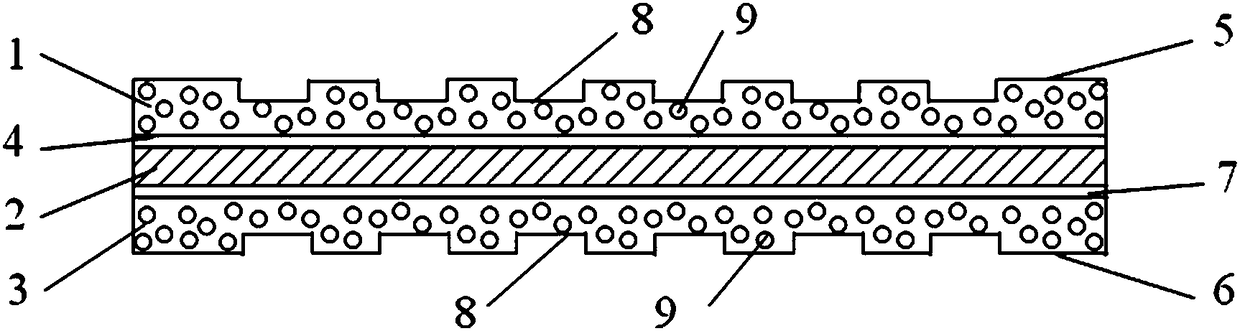

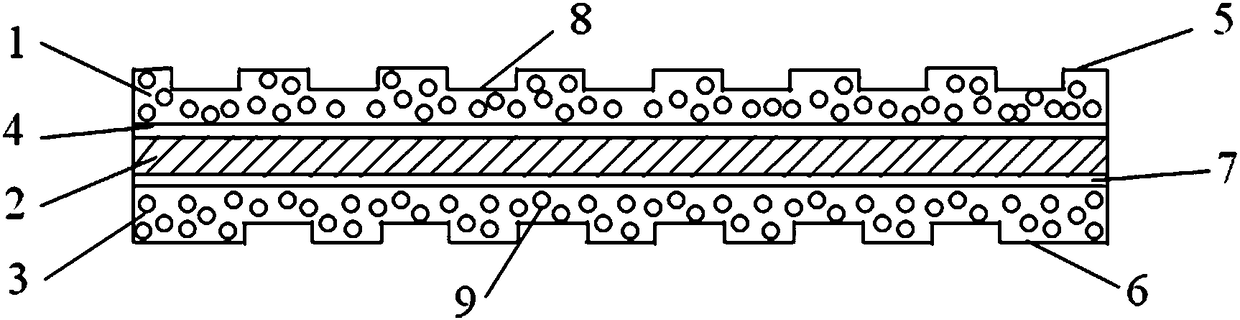

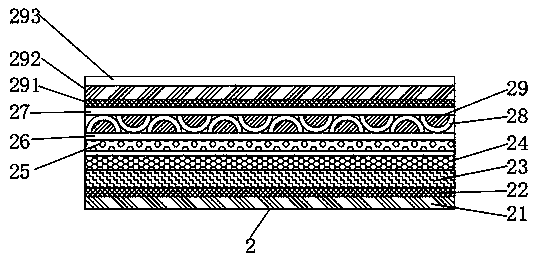

Sound-insulation elastic plastic floor

InactiveCN103407253AIncreasing the thicknessEnhanced elastic cushioning effectSynthetic resin layered productsFlooringEpoxyPolyvinyl chloride

The invention discloses a sound-insulation elastic plastic floor. The floor comprises a surface layer, an interface layer and a base layer, wherein the surface layer comprises, by weight, 80-90 parts of a polyvinyl chloride resin, 100-120 parts of calcium carbonate, 15-25 parts of dioctyl phthalate, 10-15 parts of a zinc-barium composite stabilizer, 1-5 parts of an epoxy resin, 1-5 parts of pentaerythritol and 0.5-2 parts of trioctyl ester; the interface layer comprises, by weight, 100-120 parts of the polyvinyl chloride resin, 20-30 parts of calcium carbonate, 50-60 parts of dioctyl phthalate, 0.5-3 parts of pentaerythritol, 0.5-2 parts of the trioctyl ester and 0.5-2 parts of an AC foaming agent; and the base layer comprises, by weight, 90-120 parts of the polyvinyl chloride resin, 60-70 parts of dioctyl phthalate, 3-8 parts of barium stearate, 2-6 parts of pentaerythritol, 1-3 parts of the trioctyl ester and 3-8 parts of acetyl citrate.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

