Electromagnetic shielding silver paste for communication equipment and preparation method thereof

A technology for electromagnetic shielding and communication equipment, applied in the field of electromagnetic shielding silver paste for communication equipment and its preparation, can solve the problems of poor shielding effect, high curing temperature, poor conductivity, etc., and achieve good shielding effect, stable adhesion, excellent The effect of printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

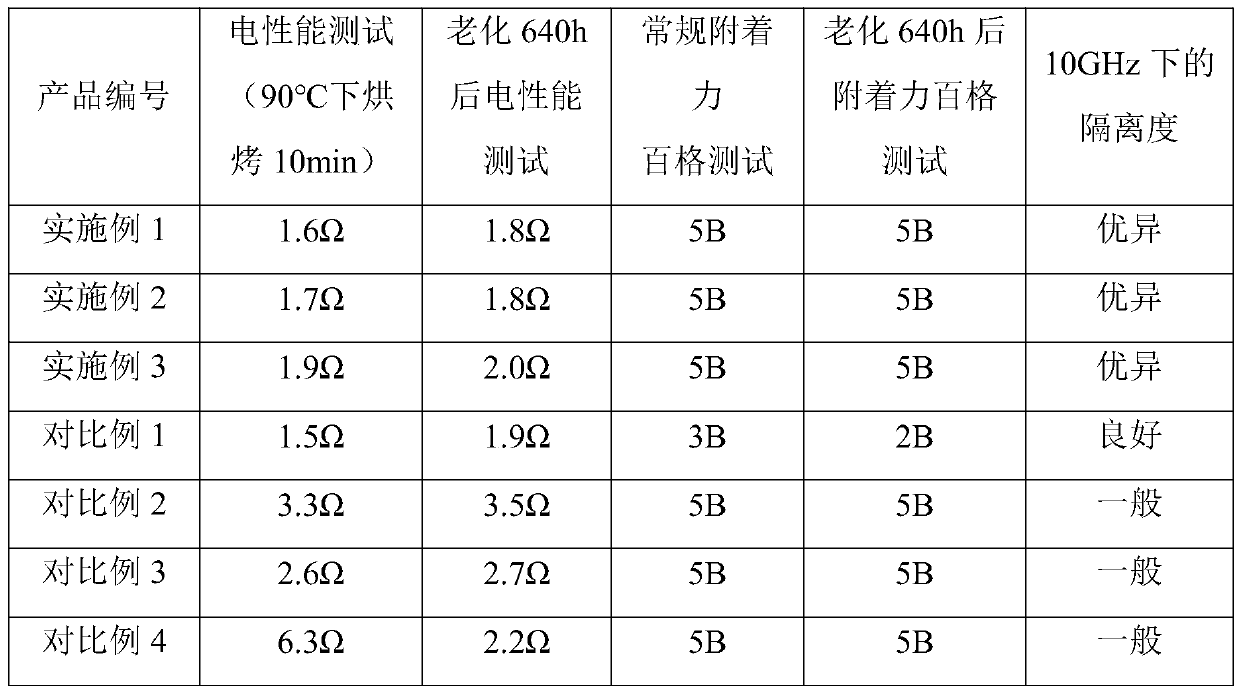

Examples

Embodiment 1

[0028] A preparation method of electromagnetic shielding silver paste for communication equipment:

[0029] (1) Take by mass percentage: 1% phenolic resin, 7% phenoxy resin, 22% diethylene glycol ethyl ether acetic acid, 60% diethylene glycol butyl ether acetate, 10% KH560, in Heating and stirring at 50-100°C to obtain an organic carrier;

[0030] (2) Add 100g of titanium hydride to 180g of Schiff's base, mix well and add to 1200g of N-methylpyrrolidone solvent together, heat and react at 70-90°C for 0.5-2h, after filtering, wash the filter residue with ethanol for 2- 3 times, filter ethanol, and dry at room temperature to obtain the metal chelate; wherein, the D50 of the titanium hydride is 0.5 μm; the molecular weight of the Schiff base is 6000;

[0031] (3) Take silver powder A45g, silver powder B15g, organic vehicle 48g prepared by step (1) and metal chelate additive 2g prepared by step (2), mix and roll to obtain the electromagnetic shielding silver paste. Wherein, the ...

Embodiment 2

[0033](1) Weighing by mass percentage: 2% ABS resin, 4% phenoxy resin, 40% DBE, 40% diethylene glycol butyl ether acetate, 6% KH570, 8% 90-degree open Ring curing agent, heating and stirring at 50-100°C to obtain an organic vehicle;

[0034] (2) Add 100g of titanium hydride to 200g of Schiff's base, mix well and add to 1000g of N-methylpyrrolidone solvent together, heat and react at 70-90°C for 0.5-2h, after filtering, wash the filter residue with ethanol for 2- 3 times, filter ethanol, and dry at room temperature to obtain the metal chelate; wherein, the D50 of the titanium hydride is 1.0 μm; the molecular weight of the Schiff base is 8000;

[0035] (3) Weigh 50 g of silver powder A, 10 g of silver powder B, 39 g of organic carrier prepared in step (1) and 1 g of metal chelate auxiliary agent prepared in step (2), mix and roll to obtain the electromagnetic shielding silver paste. Wherein, the silver powder A is flake silver powder, the particle size distribution is 3.0-4.0 μ...

Embodiment 3

[0037] (1) Take by mass percentage: 2% phenolic resin, 2% polyester resin, 50% diethylene glycol ethyl ether acetic acid, 16% diethylene glycol butyl ether acetate, 5% KH550, 10 % of 90-degree ring-opening curing agent and 5% of lecithin are heated and stirred at 50-100°C to obtain an organic vehicle;

[0038] (2) Add 100g of titanium hydride to 250g of Schiff's base, mix well and add to 1000g of N-methylpyrrolidone solvent together, heat and react at 70-90°C for 0.5-2h, after filtering, wash the filter residue with ethanol for 2- 3 times, filter ethanol, and dry at room temperature to obtain the metal chelate; wherein, the D50 of the titanium hydride is 1.2 μm; the molecular weight of the Schiff base is 10000;

[0039] (3) Take by weighing silver powder A 60g, silver powder B 5g, the organic carrier 34.9g that step (1) prepares and the metal chelate auxiliary agent 0.1g that step (2) prepares, mix, roll, obtain described electromagnetic shielding silver pulp. Wherein, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com