Modification method for Y-type molecular sieve

A molecular sieve and modification technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of non-framework aluminum crystallinity loss, molecular sieve reduction, acid content reduction, etc., to achieve stability and heavy oil Improvement of conversion ability, improvement of acid distribution, and improvement of silicon-aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

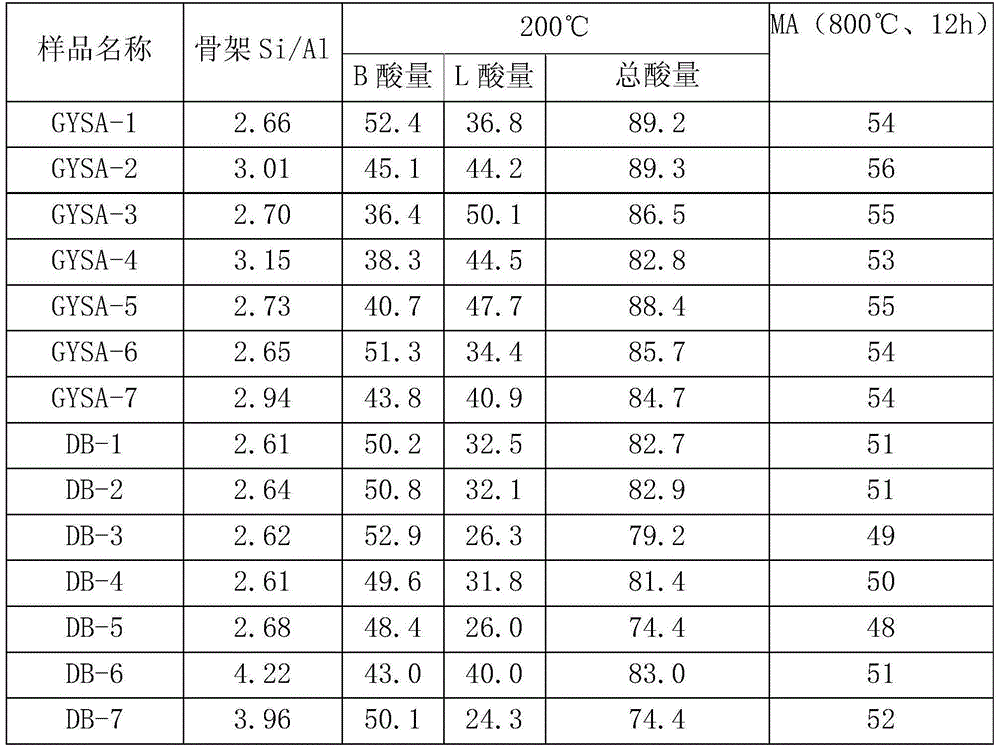

Examples

Embodiment 1

[0017] With 20g (dry base) industrial NaY molecular sieve (Na 2 O 13.1%, crystallinity 85%, skeletal silicon-aluminum atomic ratio 2.62, Sinopec Changling Catalyst Factory) mixed with 160g glycerin and 200g deionized water, stirred evenly and heated to 150°C for depolymerization for 4h; then depolymerized After the final slurry was allowed to stand and cooled to room temperature, 24g of TPAOH solution (mass fraction 25wt%) was added under vigorous stirring, and after stirring for 30 minutes, 20mL of sodium metaaluminate (Al 2 o 3 Content 190g / L) was added thereinto, continued to stir for 30 minutes and then added 3mL water glass solution (SiO 2 The content is 250g / L, the modulus is 3.3), and the temperature is raised to 70°C under stirring for 2 hours. Subsequently, the above slurry was transferred to a stainless steel crystallization kettle for crystallization at 110°C for 10 h, and the obtained product was filtered, washed, and dried, and then calcined at 550°C for 2 h, an...

Embodiment 2

[0019] Mix 20g (dry basis) industrial NaY molecular sieve (same as above) with 60g glycerol and 160g deionized water, stir evenly and heat up to 180°C for depolymerization for 2 hours; Add 32g TEAOH solution (mass fraction 25wt%) under stirring, stir 80mL aluminum sulfate (Al 2 o 3 Content 90g / L) was added thereinto, and after stirring for 30 minutes, 8.5mL of water glass solution was added, and the temperature was raised to 60°C for aging for 2h while stirring. Subsequently, the above slurry was transferred to a stainless steel crystallization kettle for crystallization at 100°C for 20 hours, and the obtained product was filtered, washed, and dried, and then calcined at 600°C for 2 hours, and the obtained molecular sieve was designated as GYSA-2. The powder diffraction XRD pattern shows that it has the characteristics of a typical Y-type molecular sieve.

Embodiment 3

[0021] Mix 20g (dry basis) industrial NaY molecular sieve (same as above) with 110g glycerin and 200g deionized water, stir evenly and heat up to 100°C for depolymerization for 8 hours; Add 30g of TPAOH solution and 18g of TEAOH solution under stirring, after stirring for 30 minutes, add 80mL of sodium metaaluminate into it at room temperature, continue stirring for 30 minutes, then add 5.5g of tetraethoxy silicon, heat up to 80°C and age for 2h under stirring . Subsequently, the above slurry was transferred to a stainless steel crystallization kettle for crystallization at 100°C for 8 hours, and the obtained product was filtered, washed, and dried, then calcined at 700°C for 2 hours, and the obtained molecular sieve was designated as GYSA-3. The powder diffraction XRD pattern shows that it has the characteristics of a typical Y-type molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com