Production process and production device of ultrafine boron carbide micropowder

A production process and production device technology, which is applied in the production process and production device field of ultra-fine boron carbide powder, can solve the problems that the boron carbide powder is not fine enough, the loss of the material to be ground is increased, and the energy consumption is high, and achieves good fluidity and dust. Low yield, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

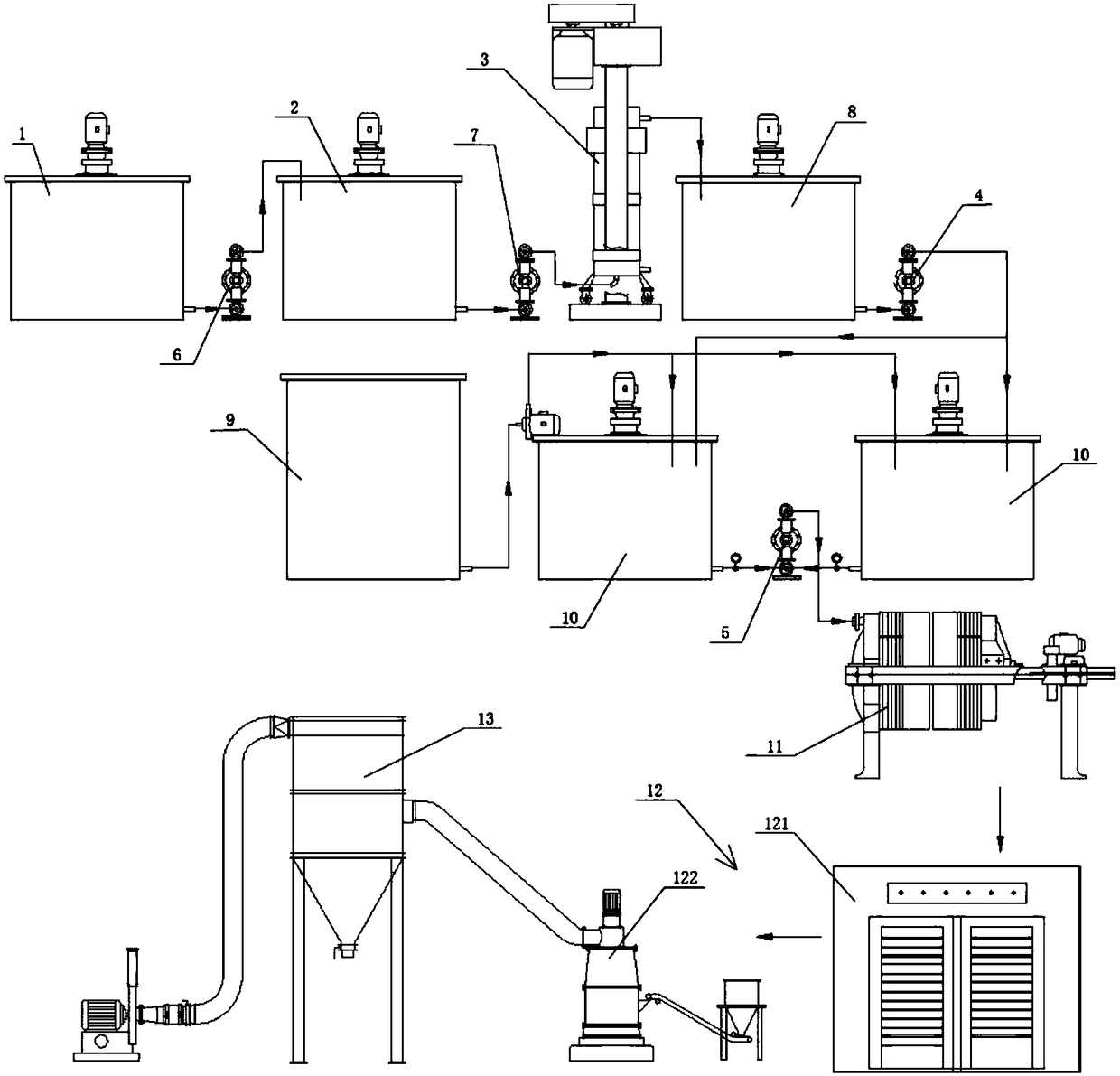

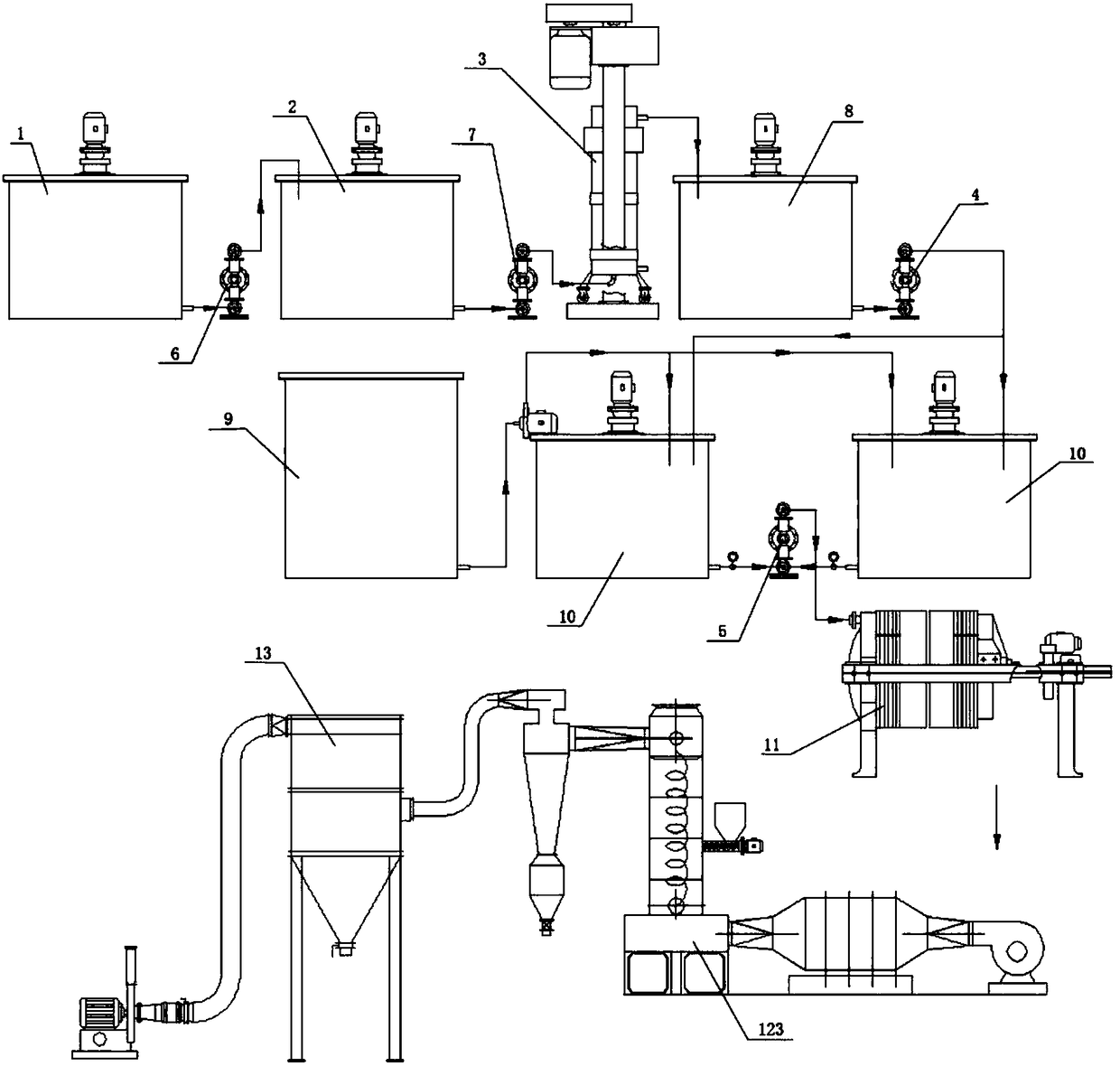

Image

Examples

Embodiment 1

[0031] A production process of ultra-fine boron carbide micropowder, comprising the following steps:

[0032] (1) Pulverization: Take 200kg of boron carbide particles (D50=20μm), 300kg of grinding media and 300kg of water, put them into a wet grinder, the speed of the wet grinder is 500r / min, and the pump flow rate is 3-5 liters / hour , grinding at 40°C for 40 hours until the ground slurry D50<0.5 μm, wherein the boron carbide particle size is less than or equal to 20 μm, wherein the content of iron element and compound is less than 0.2wt%, and the content of aluminum element and compound is less than 0.1wt%, silicon element and compound content is less than 0.25wt%;

[0033] (2) Purification: pump the ground slurry into a reaction tank, add 25 kg of hydrofluoric acid, heat to 80° C., keep warm for 5 hours, stir for 10 minutes per hour, continue to react for 20 hours, and rinse with water until ph=5 -6, add 1 kg of hydrochloric acid and 5 kg of nitric acid, heat to 80°C, keep ...

Embodiment 2

[0040] A production process of ultra-fine boron carbide micropowder, comprising the following steps:

