A kind of hydrocracking catalyst and its preparation method and application

A hydrocracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem that the yield of light oil with product density cannot meet the requirements, and the yield of light fuel oil is low, etc. problems, to achieve high selectivity, good activity stability, and improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

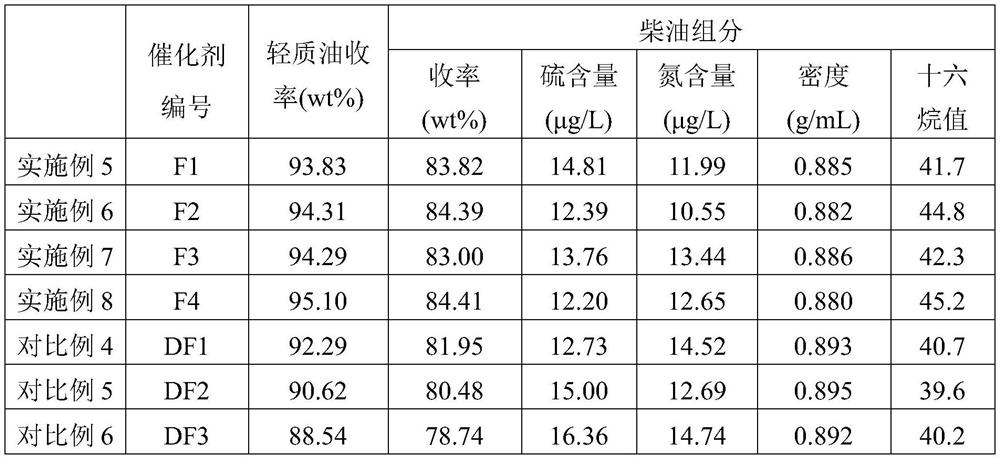

Examples

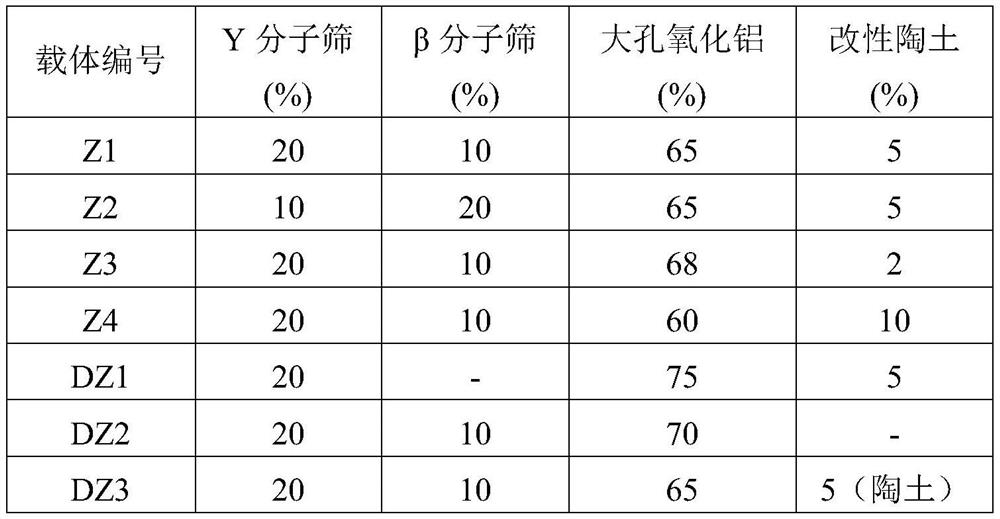

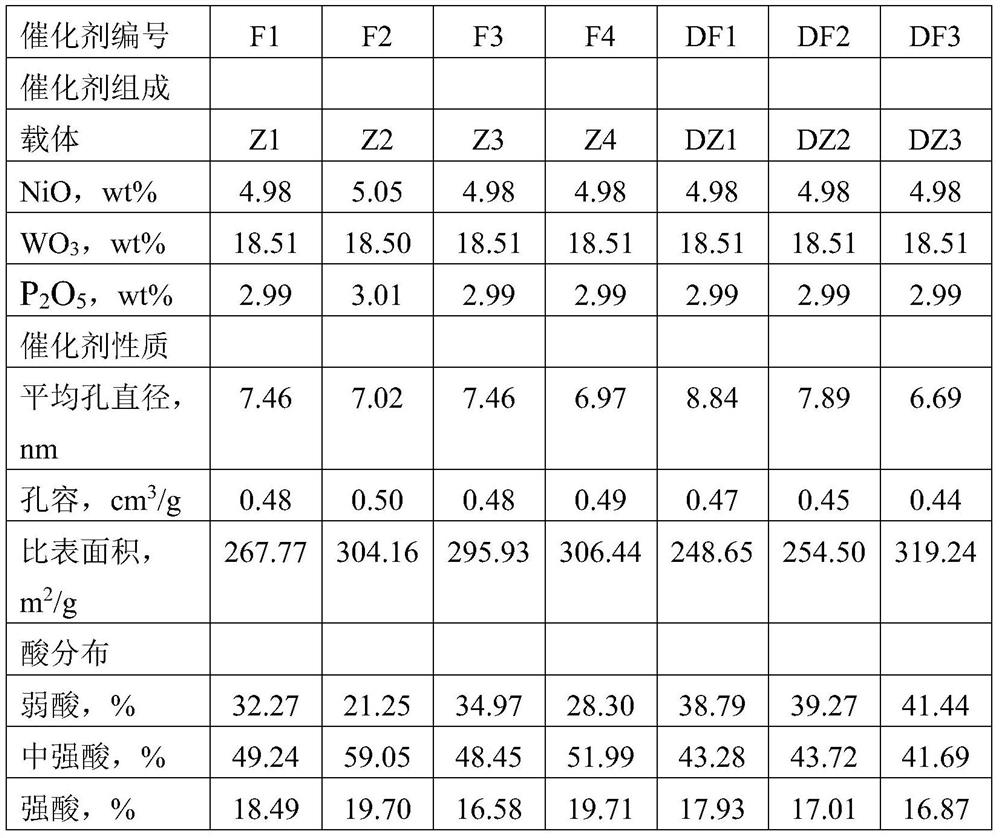

Embodiment 1

[0057] (1) Mix 41.28g of Y molecular sieve, 21.96g of β molecular sieve, 186.78g of macroporous alumina and 11.12g of modified pottery clay, then add 1.52g of crushing aid Selina powder, and add 2g of HNO 3 / 100cm 3 The acid solution was mixed and kneaded, extruded into a five-tooth spherical shape, dried at 120°C for 8 hours, and roasted in a muffle furnace for 4 hours at 550°C to obtain the catalyst carrier Z1;

[0058] (2) Weigh 38.94g of ammonium metatungstate, 39.46g of nickel nitrate, and 4.87g of phosphoric acid, and dissolve them in deionized water to form impregnating solutions A 1 , B 1 、C 1 , using equal volume impregnation, the carrier obtained in step (2) was placed in A 1 Immerse at medium and normal temperature for 6 hours, rotate and evaporate on a rotary evaporator for 4 hours under vacuum at 60°C, place in an oven at a constant temperature of 120°C for 8 hours; then put it in a muffle furnace and roast at 500°C for 3 hours, and then impregnate separately ...

