Calcium carbonate and preparation method thereof

A technology for calcium carbonate and calcium raw materials, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of inability to effectively control the particle size distribution of calcium carbonate products, low purity of porous light calcium carbonate products, uneven product particle size distribution, etc. Good liquid-solid separation performance, strong industrial operability, and the effect of realizing the concept of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

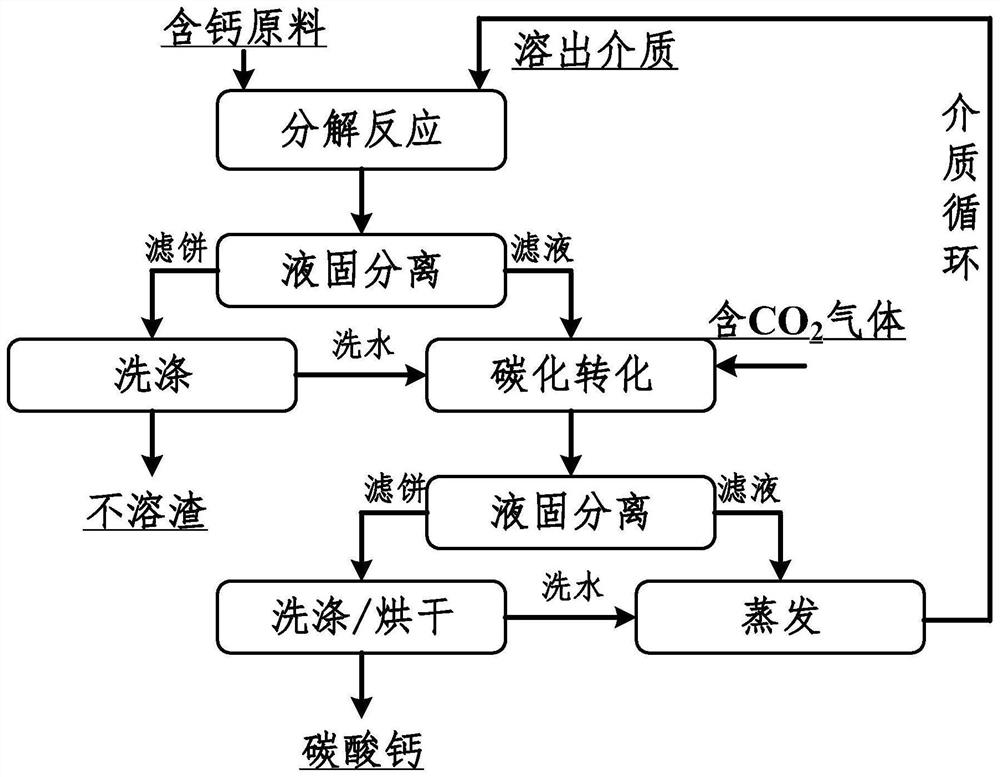

Method used

Image

Examples

Embodiment 1

[0057] The present embodiment provides a kind of preparation method of calcium carbonate, adopts industrial lime as calcium-containing raw material, and its chemical composition is as shown in table 1:

[0058] Table 1

[0059]

[0060] Described preparation method comprises the steps:

[0061] (1) Mix industrial lime with hydrochloric acid solution, carry out the decomposition reaction at 20 DEG C for 3 hours, and the calcium chloride-containing feed liquid after the reaction undergoes liquid-solid separation to obtain calcium chloride-containing solution and insoluble slag;

[0062] Wherein, the ratio of HCl to the amount of CaO in industrial lime is 1.6:1; the washing water obtained by washing the insoluble slag is mixed with the calcium chloride-containing solution;