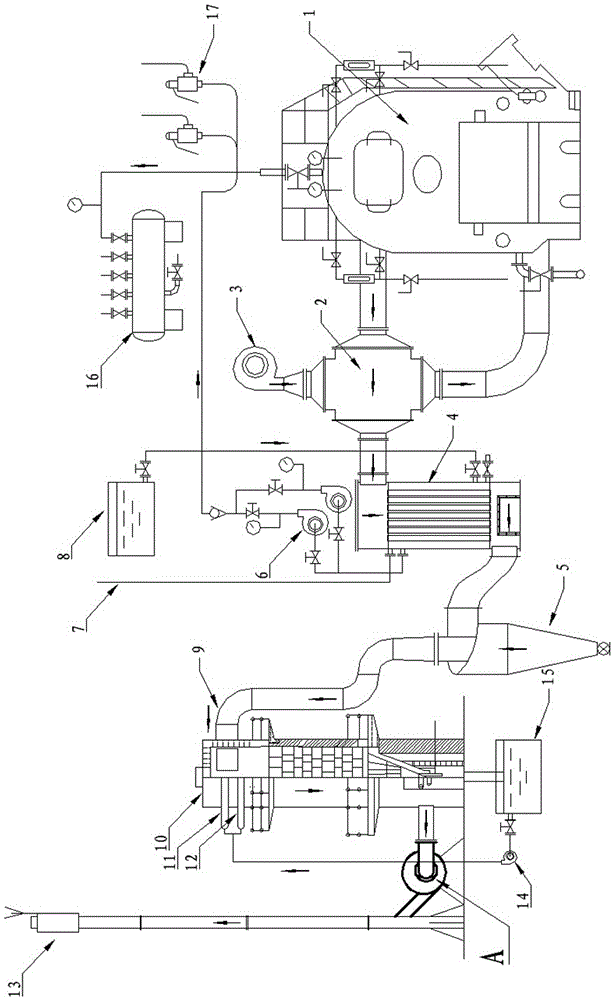

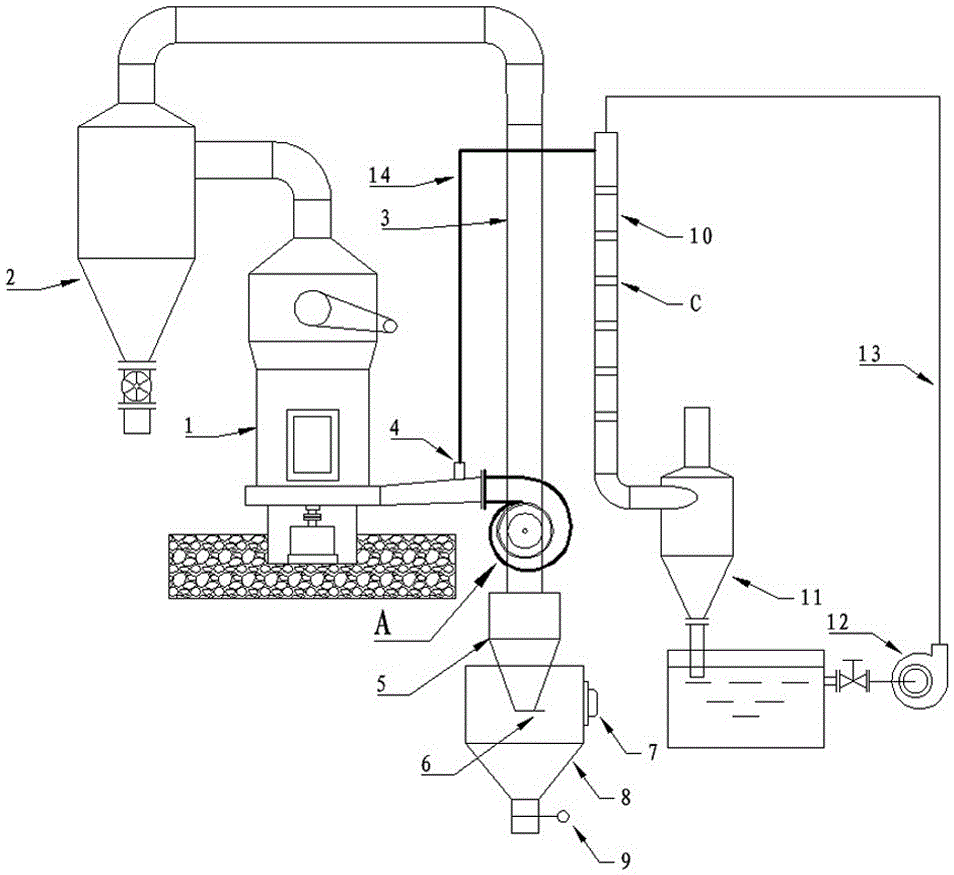

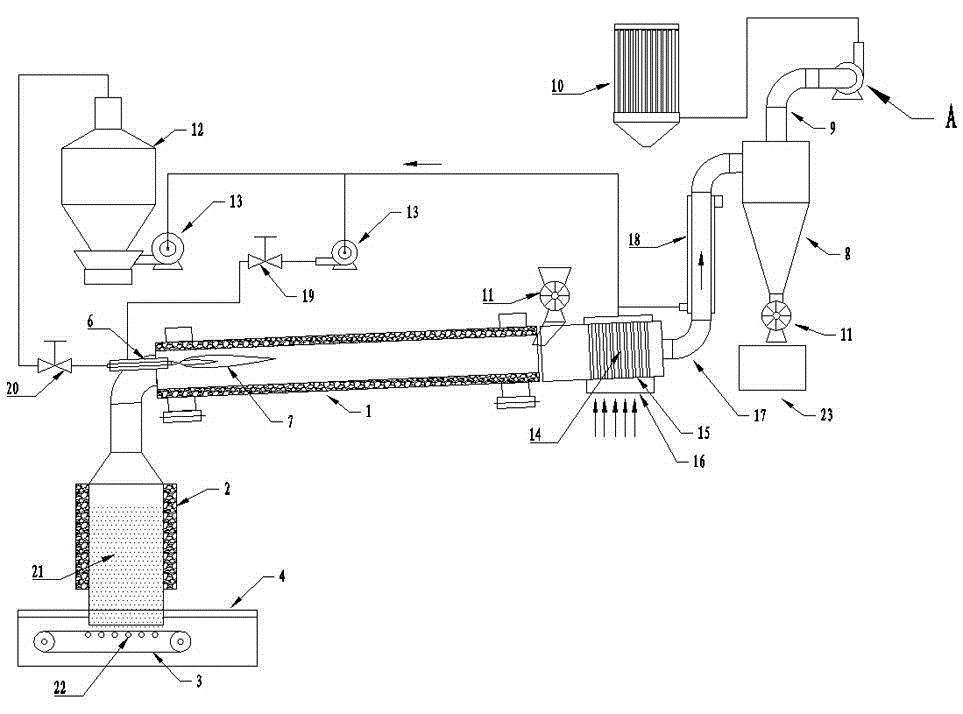

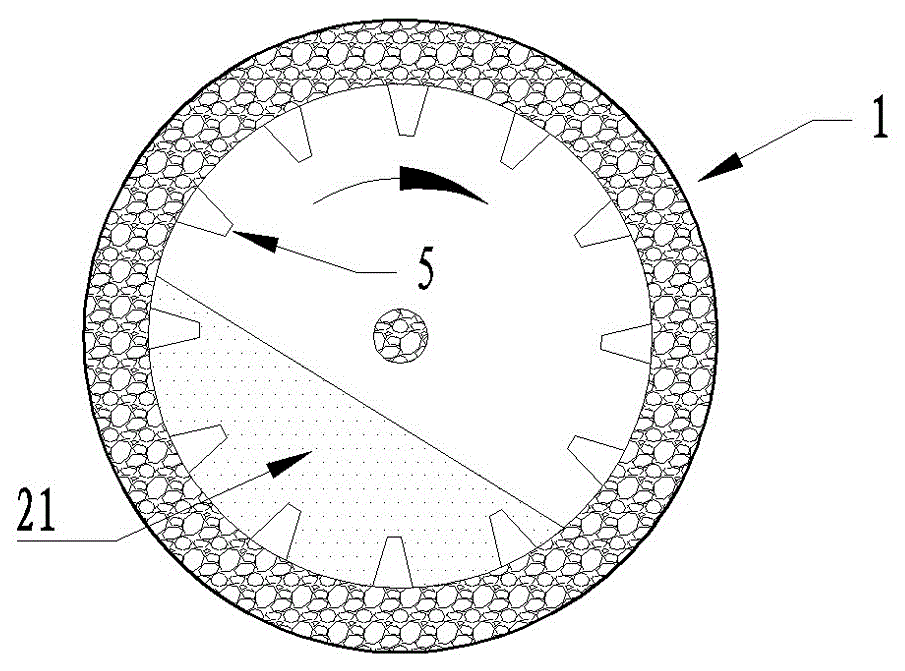

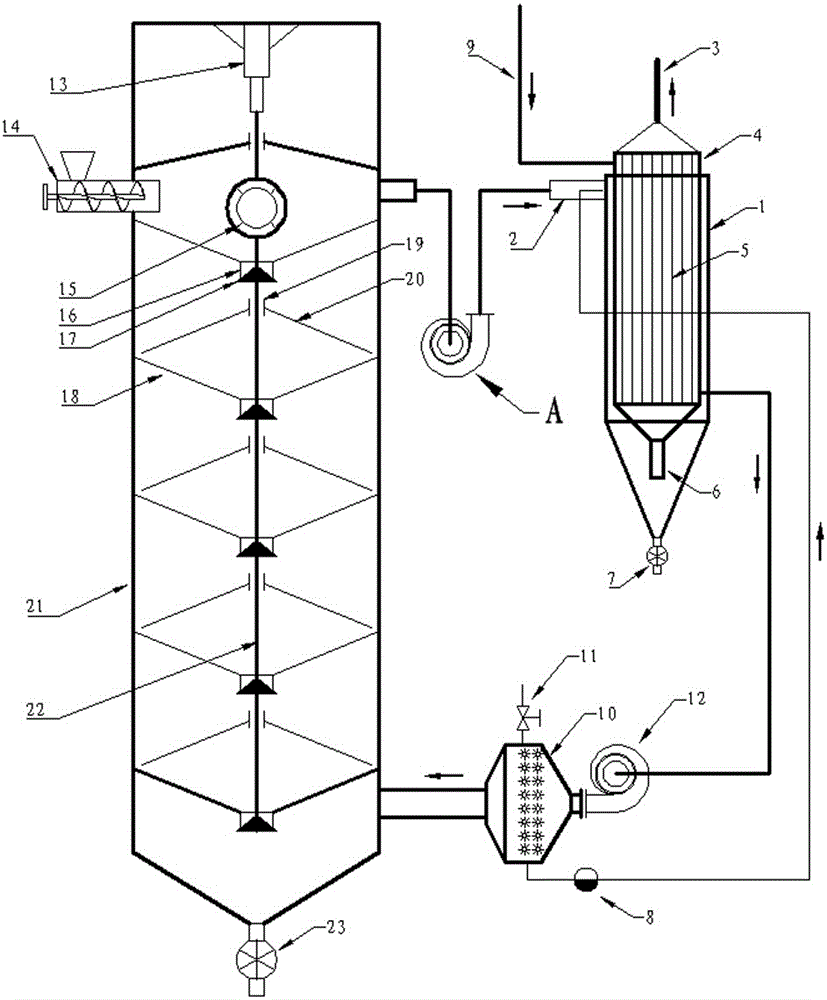

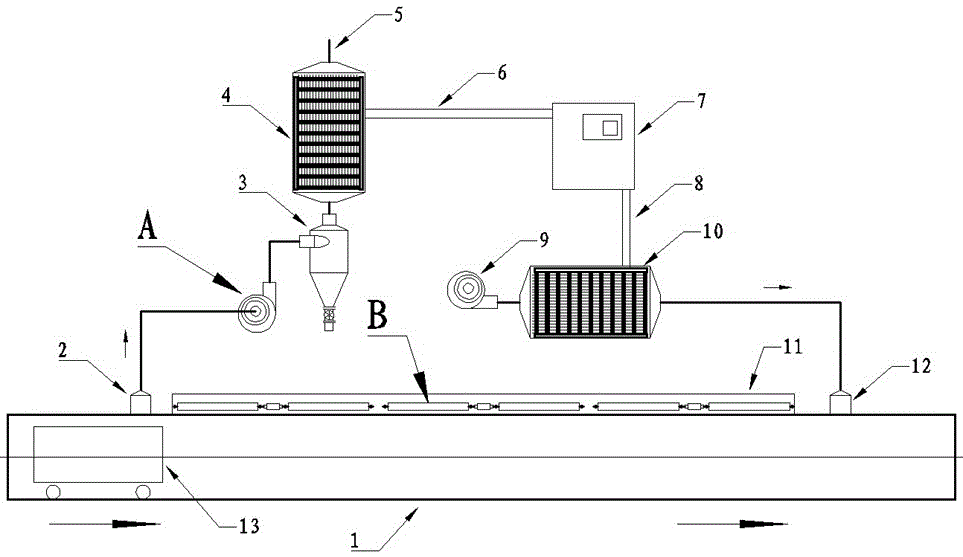

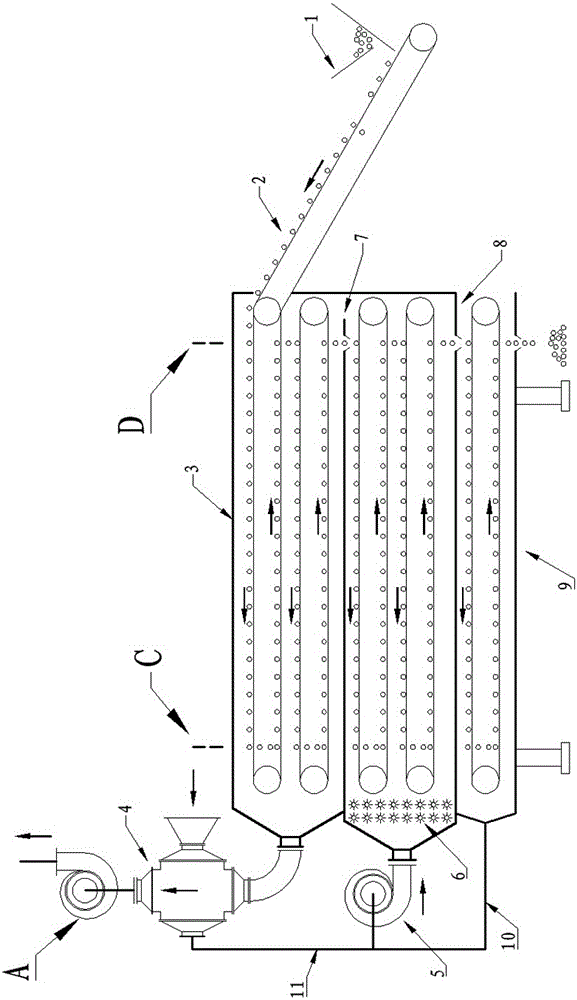

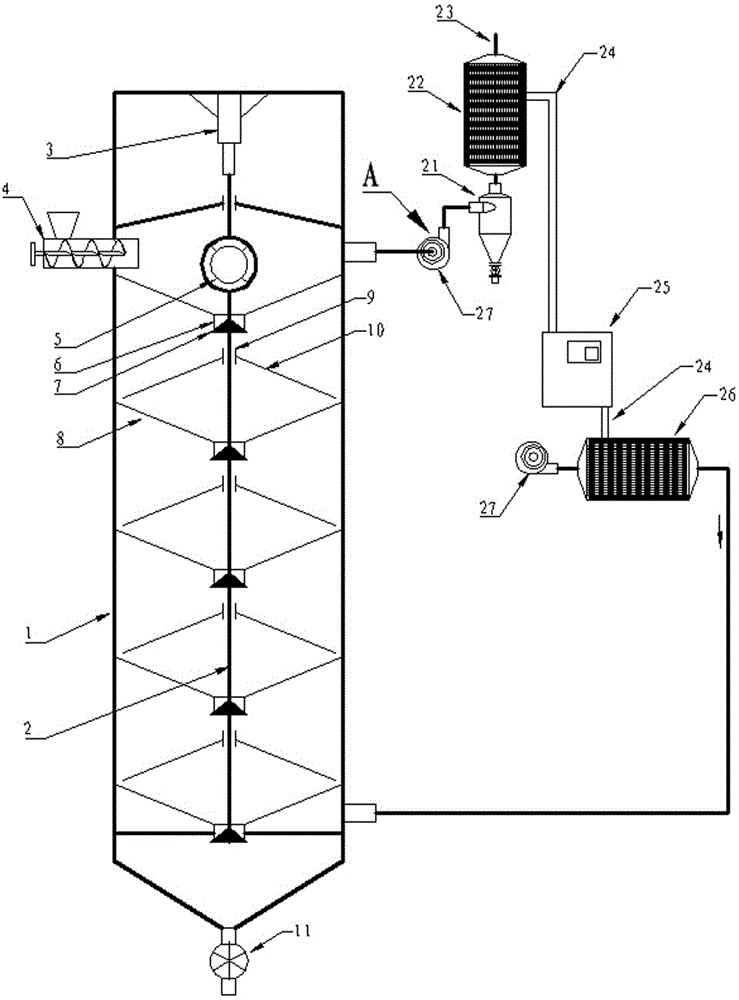

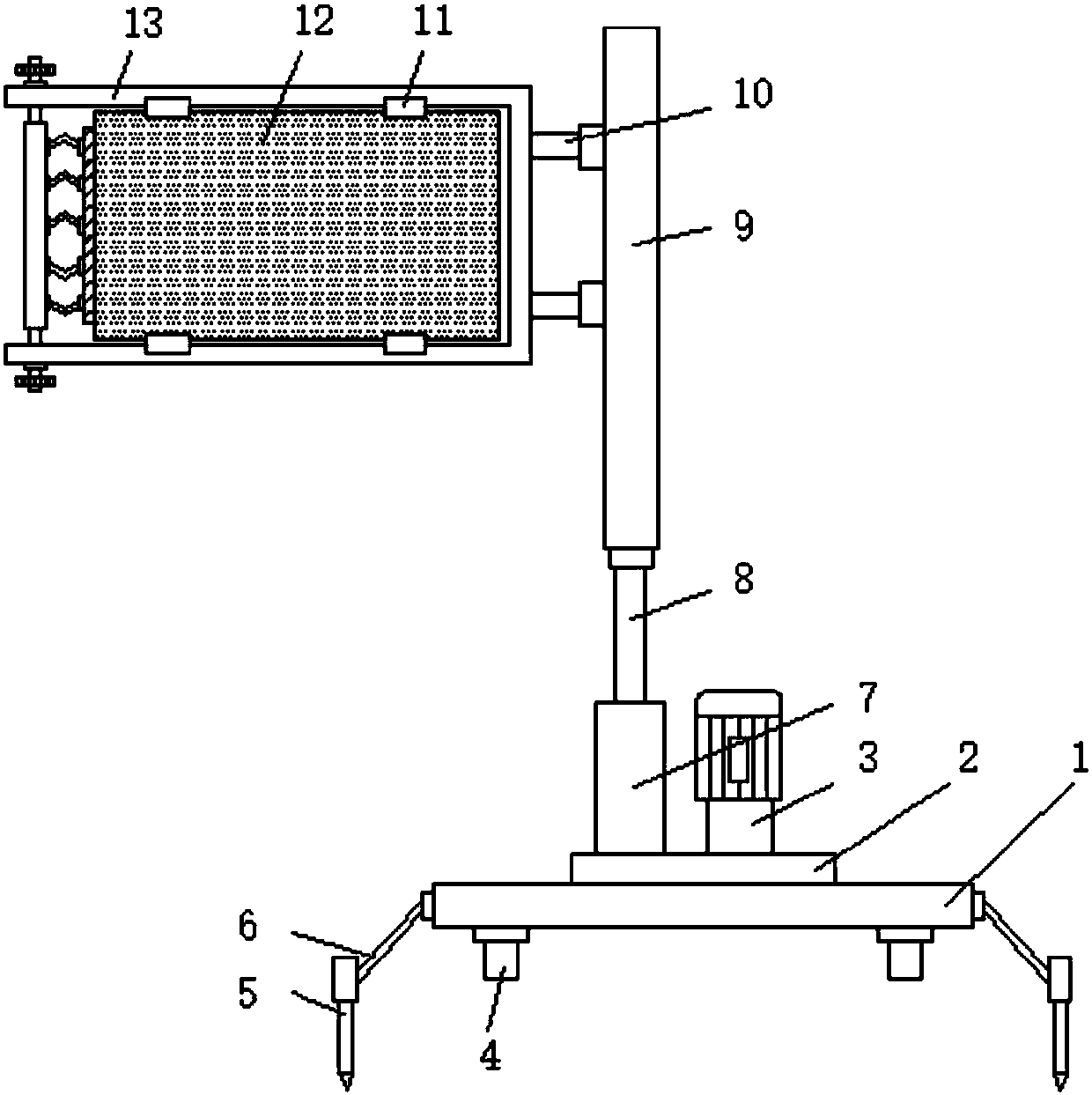

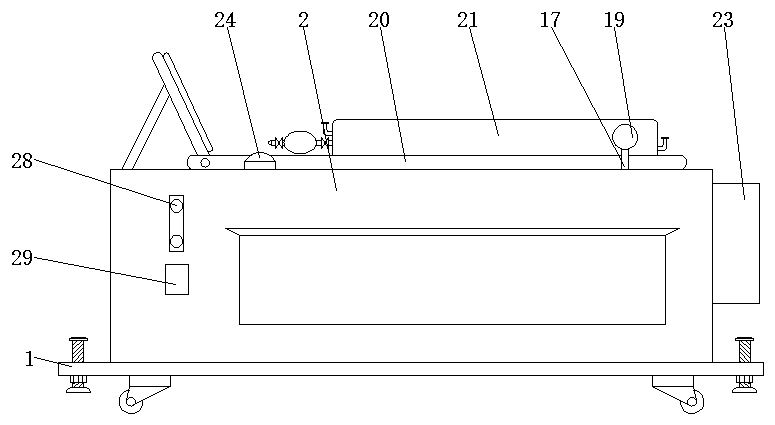

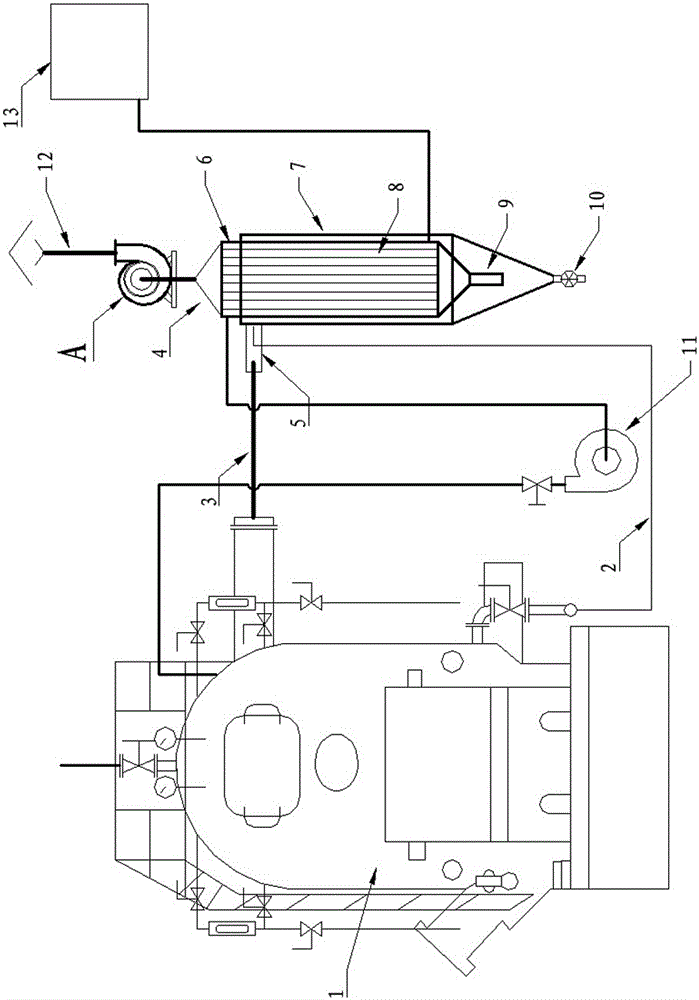

Tail gas recovery dust removal type coal-fired boiler

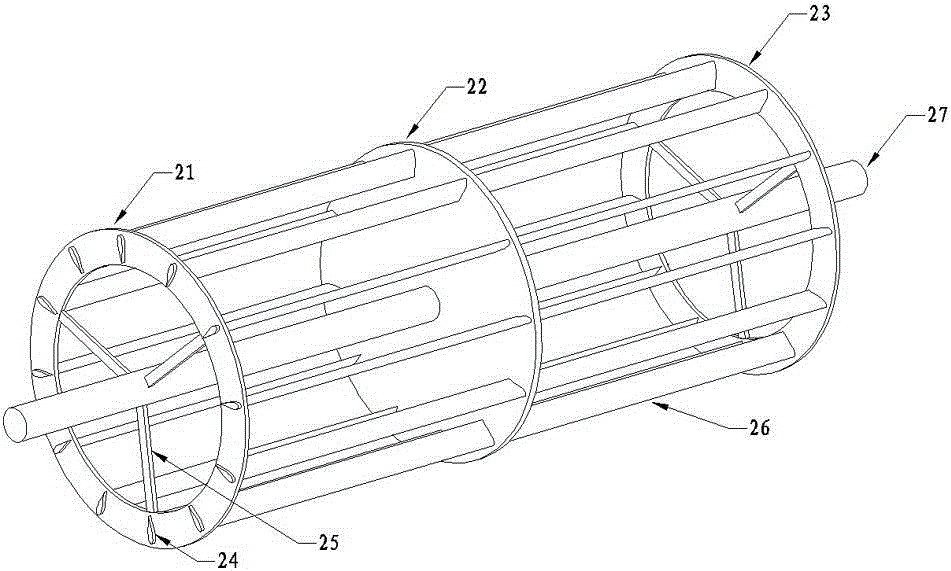

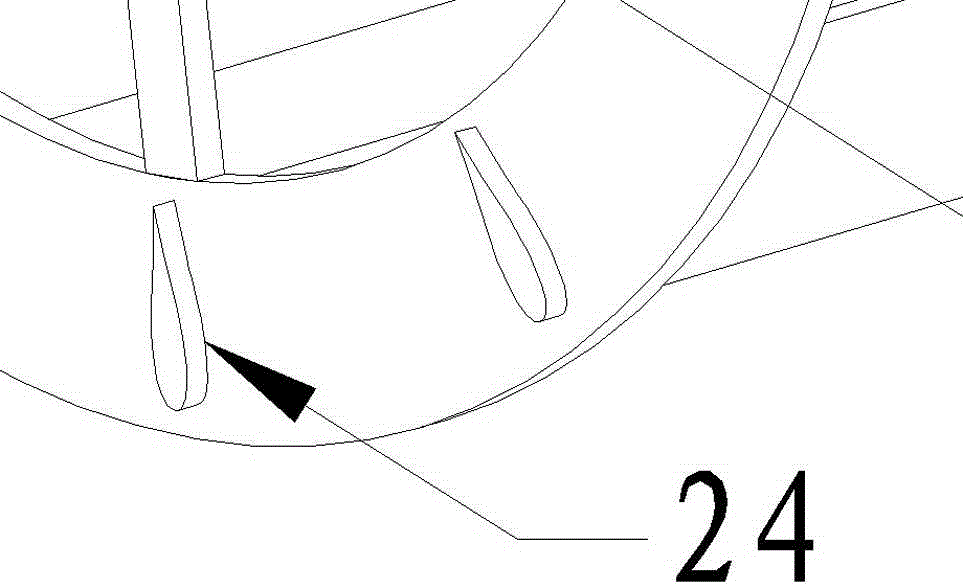

ActiveCN105066157ADoes not affect dynamicDoes not affect balancePump componentsCombustion processAir preheaterEngineering

The invention discloses a tail gas recovery dust removal type coal-fired boiler. The tail gas recovery dust removal type coal-fired boiler comprises a boiler body and an induced draft fan. A tail gas tube of the boiler body is connected with the inducted draft fan through an air preheater, a water preheater, a cyclone dust collector and a granite dust collector, and then evacuation is carried out. The air inlet end of the shell side of the air preheater is connected with an air blower, and the air outlet end of the shell side of the air preheater is connected with the boiler body. A water inlet tube of the shell side of the water preheater is connected with a high-position pool, and a water outlet tube of the shell side of the water preheater is connected with a boiler water inlet pump. An impeller of the inducted draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. Two-stage counterflow heat exchange and dry-wet dust removal are carried out on boiler tail gas to achieve tail heat recovery and dust removal operation, and energy saving and emission reducing are achieved. Due to the structure with the inverted-drop-shaped blades and the dish-shaped back plate, dust on the impeller of the induced draft fan is removed in real time, and meanwhile the strength of the impeller of the fan is increased; and stability is improved, potential safety hazards caused by dust accumulation are effectively eradicated, and wide application prospects are achieved.

Owner:山东格林凯瑞精密仪器有限公司

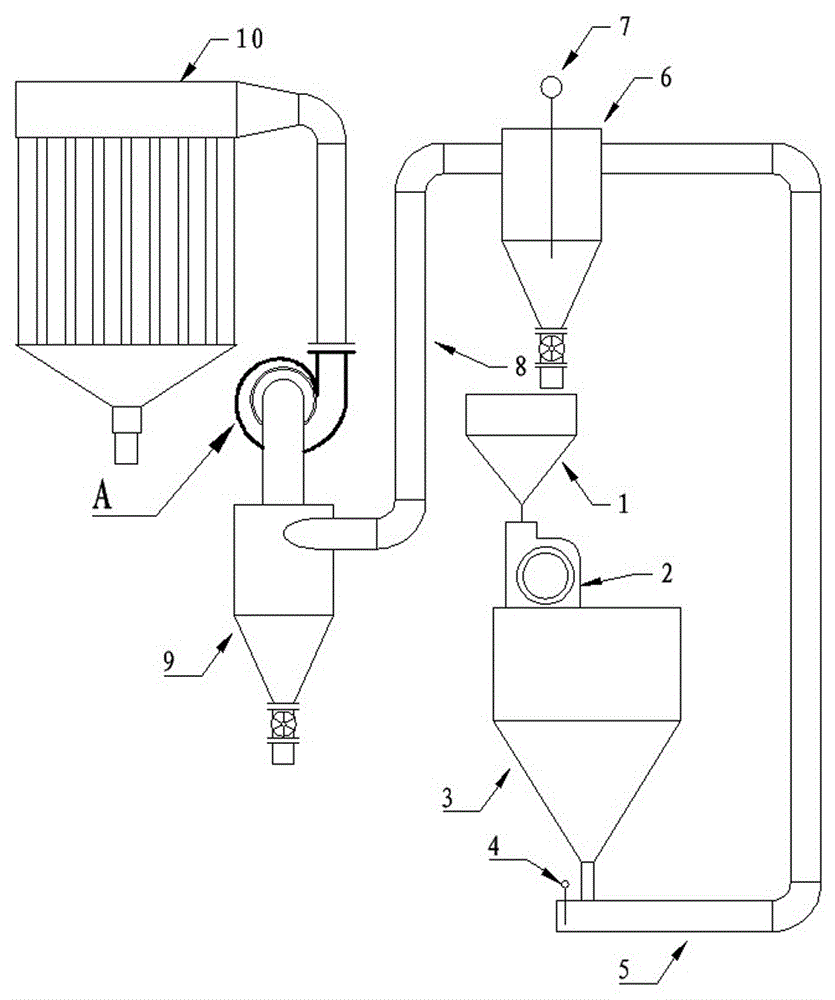

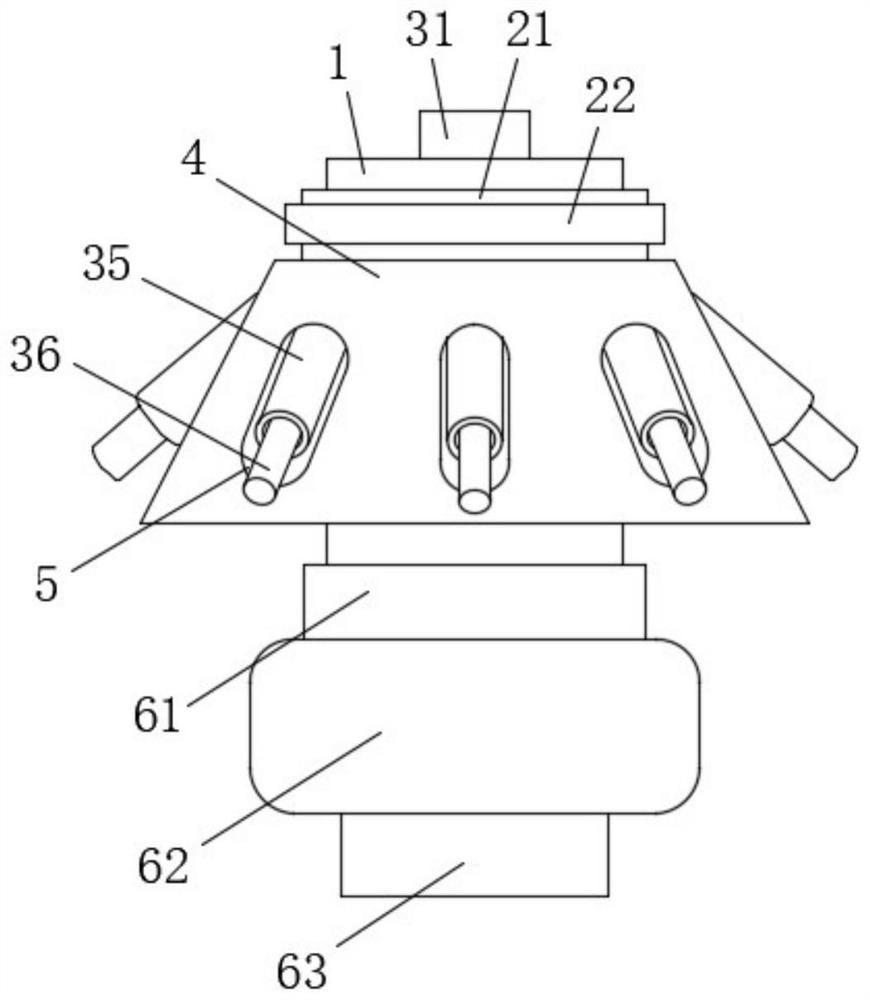

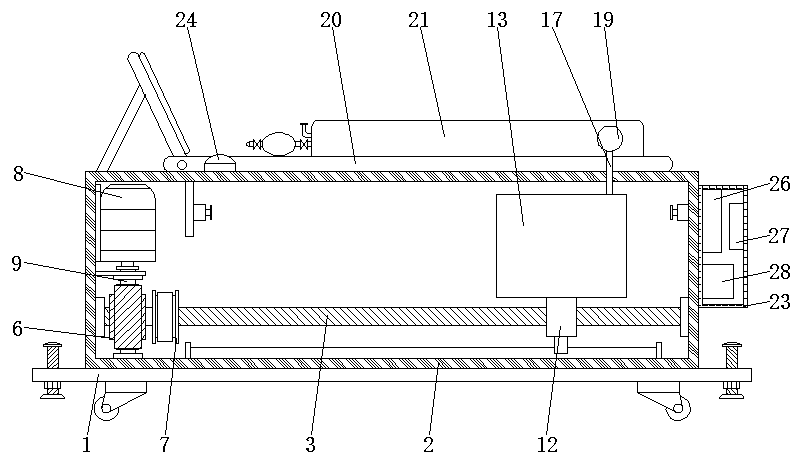

Air suction type grinder for polygonum cuspidatum

InactiveCN105013592AImprove rigidityImprove carrying capacityPump componentsVortex flow apparatusAir volumeInvolute

The invention discloses an air suction type grinder for polygonum cuspidatum. The air suction type grinder for the polygonum cuspidatum comprises a grinder body and an induced draft fan, wherein the discharging end of the grinder body is connected with the induced draft fan through a material storage case, air suction pipes and a cyclone separator; a ventilation door used for adjusting air volume is arranged on one of the air suction pipes; an impeller of the induced draft fan is of a structure with blades in a hollow wedge shape and a backboard in a dish shape; and the shape contour line of the induced draft fan is an involute. By means of the air suction type grinder for the polygonum cuspidatum, sorting of particles and cooling and temperature drop of the material are achieved in the pneumatic transmission process; the return and secondary grinding of the coarse particles are completed in one step, the qualified output of the material is achieved, and meanwhile dust capture is achieved; the timely and smooth discharging of the grinder is guaranteed by an air suction system, the material is prevented from being excessively ground, and electric power is saved; by means of the structure with the blades in the hollow wedge shape and the backboard in a dish shape, the real-time cleaning of dust on the impeller of the induced draft fan and the increase of the strength of the impeller of the draught fan are achieved; the stability is improved, and safety accidents caused by dust accumulation are effectively eradicated; and the application prospect is wide.

Owner:JISHOU UNIVERSITY

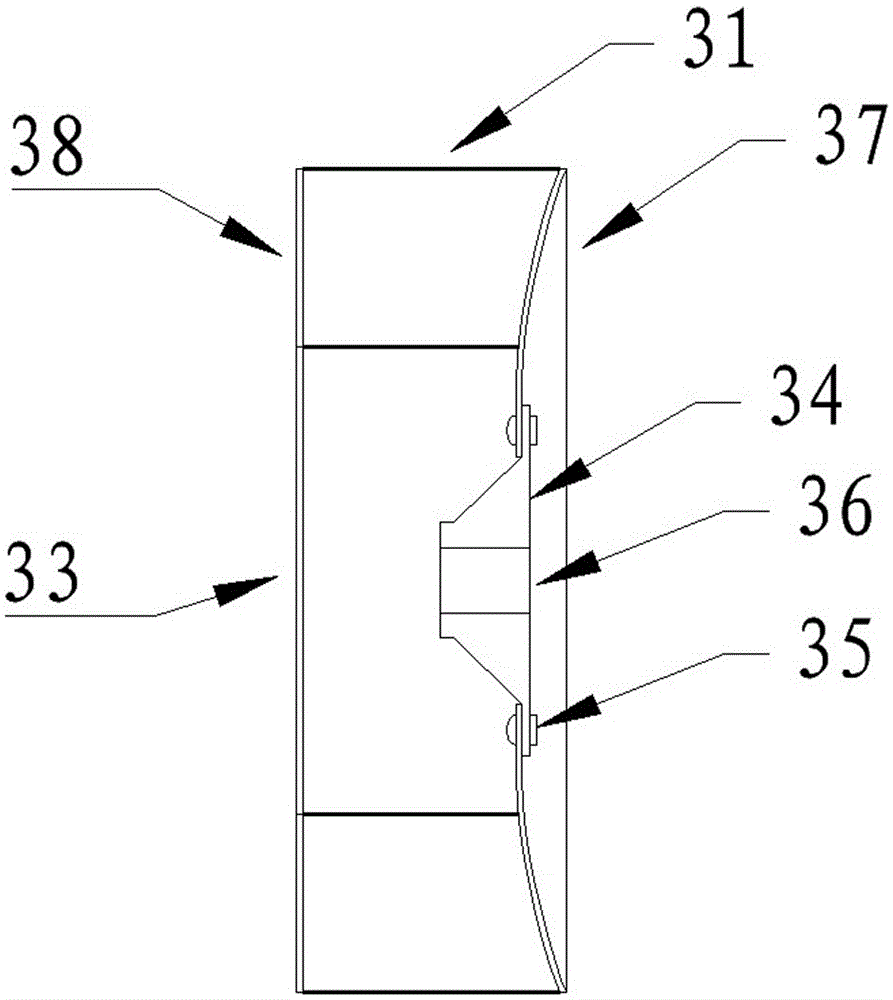

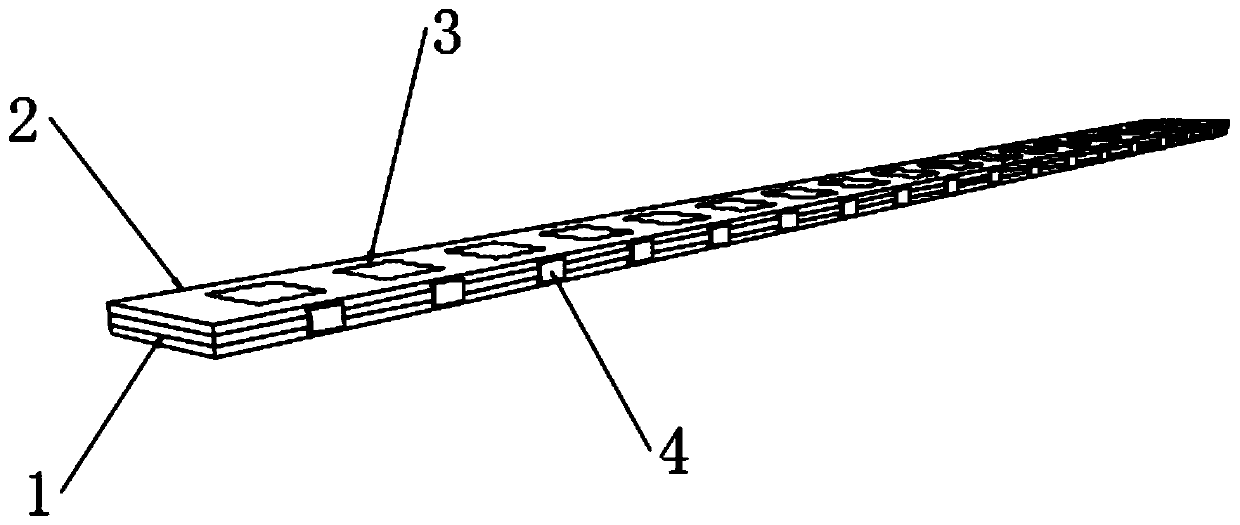

Railway liner plate for vibration reduction and noise reduction and preparation method of railway liner plate

InactiveCN108148220AStrong ability to withstand pressureGuaranteed mechanical strengthSynthetic resin layered productsMicrosphereRadiation resistance

The invention discloses a railway liner plate for vibration reduction and noise reduction, which relates to the field of railway vibration reduction parts. The railway liner plate for the vibration reduction and noise reduction comprises an upper surface layer and a lower surface layer which are made of 98 to 99.5 parts by weight of viscous resin and 0.5 to 2 parts of expansion microspheres, wherein the viscous resin comprises polyester, polyolefin and liquid rubber, and a shaping temperature of the expansion microspheres is higher than a melting temperature of the viscous resin. The railway liner plate for the vibration reduction and noise reduction has excellent elasticity, high vibration absorption capacity, good damping performance and excellent damping effect, and the absorbed energywhen in stress is large; and the railway liner plate also has the advantages of oil resistance, wear resistance, chemical corrosion resistance, radiation resistance and the like, and is small in compression deformation, high in mechanical strength, good in electric insulation performance and widely applicable to the high-speed railway tracks.

Owner:武汉鼎瑞新材料有限责任公司

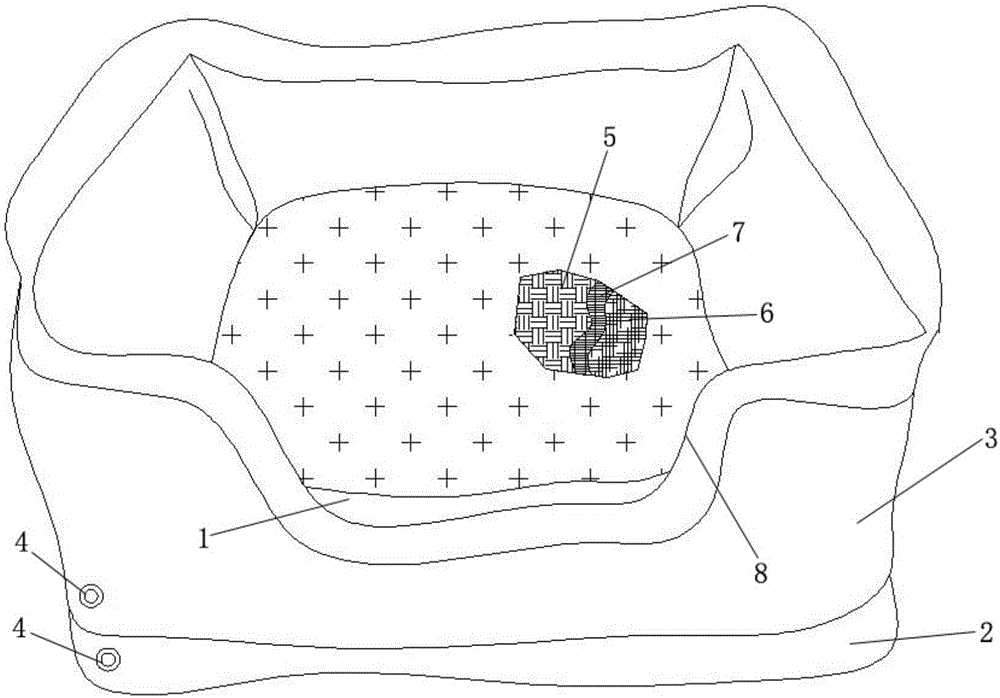

Inflatable pet house having silver ion antibacterial function

InactiveCN106135026ALying down is soft and comfortableEnhanced elastic cushioning effectSynthetic resin layered productsAnimal housingDiseaseEngineering

The invention discloses an inflatable pet house having a silver ion antibacterial function. The pet house comprises a house body, a house pad and a house cover, wherein the house body comprises a house bottom located at the lower part and a side wall which is located at the upper part and surrounds the house bottom; the house body adopts an inflatable bag structure provided with inflating ports; the house body is covered with the house cover; the house pad is laid in the house body and is made of a nano-silver antibacterial nylon fabric; a double-inner-core layer is arranged in the house pad and comprises a heating cotton layer and a PP cotton layer. The pet house adopts the inflatable house body structure, has an elastic buffer effect, is high in comfort degree, resistant to water washing, warm in winter and cool in summer, has silver ion antibacterial and deodorizing functions, can effectively prevent bacteria from breeding and can avoid induction of diseases of a pet.

