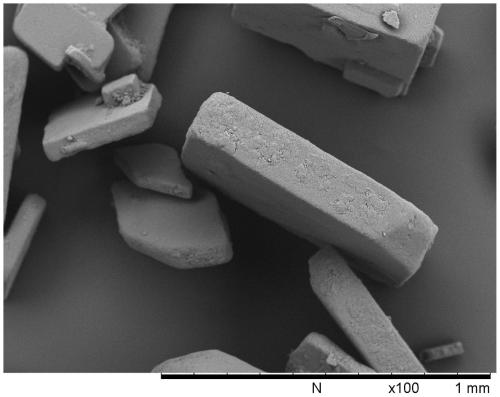

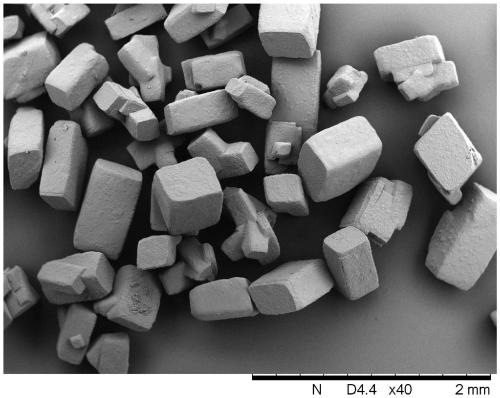

Method for preparing anhydrous betaine crystals with ultra-uniform granularity

A technology of anhydrous betaine and crystals, which is applied in the field of preparation of food-grade cubic anhydrous betaine crystals, and can solve problems such as changing the crystal habit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

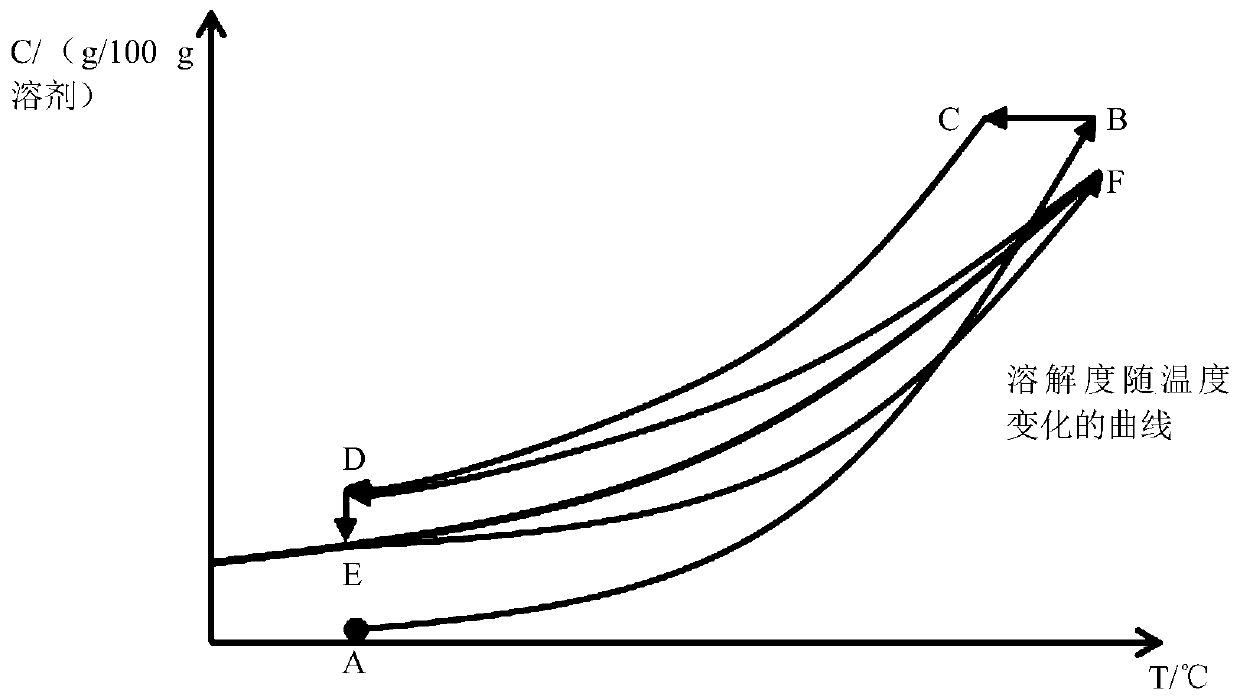

Method used

Image

Examples

Embodiment example 1

[0043] Add 31.2g of anhydrous betaine powder and 120g of absolute ethanol in the crystallizer, the mass ratio of anhydrous betaine powder and solvent is 0.26:1. The stirring speed is set to 400r / min, and the temperature is raised at a heating rate of 7°C / min to dissolve the betaine powder, and the temperature of the solution reaches the boiling point of the crystallization system.

[0044] Cool down rapidly, the cooling rate is 0.5°C / min, when the solution temperature drops to 80.2°C, there are crystal nuclei in the solution, at this time, put 1.1g of anhydrous betaine powder into the solution, that is, the dosage is 0.009g / g solvent , crystal nuclei exploded immediately in the solution, and continued to cool down to room temperature at a cooling rate of 0.05°C / min.

[0045] When the temperature of the solution drops to 25°C, do not filter for the time being, and put 10g of anhydrous betaine powder into the crystallizer again, that is, the dosage is 0.08g / g solvent, and the ad...

Embodiment example 2

[0049] Add 31.1g of anhydrous betaine powder and 120g of absolute ethanol in the crystallizer, the mass ratio of anhydrous betaine powder and solvent is 0.26:1. The stirring speed is set to 400r / min, and the temperature is raised at a heating rate of 6°C / min to dissolve the betaine powder, and the temperature of the solution reaches the boiling point of the crystallization system.

[0050] Cool down rapidly, the cooling rate is 0.5°C / min, when the solution temperature drops to 80.1°C, there are crystal nuclei in the solution, at this time, put 0.5g of anhydrous betaine powder into the solution, that is, the dosage is 0.004g / g solvent , the crystal nuclei exploded immediately in the solution, and continued to cool down to room temperature at a cooling rate of 0.5°C / min.

[0051] When the temperature of the solution is lowered to 23°C, do not filter for the time being, and put 15g of anhydrous betaine powder into the crystallizer again, that is, the dosage is 0.12g / g solvent, an...

Embodiment example 3

[0055] Add 31.5g of anhydrous betaine powder and 120g of absolute ethanol in the crystallizer, the mass ratio of anhydrous betaine powder and solvent is 0.26:1. The stirring speed is set to 400r / min, and the temperature is raised at a heating rate of 5°C / min to dissolve the betaine powder, and the temperature of the solution reaches the boiling point of the crystallization system.

[0056] Cool down rapidly, the cooling rate is 0.5°C / min, when the solution temperature drops to 80.4°C, crystal nuclei are precipitated in the solution. At this time, 0.1g of anhydrous betaine powder is put into the solution, that is, the dosage is 0.0008g / g solvent , crystal nuclei were precipitated explosively in the solution immediately, and continued to cool down to room temperature at a cooling rate of 0.2°C / min.

[0057] When the temperature of the solution is lowered to 20°C, do not filter for the time being, and drop 14g of anhydrous betaine powder into the crystallizer again, that is, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com