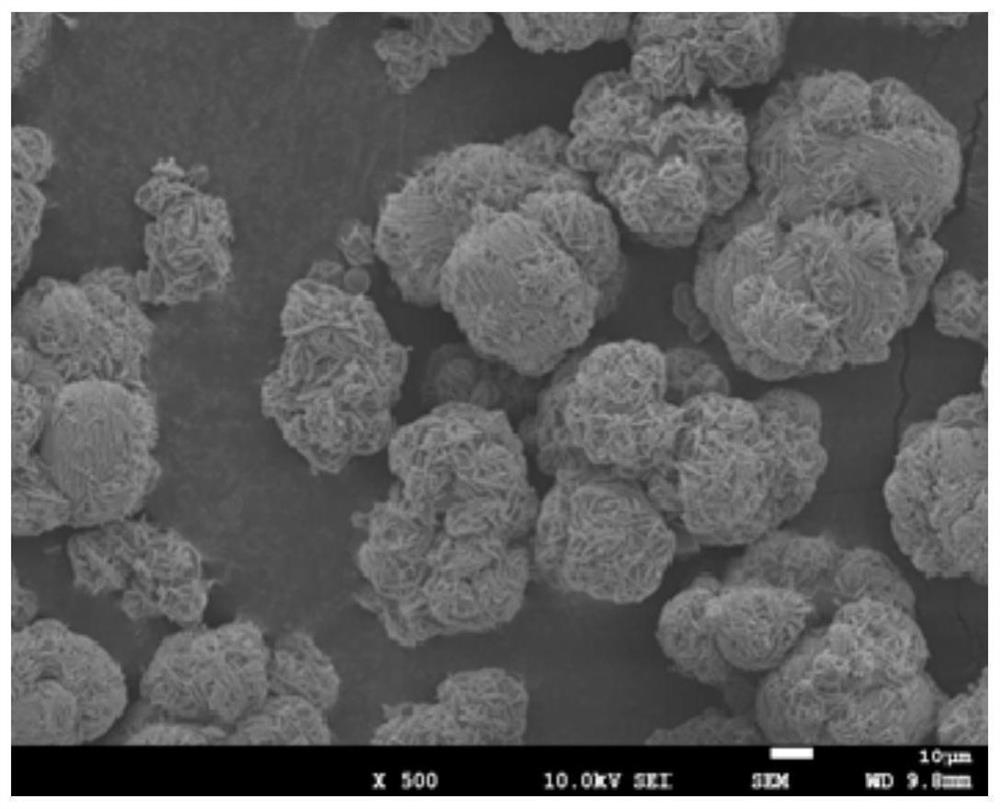

[0063] (2) gradually add calcium chloride solution described in step (1) in the carbonization reactor of prestored water, and feed carbon dioxide gas to carry out carbonization reaction simultaneously, co...

Embodiment 2

[0066] This embodiment provides a method for preparing calcium carbonate, using calcium carbide slag in a place in Henan as a calcium-containing raw material, and the preparation method includes the following steps:

[0067] (1) Mix calcium carbide slag with ammonium chloride solution, and carry out a decomposition reaction at 100°C for 0.05h. After the reaction, the calcium chloride-containing feed liquid undergoes liquid-solid separation to obtain calcium chloride-containing solution and insoluble slag;

[0068] Among them, the NH 4 The ratio of Cl to the amount of CaO in the calcium carbide slag is 2.4:1; the washing water obtained by washing the insoluble slag is mixed with the calcium chloride-containing solution;

[0069] (2) Gradually add the calcium chloride solution described in step (1) into the carbonization reactor of the carbonization mother liquor described in pre-stored embodiment 1, and feed carbon dioxide gas to carry out carbonization reaction at the same tim...

Embodiment 3

[0072] The present embodiment provides a kind of preparation method of calcium carbonate, adopts industrial lime described in embodiment 1 as calcium-containing raw material, and described preparation method comprises the steps:

[0073] (1) Industrial lime is mixed with ammonium nitrate solution, and a decomposition reaction is carried out at 50° C. for 1 hour. After the reaction, the calcium nitrate-containing feed liquid is subjected to liquid-solid separation to obtain calcium nitrate-containing solution and insoluble slag;

[0074] Among them, the NH 4 NO 3 The ratio to the amount of CaO in industrial lime is 2.0:1; the washing water obtained by washing the insoluble slag is mixed with the calcium chloride-containing solution;

[0075] (2) In the carbonization reactor of the carbonization mother liquor described in pre-stored embodiment 2, gradually add the calcium nitrate solution described in step (1), and simultaneously feed carbon dioxide gas to carry out carbonizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com