CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for alkaline sapphire substrate and preparation method thereof

A sapphire substrate and polishing liquid technology, applied in the field of polishing liquid, can solve the problems of low CMP removal rate, influence on LED production, unstable surface quality, etc., and achieve the effect of improving polishing removal rate, improving surface quality, and low-damage polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of mixed abrasive alkaline sapphire substrate material CMP polishing liquid, described preparation method comprises the following steps:

[0038] a) Take nano-SiO with a particle size of 20nm 2 Sol 931ml, put it into 2000ml deionized water while stirring at room temperature, prepare nano-silica sol suspension, and then take the particle size as 20nmA1 2 o 3 Auxiliary abrasive 60ml, fully stir clockwise while adding, time is 15 minutes, make SiO 2 Sol suspension with A1 2 o 3 The aqueous suspension is fully mixed to form a sapphire polishing liquid with mixed abrasives. The polishing liquid is suspended and has the same particle size;

[0039] b) Then add 3ml of FA / O type I non-ionic surfactant and 6ml of FA / OII type chelating agent in the suspension, stir well while adding, and finally add hydroxyethylethylenediamine to adjust the pH value of the suspension to 12 to obtain a polishing solution; wherein, nano-SiO 2 The mass fraction of ...

Embodiment 2

[0043] A kind of preparation method of mixed abrasive alkaline sapphire substrate material CMP polishing liquid, described preparation method comprises the following steps:

[0044] a) Take nano-SiO with a particle size of 30nm 2 Sol 311ml, put it into 2650ml deionized water while stirring at room temperature, prepare nano-silica sol suspension, and then take the particle size as 30nmA1 2 o 3 Auxiliary abrasive 30ml, fully stir clockwise while adding, time is 20 minutes, make SiO 2 Sol suspension with A1 2 o 3 The aqueous suspension is fully mixed to form a sapphire polishing liquid with mixed abrasives. The polishing liquid is suspended and has the same particle size;

[0045] b) Then add 3ml of FA / O type I non-ionic surfactant and 6ml of FA / OII type chelating agent in the suspension, stir well while adding, and finally add hydroxyethylethylenediamine to adjust the pH value of the suspension to 10 to obtain a polishing solution; wherein, nano-SiO 2 The mass fraction ...

Embodiment 3

[0049] A kind of preparation method of mixed abrasive alkaline sapphire substrate material CMP polishing liquid, described preparation method comprises the following steps:

[0050] a) Take nano-SiO with a particle size of 40nm 2 Sol 465ml, put it into 2500ml deionized water while stirring at room temperature, prepare nano-silica sol suspension, and then take the particle size as 40nmA1 2 o 3 Auxiliary abrasive 30ml, fully stir clockwise while adding, time is 25 minutes, make SiO 2 Sol suspension with A1 2 o 3 The aqueous suspension is fully mixed to form a sapphire polishing liquid with mixed abrasives. The polishing liquid is suspended and has the same particle size;

[0051] b) Then add 2ml of FA / O type I non-ionic surfactant and 3ml of FA / OII type chelating agent in the suspension, stir well while adding, and finally add hydroxyethylethylenediamine to adjust the pH value of the suspension to 13 to obtain a polishing solution; wherein, nano-SiO 2 The mass fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

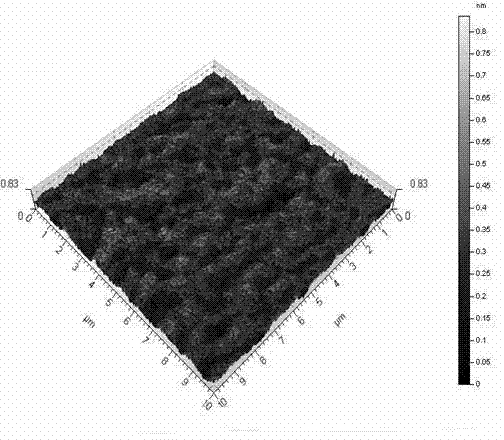

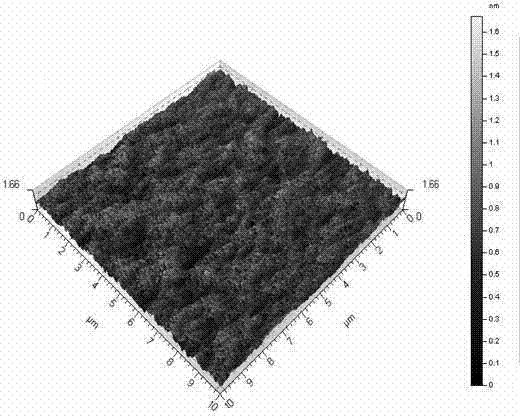

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com