Alloy powder for mining exploration and collection tool, and preparation method of alloy powder

A technology of alloy powder and collection tools, which is applied in the field of powder metallurgy, can solve the problems of insufficient wettability, poor mechanical properties, and uneven composition of superhard materials, and achieve the effects of concentrated particle size, improved mechanical properties, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

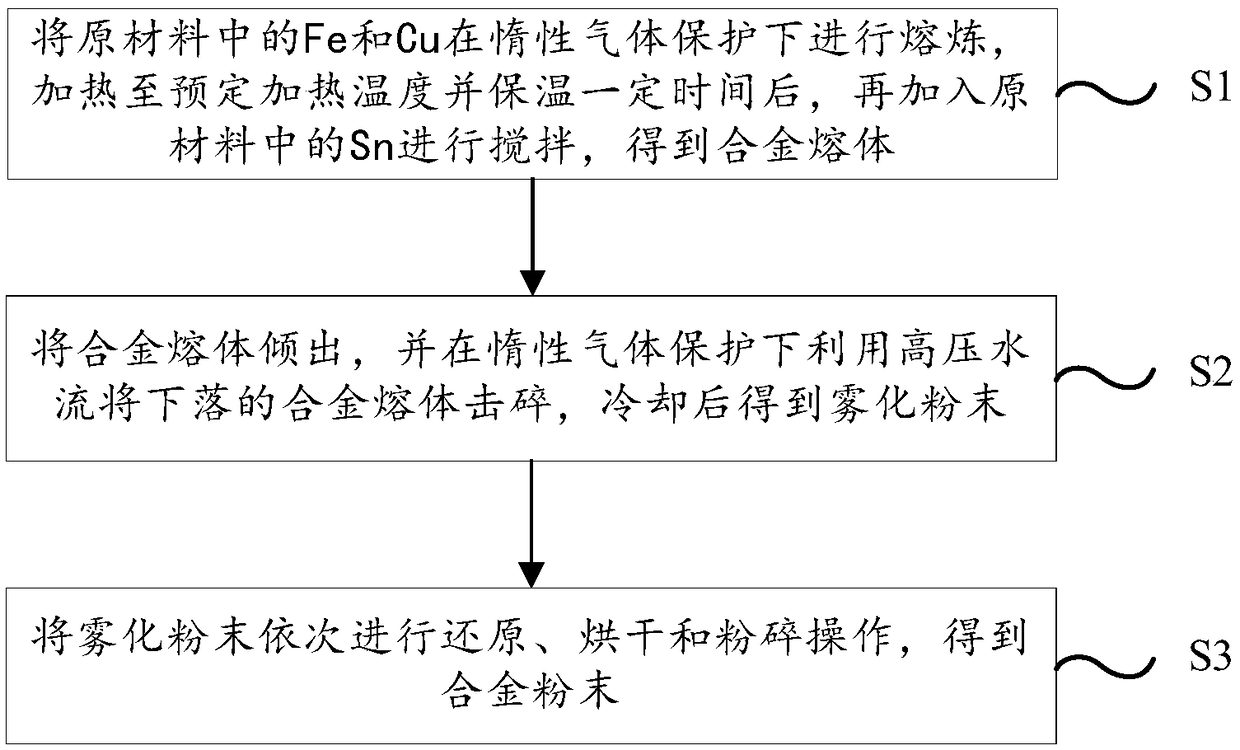

[0033] An embodiment of the present invention provides a method for preparing alloy powder for mining exploration and collection tools. The preparation method can be completed by using an intermediate frequency induction furnace. The intermediate frequency induction furnace mainly includes a melting chamber, an atomization chamber and a reduction furnace. refer to figure 1 As shown, the method includes the following steps:

[0034] S1. Melting Fe and Cu in the raw material under the protection of an inert gas, heating to a predetermined heating temperature and holding it for a certain period of time, then adding Sn in the raw material and stirring to obtain an alloy melt.

[0035] In this embodiment, in terms of mass percentage, the raw materials include 68-86% Fe, 13-25% Cu, 1-7% Sn and unavoidable impurities, which are generally C, P or O, etc. non-metallic elements.

[0036] This component contains Cu and Fe elements, among which Cu can be used as a good thermal conductiv...

Embodiment 1

[0073] According to the mass ratio, weigh 25% of high-purity copper ingots, 7% of high-purity tin ingots and the balance of high-purity iron ingots, then put the high-purity iron ingots and high-purity copper ingots into the melting chamber of the intermediate frequency induction furnace, and then place the melting chamber Evacuate the spray chamber and the spray chamber to a vacuum degree of 20 Pa, and fill it with high-purity argon gas with a purity of 99.9% until the pressure in the melting chamber and spray chamber reaches 1 atmosphere.

[0074] Start the medium frequency induction furnace to raise the temperature of the smelting chamber to 1430°C, with a heating rate of 30°C / min below 1000°C and 10°C / min above 1000°C, and then keep warm for 40 minutes. Then, the high-purity tin ingot is added by a trace element feeding device, and the alloy melt is stirred for 30 minutes by a stirring device. During the stirring process, a slag removal device is used to remove a layer of ...

Embodiment 2

[0079] According to the mass ratio, weigh 19% high-purity copper ingots, 4% high-purity tin ingots and the balance of high-purity iron ingots, then put the high-purity iron ingots and high-purity copper ingots into the melting chamber of the intermediate frequency induction furnace, and then put the melting chamber Evacuate the spray chamber and the spray chamber to a vacuum degree of 20 Pa, and fill it with high-purity argon gas with a purity of 99.9% until the pressure in the melting chamber and spray chamber reaches 1 atmosphere.

[0080] Start the medium-frequency induction furnace to raise the temperature of the melting chamber to 1450°C, with a heating rate of 30°C / min below 1000°C and 10°C / min above 1000°C, and then keep warm for 35 minutes. Then, the high-purity tin ingot is added by a trace element feeding device, and the alloy melt is stirred for 30 minutes by a stirring device. During the stirring process, a slag removal device is used to remove a layer of melt on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com