Owner:杭州华元田田宠物用品有限公司

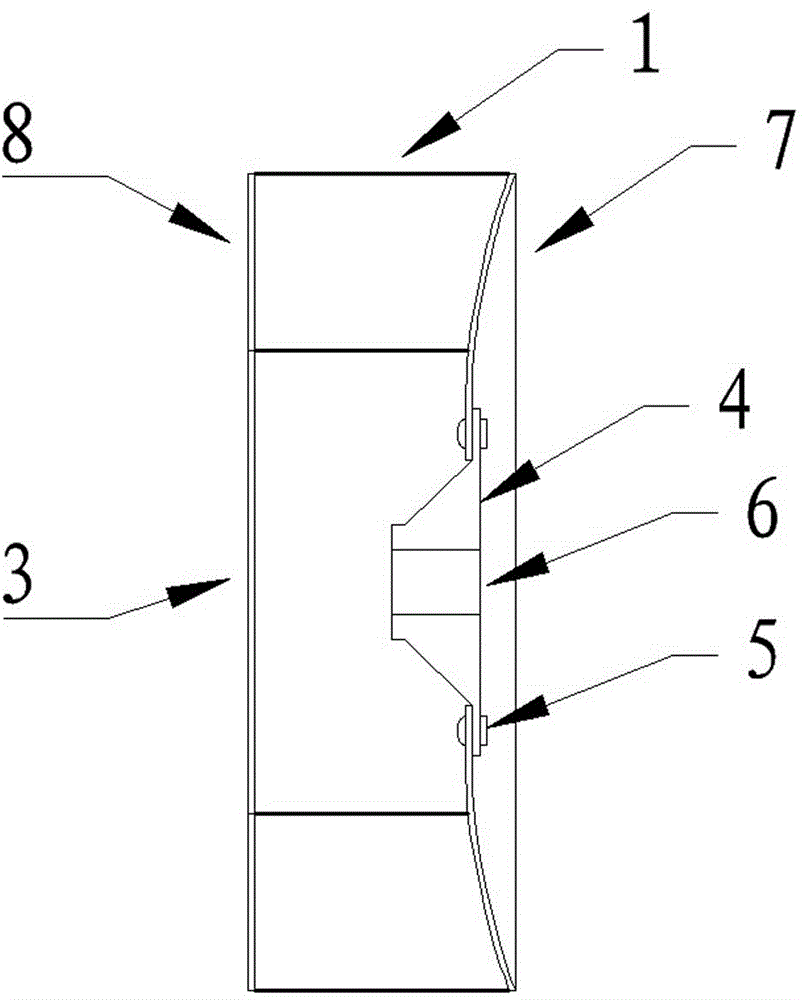

Packaging and transportation box and packaging method for casting valve

InactiveCN107082156AImprove protectionEnhanced elastic cushioning effectPackaging vehiclesContainers for machinesEngineeringAirbag

The invention discloses a packaging and transportation box and a packaging method for a casting valve. The packaging and transportation box comprises a box body, a box cap, an upper protective shell and a lower protective shell. The bottom of the lower protective shell is connected with the box body through a first airbag belt. The other two side faces of the lower protective shell and the upper protective shell are each bonded with a second airbag belt through glue. The casting valve packaged through foam is put into a lower casting valve storage cavity of the lower protective shell. Tape is adopted for layer-upon-layer winding along the peripheries of the upper protective shell and the lower protective shell. According to the packaging and transportation box and the packaging method for the casting valve, the casting valve is wrapped with the foam and then put into the upper protective shell and the lower protective shell which are made from foam boards, and layer-upon-layer winding is conducted through the tape so that the casting valve can be avoided from separating from the upper protective shell and the lower protective shell, and the peripheries of the upper protective shell and the lower protective shell are partitioned from the box body and the box cap through the first airbag belt and the second airbag belts, so that the casting valve is completely packaged and avoided from being damaged due to collision in transportation.

Owner:HEXIAN KEJIA VALVE CASTING

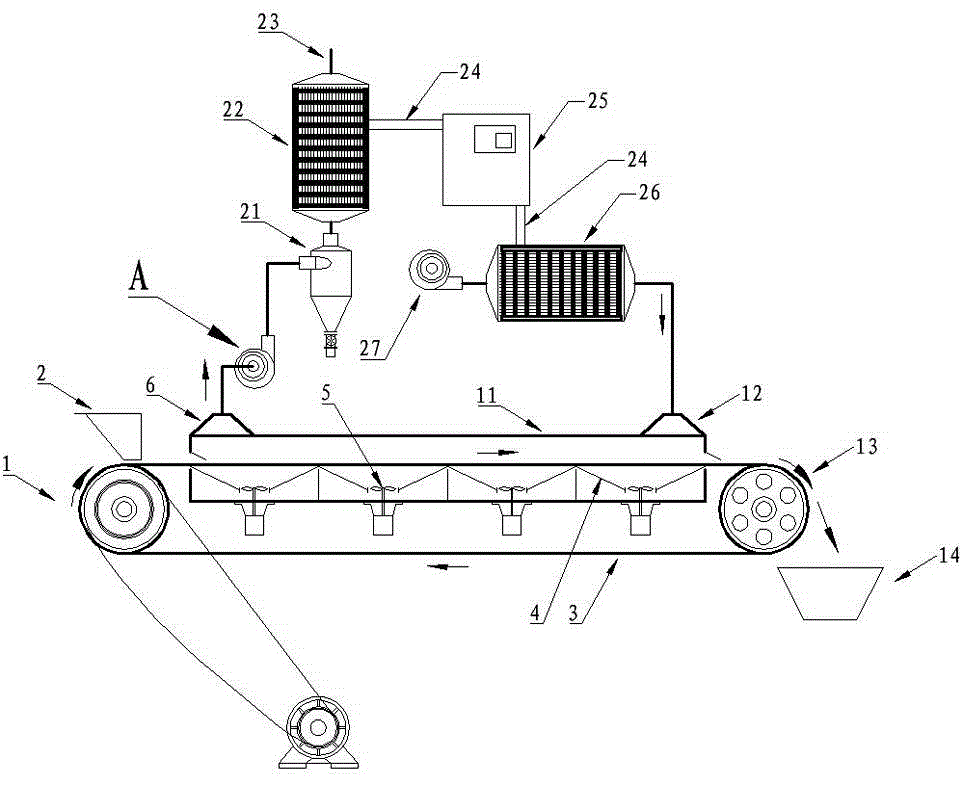

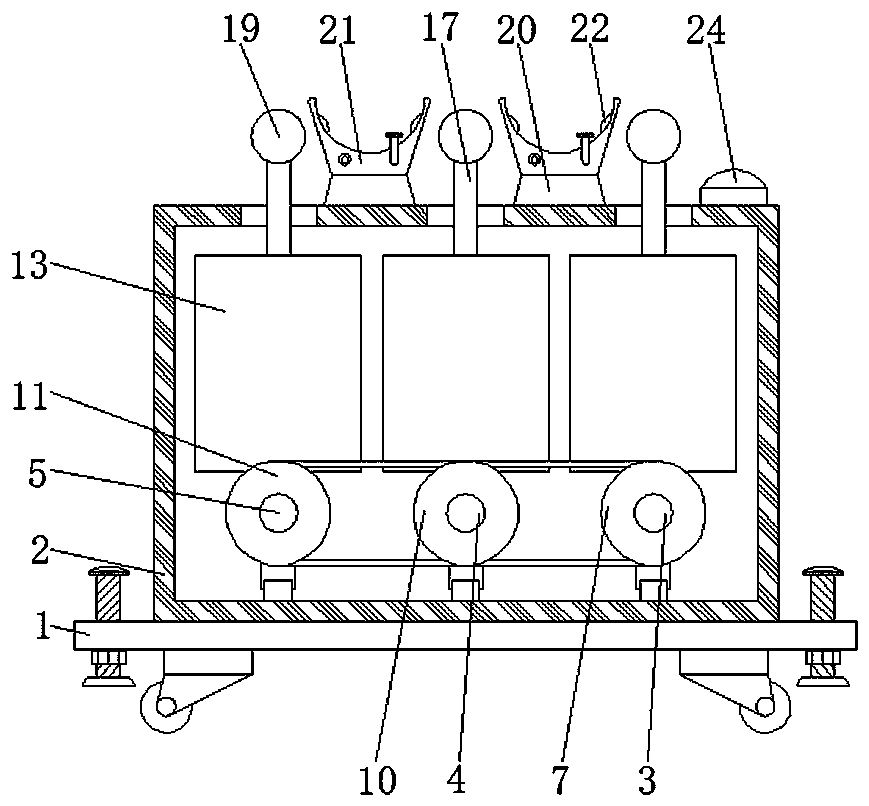

Raymond mill system with draught fan free of dust retention

The invention discloses a Raymond mill system with a draught fan free of dust retention. An air current circulation milling discharging system is formed by the draught fan, a Raymond mill, a cyclone separation discharging device and an air return duct; a pressure-equalizing exhaust branch pipe is connected with the upper end of a cyclone pipe, multiple cyclones are arranged in the cyclone pipe, the lower end of the cyclone pipe is connected with a cyclone separator in the tangent direction, and a lower pipe orifice of the cyclone separator immerges into a circulation water tank which is connected with the upper end of the cyclone pipe; and an impeller of the draught fan is of a structure that blades are in a hollow and wedged shape and the backing plate is in a disc shape, and the contour line of the appearance of the draught fan is an evolvent. According to the Raymond mill system with the draught fan free of the dust retention, due to the fact that the cyclone pipe and the cyclones are arranged, low-resistance pressure-equalizing exhaust is achieved, and dust overflow caused by positive pressure of the system is eliminated; by means of the circulation water tank, wet-method high-efficiency dust removal and mineral powder recycling are achieved; and by means of the structure that the blades are in the hollow and wedged shape and the backing plate is in the disc shape, real-time cleaning of the dust on an impeller of the draught fan is achieved, the impeller strength of the draught fan is increased, the stability is enhanced, safety accidents caused by dust accumulation is effectively eradicated, and the application prospect is wide.

Owner:JISHOU UNIVERSITY

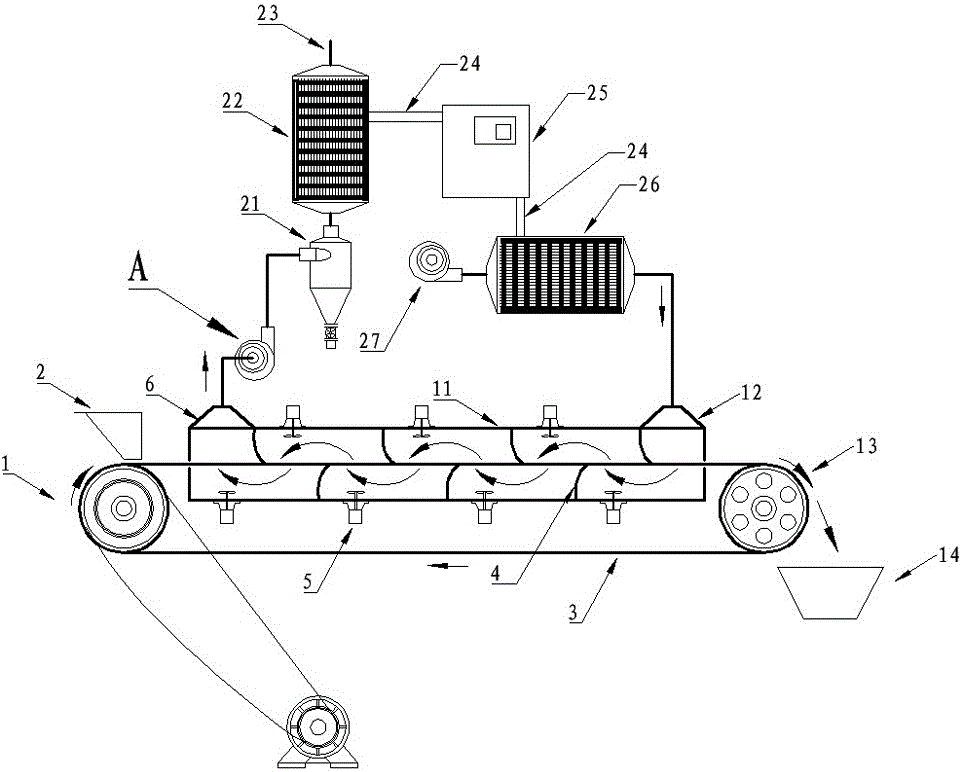

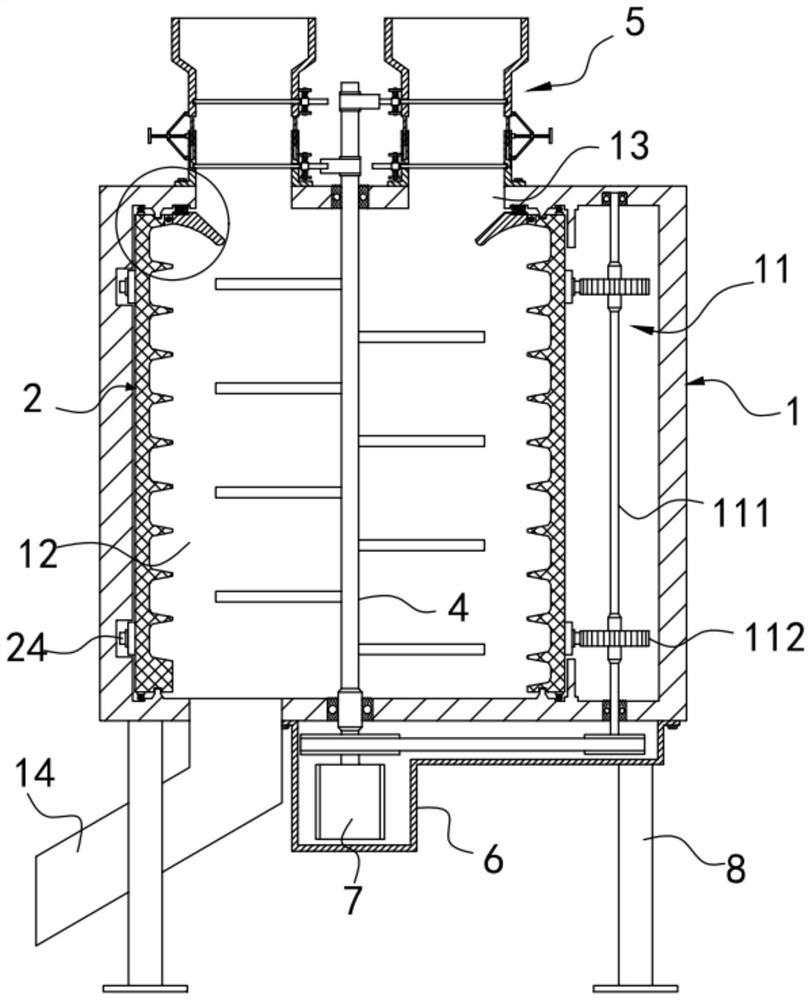

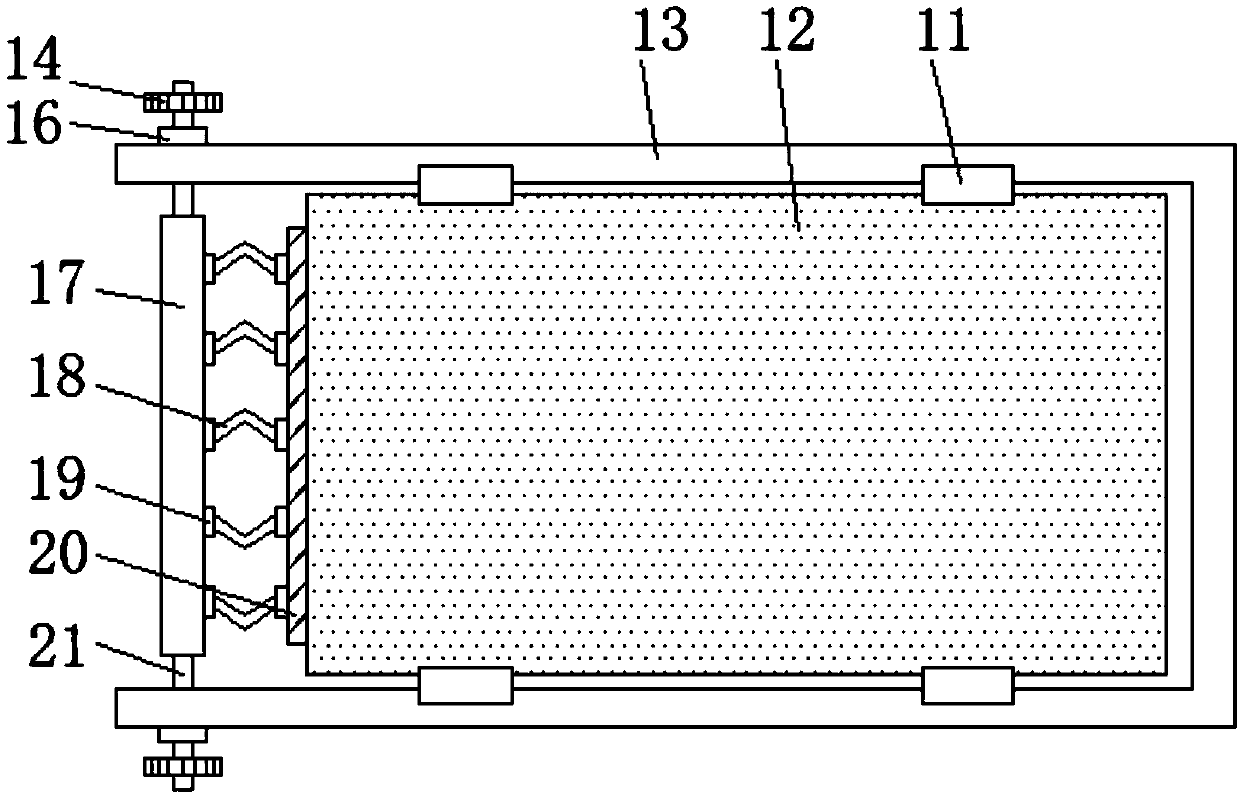

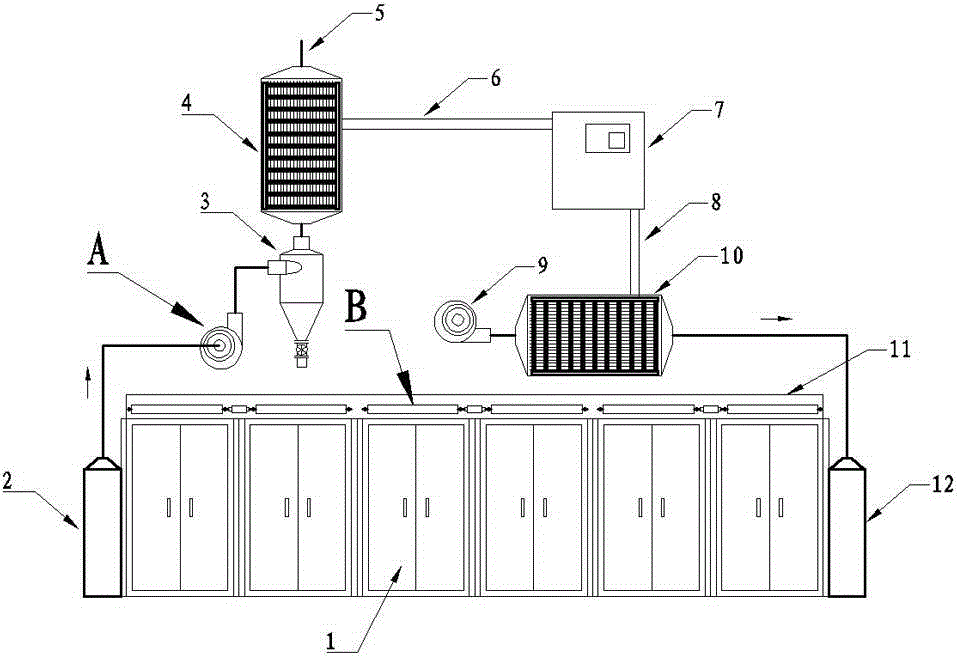

Heat pump type exhaust heat utilization counterflow dryer

ActiveCN105066642ADoes not affect dynamicDoes not affect balanceDrying solid materials with heatPump componentsImpellerEngineering

The invention discloses a heat pump type exhaust heat utilization counterflow dryer. A draught hood of the dryer is connected with an induced draft fan, and the induced draft fan is emptied after being connected with an evaporator of a heat pump system through a cyclone dust collector; the evaporator of the heat pump system is connected with a host through a refrigerant pipe, and the host is connected with a condenser through a refrigerant pipe; the air outlet end of a blast blower is connected with an air inlet housing through the condenser; an impeller of the induced draft fan is provided with blades shaped like hollow wedges, and a back plate is of a dish-shaped structure; and the outer contour line of the induced draft fan is an involute. The heat pump type exhaust heat utilization counterflow dryer is provided with the induced draft fan, a heat exchanger and a sealed conical hopper which is arranged below a sieve plate steel strip, and the conical hopper is internally provided with an axial fan, so that the penetration-type counterflow low-temperature drying of materials is realized, and the heat pump system is particularly suitable for recovering heat of low-temperature tail gases; and the blades are shaped like hollow wedges, and the back plate is of the dish-shaped structure, so that dust on the impeller of the induced draft fan can be cleared in real time, the strength of the impeller of the fan is improved, the stability is improved, safety accidents caused by dust accumulation is effectively avoided. Therefore, the heat pump type exhaust heat utilization counterflow dryer has a broad application prospect.

