Self circulation array pipe reaction device with efficient mixer and reaction method using same

A technology of reaction device and tubular reactor, which is applied in the field of reactors, can solve the problems of easy side reactions, limited volume, small specific surface area, etc., and achieve the effect of being conducive to market promotion, uniform material mixing, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

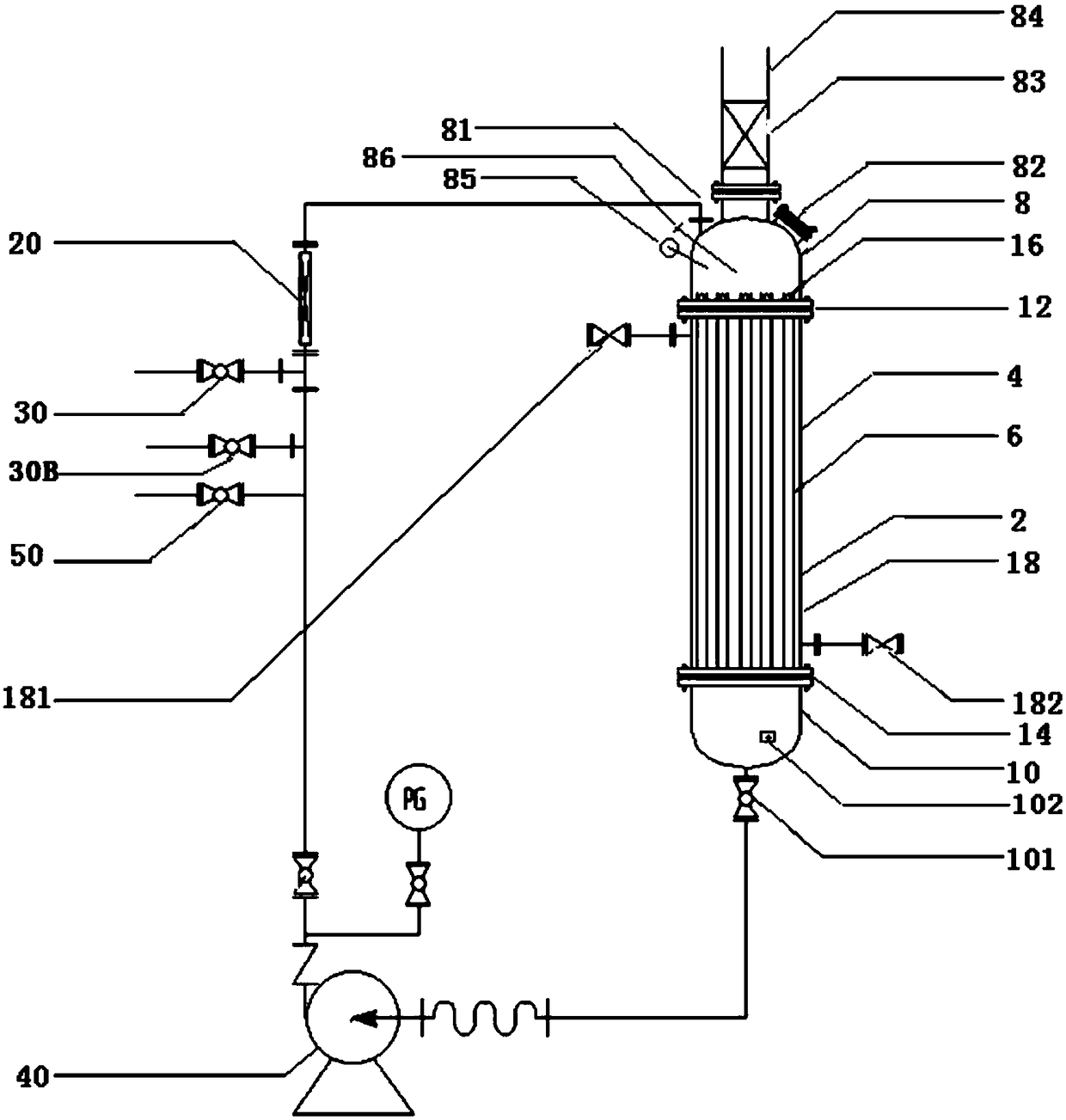

[0148] One, in the self-circulation tubular reaction device with high-efficiency mixer of the present invention:

