A method for continuous and controllable preparation of nano-silica spherical particles

A technology of nano-silica and silicon oxide particles, which is applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of high cost and complicated operation, and achieve high production efficiency, simple post-processing, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 528g of methyl orthosilicate and 660g of methanol into a 2L beaker, and stir for 30min to form solution A; then add 247.5g of deionized water, 412.5g of sodium hydroxide (30wt%) and 528g of methanol into a 2L beaker, and stir for 30min Solution B is formed. The prepared two cups of solutions A and B are pumped into the T-shaped microchannel mixer by the metering pump at the same time. The feeding angle of the two liquids is 90 degrees. The inner diameter of the microchannel used is 0.68mm and the length of the microchannel is 60cm. At this time, the microwave controlled heating temperature was 98° C., and the heating residence time was 1 h. After solid-liquid separation, the product was placed in a constant temperature and humidity box at a temperature of 85°C and a humidity of 90%, and dried for 12 hours.

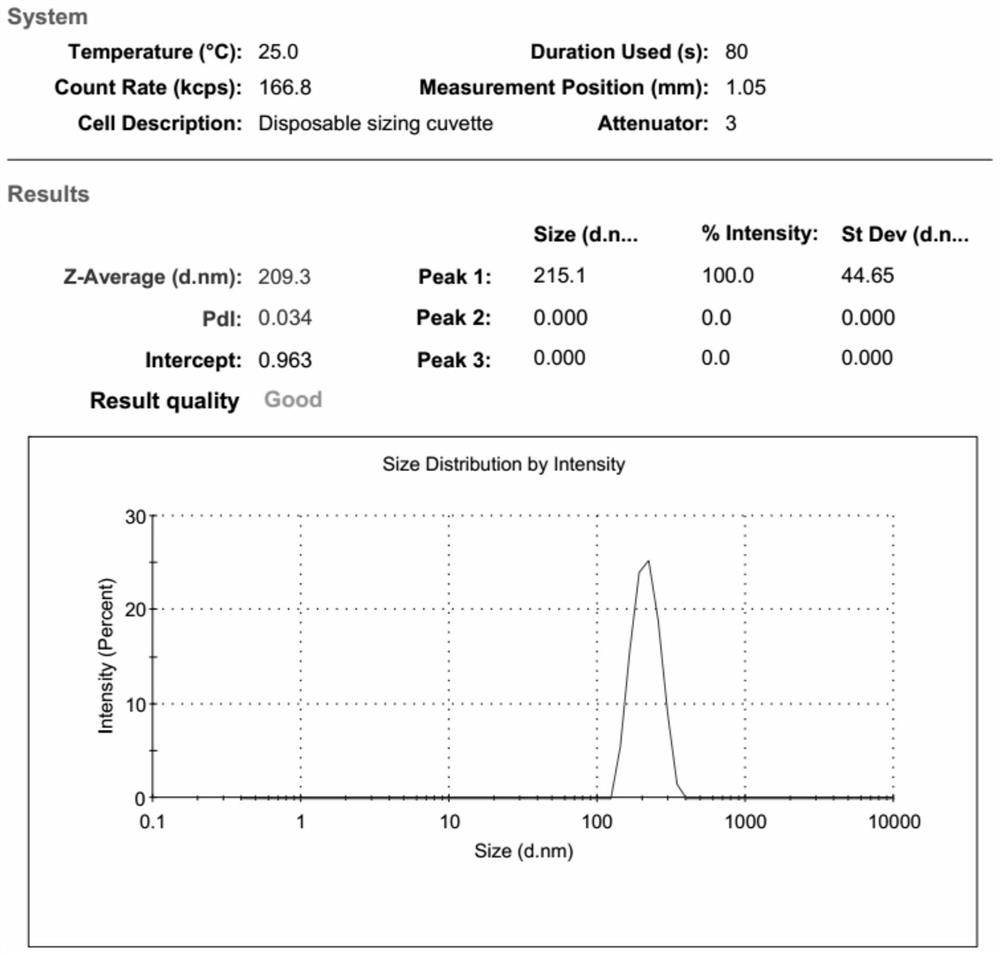

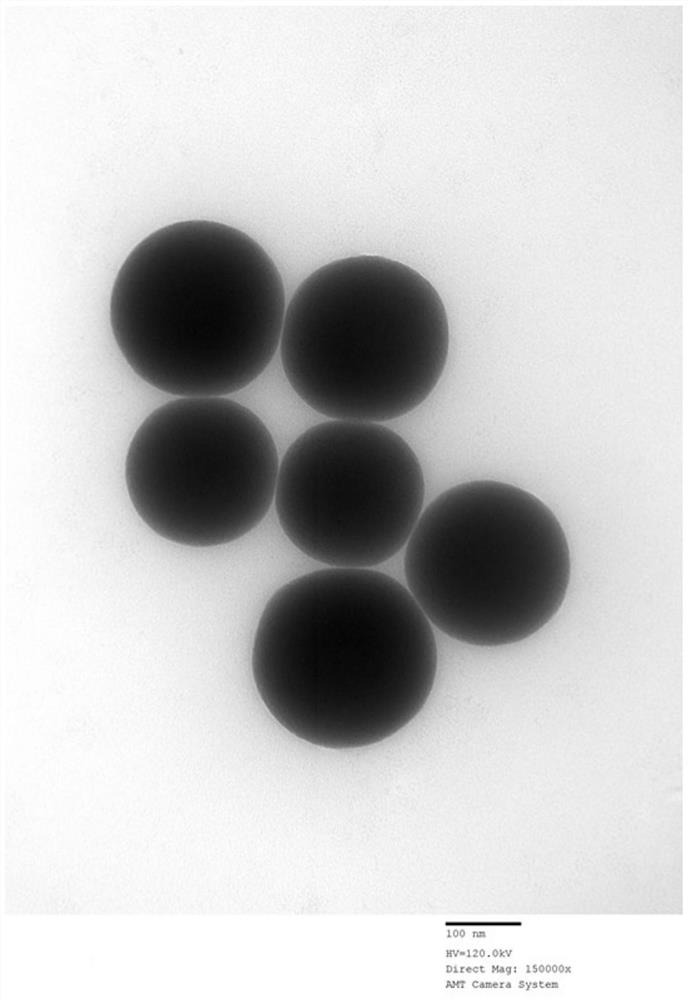

[0036] Gained product analyzes particle size with Malvern laser particle size analyzer, and its average particle diameter is 209.3nm, and concentration PDI val...