Owner:FOSHAN GUANGTENG NEW ENERGY CO LTD

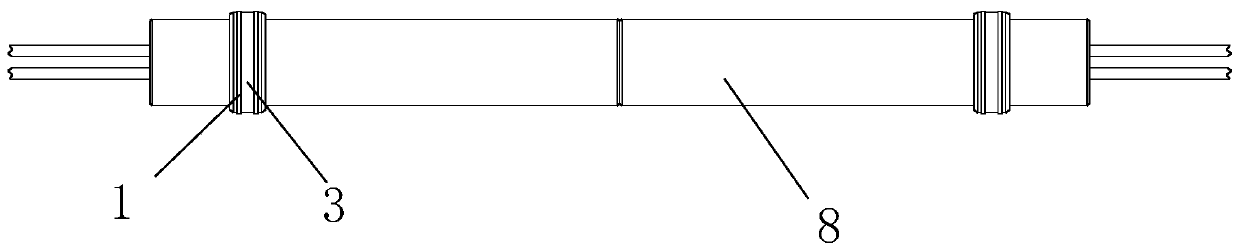

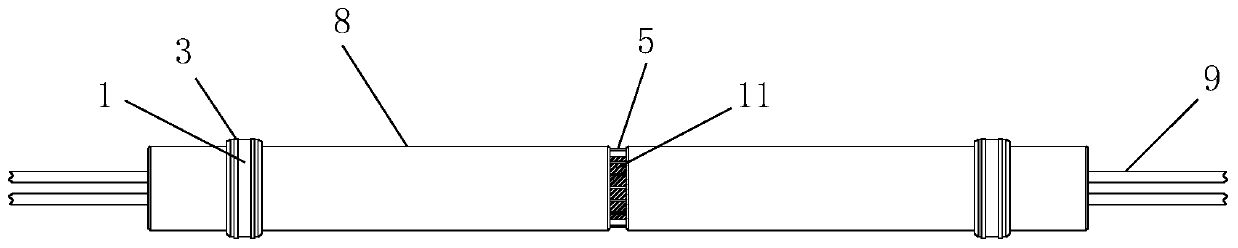

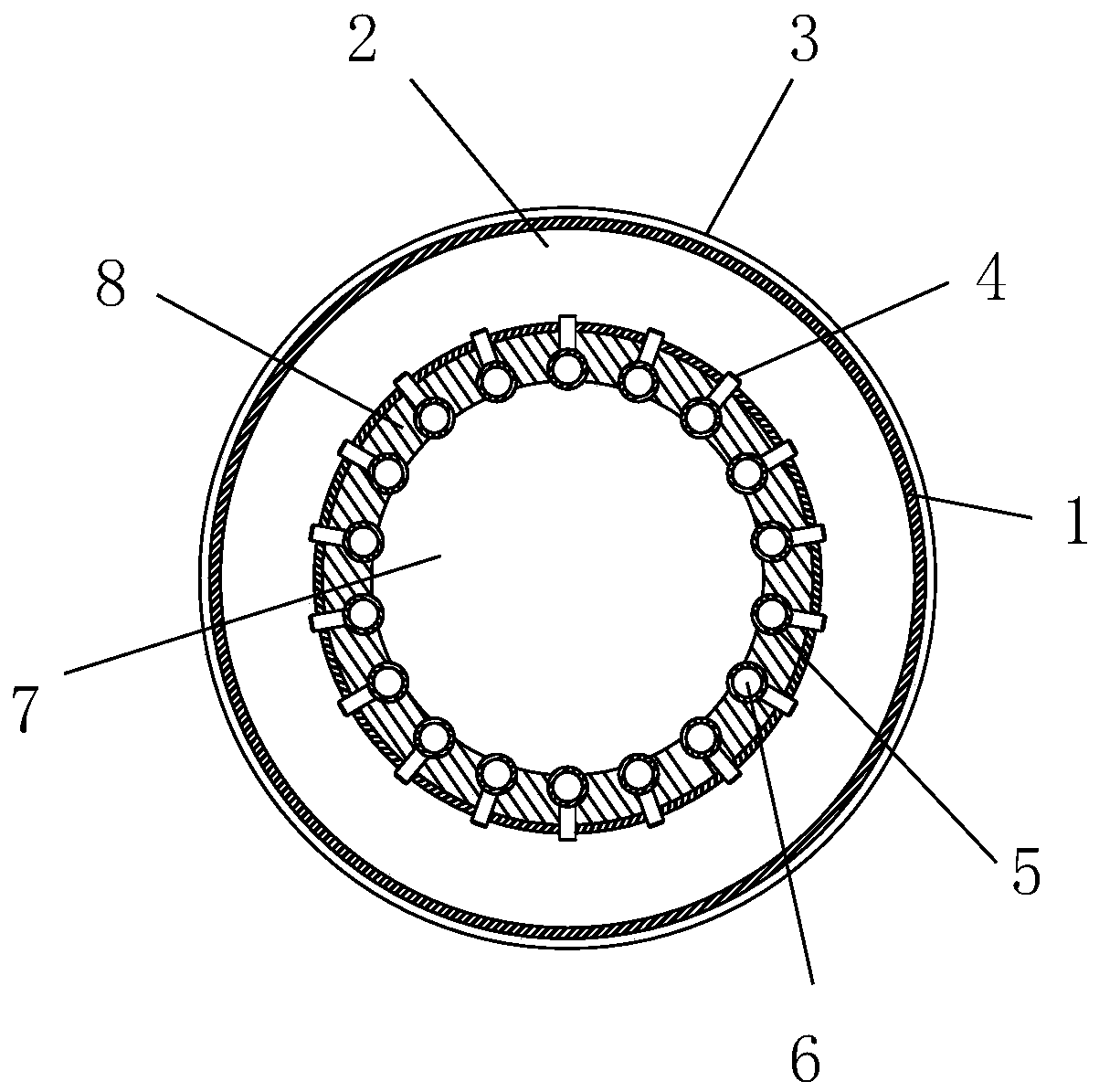

Safe composite cable

ActiveCN110444329AReduce entryExtended service lifeClimate change adaptationInsulated cablesEngineeringMoisture

The invention discloses a safe composite cable, which comprises a cable sheath layer consisting of more than one protective sleeve, wherein each protective sleeve has a cable protection cavity thereinat the middle; a cable core is arranged in the cable protection cavities; one end of each protection sleeve is provided with an assembling convex portion; and the assembling convex portions on the adjacent sides are assembled and sealed in the protective sleeve at the same side. The composite cable of the invention has very good tensile resistance and can fill a hole by means of the expansion ofan elastic inflatable belt when one protective sleeve has the hole in order to prevent the external moisture from entering and causing a short circuit, thereby increasing the safety of the cable.

Owner:JIANGSU DICHENG CABLE

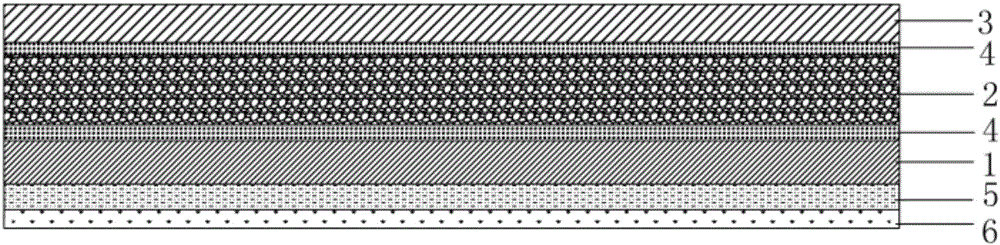

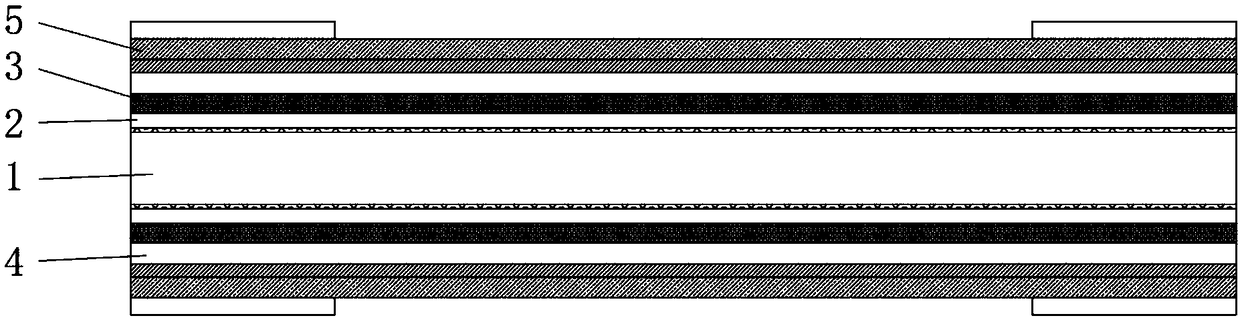

Shock-proof waterproof coiled material and preparation method

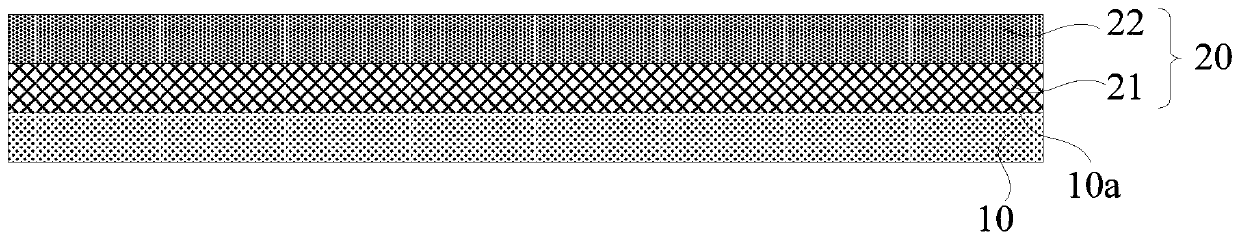

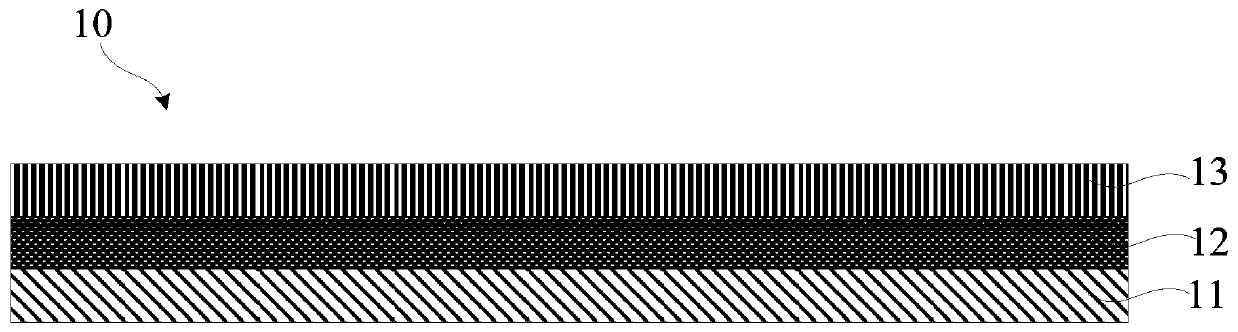

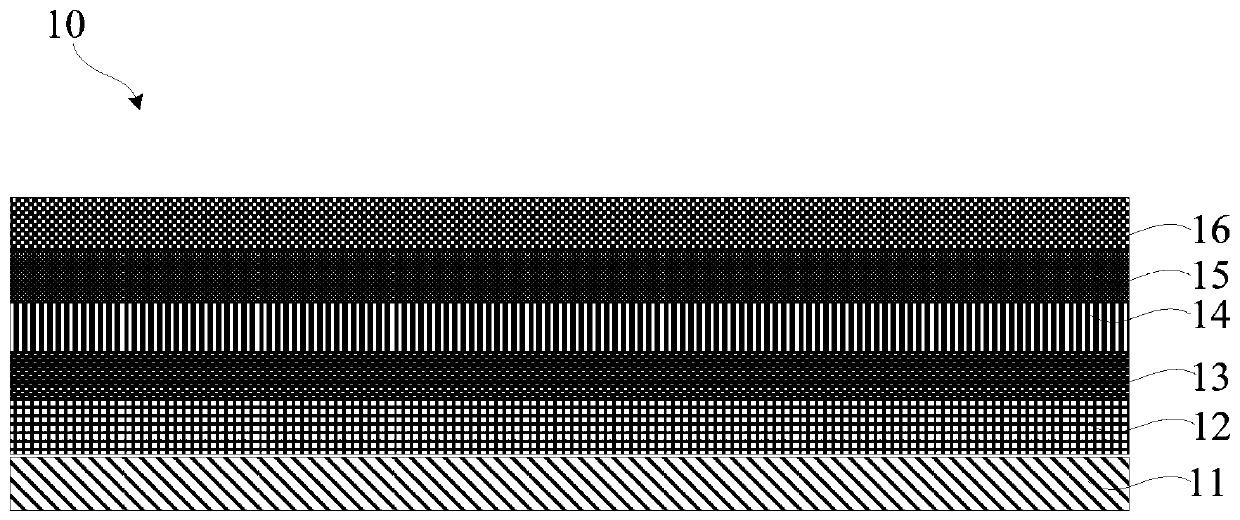

InactiveCN106671537AImprove shock absorption and cushioning effectSolve the difficulty of handlingSynthetic resin layered productsLaminationAdhesiveProtection layer

The invention discloses a shock-proof waterproof coiled material and a preparation method, which belongs to the technical field of the waterproof coiled material. The shock-proof waterproof coiled material comprises a base material layer, wherein the upper surface of the base material layer is provided with an elastic buffer layer, the upper surface of the elastic buffer layer is provided with a flexible waterproof layer, and the elastic buffer layer is respectively connected with the base material layer and the flexible waterproof layer by virtue of an adhesive layer; the lower surface of the base material layer is provided with a self-adhesion waterproof layer, and the lower surface of the self-adhesion waterproof layer is also provided with a protection layer. The preparation method comprises the following steps: smearing the adhesion layer on the upper surface of the base material layer, and adhering the elastic buffer layer onto the upper surface of the adhesive; adhering the flexible waterproof layer onto the upper surface of the elastic buffer layer; and smearing the self-adhesion waterproof layer at the lower surface of the base material layer, and then adhering a protective layer. The waterproof coiled material not only has a good waterproof effect, but also has an excellent shock-proof effect, and can protect a building against collision damage; and moreover, the preparation method is simple and easy and has good application value.

Owner:HEFEI ZHONGKE FUHUA NEW MATERIAL

Manganese processing rotary kiln system with gas furnace supplying heat and draught fan being free of dust accumulation

ActiveCN105066684AEasy flipIncrease the heating areaPump componentsRotary drum furnacesCombustorManganese

The invention discloses a manganese processing rotary kiln system with a gas furnace supplying heat and a draught fan being free of dust accumulation. A rotary kiln is arranged in an inclined mode. A combustor is arranged in the rotary kiln and connected with an air control valve and a gas control valve. An air lock is arranged at the higher end of the rotary kiln for feeding and connected with a dust remover through a fin section and an air pipe. A cover cylinder is arranged outside the fin section, a sleeve type air heat exchanger is arranged outside the air pipe, and the cover cylinder is connected with the gas control valve and the air control valve after being joined with a lower air suction port of the air heat exchanger. The draught fan is of a structure with blades being in a reverse drop shape and a back plate being in a butterfly shape. A convex refractory plate is arranged in the rotary kiln. Through the convex refractory plate, the heat transfer area of the rotary kiln is increased, material stirring is promoted, and heat efficiency is easily improved; through the fin section and the air heat exchanger, tail heat is utilized, and combustion is facilitated; through shock chilling liquid, the environmental protection pressure of production liquid expansion is effectively relieved; because the draught fan is free of dust accumulation, safety accidents are effectively eradicated. The manganese processing rotary kiln system is especially suitable for manganese ore firing processing and has broad application prospects.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

Lift-off pile foundation structure for soft soil foundation

InactiveCN112482417ATo achieve reinforcementEasy to fixProtective foundationStructural engineeringSteel ball

The invention discloses a lift-off pile foundation structure for a soft soil foundation, and belongs to the technical field of pile foundations. The lift-off pile foundation structure comprises a shell, wherein a reinforcing mechanism is arranged in the shell; and the outer side of the shell is provided with an outer cover ion a sleeved mode, the upper surface of the outer cover is fixedly connected with a positioning mechanism, and the positioning mechanism is detachably connected to the outer side of the shell. According to the lift-off pile foundation structure for the soft soil foundation,by arranging the reinforcing mechanism, when a supporting column is hammered, the supporting column moves downwards and drives a triangular block to move downwards, at the moment, the triangular block extrudes a sliding block, the sliding block is extruded to drive one ends of first inserting rods to move, the first inserting rods move in first sliding sleeves, at the moment, the first insertingrods can be inserted into soil, meanwhile, when a hemisphere block at the upper portion moves downwards, two hemisphere blocks get close to each other, at the moment, the hemisphere blocks can extrudesteel balls, the steel balls can move after being extruded, at the moment, the steel balls can drive second inserting rods to move, and meanwhile, the plurality of second inserting rods can be inserted into the soil, so that the shell is reinforced, and then a pile foundation is stabler during fixing.

Owner:温州茧麦环保科技有限公司

Heat pump type drying machine capable of utilizing waste heat and achieving penetrating countercurrent

ActiveCN105021007ADoes not affect dynamicDoes not affect balanceHeat recovery systemsDrying gas arrangementsImpellerEngineering

The invention discloses a heat pump type drying machine capable of utilizing waste heat and achieving penetrating countercurrent. An air draft hood and an air inlet hood are arranged at the two ends of a drying machine case body respectively, the air draft hood is connected with an induced draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector and then is emptied; the evaporator of the heat pump system is connected with a host through a refrigerant pipe, and the host is connected with a condenser through the refrigerant pipe; the air outlet end of an air blower is connected with the air inlet hood through a condenser; and multiple soft partition plates which are vertically arranged and divide an upper machine case body and a lower machine case body into multiple units are arranged in the drying machine case body. According to the heat pump type drying machine capable of utilizing the waste heat and achieving the penetrating countercurrent, by means of the induced draft fan, the partition plates and axial fans, the penetrating countercurrent drying is exquisitely achieved, and the work efficiency is improved; the heat pump type waste heat utilization is suitable for heat recovery of tail gas with lower temperature and is particularly efficient, convenient and rapid; and by means of the structure that blades are in a hollow and wedged shape and the backing plate is in a disc shape, real-time cleaning of dust on an impeller is achieved, the impeller strength of the induced draft fan is increased, the stability is enhanced, safety accidents caused by dust accumulation is effectively eradicated, and the application prospect is wide.

Owner:ANHUI OURUIDA ELECTRICAL APPLIANCE TECH

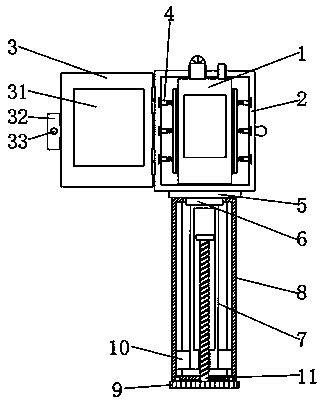

Drop-resistant hand-held gas detector for photocatalytic production

ActiveCN109061070AReduced chance of slippingAvoid damageGas analyser construction detailsPhase detectorGas detector

The invention discloses a drop-resistant hand-held gas detector for photocatalytic production in the technical field of gas detectors. The drop-resistant hand-held gas detector comprises a gas detector main body, wherein a protective shell is arranged on an outer wall of the gas detector main body; inner walls at the left side and the right side of an inner cavity of the protective shell are laminated with the outer wall of the gas detector main body through fasteners with the same structure; the bottom of a mounting block is in threaded connection with a movable rod; an outer rod movably sleeves the outer wall of the movable rod; a turn table is arranged at the bottom of the outer rod; rotating balls are arranged at the left side and the right side of the top of the turn table; a threadedrod is welded at the center of the top of the turn table; an assembly slot is formed in the outer wall at the rear end of the protective shell; a support assembly is arranged in the assembly slot; according to the gas detector, an arc-shaped groove is formed in the outer rod; friction ridges are arranged on the arc-shaped groove; and skid-proof stripes are arranged on the outer wall of the outerrod, so that the friction force between an operator's hand and a rod body is improved; and meanwhile, an operator's arm and the rod body are fixed through an elastic belt, so that the sliding probability of the gas detector is reduced.

Owner:安徽星源环境科技有限公司

Hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization

ActiveCN105020984ADoes not affect dynamicDoes not affect balanceDrying solid materials with heatHearth type furnacesAir blowerCyclonic spray scrubber

The invention discloses a hot-air drying machine capable of utilizing waste heat and achieving penetrating countercurrent fluidization. The upper portion of a drying tower is connected with an induced draft fan, and the induced draft fan is connected with a cyclone dust removing waste heat efficient recoverer formed by a tube-type heat exchanger and a cyclone dust collector in an overlapped manner in the tangent direction and then is emptied; the air inlet end of the shell side of the tube-type heat exchanger is communicated with the atmosphere, and the air outlet end of the shell side of the tube-type heat exchanger is connected with the lower portion of the drying tower through an air blower and a steam finned heater; and an impeller of the induced draft fan is of a structure that blades are in a hollow and wedged shape and the backing plate is in a disc shape, and the contour line of the appearance of the induced draft fan is an evolvent. According to the hot-air drying machine capable of utilizing the waste heat and achieving the penetrating countercurrent fluidization, creative integration is conducted on waste heat utilization and dust removal, the cyclone dust removing waste heat efficient recoverer is designed out, the equipment input is reduced, and the work efficiency is improved; and due to the fact that sieve mesh cone covers, sieve mesh cone discs, discharging tubes, a stretching vibration transmission shaft and conical plugs are arranged, penetrating, countercurrent, boiling and fluidization drying of materials are exquisitely and perfectly achieved, more energy is saved, the drying quality is higher, the power consumption of the induced draft fan is lower, and the application prospect is wider.

Owner:重庆信奇建材机械制造有限公司

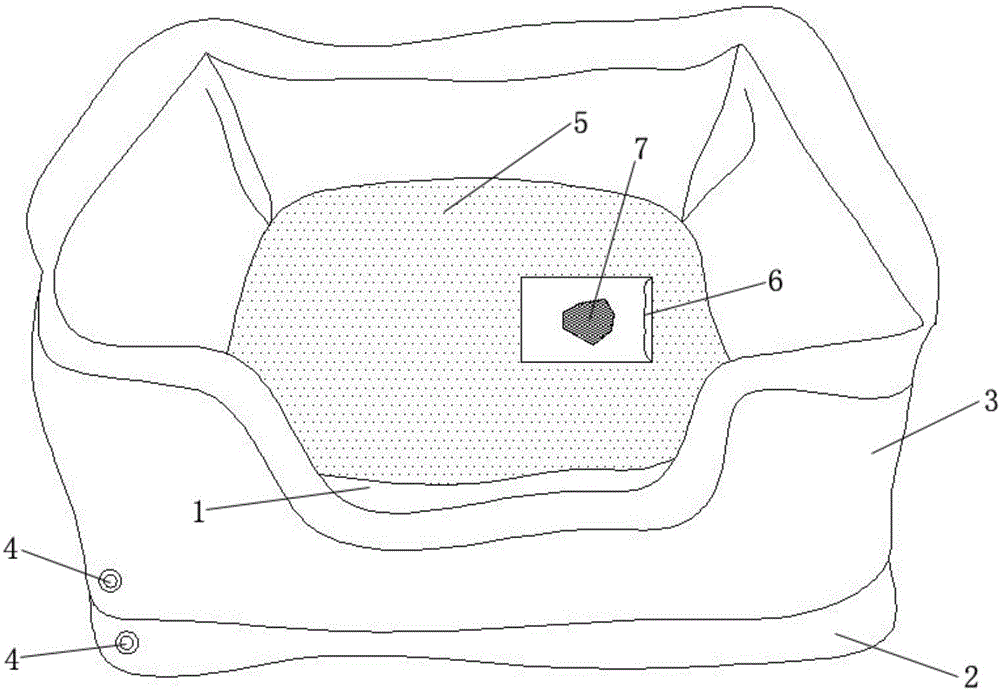

Antibacterial inflatable pet bed

InactiveCN106305455ALying down is soft and comfortableEnhanced elastic cushioning effectAnimal housingCushioningDisease

The invention discloses an antibacterial inflatable pet bed, which comprises a bed body, a bed cushion and a bed cover, wherein the bed body consists of a bed bottom positioned on the lower part and a side skirt positioned on the upper part around the bed bottom, is of an inflatable bag structure with an inflation port, and is wrapped with the bed cover; the bed cushion is laid on the inner side of the bed body; a photocatalyst material is attached to the bed cushion by a spraying process. The antibacterial inflatable pet bed has the inflatable bed body structure, elastic cushioning effects and antibacterial and deodorization effects, and is high in comfort degree, washable, warm in winter and cool in summer, breeding of bacteria can be effectively prevented, and induction of the disease of a pet can be avoided.

