Coating for automobile sealing strip and preparation method thereof

A technology for automotive sealing strips and coatings, applied in epoxy resin coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc. Effect of hardness, enhanced wear coefficient, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

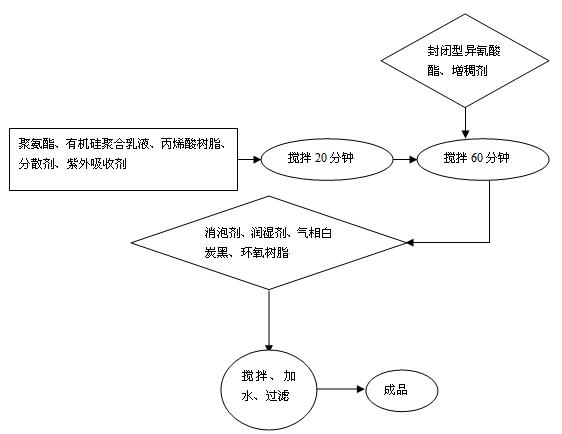

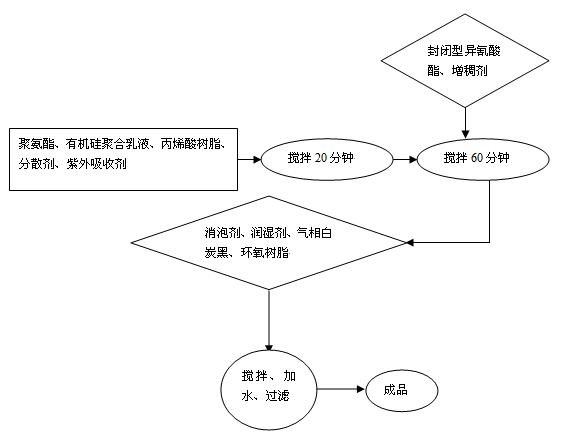

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Please refer to figure 1 146.41g of polyurethane resin, 52.13g of silicone monomer polymerized emulsion resin, 83.07g of acrylic resin, 4.88g of dispersant, and 2.91g of ultraviolet absorber were added to the reaction kettle, and the mixture was stirred at a stirring speed of 1000r / min. Mix the materials for 20 minutes, wherein the dispersant and UV absorber need to be added linearly with stirring. The dispersant can be a copolymer solution with pigment adsorption groups or a high molecular weight block copolymer solution with pigment affinity groups. Such as BFK pigment special dispersant.

[0029] Then, 4.36 g of blocked isocyanate and 5 g of thickener were added, stirred and dispersed for 60 minutes. Wherein the thickener is added slowly with stirring, and the thickener can be carboxymethyl cellulose, hydroxyethyl cellulose, hydroxypropyl me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com