[0149] There are 25 tubes, the inner diameter of each tube is 1.5cm, and the length of each tube is 50cm (the total volume of the inner diameter of all tubes is calculated as 0.0022m 3 (about 2.2L), heat exchange area 0.589m 2 );

[0150] Upper and lower heads: inner diameter 19.5cm, height 20cm, (the content volume of the upper and lower heads is calculated to be about 0.0059m 3 )

[0151] The total volume of the above is 0.0081m 3 (about 8.1L).

[0152] 2. First explore the reaction situation in the small test. According to the results of the small test, the time for the material to react completely in the reactor is 65 seconds, that is, the residence time of the reaction solution in the tube is set to 65 seconds, so the reaction flux of the material is Tube volume / residence time, that is, 2.2L / (65s / 60)=2.03L / min in this embodiment, that is, the reaction fl...

Embodiment 2

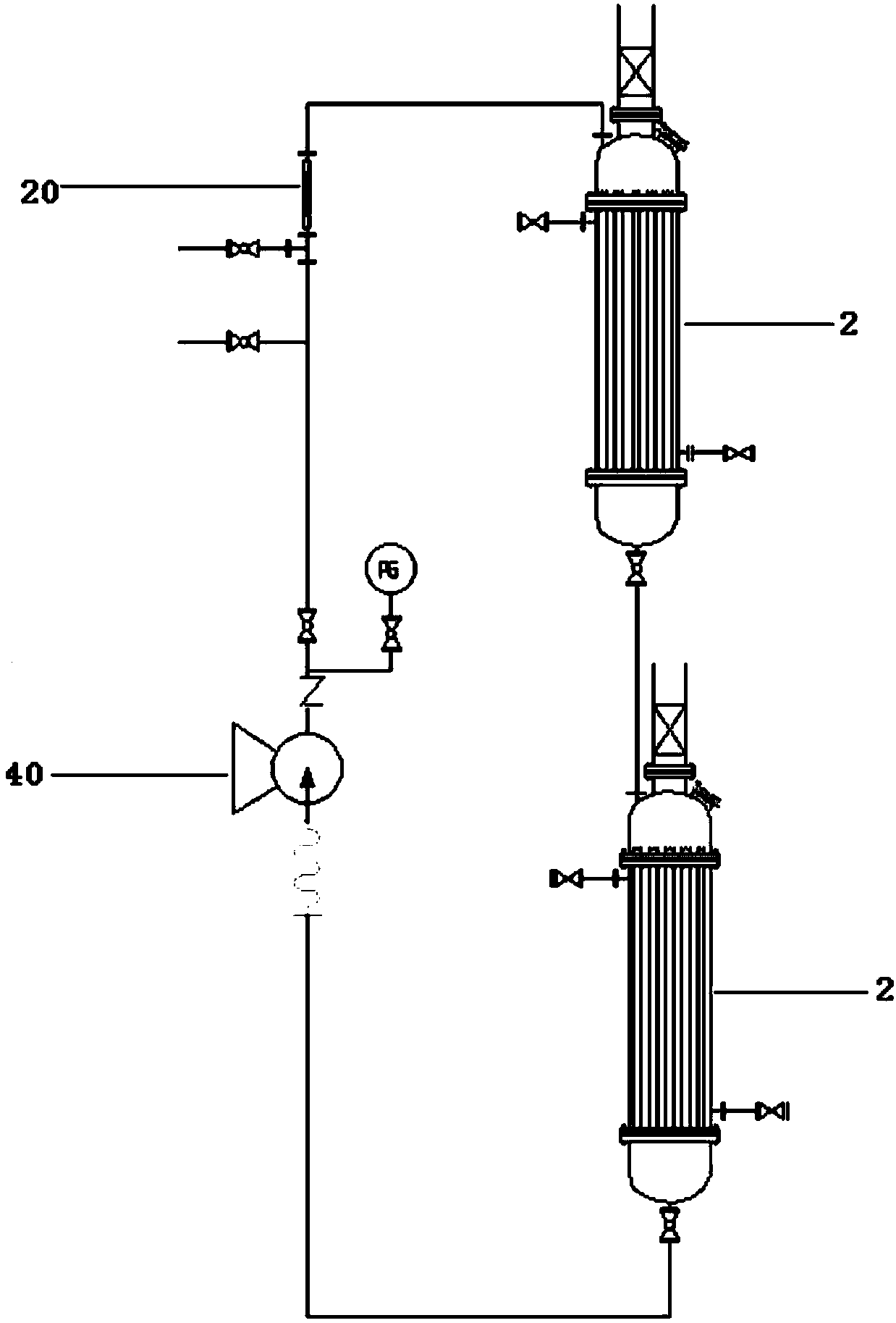

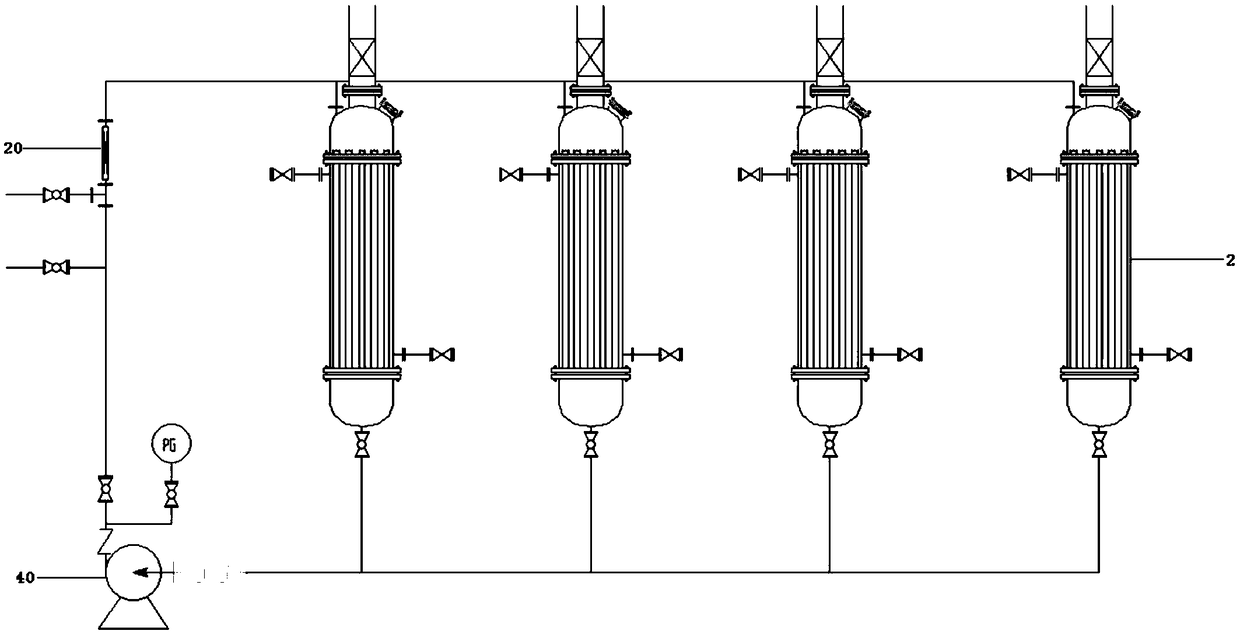

[0172] The reaction apparatus of embodiment 1 is connected in parallel, according to the reaction method of embodiment 1, consume raw material 7-chloro-6-fluoro-1,4-dihydro-4-oxoquinoline-3-carboxylic acid ethyl ester (200kg), The output and yield of the reaction results are twice that of Example 1, the product purity is 99.1%, and the time is 4.40 hours.

Embodiment 3

[0174] The same as the reaction method of Example 1, the difference is that the tube reactor used in Example 3 is a tube reactor with heat transfer fins; the raw material 7-chloro-6-fluoro-1,4-di Hydrogen-4-oxoquinoline-3-carboxylic acid ethyl ester 100kg, the final product obtained was 108.0kg, the purity was 99.5%, the yield was 98.8%, and it took 4.21h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com