Owner:HANGZHOU HUAYUAN PET PROD CO LTD

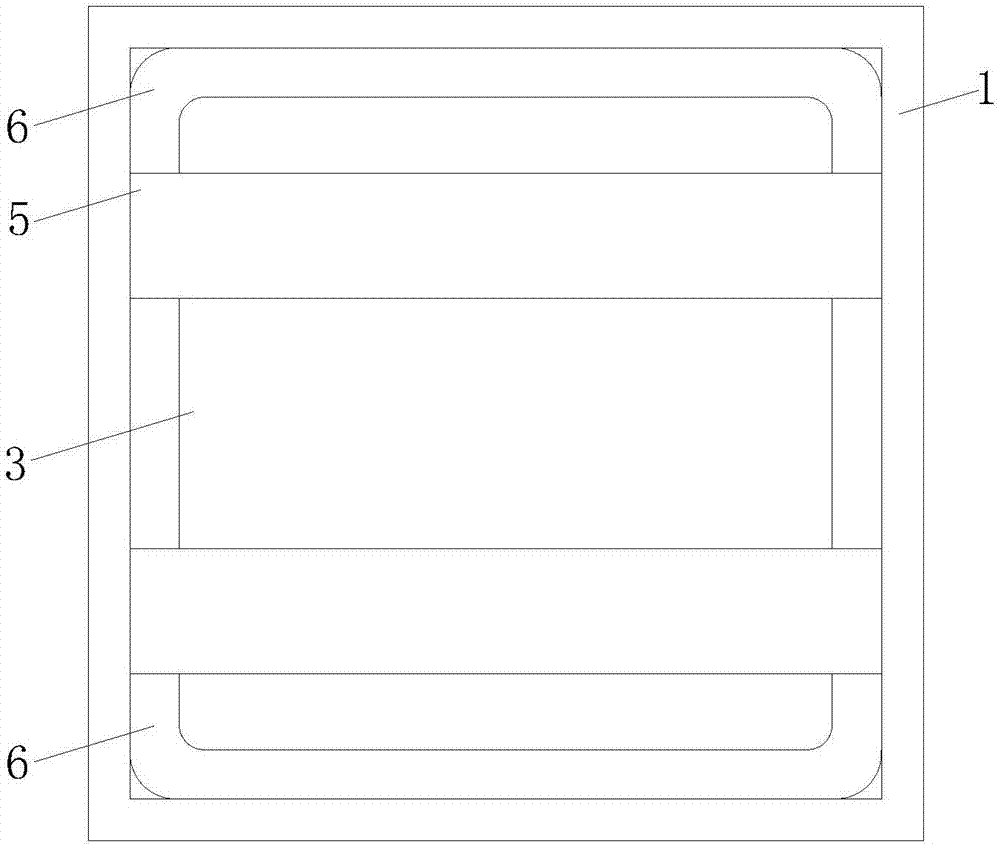

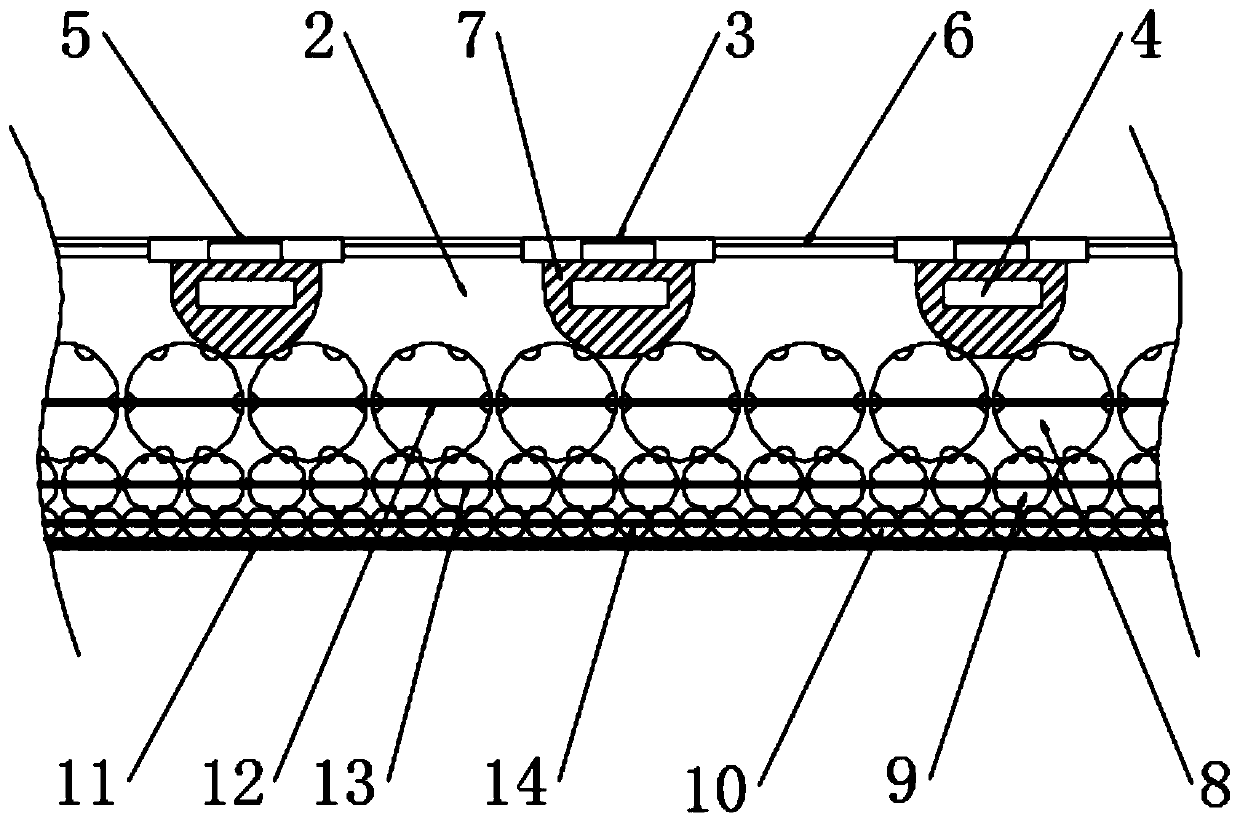

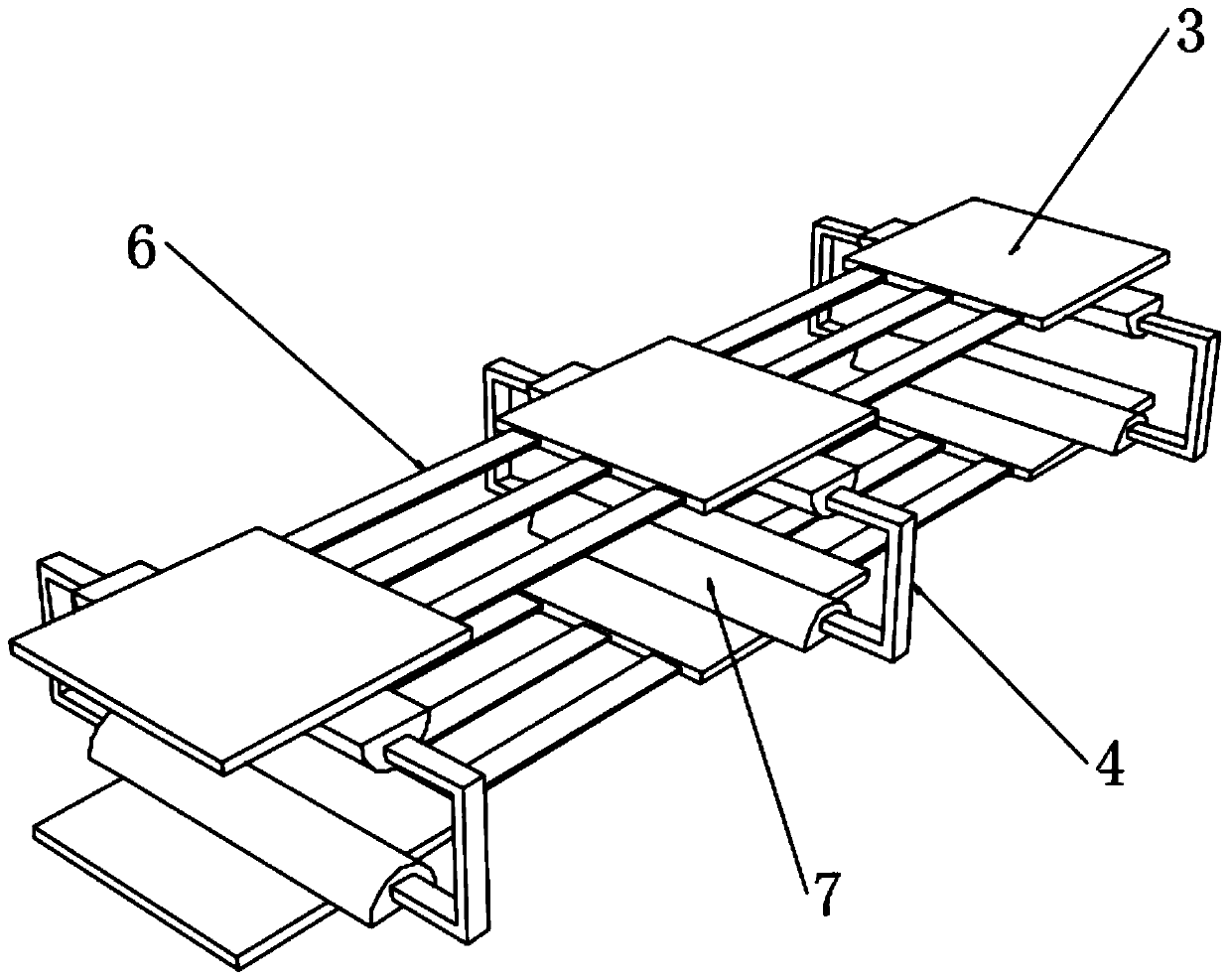

Force dispersion type cold-rolled shipment interlayer padding

PendingCN111216418AImprove the strength of forceReduce padding costsSynthetic resin layered productsVehicle componentsCushioningHigh density

The invention discloses a force dispersion type cold-rolled shipment interlayer padding. A three-layer fiberboard can be used as a core material, two sides of the core material are wrapped with high-density sponges, a composite force dispersion layer is inlaid in the high-density sponge, a force transmission structure arranged on the surface of the sponge is used for pre-dispersing the received force and then transmitting the pre-dispersed force to the composite force dispersion layer, the force is dispersed layer by layer and partially counteracted by utilizing the elasticity of the force dispersion layer itself and the distribution characteristics of a spherical structure, a good cushion protection effect can be achieved on the product, meanwhile, internal optimization is carried out ona single force dispersion layer, a special-shaped net is used for enhancing the integrality of the force dispersion layer, and a special force buffering layer is arranged among force dispersing ballsforming the force dispersion layer. According to the invention, a good elastic buffering effect is kept while the requirements for bundling, winding, cushioning and protection are met, the effect of coping with instantaneous impact hardening protection is also achieved, the force dispersion strength of the force dispersion layers is improved, the reliability of product cushioning and protection isextremely high, and the interlayer padding can be recycled, and the cushioning and protection cost of exported products can be greatly reduced in the long term.

Owner:TAIZHOU YUXIN HOISTING EQUIP

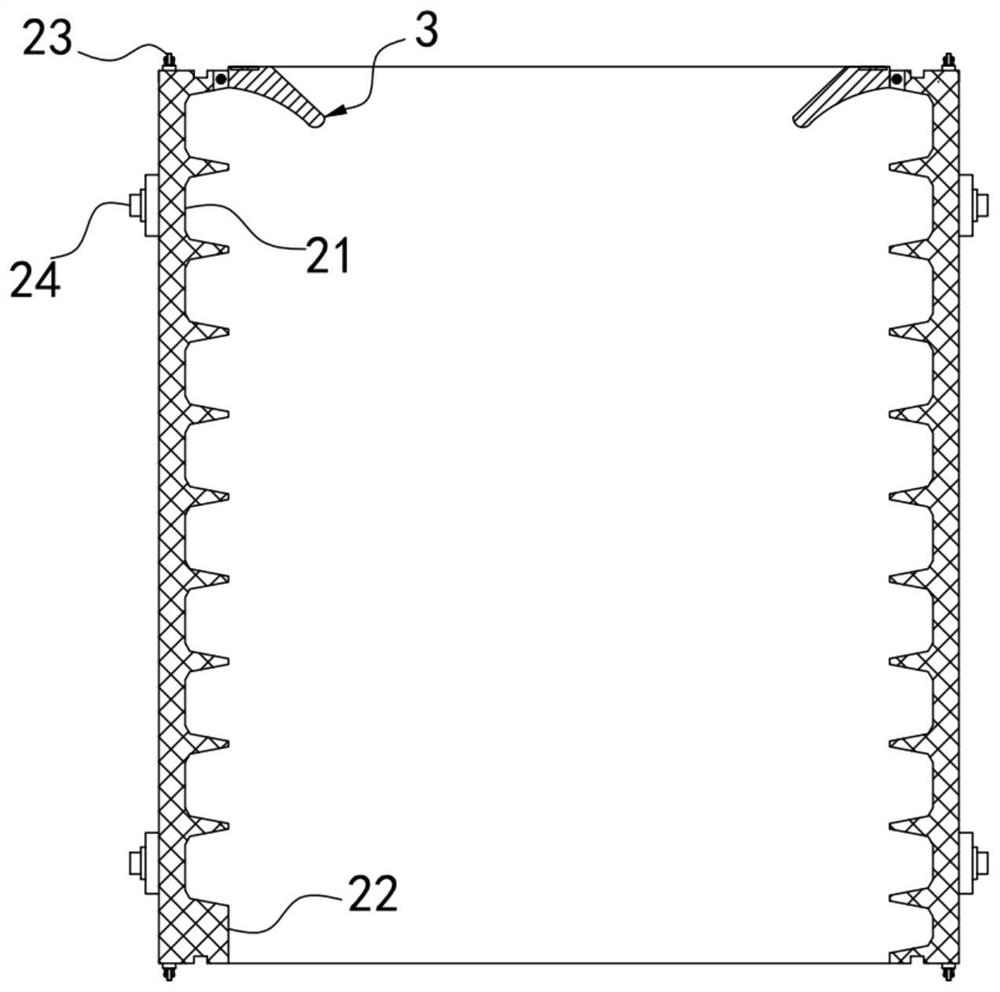

Cyclone dust removal heat pump type tunnel drying device

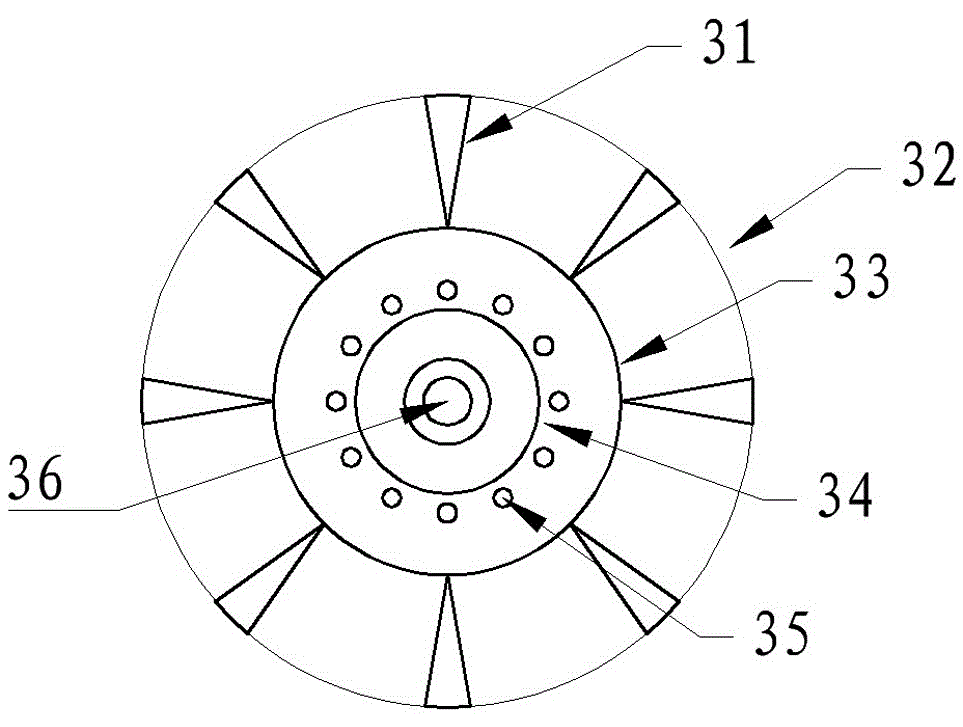

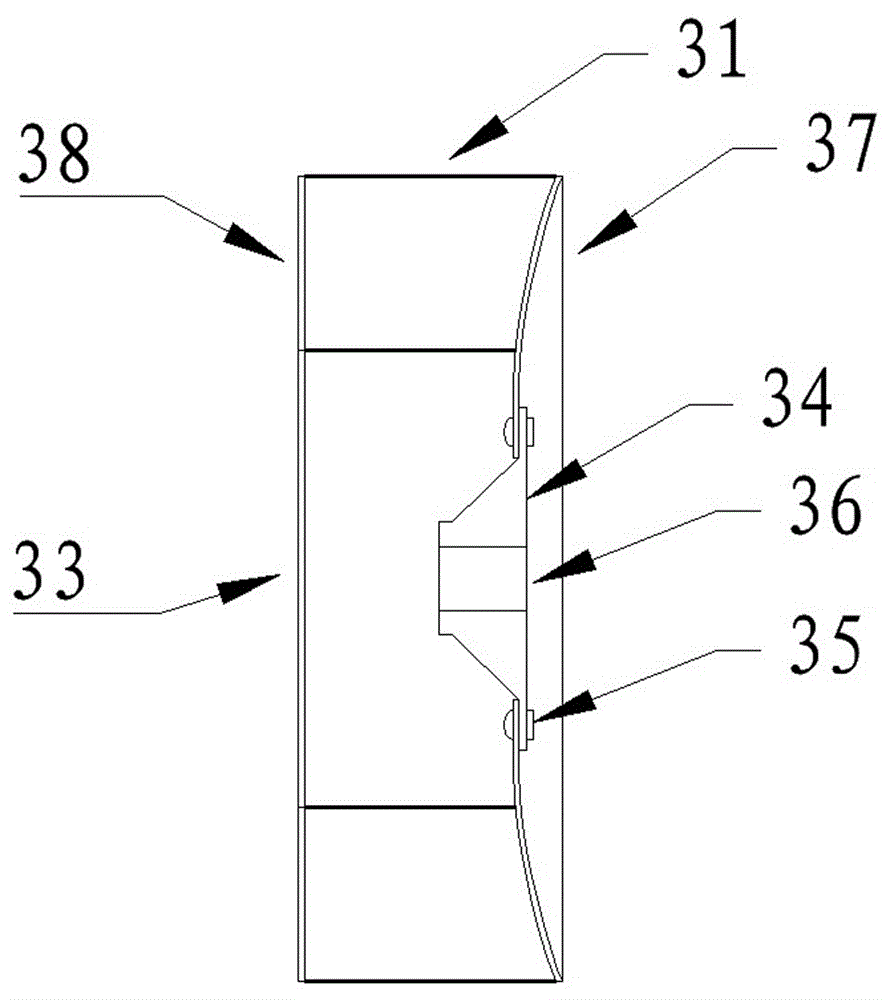

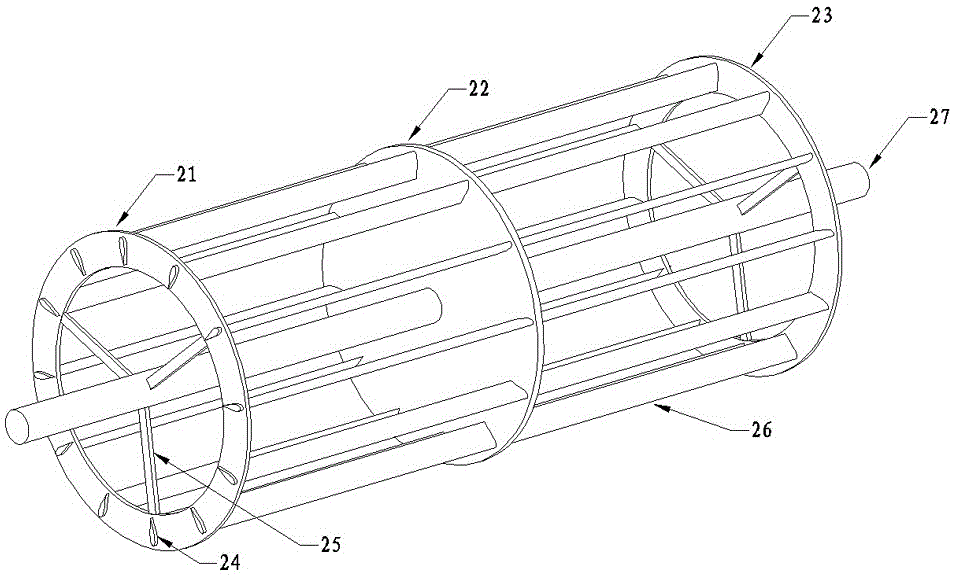

ActiveCN105066629AHigh wind resistance bendingHigh strengthDrying gas arrangementsDrying machines with progressive movementsImpellerCyclone

The invention discloses a cyclone dust removal heat pump type tunnel drying device. A trolley is arranged on a track path of a tunnel, an internal recycling long-shaft fan is arranged in the tunnel, the long-shaft fan comprises a long shaft and blades which are all shaped like a long stripe, and the cross section of each blade is a shaped like a hollow reversed water drop symmetrical to the radial direction and the center of an impeller shaft; the two ends of each blade are inserted into end plates respectively, and the long shaft is connected and fixed with the end plates through spokes; the two ends of the closed type tunnel are provided with an air draft hood and an air intake hood respectively, the air draft hood is connected with a draft fan, and the draft fan is connected with an evaporator through a cyclone dust collector for emptying; the evaporator of a heat pump system is connected with a main machine which is connected with a condenser; an air outlet end of an air blower is connected into an air hood through the condenser; the draft fan and the long-shaft fan impellers are both designed to be of a hollow symmetrical structure, dirt retention does not exist, and lightness, firmness and durability are achieved. According to the cyclone dust removal heat pump type tunnel drying device, heat pump cross flow drying and tail heat recovery are suitable for being adopted by a low-temperature drying system, destroy to heat sensitive components can be prevented, and the system can complete drying, dust removing and heat recovery efficiently with low energy.

Owner:倡创(上海)咨询管理事务所

Mesh turning plate type drying machine utilizing exhaust heat

ActiveCN104990393ADoes not affect dynamicDoes not affect balancePump componentsDrying gas arrangementsImpellerFresh air

The invention discloses a mesh turning plate type drying machine utilizing exhaust heat. A drying machine box body is provided with a mesh turning plate type conveyor from top to bottom, the drying machine box body is divided into an upper drying zone, a middle drying zone and a lower drying zone, the upper drying zone is connected with an induced draft fan through an air heat exchanger, emptying is conducted on the upper drying zone, a fresh air outlet of the air heat exchanger is connected with an air inlet of an air blower, an air outlet of the air blower is connected with a steam fin heater in the middle drying zone, an induced draft fan impeller is of a structure with hollow and wedge-shaped blades and a disc-shaped backing plate, and the outline of the induced draft fan is an evolvent. According to the mesh turning plate type drying machine utilizing the exhaust heat, exhaust heat utilization is concise and reasonable, damp and hot exhaust gas which is subjected to heat recovery is discharged through the induced draft fan, effective cooling is conducted on dried materials, the exhaust heat utilization is further conducted, and energy conservation and emission reduction are facilitated; by means of the structure with the hollow and wedge-shaped blades and the disc-shaped backing plate, real-time cleaning of dust is achieved, impeller strength of the induced draft fan is increased, the stability is enhanced, accidents caused by dust accumulation are effectively avoided, and the application prospect is broad.

Owner:和县伊迈炭业有限责任公司

Mechanical automatic feeding and mixing device

ActiveCN113694810AWell mixedGood effectTransportation and packagingRotary stirring mixersMixing effectSmart manufacturing

The invention belongs to the technical field of intelligent manufacturing, and discloses a mechanical automatic feeding and mixing device which comprises a shell with a feeding port and a discharging port formed in the top and the bottom respectively, a mixing cavity communicated with the feeding port and the discharging port is formed in the shell, a stirring component is arranged in the mixing cavity, a mixing inner cylinder capable of axially rotating around the mixing cavity is arranged in the mixing cavity, two ends of the mixing inner cylinder are respectively in sealing fit with the inner wall of the mixing cavity, the mixing cavity forms a mixing inner cavity on the inner side of the mixing inner cylinder, and the stirring component is arranged in the mixing inner cavity; and a spiral structure used for lifting materials is arranged on the inner side wall of the mixing inner cylinder in the circumferential direction, at least one spirally-rising material lifting groove is formed in the spiral structure, and blocking edges extending towards the inner side direction are arranged at the top and the bottom of the mixing inner cylinder. According to the invention, materials can be mixed more uniformly, the mixing effect is better, and mechanical automation combining feeding and quantification can be realized.

Owner:SICHUAN UNIV

Heat pump type tail heat recovery and penetrating counterflow fluidized drying machine

ActiveCN105066653AImprove rigidityImprove carrying capacityDrying solid materials with heatPump componentsDrop-shapedAir blower

The invention discloses a heat pump type tail heat recovery and penetrating counterflow fluidized drying machine. A material seal spiral feeding machine is arranged on the upper portion of a drying tower, and an air-lock valve discharging machine is arranged at the bottom of the drying tower. The upper portion of the drying tower is connected with an inducted draft fan, and the induced draft fan is connected with an evaporator of a heat pump system through a cyclone dust collector, and then evacuation is carried out. The evaporator of the heat pump system is connected with a main engine through a refrigerant pipe, and the main engine is connected with a condenser through a refrigerant pipe. The air outlet end of an air blower is connected with the lower portion of the drying tower through the condenser. An impeller of the induced draft fan is provided with a structure with hollow inverted-drop-shaped blades and a dish-shaped back plate. The contour line of the appearance of the induced draft fan is an involute. Screen mesh cone covers, screen mesh cone discs, a blanking tube, a telescopic vibration transmission shaft and a conical plug are arranged, so that penetrating, counterflow, boiling and fluidized drying on materials are achieved ingeniously and perfectly, and a classic boiling counterflow drying mode is thoroughly exceeded; and more energy is achieved, the drying quality is higher, the power consumption of the fan is lower. The heat pump type tail heat recovery and penetrating counterflow fluidized drying machine is especially suitable for recovery of heat of low-temperature tail gas.

