Sound-insulation elastic plastic floor

An elastic plastic and floor technology, applied in the field of building materials, can solve the problems of lack of performance, high elasticity and sound insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

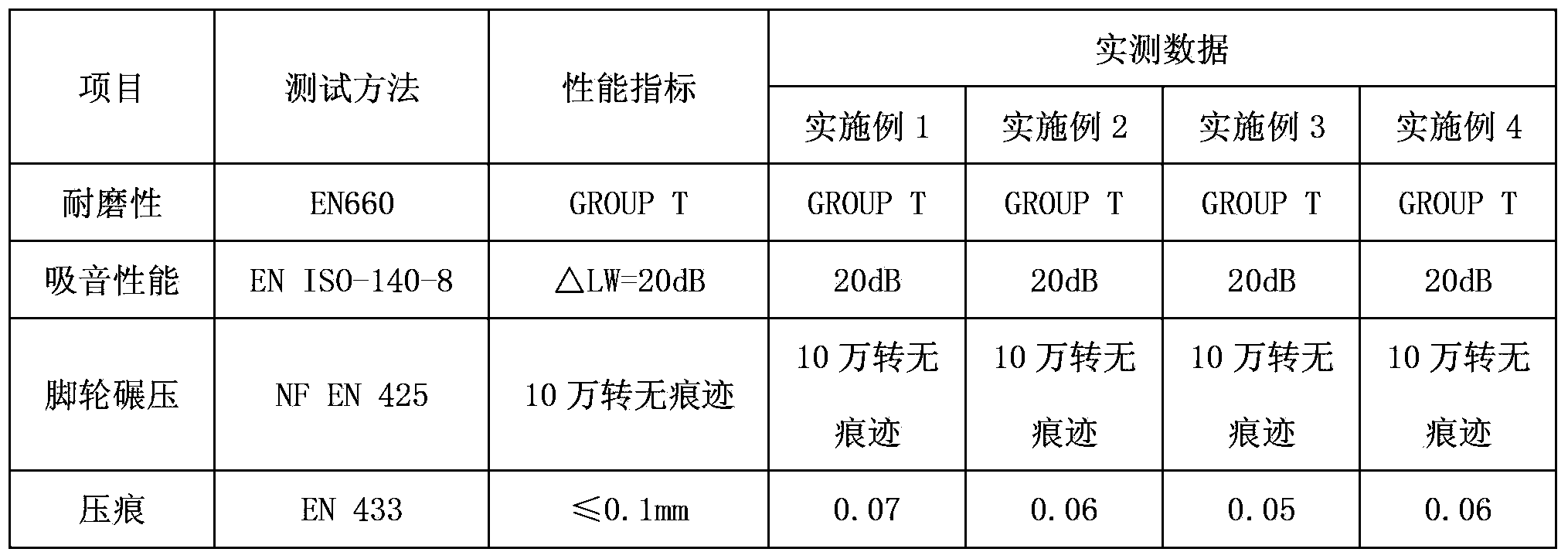

Examples

Embodiment 1

[0013] A sound-insulating elastic plastic floor, comprising a surface layer, a middle layer and a bottom layer, wherein the components of each layer include by weight parts:

[0014] Surface layer: 80 parts of polyvinyl chloride resin, 100 parts of calcium carbonate, 15 parts of dioctyl phthalate, 10 parts of zinc barium composite stabilizer, 1 part of epoxy resin, 1 part of pentaerythritol, 0.5 part of trioctyl ester;

[0015] Middle layer: 100 parts of polyvinyl chloride resin, 20 parts of calcium carbonate, 50 parts of dioctyl phthalate, 0.5 part of pentaerythritol, 0.5 part of trioctyl ester, 0.5 part of AC foaming agent;

[0016] Bottom layer: 90 parts of polyvinyl chloride resin, 60 parts of dioctyl phthalate, 3 parts of barium stearate, 2 parts of pentaerythritol, 1 part of trioctyl ester, and 3 parts of acetyl citrate.

[0017] The above-mentioned sound-insulating elastic plastic floor is prepared by the following steps:

[0018] (1) Mix the components of the surface ...

Embodiment 2

[0023] A sound-insulating elastic plastic floor, comprising a surface layer, a middle layer and a bottom layer, wherein the components of each layer include by weight parts:

[0024] Surface layer: 83 parts of polyvinyl chloride resin, 105 parts of calcium carbonate, 18 parts of dioctyl phthalate, 12 parts of zinc-barium composite stabilizer, 2 parts of epoxy resin, 2 parts of pentaerythritol, and 1 part of trioctyl ester;

[0025] Middle layer: 105 parts of polyvinyl chloride resin, 23 parts of calcium carbonate, 52 parts of dioctyl phthalate, 1 part of pentaerythritol, 1 part of trioctyl ester, 1 part of AC foaming agent;

[0026] Bottom layer: 100 parts of polyvinyl chloride resin, 63 parts of dioctyl phthalate, 5 parts of barium stearate, 3 parts of pentaerythritol, 1 part of trioctyl ester, and 4 parts of acetyl citrate.

[0027] The above-mentioned sound-insulating elastic plastic floor is prepared by the following steps:

[0028] (1) Mix the components of the surface l...

Embodiment 3

[0033] A sound-insulating elastic plastic floor, comprising a surface layer, a middle layer and a bottom layer, wherein the components of each layer include by weight parts:

[0034] Surface layer: 88 parts of polyvinyl chloride resin, 112 parts of calcium carbonate, 22 parts of dioctyl phthalate, 14 parts of zinc barium composite stabilizer, 4 parts of epoxy resin, 4 parts of pentaerythritol, 1.5 parts of trioctyl ester;

[0035] Middle layer: 115 parts of polyvinyl chloride resin, 26 parts of calcium carbonate, 57 parts of dioctyl phthalate, 2.3 parts of pentaerythritol, 1.5 parts of trioctyl ester, 1.5 parts of AC foaming agent;

[0036] Bottom layer: 110 parts of polyvinyl chloride resin, 68 parts of dioctyl phthalate, 6 parts of barium stearate, 5 parts of pentaerythritol, 2 parts of trioctyl ester, 7 parts of acetyl citrate.

[0037] The above-mentioned sound-insulating elastic plastic floor is prepared by the following steps:

[0038] (1) Mix the components of the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com