Embodiment 2

[0038] Add 733.2g of tetraethyl orthosilicate and 670.8g of isopropanol into a 2L beaker, and stir for 30min to form solution A; then add 351g of deionized water, 382.2g of concentrated ammonia water and 670.8g of isopropanol into a 2L beaker, and stir Solution B was formed in 30 min. The prepared two cups of solutions A and B are pumped into the T-shaped microchannel mixer by the metering pump at the same time. The feeding angle of the two liquids is 90 degrees. The inner diameter of the microchannel used is 1mm and the length of the microchannel is 16cm. At this time, the microwave controlled heating temperature was 120° C., and the heating residence time was 0.5 h. After solid-liquid separation, the product was placed in a constant temperature and humidity box at a temperature of 90°C and a humidity of 50%, and dried for 18 hours.

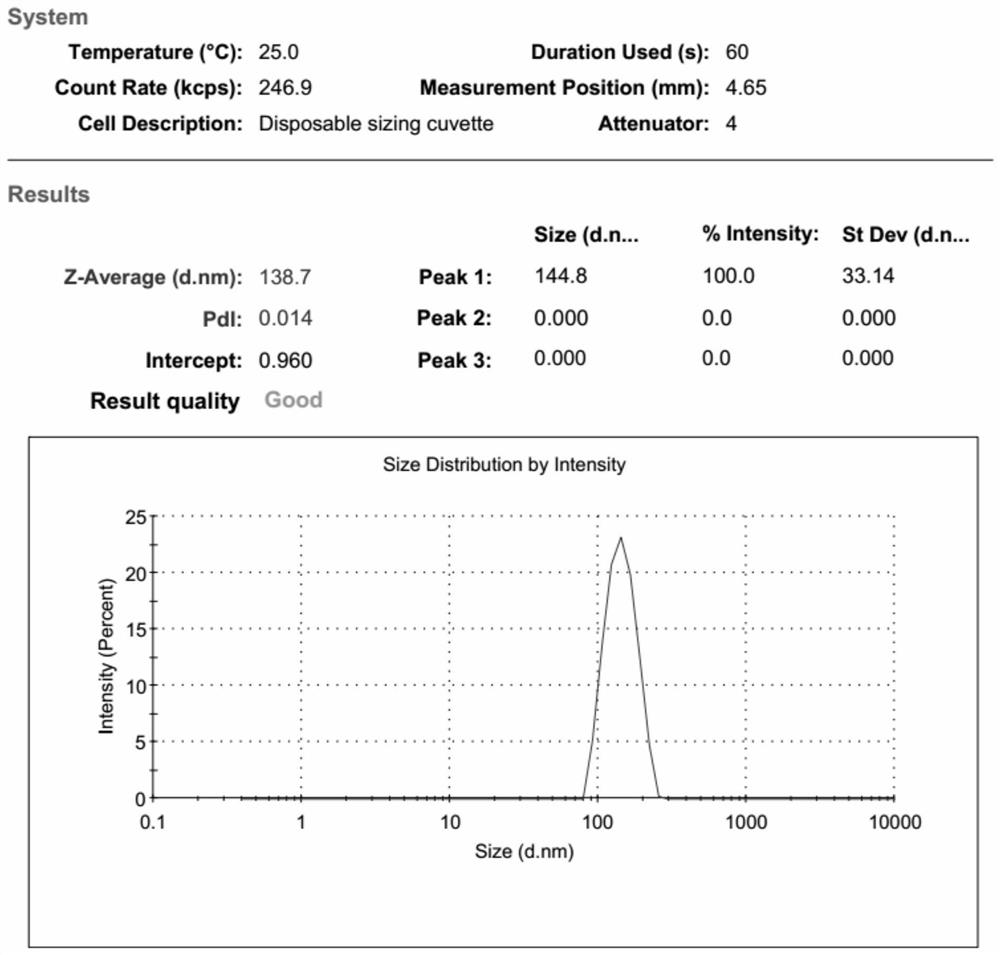

[0039]Gained product analyzes particle size with Malvern laser particle size analyzer, and its average particle diameter is 138.7nm, and conce...

Embodiment 3

[0041] Add 72.5g of methyl orthosilicate and 971.5g of ethanol into a 2L beaker, and stir for 30min to form solution A; then add 580g of deionized water, 290g of concentrated ammonia water and 174g of isopropanol into a 2L beaker, and stir for 30min to form solution B . The prepared two cups of solutions A and B are pumped into the T-shaped microchannel mixer by the metering pump at the same time. The feeding angle of the two liquids is 90 degrees. The inner diameter of the microchannel used is 0.8mm and the length of the microchannel is 40cm. At this time, the microwave controlled heating temperature was 78° C., and the heating residence time was 2 h. After solid-liquid separation, the product was placed in a constant temperature and humidity box at a temperature of 90°C and a humidity of 50%, and dried for 24 hours.

[0042] Gained product analyzes particle size with Malvern laser particle size analyzer, and its average particle diameter is 27.45nm, and concentration PDI va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com