Owner:JIANGSU XUEMEI REFRIGERATION EQUIP

Traffic electronic information display screen

ActiveCN107917322AEasy to liftConvenient and efficient liftingNon-rotating vibration suppressionStands/trestlesFixed frameEngineering

The invention discloses a traffic electronic information display screen. The traffic electronic information display screen comprises a supporting bottom plate, rivets and T-shaped bolts; a fixed seatis installed on the supporting bottom plate, chains are connected to four corners of the supporting bottom plate, and piles are fixed to one ends of the chains and inserted into the ground; a telescopic barrel and a motor are installed on the fixed seat; an electric hydraulic push rod is connected to the telescopic barrel, and one end of a fixed rod is provided with a fixed frame which is internally provided with a display screen body; spring compression slices are uniformly distributed on a movable rod, and a rubber compression plate is fixed to one ends of the spring compression slices; andthe fixed frame is provided with square slide grooves, and the square slide grooves are provided with limiting blocks. According to the traffic electronic information display screen, one side of the movable rod is provided with the rubber compression plate, iron rods at the two ends of the movable rod penetrate through the square slide grooves and the limiting blocks, thus, the movable rod can push the rubber compression plate to tightly press the display screen body and can be fixed through locking bolts, and the stability of the display screen body is ensured.

Owner:扬州市法马智能设备有限公司

Cyclone dust removal heat pump type drying room

ActiveCN105180597ADoes not affect dynamicDoes not affect balancePump componentsDrying gas arrangementsCycloneImpeller

The invention discloses a cyclone dust removal heat pump type drying room. An internal recycle long-shaft draught fan is arranged in the drying room and comprises a long shaft and blades; the blades are long-strip-shaped; the cross section of each blade is centrosymmetric hollow reverse drop-shaped in the radial direction of an impeller shaft; two ends of the blades are inserted in end discs; the long shaft is connected with and fixed with the end discs through spokes; a draught hood and an air inlet hood are arranged at two ends of the drying room; the draught hood is connected with an induced draft fan; the induced draft fan is connected with the evaporator of a heat pump system via a cyclone dust collector for evacuation; the evaporator of the heat pump system is connected with a host machine; the host machine is connected with a condenser via a refrigerant pipe; the air outlet end of an air blower is connected with the air inlet hood via the condenser; the induced draft fan and the impeller of the long-shaft draught fan are arranged into hollow symmetrical structures, do not accumulate dust, and are firm and durable. The heat pump dries in a cross flow manner, recycles residual heat, is particularly suitable for being adopted by a lower drying temperature system, prevents nutritional ingredients of thermosensitive substances from being destroyed, and completes drying, dust removal and heat recovery in an efficient and low energy consumption manner.

Owner:湖南美林住宅工业有限公司

Physical exercise device with leg muscle relaxing performance and using process thereof

ActiveCN108567564AEnhance massage relaxation effectEasy to relaxVibration massagePhysical exerciseEngineering

The invention discloses a physical exercise device with leg muscle relaxing performance. The device comprises a base plate. The top of the base plate is fixedly connected with a chassis, and a first screw, a second screw and a third screw are respectively connected between two sides of the inner wall of the chassis through bearings in a rotating mode. A transmission worm wheel and a first belt pulley are sequentially sleeved on the outer surface of one end of the first screw from left to right, and one side of the inner wall of the chassis is fixedly connected with a moving motor through a connecting block. One end of an output shaft of the moving motor is fixedly connected with a transmission worm adapted to the transmission worm wheel. The device relates to the technical field of physical exercise facilities. By means of the physical exercise device with leg muscle relaxing performance and the using process of the device, the massage relaxation effect is greatly enhanced, people do to need to spend a lot of time to massage the legs, and the legs of the people can be massaged and relaxed quickly and conveniently by the automatic device, so that the people can relax leg muscles conveniently.

