Benzene and synthesis gas alkylation catalyst as well as preparation method and application thereof

A catalyst and fluoroalkane technology, applied in the field of benzene and synthesis gas alkylation catalyst and its preparation, can solve the problems of uneven distribution of metals and acid centers, low selectivity of light aromatics, low reactivity, etc., and achieve the source of raw materials Sufficient, improved conversion rate, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0063] Preparation of vector a.

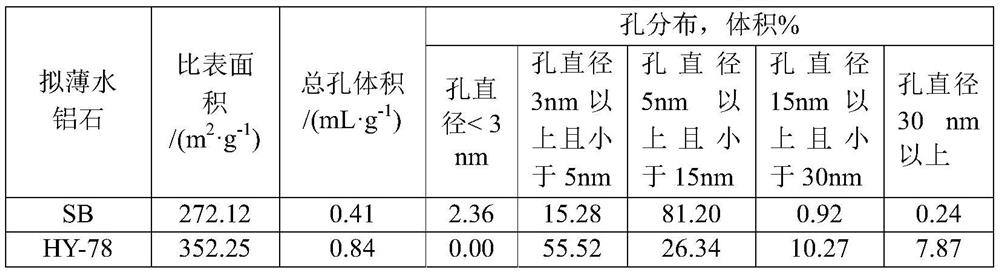

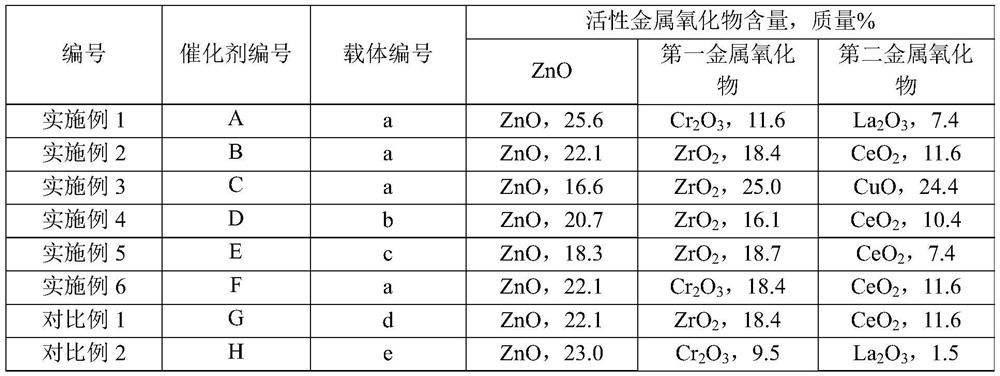

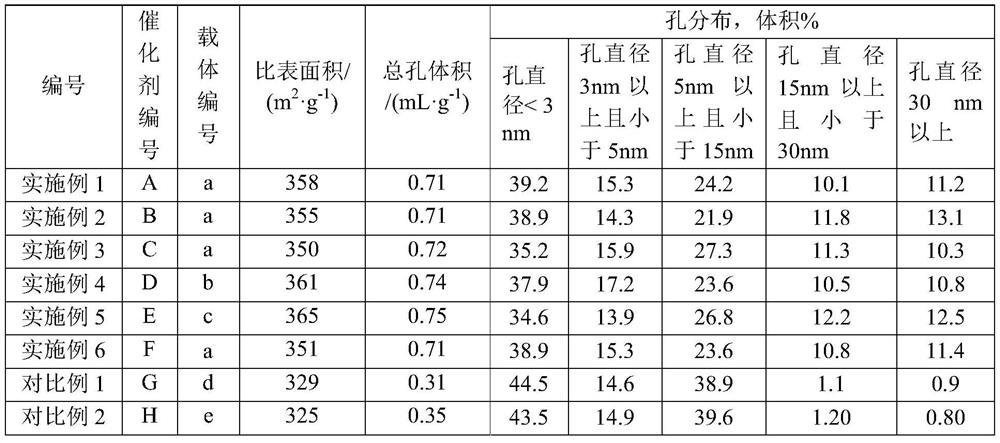

[0064] SiO 2 / Al 2 o 3 65g of hydrogen ZSM-5 molecular sieve with a molar ratio of 27, SiO 2 / Al 2 o 3 5g of hydrogen-type EU-1 molecular sieve with a molar ratio of 35 and 42.9g of macroporous pseudoboth aluminum powder (HY-78) were thoroughly mixed, and then 50mL of dilute nitric acid with a concentration of 3.5% by mass was added, kneaded and then extruded into strands. Dry at 120° C. for 4 hours, and bake at 540° C. for 4 hours in an air atmosphere to obtain a carrier, which contains 65% by mass of HZSM-5, 5% by mass of HEU-1 and 30% by mass of macroporous γ-alumina.

[0065]The above-mentioned carrier was subjected to steam treatment at 440° C. for 4 hours, and then dried at 120° C. for 4 hours to obtain carrier a.

preparation example 2

[0067] Preparation of vector b.

[0068] SiO 2 / Al 2 o 3 50g of hydrogen ZSM-5 molecular sieve with a molar ratio of 38, SiO 2 / Al 2 o 3 10 g of hydrogen-type EU-1 molecular sieve with a molar ratio of 70 and 57.1 g of macroporous pseudo-both aluminum powder (HY-78) were thoroughly mixed, and then 90 mL of dilute nitric acid with a concentration of 3.5% by mass was added, kneaded, and then extruded. Dry at 120° C. for 4 hours, and bake at 540° C. for 4 hours in an air atmosphere to obtain a carrier, which contains 50 mass percent of HZSM-5, 10 mass percent of HEU-1 and 40 mass percent of macroporous γ-alumina.

[0069] The above-mentioned support was subjected to steam treatment at 460° C. for 2 h, and then dried at 120° C. for 4 h to obtain the support b.

preparation example 3

[0071] Preparation of vector c.

[0072] SiO 2 / Al 2 o 3 30g of hydrogen ZSM-5 molecular sieve with a molar ratio of 70, SiO 2 / Al 2 o 3 20g of hydrogen-type EU-1 molecular sieve with a molar ratio of 25 and 71.4g of macroporous pseudoboth aluminum powder (HY-78) were thoroughly mixed, and then 100mL of dilute nitric acid with a concentration of 3.5% by mass was added, kneaded, and then extruded. Dry at 120° C. for 4 hours, and bake at 540° C. for 4 hours in an air atmosphere to obtain a carrier, which contains 30 mass percent of HZSM-5, 20 mass percent of HEU-1 and 50 mass percent of macroporous γ-alumina.

[0073] The above-mentioned support was subjected to steam treatment at 480° C. for 6 h, and then dried at 120° C. for 4 h to obtain the support c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com