Protective shed for tunnel blasting construction

A technology for protective sheds and tunnels, applied in blasting and other directions, can solve the problems of complexity, high production cost and low protection efficiency, and achieve the effects of enhancing stability, reducing impact, and novel and unique design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

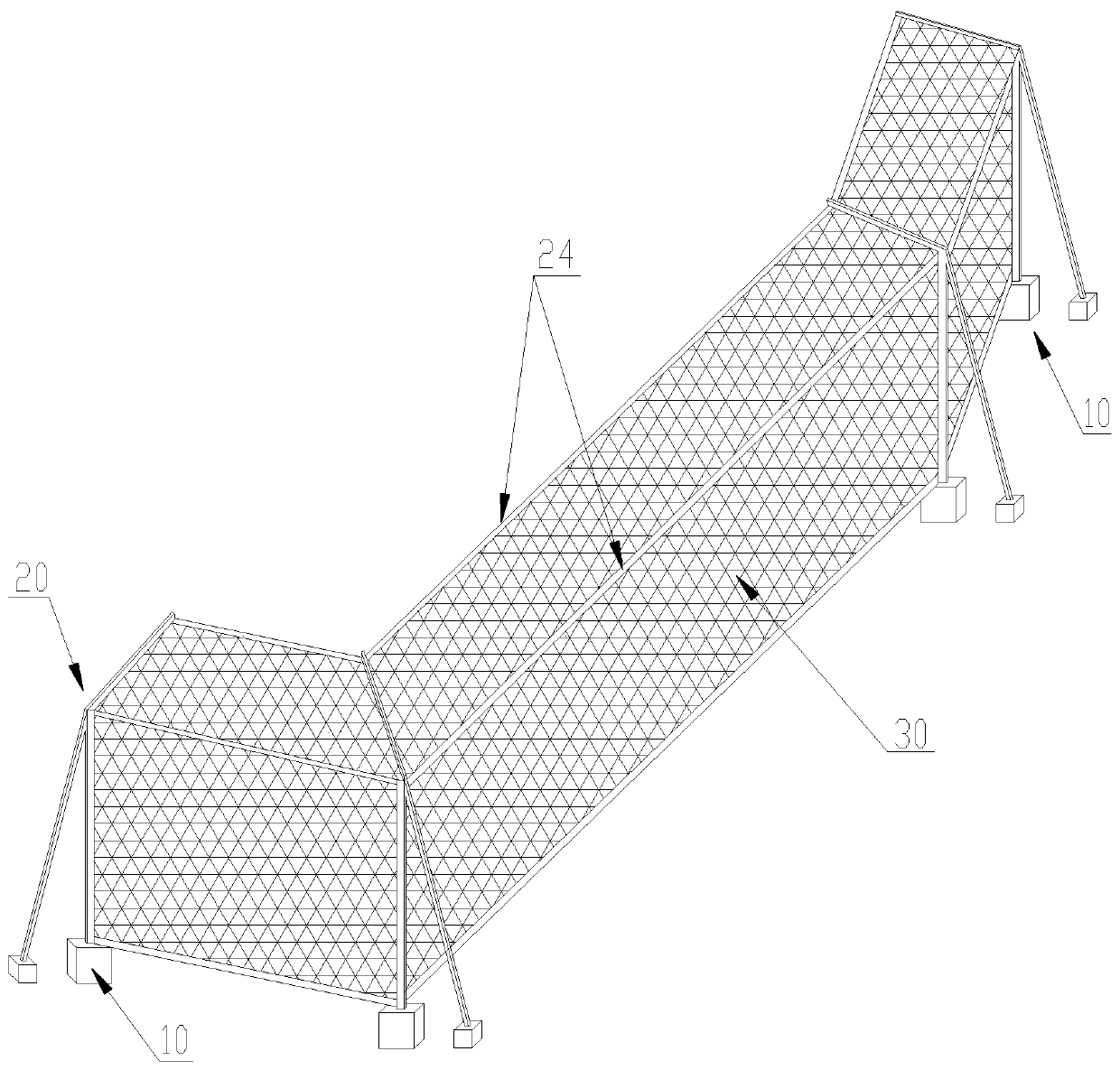

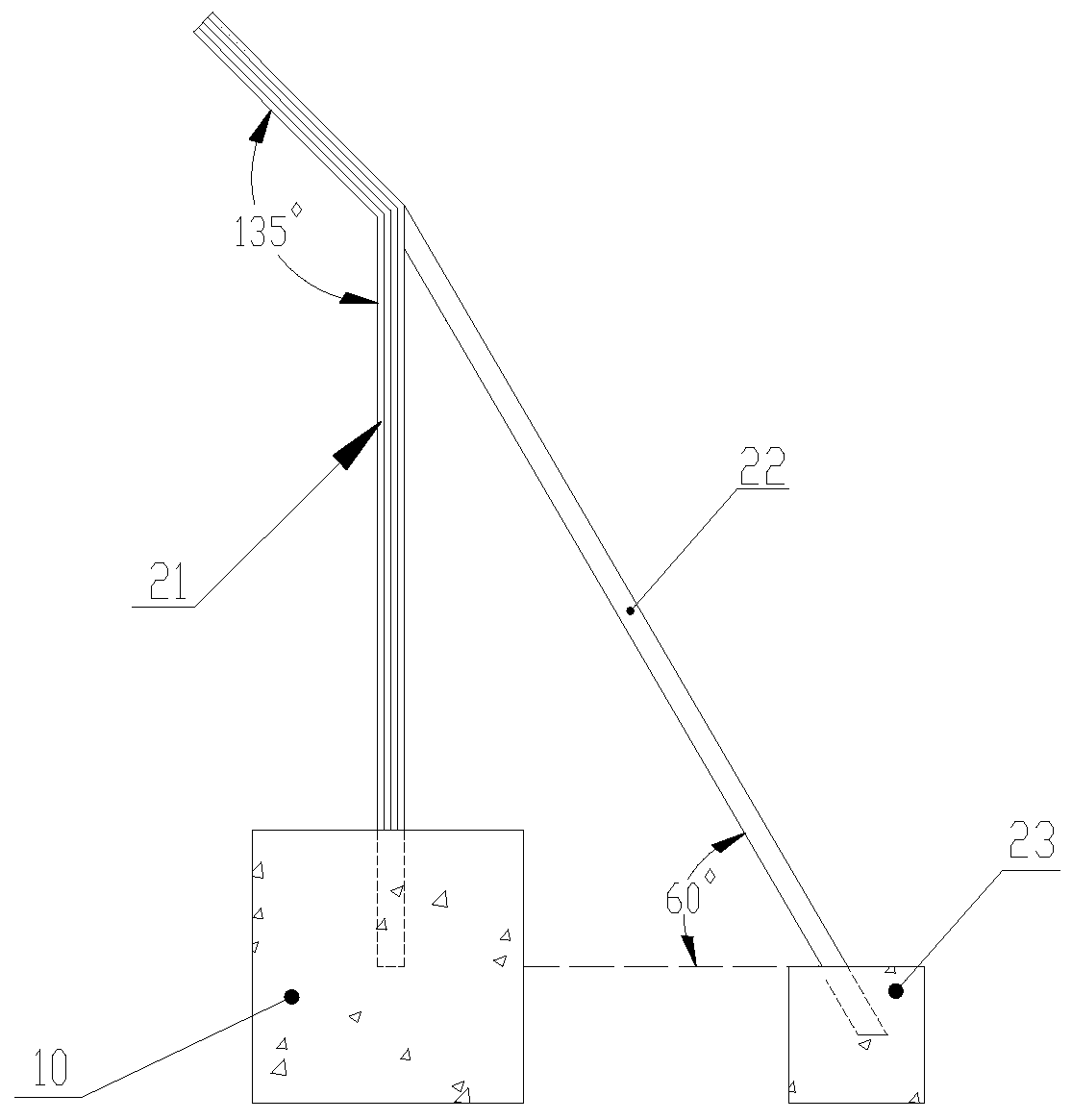

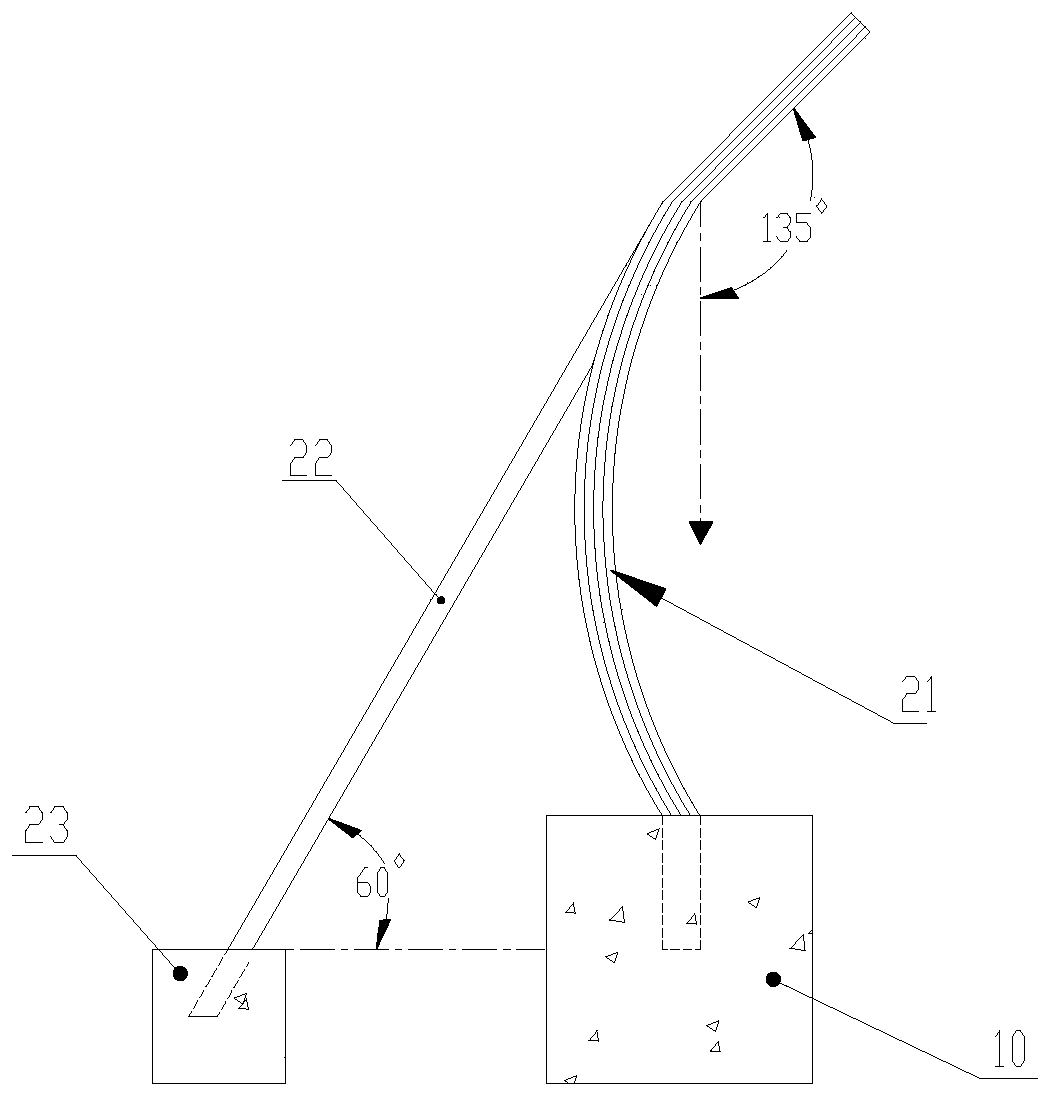

[0059] Such as figure 1 A schematic diagram of a three-dimensional structure of a tunnel blasting construction protective shed provided by an embodiment of the present invention, figure 2 The embodiment of the present invention provides a structural schematic diagram of a tunnel blasting construction protective shed whose bracket main component is an inverted L shape, image 3 A kind of tunnel blasting construction protective shed provided by the embodiment of the present invention has a C-shaped structural schematic diagram of the bracket main component as shown in the following:

[0060] A tunnel blasting construction protection shed, used for safety protection at the tunnel opening during tunnel blasting construction, to prevent external damage caused by shock waves, broken stones, and blasting noise during tunnel blasting construction, including:

[0061] Gravity base 10, support 20 and shelter protection layer 30;

[0062] There are at least three gravity bases 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com