Owner:泉州台商投资区双艺商贸有限公司

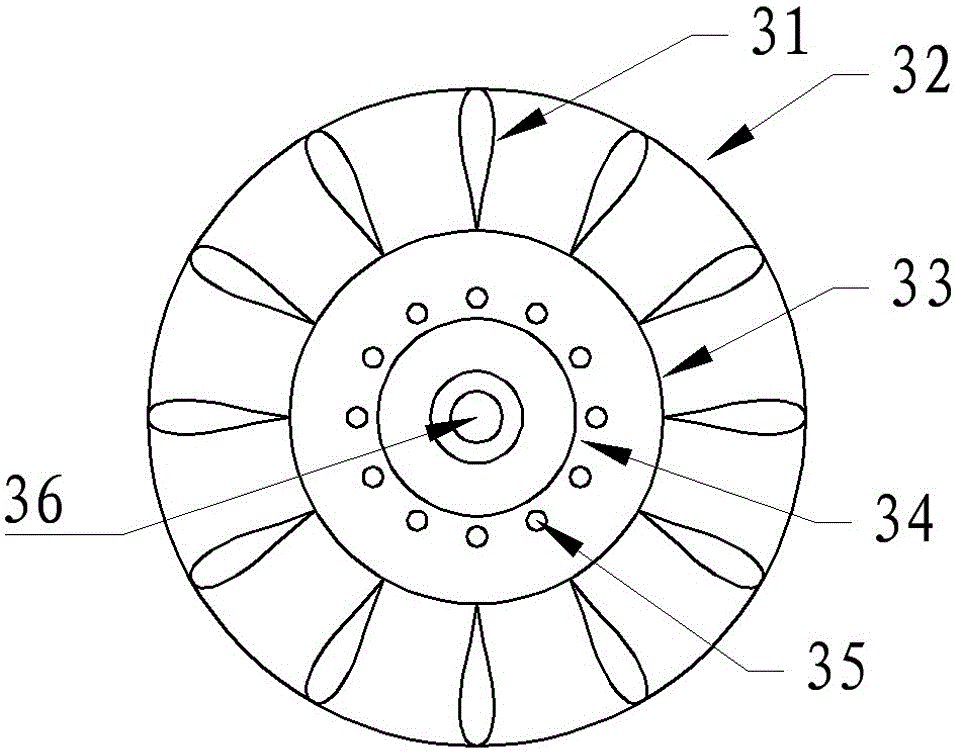

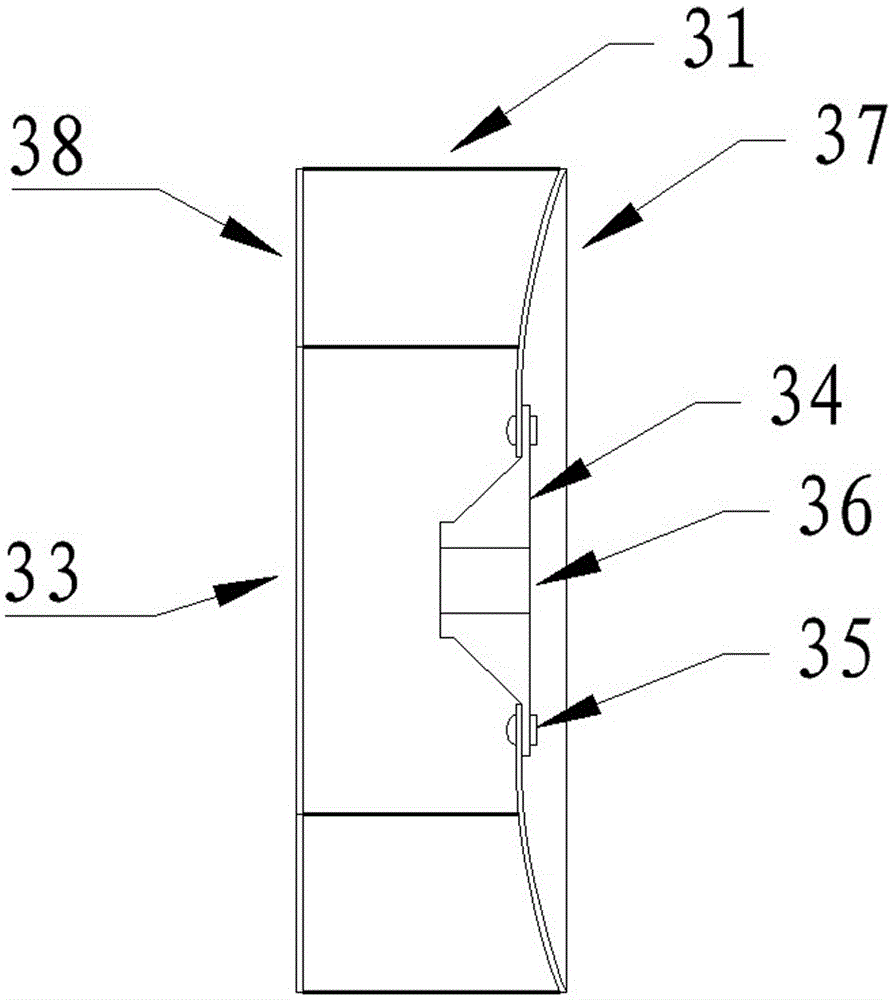

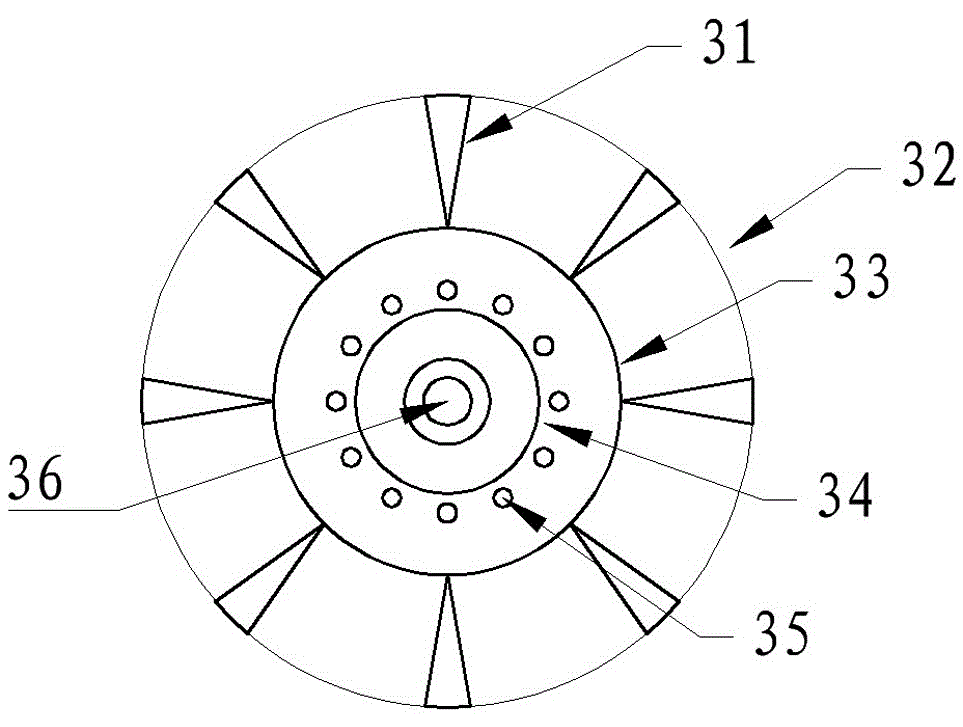

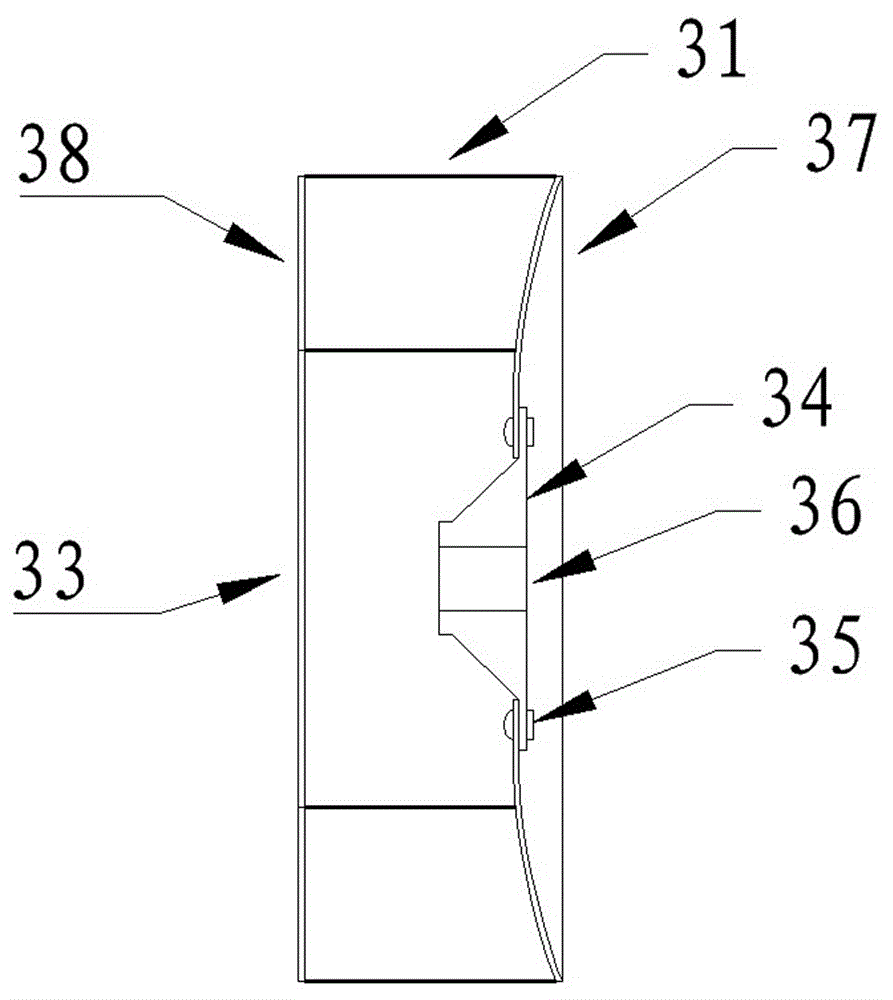

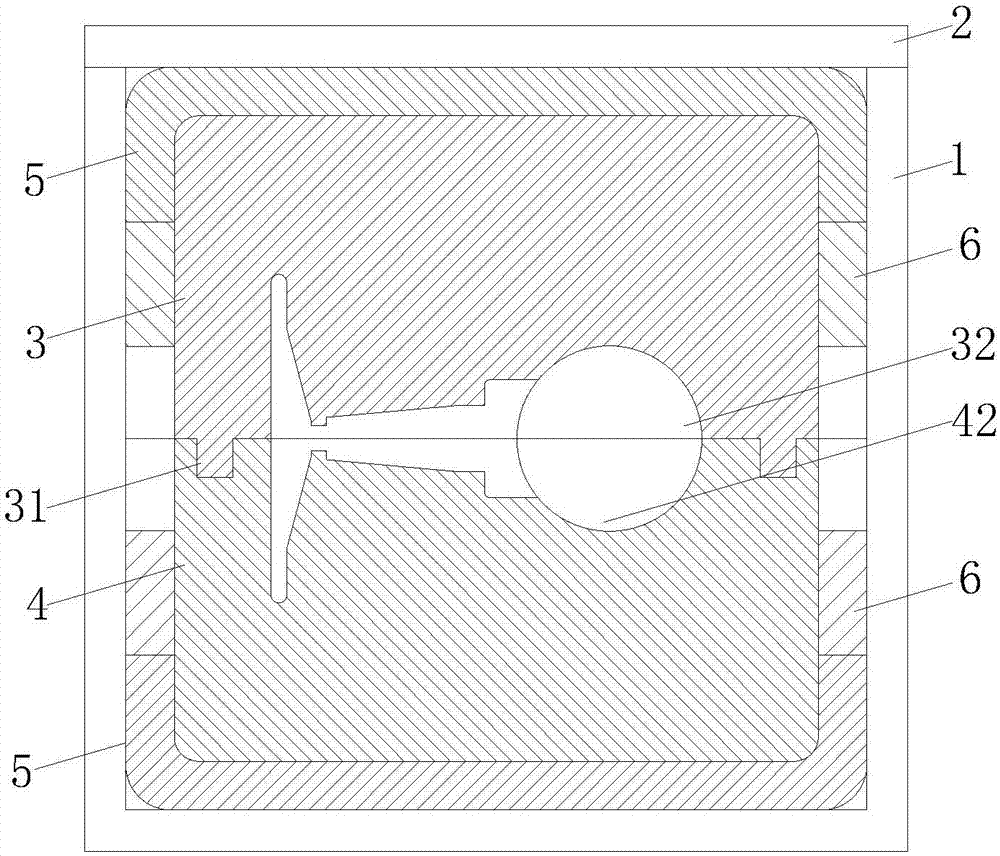

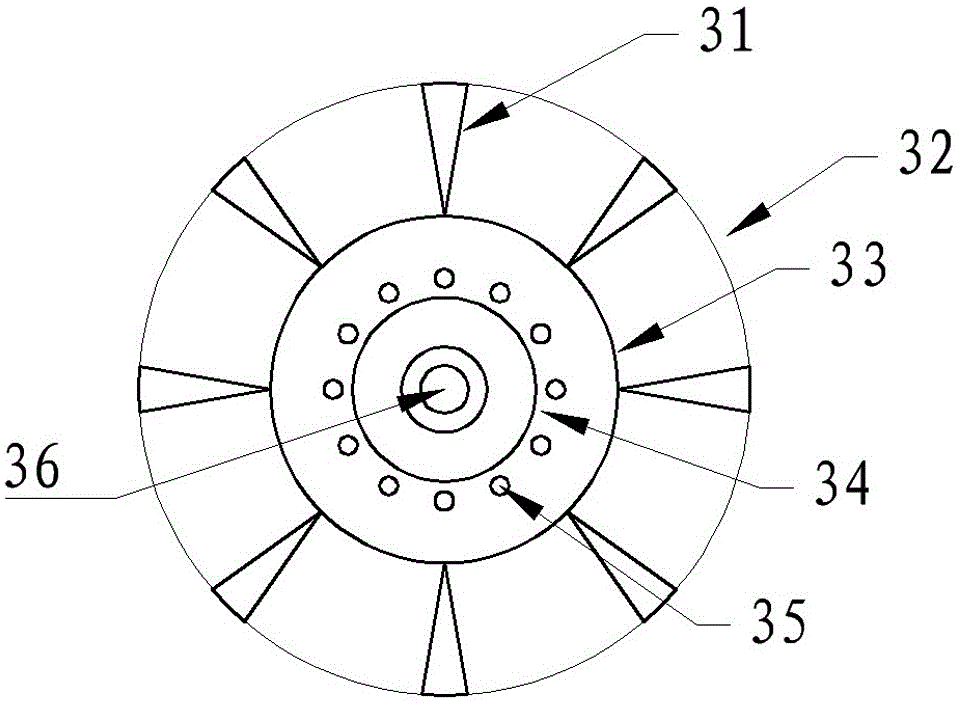

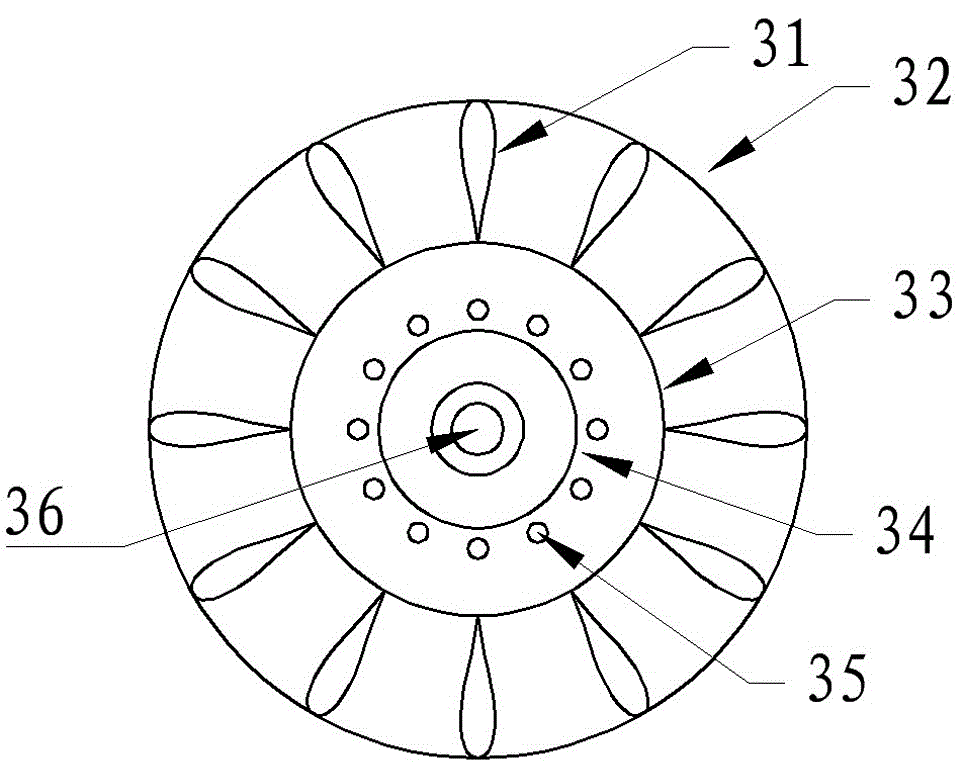

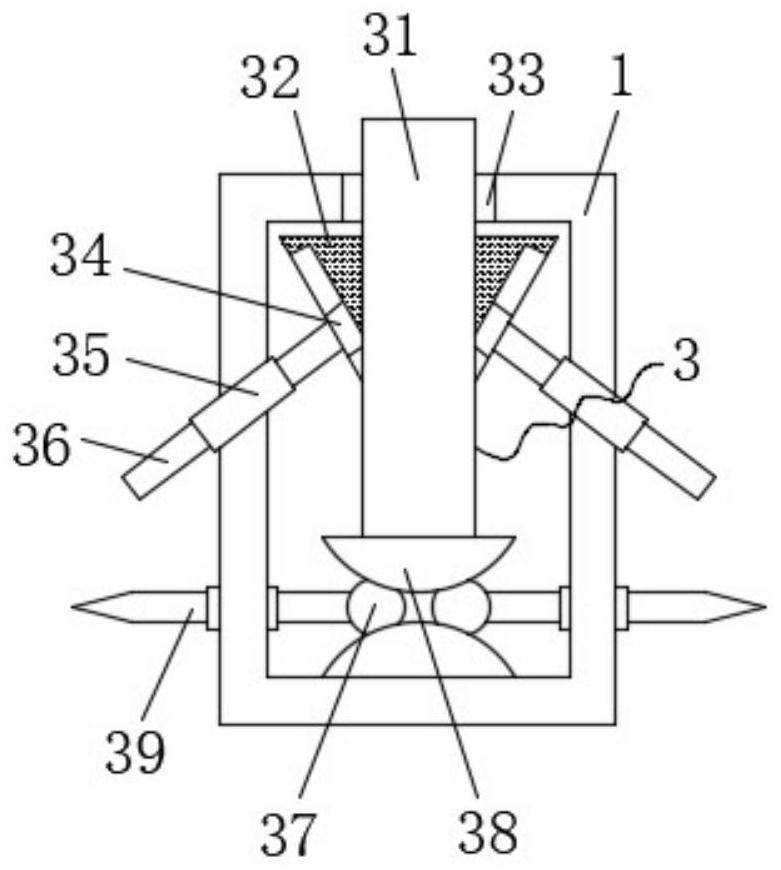

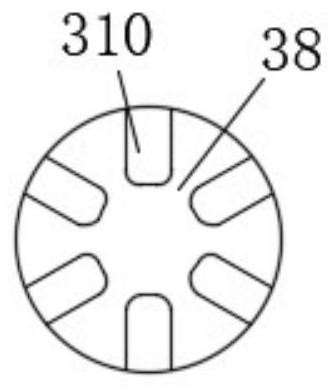

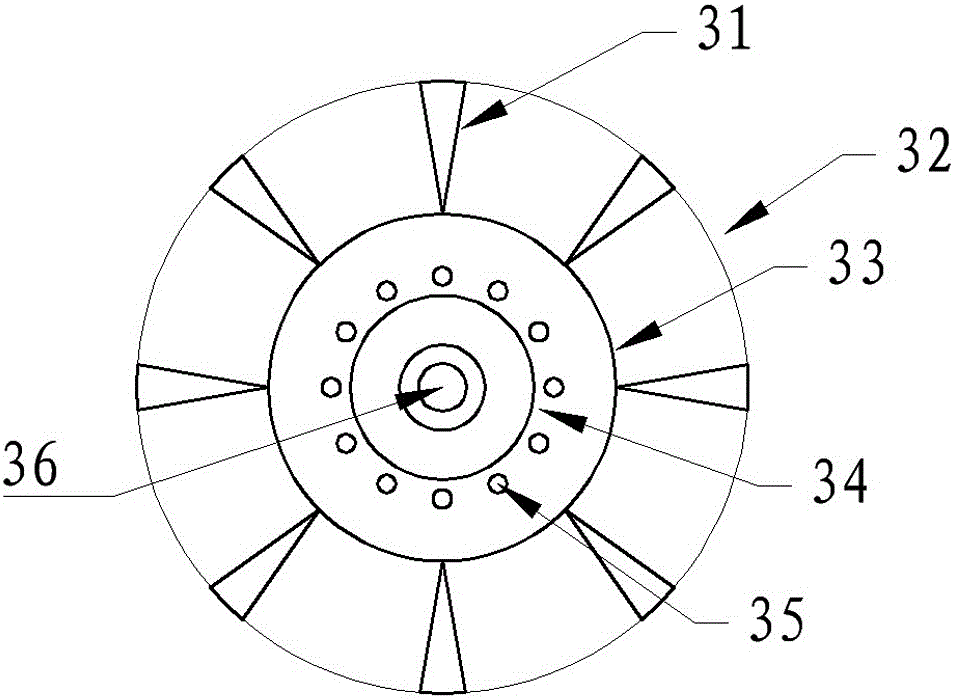

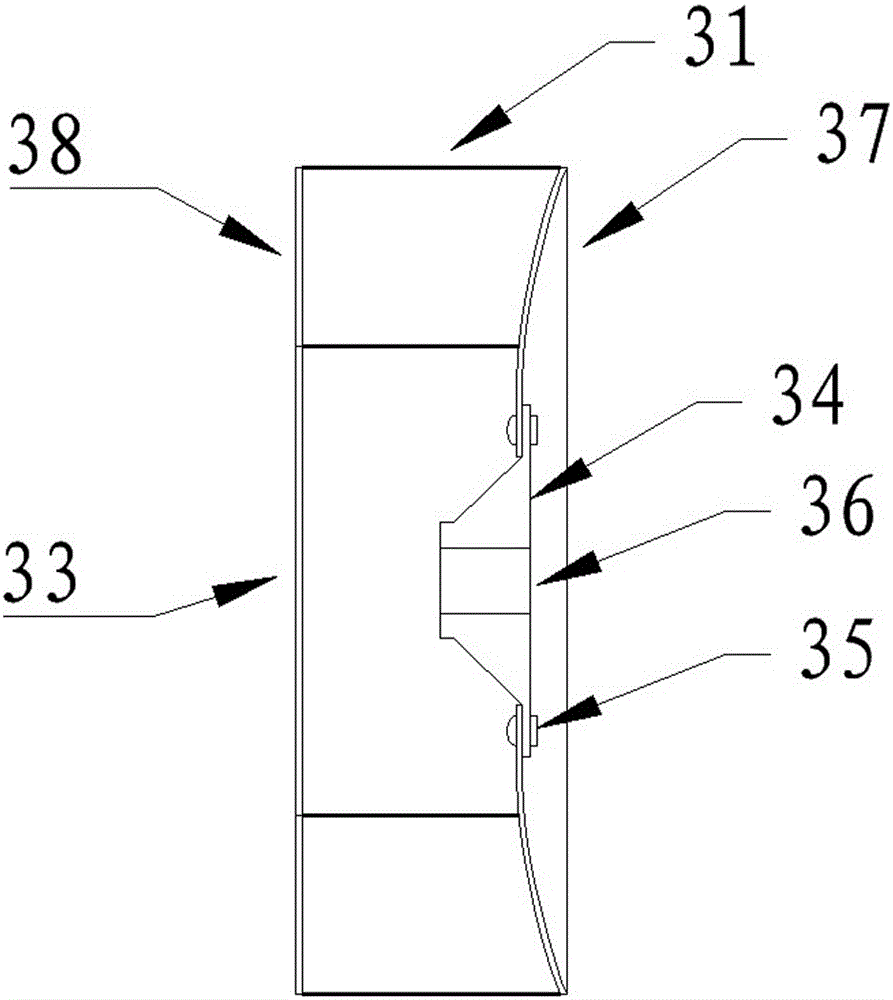

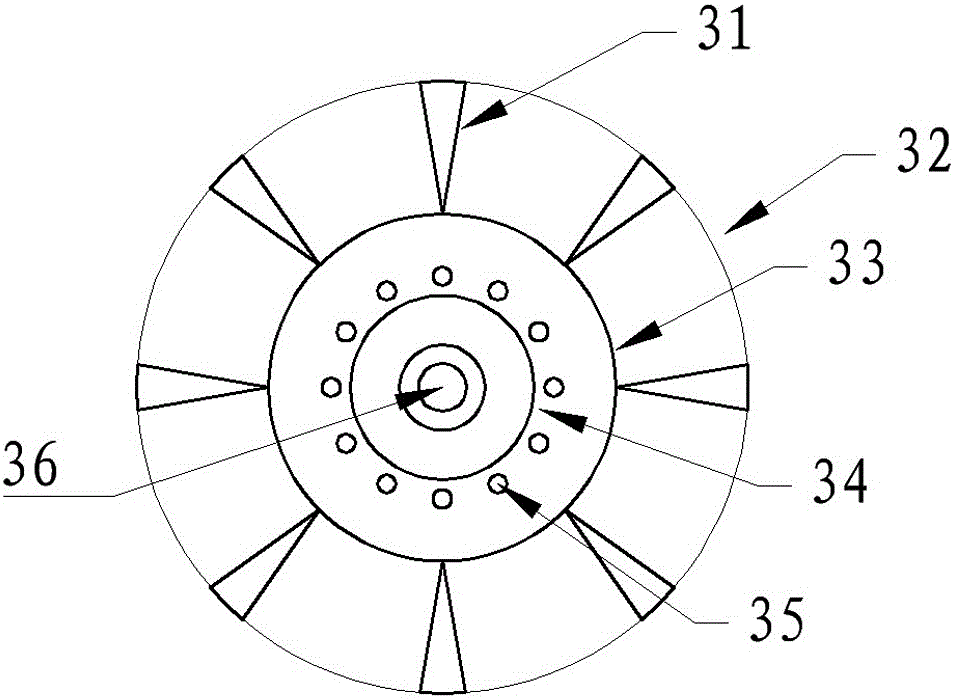

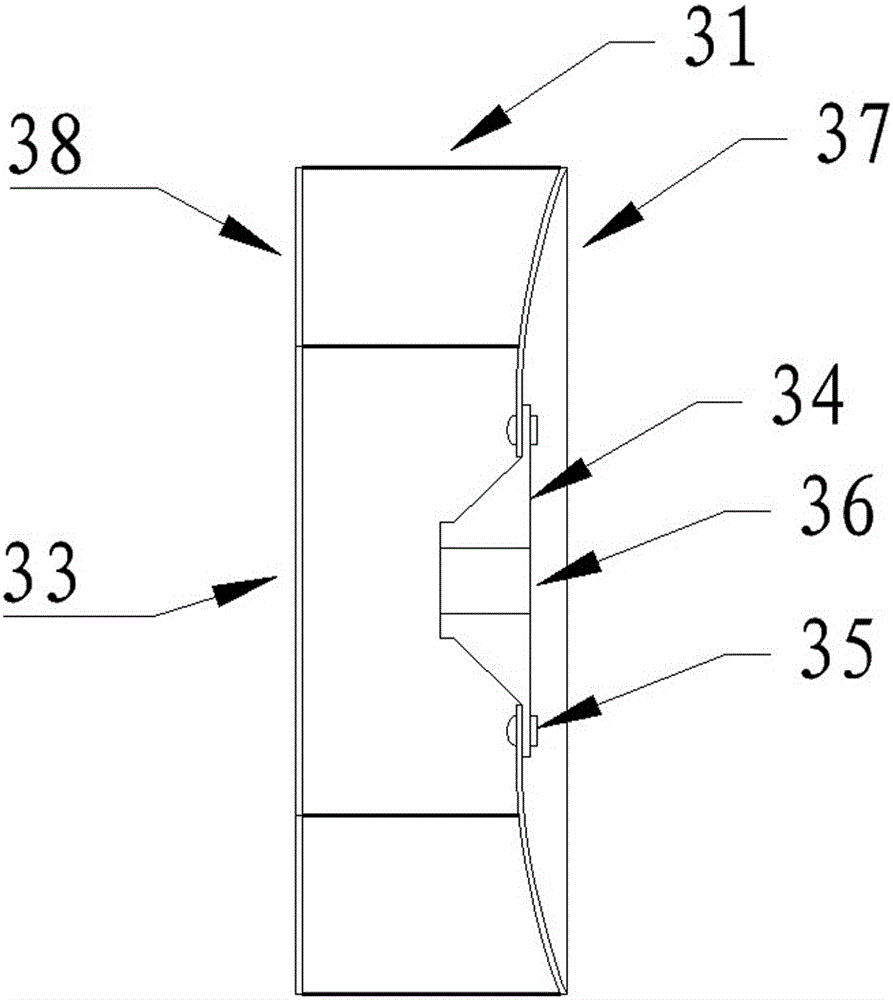

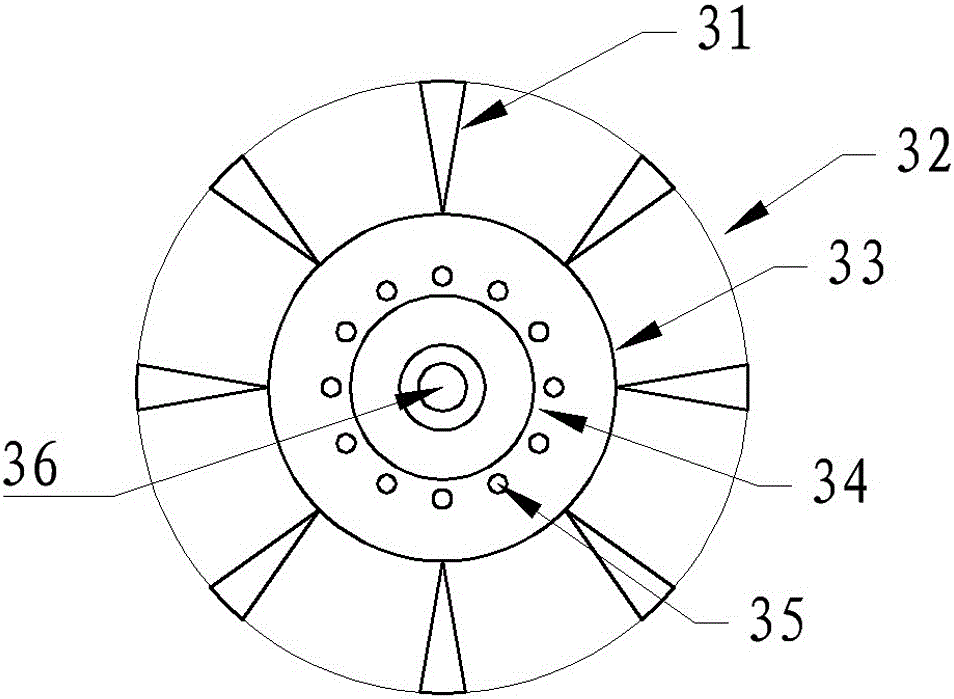

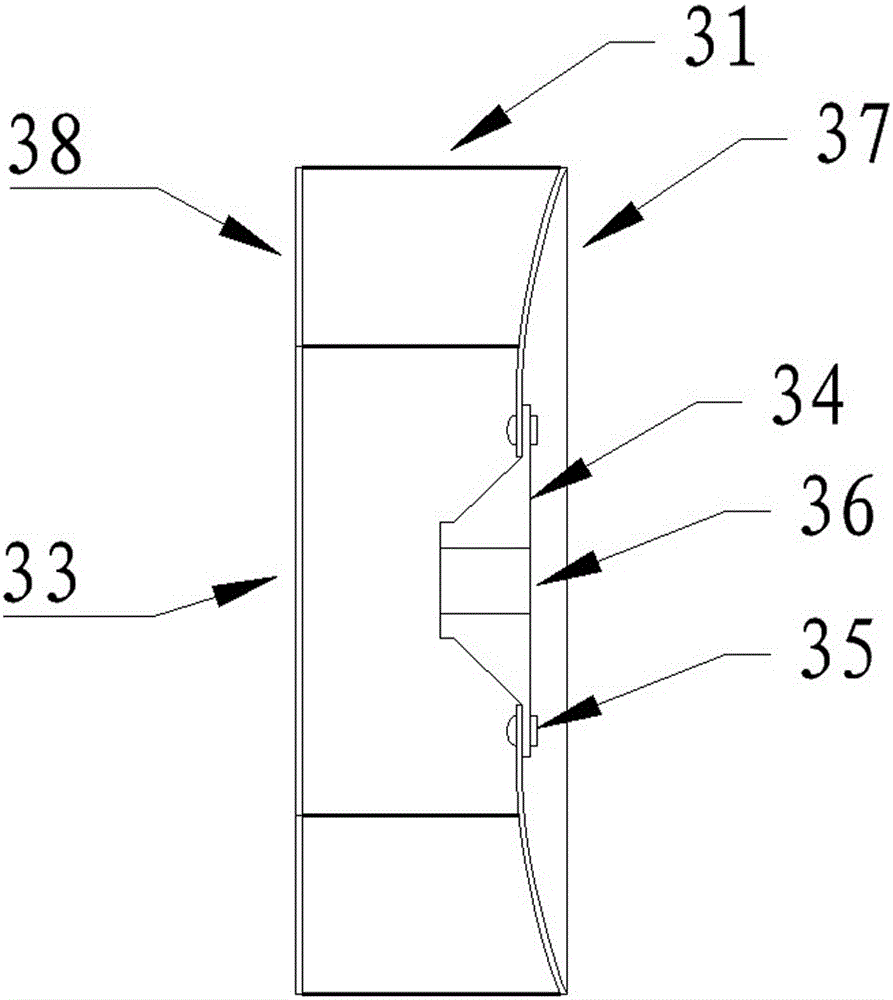

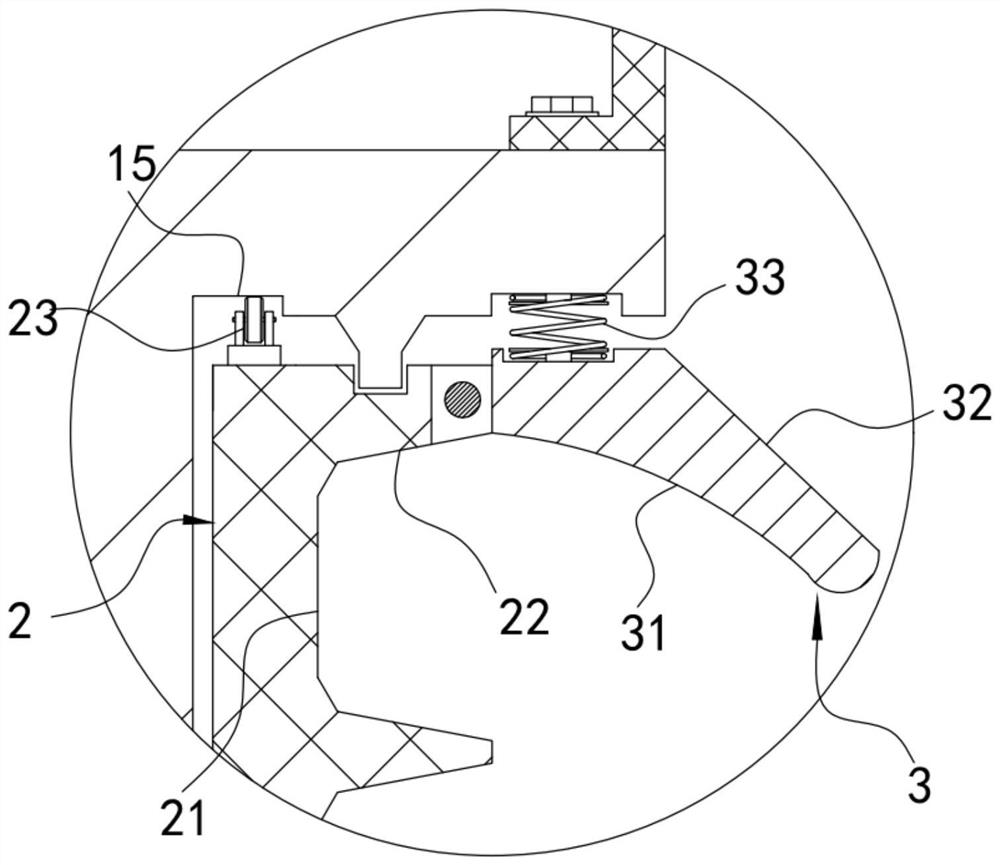

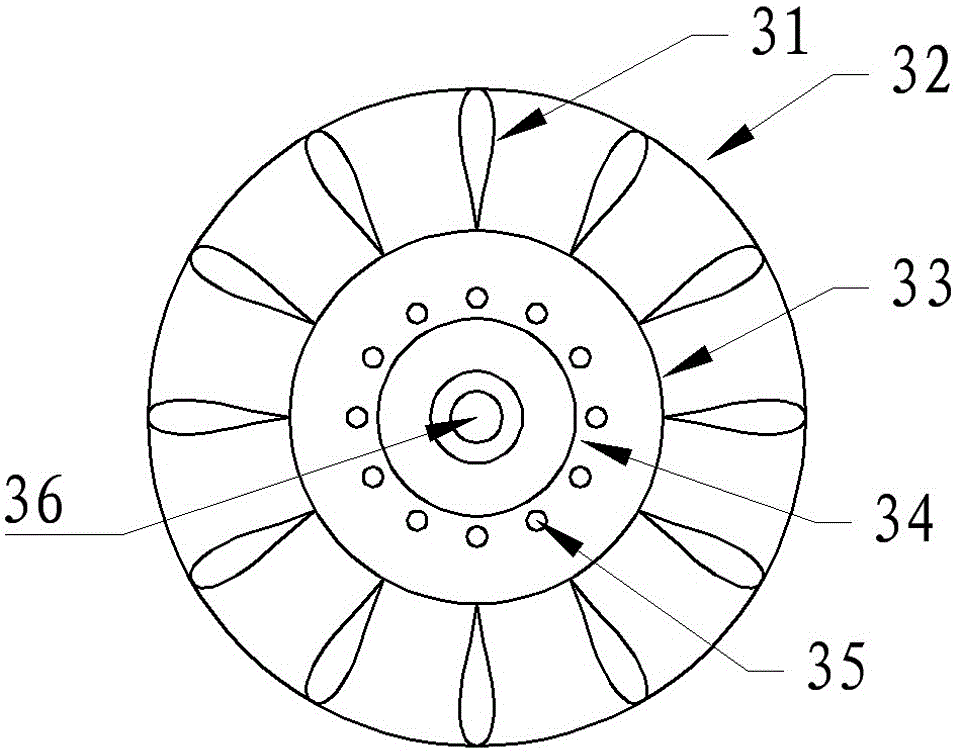

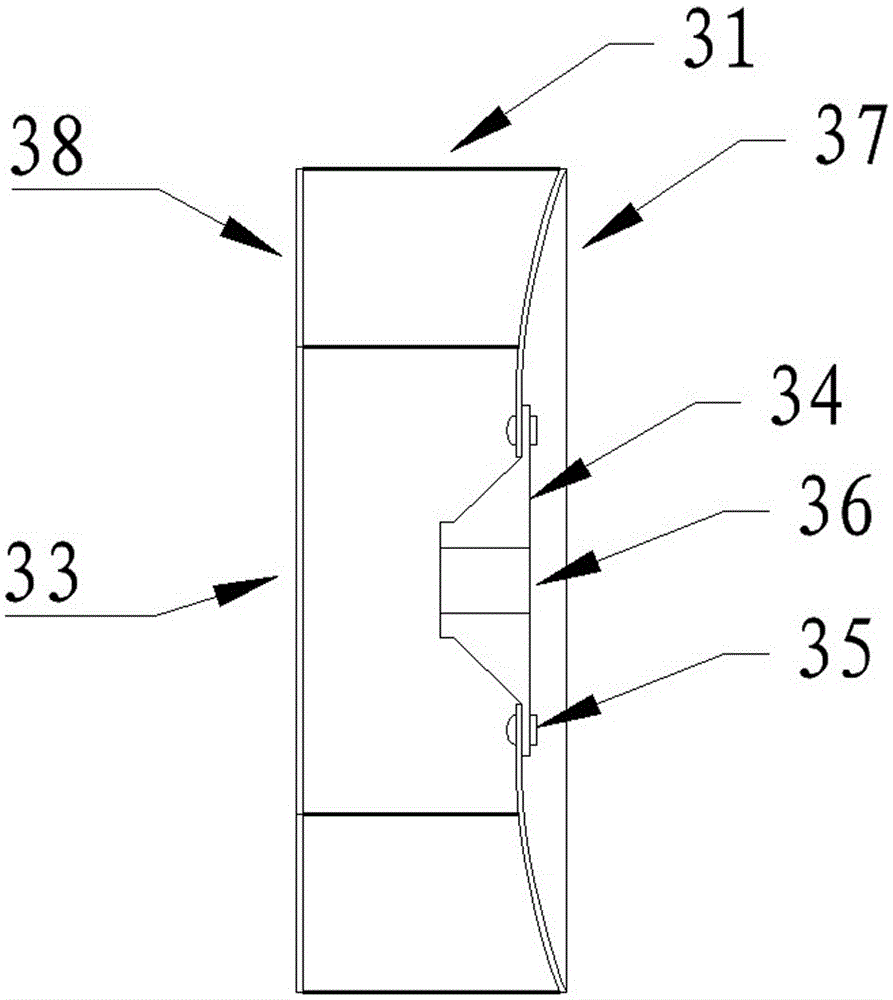

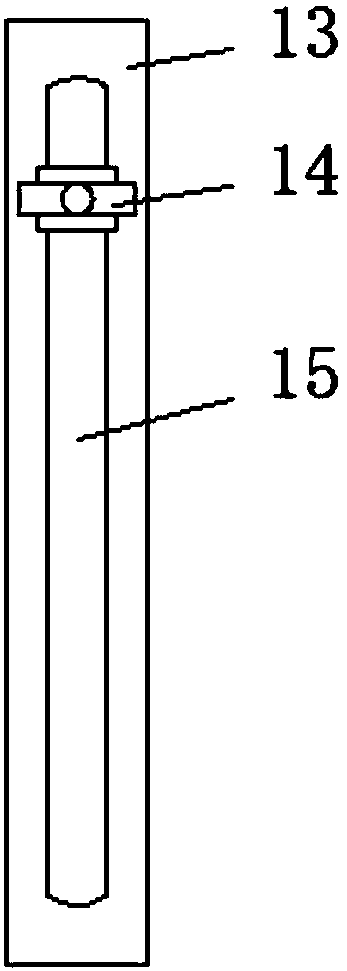

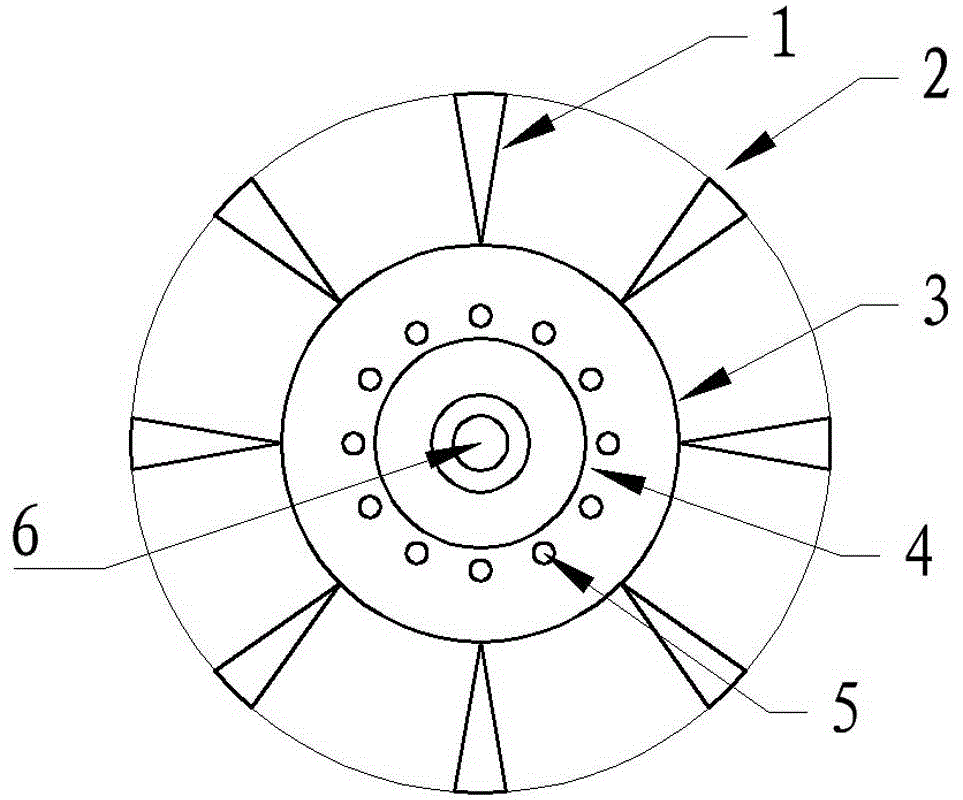

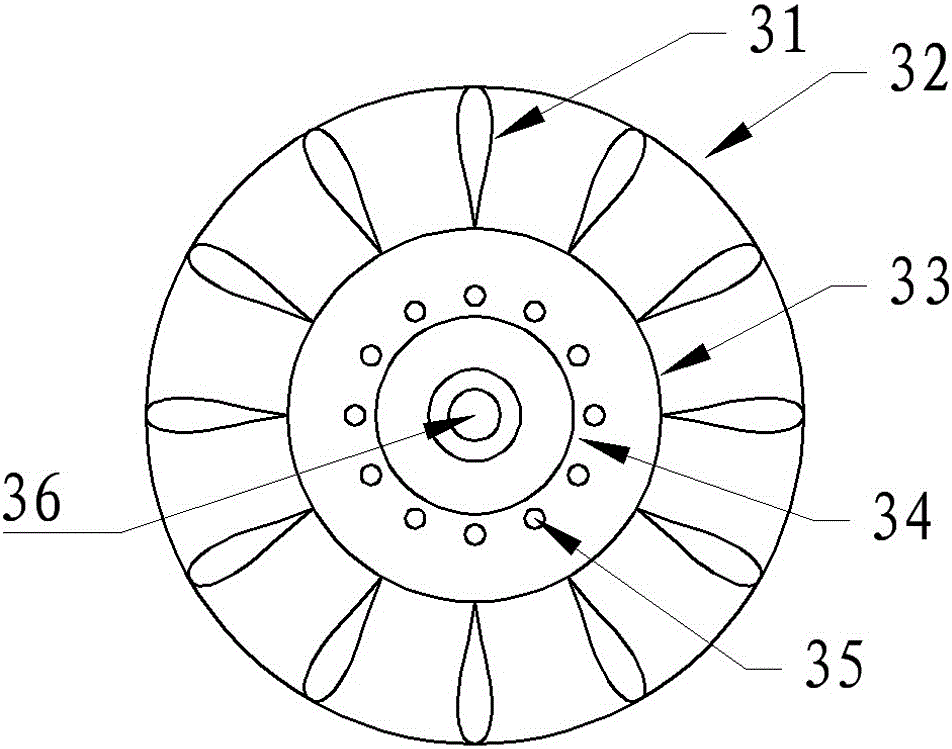

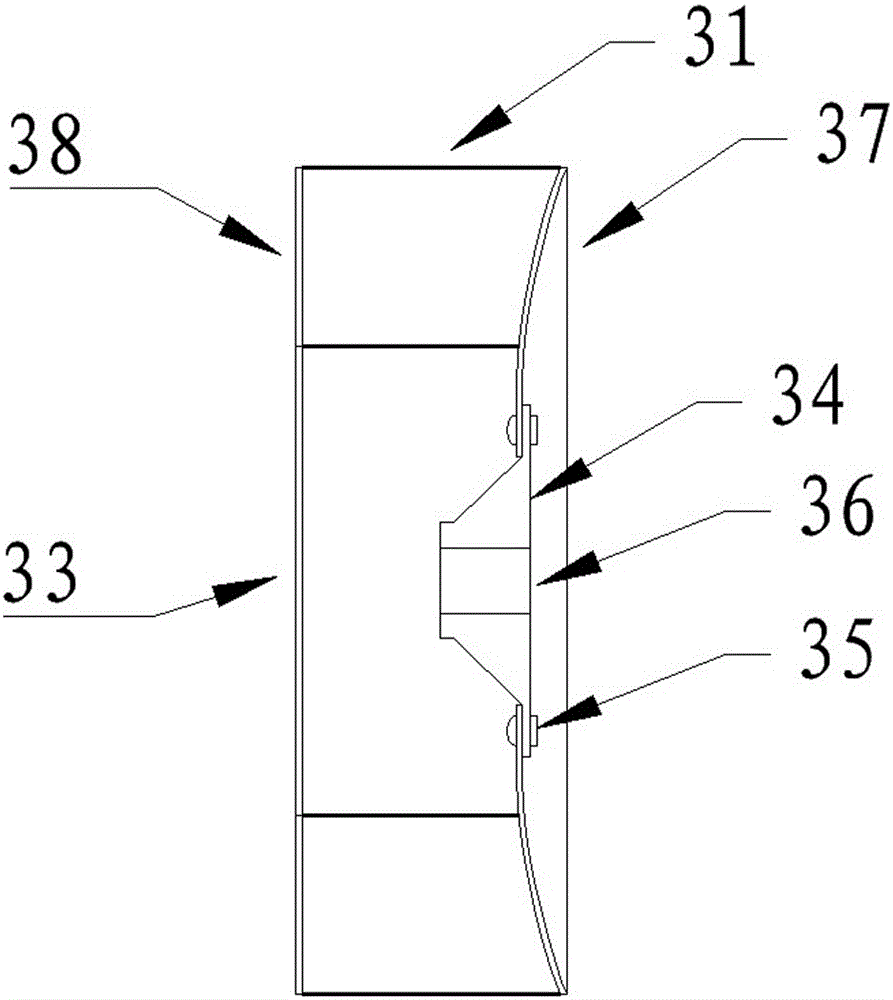

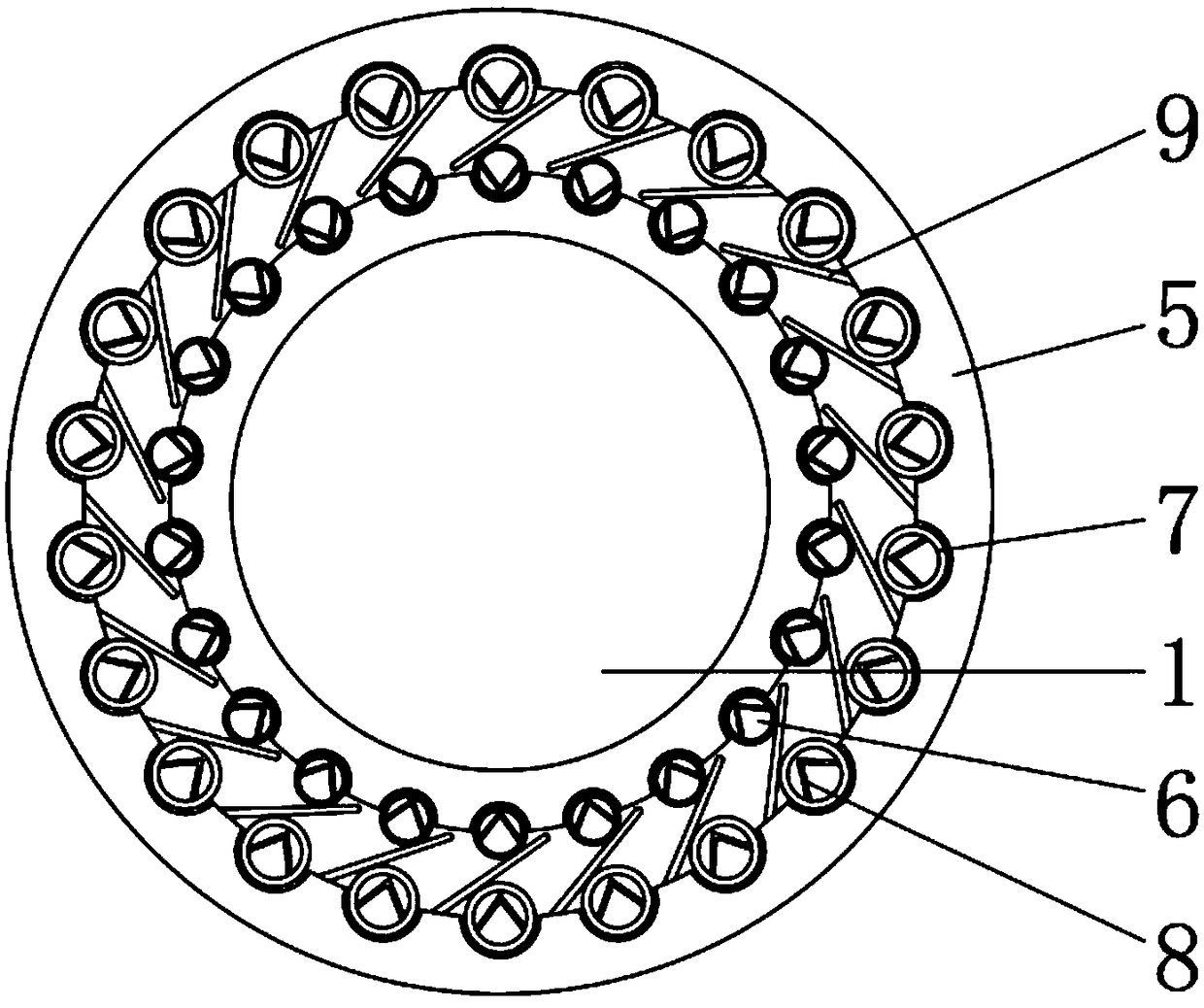

Dirt retention prevention draught fan impeller with wedge-shaped blades and disk-shaped back plate

InactiveCN104963891AIncreasing the thicknessLarge delivery air flowPump componentsPumpsImpellerCentrifugal force

The invention discloses a dirt retention prevention draught fan impeller with a wedge-shaped blades and a disk-shaped back plate. The dirt retention prevention draught fan impeller with the wedge-shaped blades and the disk-shaped back plate comprises the impeller back plate, an impeller panel and the blades, the blades are arranged to be in a hollow wedge shape symmetric about the radial direction and center of an impeller shaft, and the impeller back plate is in a disk shape; the hollow wedge-shaped blades are connected with the impeller panel and welded to the disk-shaped impeller back plate to form an impeller body; an air inlet is formed in the impeller panel, the disk-shaped impeller back plate is fixed and connected with a shaft base through rivets, and the shaft base is connected with a draught fan shaft through a shaft hole in a matched mode. When the dirt retention prevention draught fan impeller with the wedge-shaped blades and the disk-shaped back plate is used, since the blades are designed to be in a hollow wedge shape with blade shafts centrosymmetric in the radial directions, during high-speed rotating, the centrifuge self-cleaning function of the surfaces of the blades is achieved under the centrifugal force function, dirt is subjected to the centrifugal force function and can not be attached to the blades, dirt retention can not occur, and the dirt retention prevention draught fan impeller with the wedge-shaped blades and the disk-shaped back plate is particularly suitable for wide impeller large draught fans that the distance between a front end plate and a rear end plate of each impeller is large and the transporting air flow is also particularly large; by means of the disk-shaped back plate, the compressive strength is improved, and the service life of the draught fan is prolonged.

Owner:JISHOU UNIVERSITY

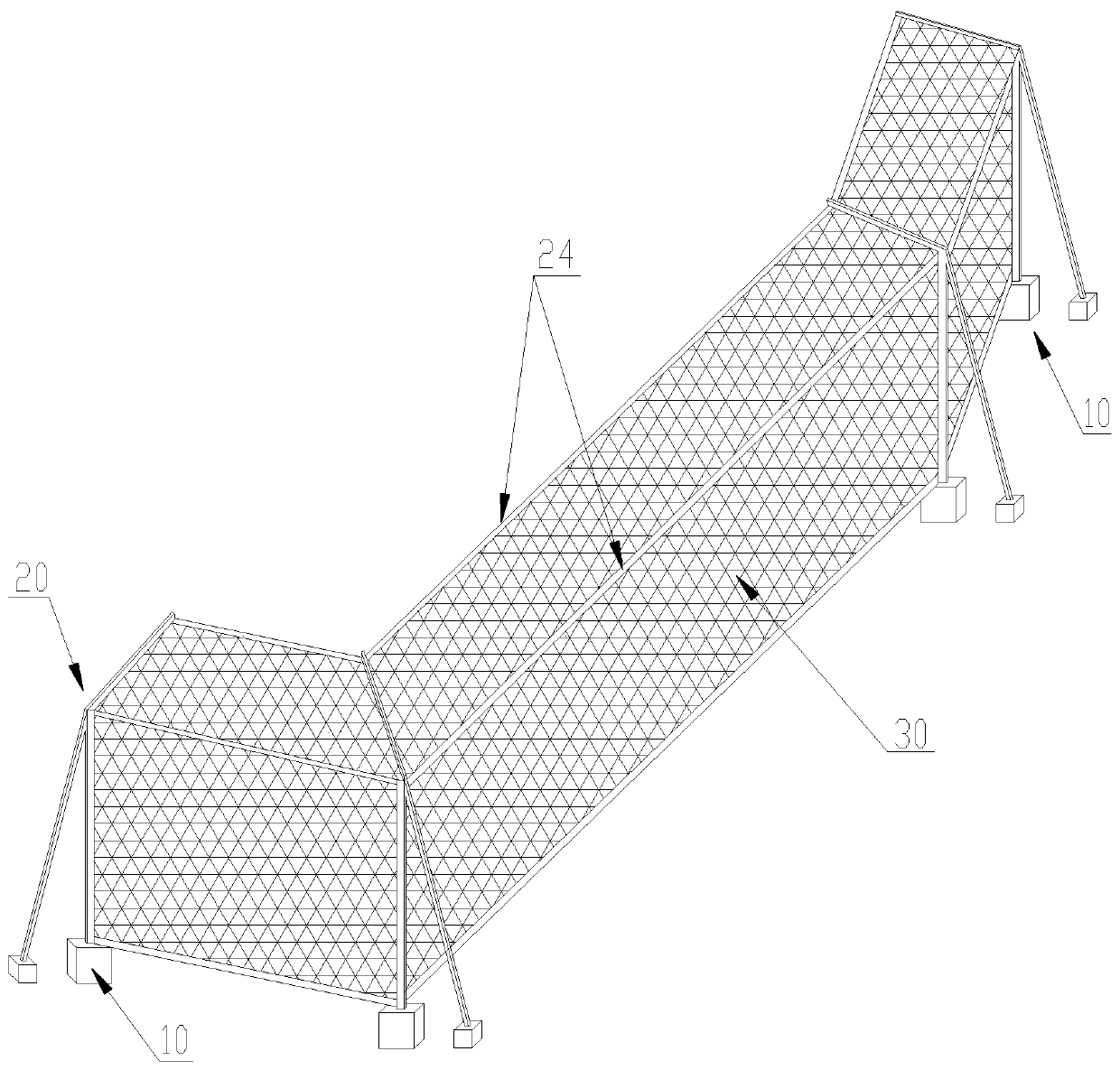

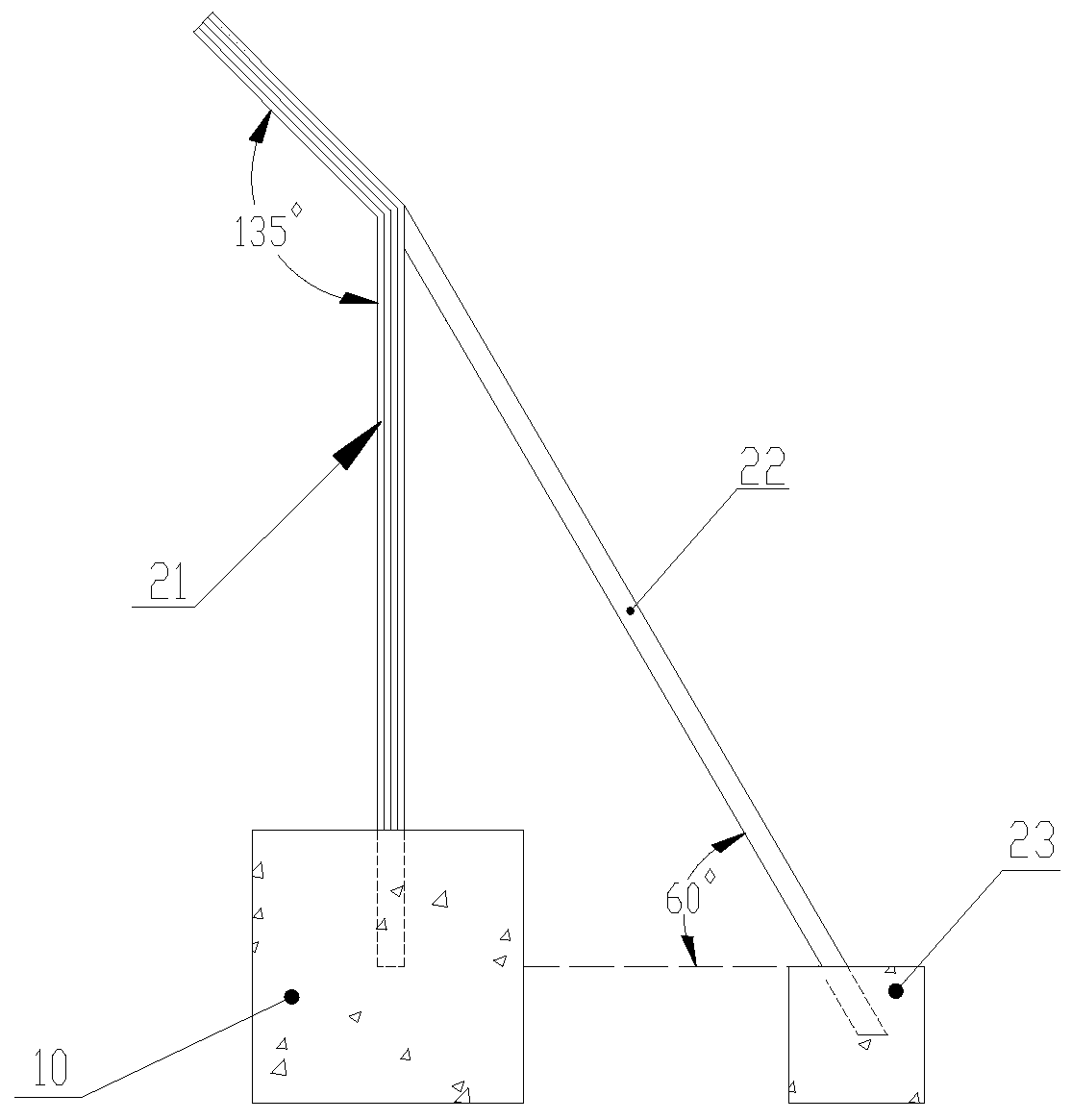

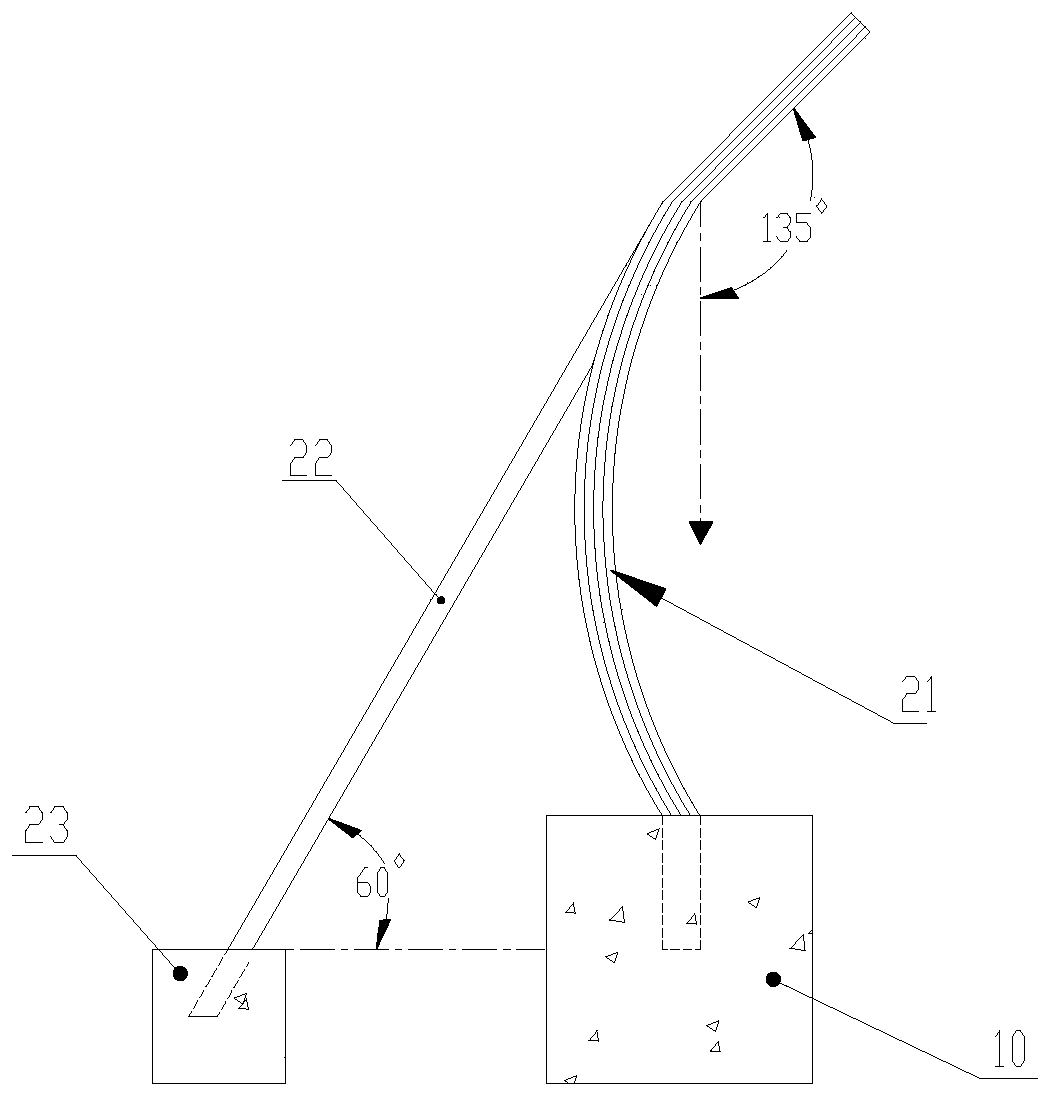

Protective shed for tunnel blasting construction

The invention discloses a protective shed for tunnel blasting construction. The protective shed forms a fan-shaped enclosure for a tunnel portal through gravity bases distributed at the position of the tunnel portal, then supports with inverted-L-shaped or C-shaped main body components are arranged on the gravity bases, a shielding protective layer which at least comprises an elastic hard fiber layer, an elastic soft fiber wave-absorbing layer and a sound-absorbing plate layer is covered on the support to form a protective shed cover for covering and shielding the tunnel portal, so as to effectively protect