Embodiment 2

[0061] (1) Mix 20.64g of Y molecular sieve, 43.91g of β molecular sieve, 186.78g of macroporous alumina and 11.12g of modified clay, then add 1.49g of crushing aid Selina powder, and add 2g of HNO 3 / 100cm 3 The acid solution was mixed and kneaded, extruded into a five-tooth spherical shape, dried at 120°C for 8 hours, and calcined in a muffle furnace for 4 hours at 550°C to obtain the catalyst carrier Z2;

[0062] (2) Weigh 40.10g of ammonium metatungstate, 40.64g of nickel nitrate, and 4.87g of phosphoric acid, and dissolve them in deionized water to form impregnating solutions A 2 , B 2 、C 2 , using equal volume impregnation, the catalyst carrier obtained in step (1) is placed in A 2 Immerse at medium and normal temperature for 6 hours, rotate and evaporate on a rotary evaporator for 4 hours under vacuum at 60°C, place in an oven at a constant temperature of 120°C for 8 hours; then put it in a muffle furnace and roast at 500°C for 3 hours, and then impregnate separately ...

Embodiment 3

[0064] Only the mass content of each component in the catalyst carrier Z3 is different from that in Example 1, see Table 1 for details, and the others are the same as in Example 1. The properties of the obtained hydrocracking catalyst F3 are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com