[0041] (1) Pulverization: Take 200kg of boron carbide particles (D50=20μm), 300kg of grinding media and 400kg of water, put them into a wet grinder, the speed of the wet grinder is 650r / min, and the pump flow rate is 3-5 liters / hour , ground at 45°C for 38 hours until the ground slurry D50<0.5 μm, wherein the particle size of the boron carbide particles is less than or equal to 20 μm, the content of iron element and compound is less than 0.2wt%, and the content of aluminum element and compound is less than 0.1wt%, silicon element and compound content is less than 0.25wt%;

[0042] (2) Purification: pump the ground slurry into a reaction tank, add 28 kg of hydrofluoric acid, heat to 80° C., keep warm for 5 hours, stir for 10 minutes per hour, continue to react for 20 hours, and rinse with water until ph=5 -6, then add 1.1kg of hydrochloric acid and 5.5kg of nitric acid, heat ...

Embodiment 3

[0049] A production process of ultra-fine boron carbide micropowder, comprising the following steps:

[0050] (1) Pulverization: Take 200kg of boron carbide particles (D50=20μm), 300kg of grinding media and 400kg of water, put them into a wet grinder, the speed of the wet grinder is 800r / min, and the pump flow rate is 3-5 liters / hour , ground at 50°C for 35 hours, until the ground slurry D50<0.5μm, wherein the boron carbide particle size is less than or equal to 20μm, wherein the content of iron element and compound is less than 0.2wt%, and the content of aluminum element and compound is less than 0.1wt%, silicon element and compound content is less than 0.25wt%;

[0051] (2) Purification: pump the ground slurry into a reaction tank, add 30 kg of hydrofluoric acid, heat to 80° C., keep warm for 5 hours, stir for 10 minutes per hour, continue to react for 20 hours, and rinse with water until ph=5 -6, add 1 kg of hydrochloric acid and 5 kg of nitric acid, heat to 80°C, keep war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com