Dirt retention prevention draught fan impeller with wedge-shaped blades and disk-shaped back plate

A fan impeller, anti-dust technology, applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of personnel and equipment safety accidents, strong vibration, etc., achieve reliable use, save materials, and have broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now in conjunction with accompanying drawing, the present invention is described in further detail.

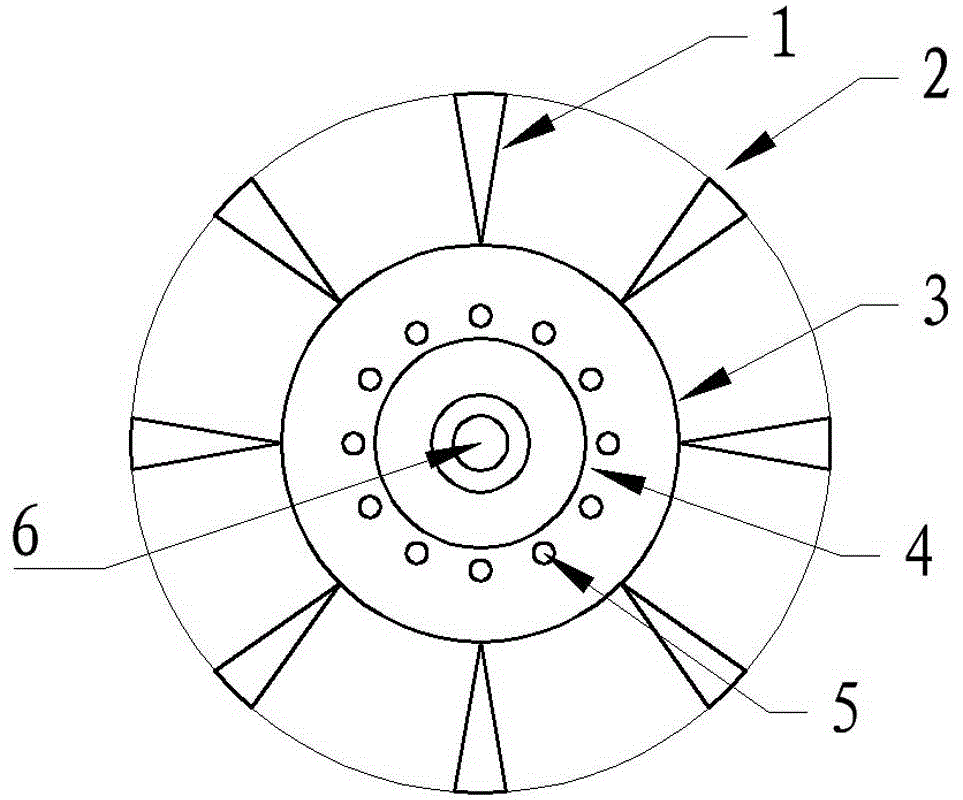

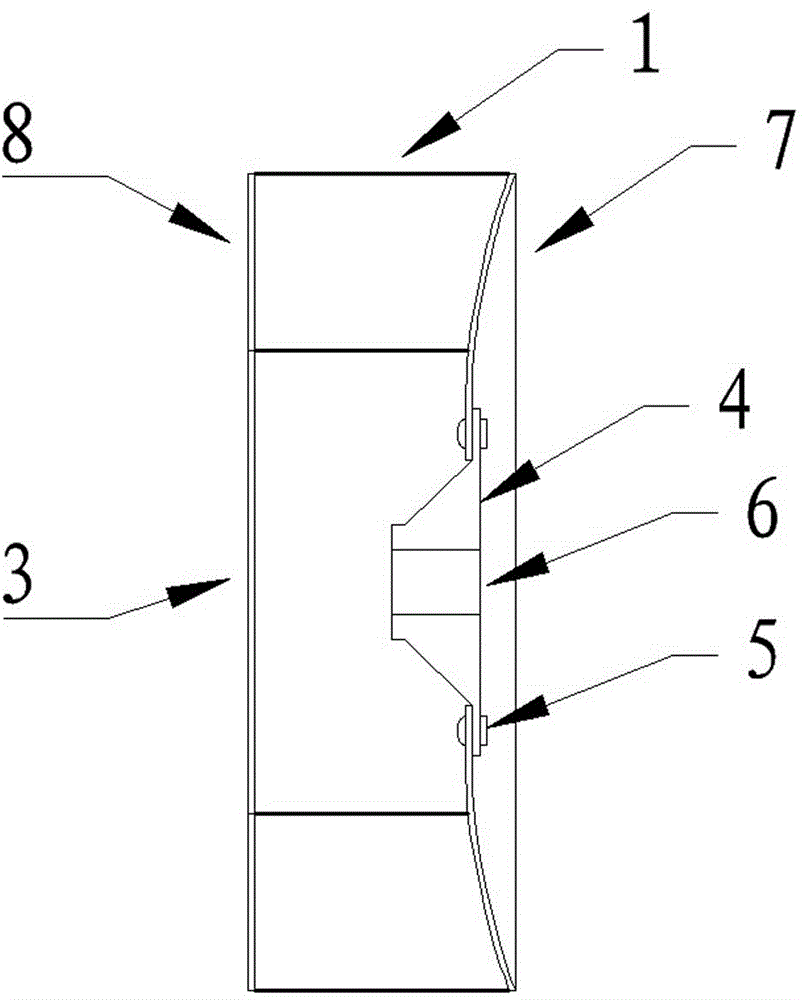

[0019] like figure 1 and figure 2 The dust-proof fan impeller shown has a wedge-shaped blade and a disc-shaped back plate, including the impeller back plate 7, the impeller panel 8 and the blade 1. The blade 1 is arranged in a hollow wedge shape radial to the impeller shaft and symmetrical to the center, and the impeller back plate 7 It is dish-shaped; the hollow wedge-shaped blade 1 is connected to the impeller panel 8 and welded with the disc-shaped impeller back plate 7 to form the impeller main body; The shaft seat 4 is mated with the fan shaft through the shaft hole 6 .

[0020] When the impeller of this fan is used, because the blade is designed as a hollow wedge, and the blade shaft is radially and center-symmetrical, when rotating at high speed, the surface of the blade has a centrifugal self-cleaning effect under the centrifugal force, so that the dust canno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com