Ultra-high molecular weight polyethylene resin and preparation method thereof

A technology of ultra-high molecular weight and polyethylene resin, which is applied in the field of polymer materials, can solve the problems of reducing the content of fine powder, achieve the effects of easy production and operation, improve the operating environment, and reduce the phenomenon of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

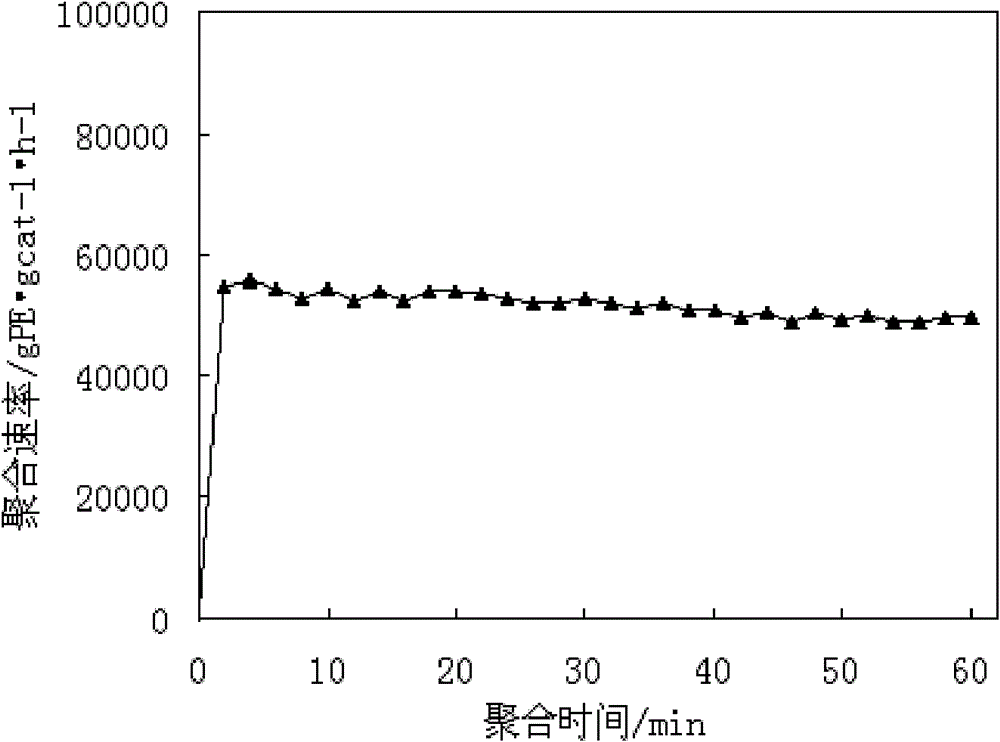

Image

Examples

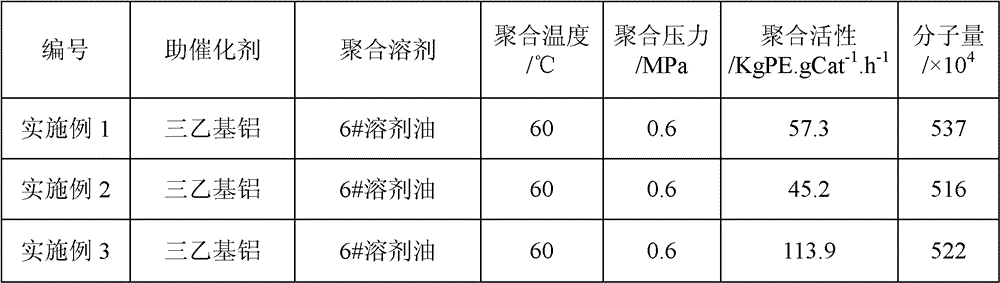

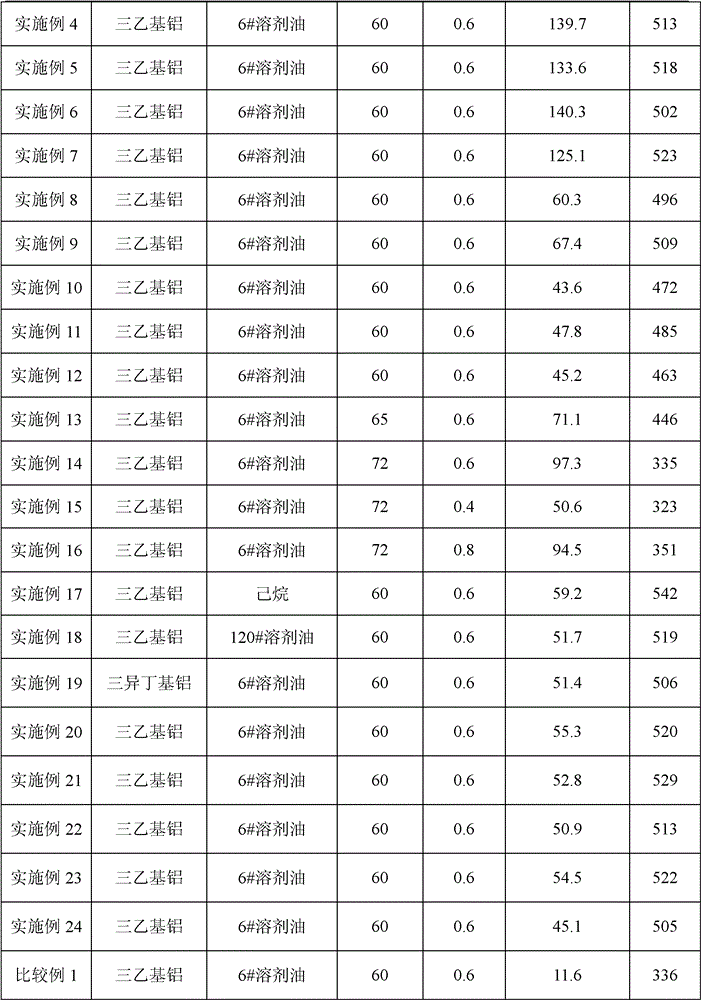

Embodiment 1

[0062] (1) Preparation of ultra-high molecular weight polyethylene catalyst

[0063] Fully clean the glass flask equipped with a stirring device and a reflux condensing system with nitrogen, and then add 60ml of n-hexane, 1g of anhydrous magnesium chloride, and 5ml of n-butanol under the protection of nitrogen, at 70°C, with a stirring speed of 250 rpm , stirred at constant temperature for 0.5 hours to obtain a magnesium alkoxide compound solution; cooled to 20°C, slowly added dropwise 5ml of SiCl 4 , after the carrier magnesium chloride is precipitated, heat up to 70°C and stir for 0.5 hours; turn on the ultrasonic generator, set the frequency to 40KHz, and the power to 50W, and treat the suspension for 3 minutes; turn off the ultrasonic generator, and continue to stir at 70°C for 0.5 hours; cool to 20°C, slowly add 4ml of titanium tetrachloride, and stir at a constant temperature of 70°C for 2 hours; wash the catalyst particles with n-hexane several times, and dry to obtain ...

Embodiment 2

[0067] (1) Preparation of ultra-high molecular weight polyethylene catalyst

[0068] Adopt the same catalyst component and preparation process as in Example 1, but in the preparation process, the treatment time of the ultrasonic generator is 0.5 minutes, the frequency of the ultrasonic generator is set to 60KHz, and the power is set to 300W.

[0069] (2) Preparation of ultra-high molecular weight polyethylene resin

[0070] Using the same polymerization conditions and polymerization process as in Example 1, the polymerization results are shown in Table 1, and the product screening data are shown in Table 2.

Embodiment 3

[0072] (1) Preparation of ultra-high molecular weight polyethylene catalyst

[0073] Using the same catalyst components and preparation process as in Example 1, but in the preparation process, the processing time of the ultrasonic generator was 5 minutes, the power of the ultrasonic generator was set to 80W, and the hydrocarbon solvent was changed to heptane.

[0074] (2) Preparation of ultra-high molecular weight polyethylene resin

[0075] Using the same polymerization conditions and polymerization process as in Example 1, the polymerization results are shown in Table 1, and the product screening data are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com