the periphery of the tunnel portal during tunnel blasting construction, and damage to the tunnel portal caused by shock waves, broken stones and blasting noise during tunnel blasting construction is prevented. The protective shed is novel and unique in design, convenient and easy to manufacture, low in cost, excellent in protection effect, high in practicability and good in expansibility, the safety of lives and properties of construction surrounding personnel can be guaranteed while the operation progress is guaranteed, social benefits are guaranteed while economic benefits areobtained for enterprises, and the protective shed has great popularization and application value.

Owner:CHINA MCC5 GROUP CORP

Tail heat recovery and dust removal integrated coal-fired boiler

ActiveCN105003927AHigh strengthReliable usePump componentsLighting and heating apparatusExhaust gasImpeller

The invention discloses a tail heat recovery and dust removal integrated coal-fired boiler. A boiler exhaust pipe is in tangential connection with a cyclone dust collector, dust is exhausted from a cone bottom through an air-lock valve after cyclone de-dusting, and exhaust enters a cone through a cyclone riser, passes through a tube nest after being uniformly dispersed, and is discharged by an exhaust pipe through an induced draft fan after being centralized by an upper tapered hopper; an impeller of the induced draft fan adopts the structure that blades are shaped like hollow reversed water droplets and a back plate is dish-shaped; the contour line of the induced draft fan is an involute. The tail heat recovery and dust removal integrated coal-fired boiler creatively integrates boiler tail heat recovery and dust removal, and a cyclone dust removal efficient tail heat recoverer is designed to complete tail heat recovery and dust removal in one step, so that the equipment investment is reduced and the working efficiency is improved; as the structure that the blades are shaped like hollow reversed water droplets and the back plate is dish-shaped is adopted, dust on the impeller of the induced draft fan can be cleaned in real time, the impeller strength of the induced draft fan is improved, the stability is enhanced, safety accidents caused by dust accumulation are effectively prevented, and the application prospect is wide.

Owner:YANGZHOU SUNLIGHT MACHINERY

Condensation water drainage pipe of wall-mounted furnace

InactiveCN109373599AEnhance the bending resistanceExtended service lifeFluid heatersEngineeringWall mount

The invention discloses a condensation water drainage pipe of a wall-mounted furnace. The condensation water drainage pipe comprises a condensation water drainage pipe main body, a large elastic tubeis annularly arrayed on the inner wall of a outer sheath, anti-folding plates are annularly arrayed on the inner wall of the outer sheath, a small elastic tube is annularly arrayed on the outer wall of the condensation water drainage pipe body, and elastic plates are arranged in the inner cavity of the large elastic tube and the inner cavity of the small elastic tube. According to the condensationwater drainage pipe, the pipe is provided with the small elastic tube, the large elastic tube and the anti-folding plates, the bending resistance is improved by utilizing the mutual extrusion pressure of the anti-folding plates, the small-sized elastic tube and the large-scale elastic tube, meanwhile, the impact force and the pressure brought by the outside can be buffered, and the service life of the condensation water drainage pipe body can be prolonged; elastic plates are arranged in the small elastic tube and the large elastic tube, and the elastic buffering capacity of the small elastictube and the large elastic tube is further improved.

Owner:江苏诺温特热能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com