Method and installation for treating wastewater containing ammonia

A technology of equipment and process, which is applied in the field of process and equipment for treating ammonium-containing wastewater, and can solve problems such as performance degradation of autotrophic denitrification equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

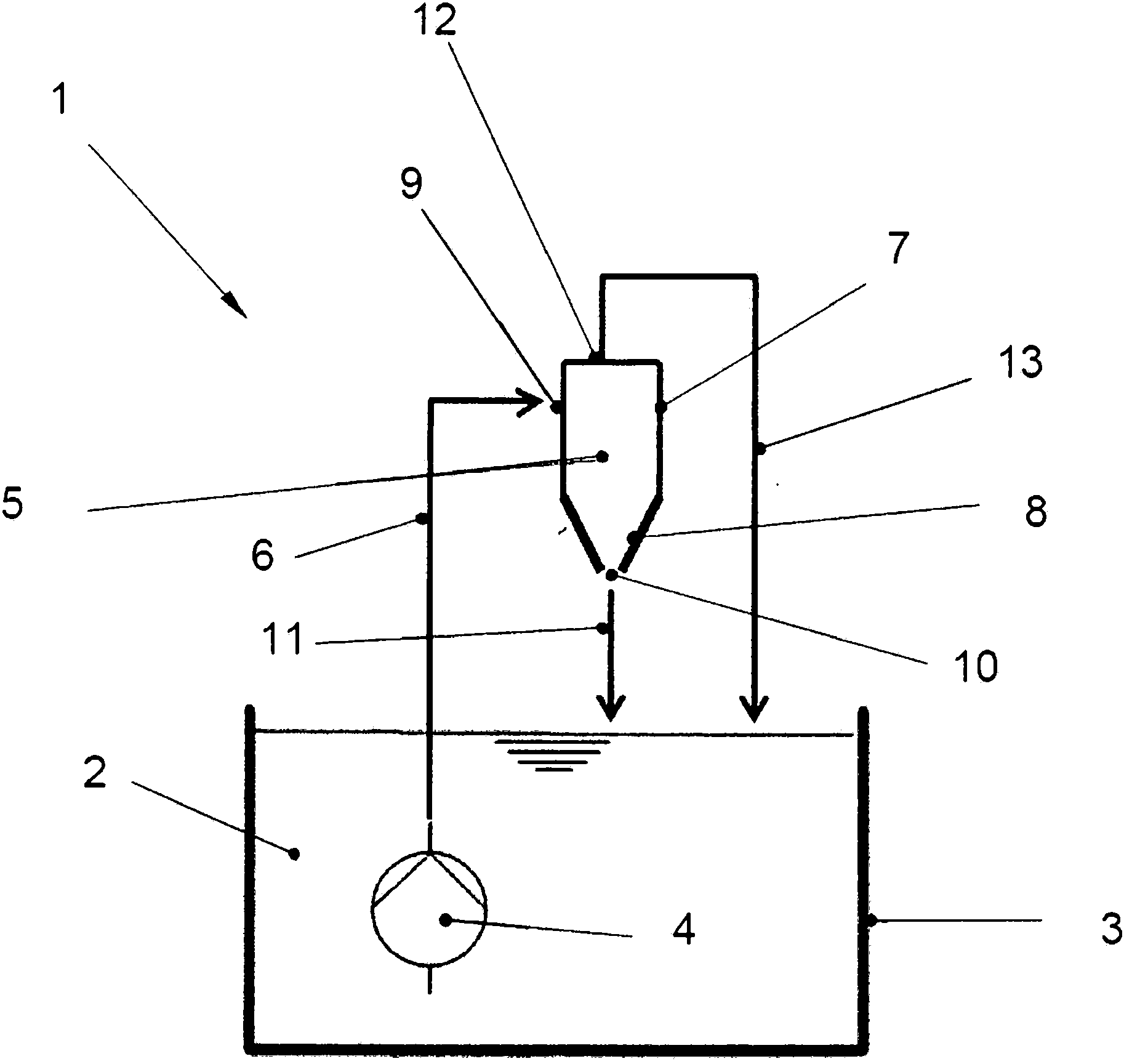

[0052] figure 1A whole autotrophic denitrification device 1 for treating ammonium-containing wastewater 2 is shown. The plant 1 can be configured as an SBR plant (sequencing batch reactor), or as a conventional activation plant with secondary purification or as a so-called membrane plant with a membrane for holding biomass. The plant 1 has at least one activation tank 3 in which the waste water 2 is mixed with suspended biomass or activated sludge and in intimate contact.

