Cloth coiling block transfer trolley

A cloth reel and transfer car technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of increased workload, damage to carts and take-up rollers, time-consuming, etc., to reduce damage, The effect of improving service life and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

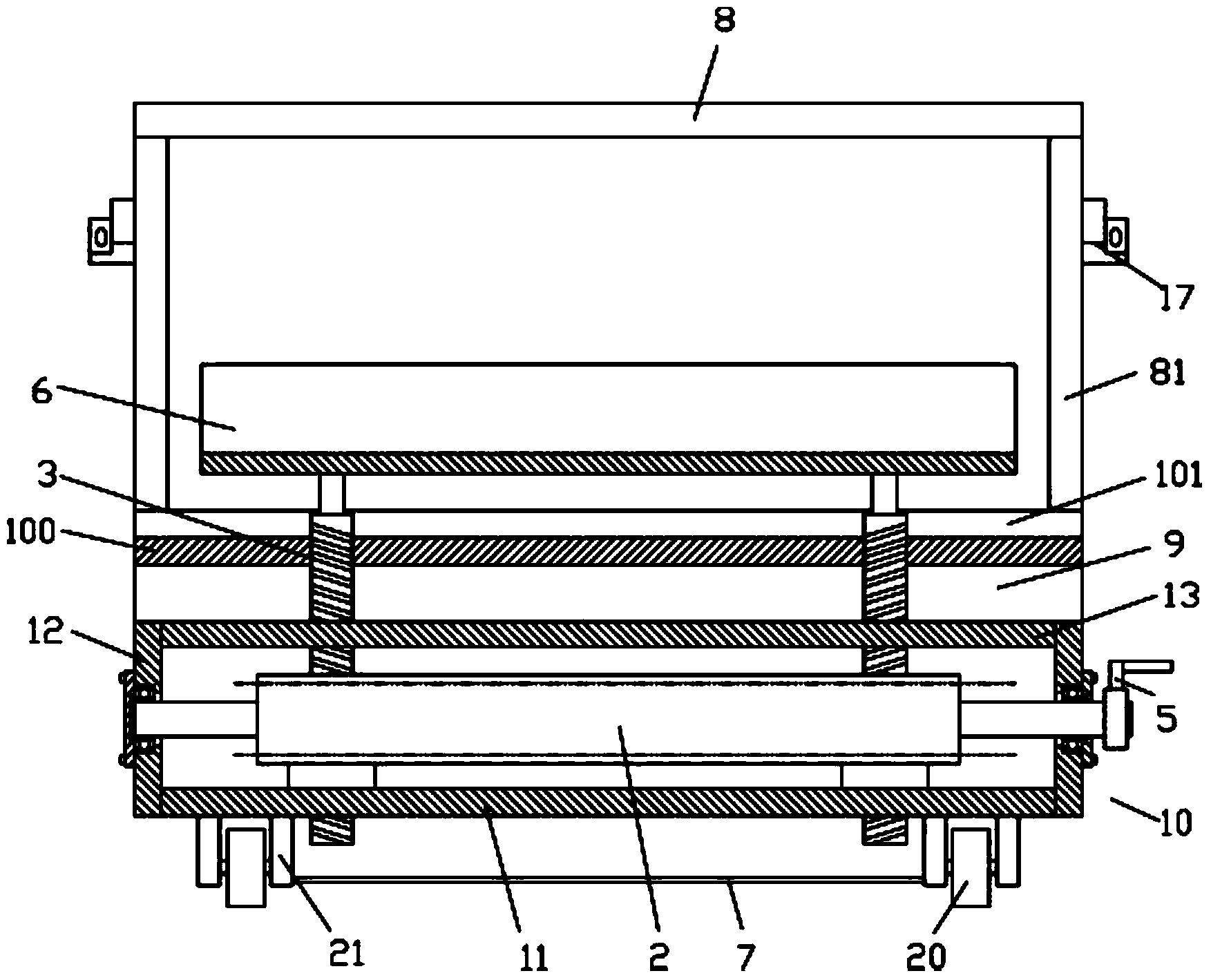

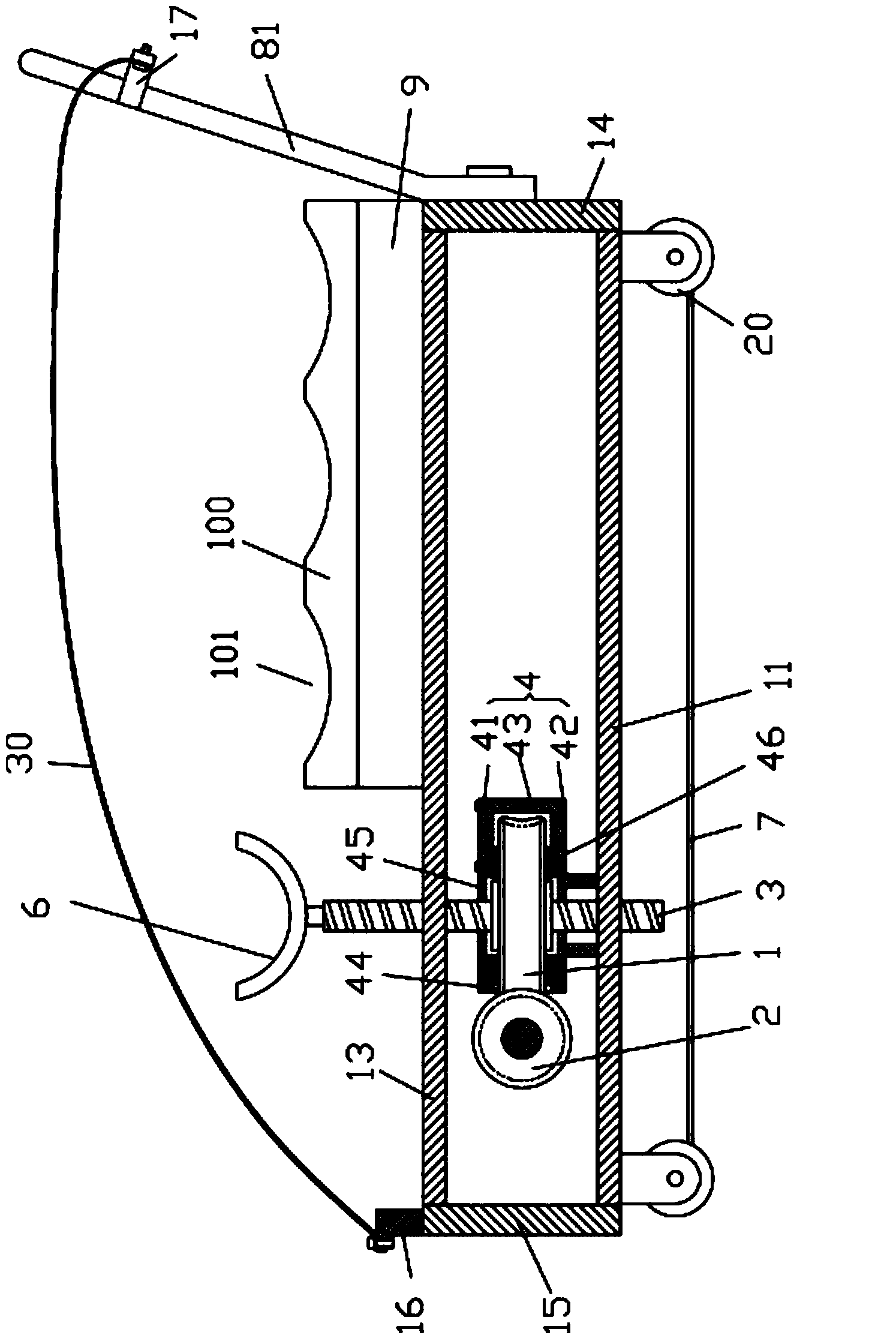

[0016] Example: see Figures 1 to 2 As shown, a cloth reel transfer vehicle includes a bottom box 10 and a wheel assembly 20 fixed on the bottom plate 11 of the bottom box 10. An adjustment assembly is provided in the bottom box 10. The adjustment assembly includes a turbine 1, a worm 2, a screw 3 and the housing 4, the two ends of the worm 2 are hinged on the left and right side panels 12 of the bottom box 10, and one end of the worm 2 protrudes from the left or right side panel 12, on which a rocker 5 is fixed. The structure of the housing 4 is that the upper housing 41 is fixed on the arc-shaped vertical plate 43 formed on the edge of the upper plane of the lower housing 42 to form the housing 4, the side wall of the housing 4 is formed with a gap 44, and the lower housing 42 is formed with a gap 44. The housing 42 is fixed on the upper plane of the base plate 11, the middle part of the upper plane of the lower housing 42 and the middle part of the lower plane of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com