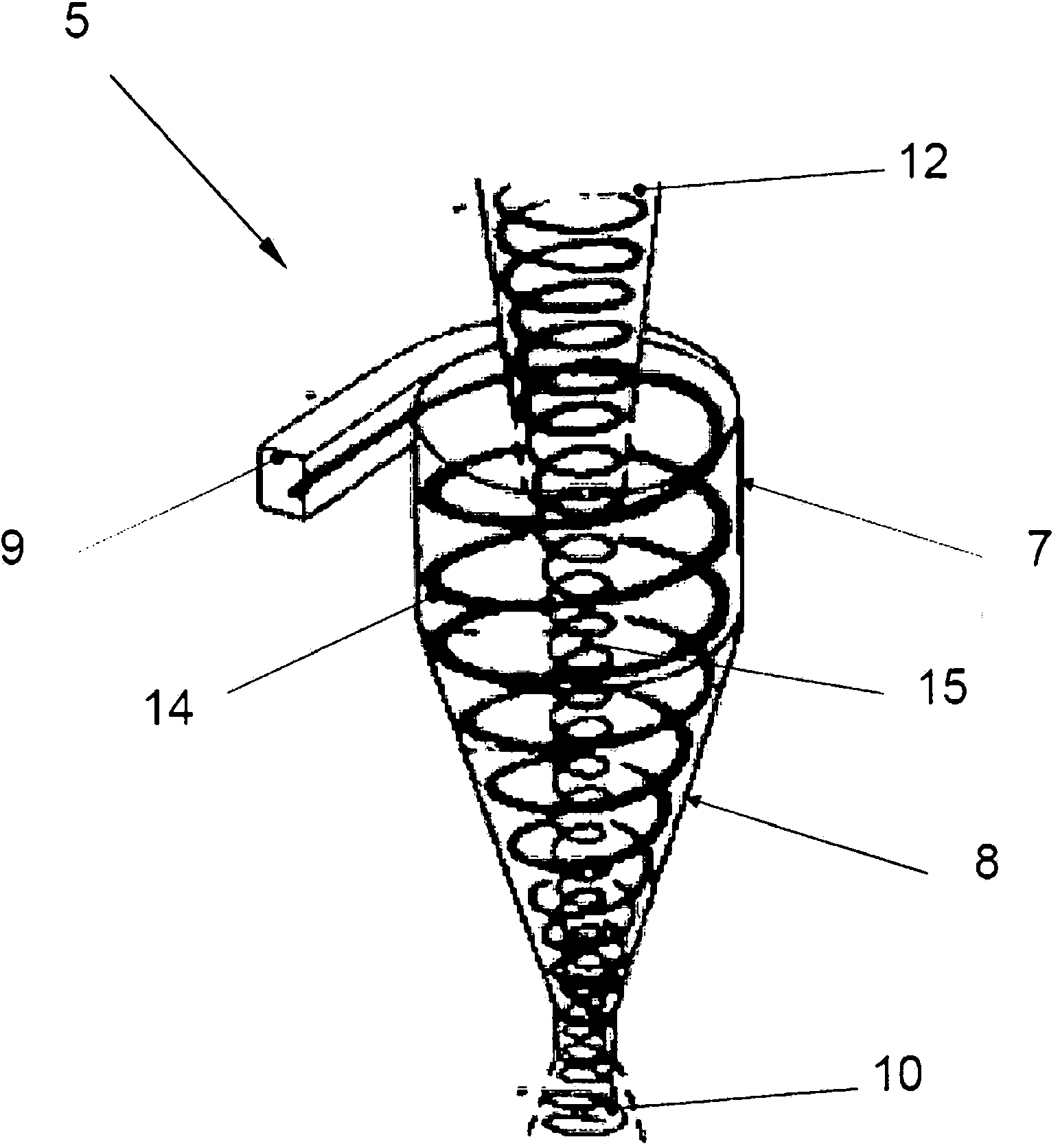

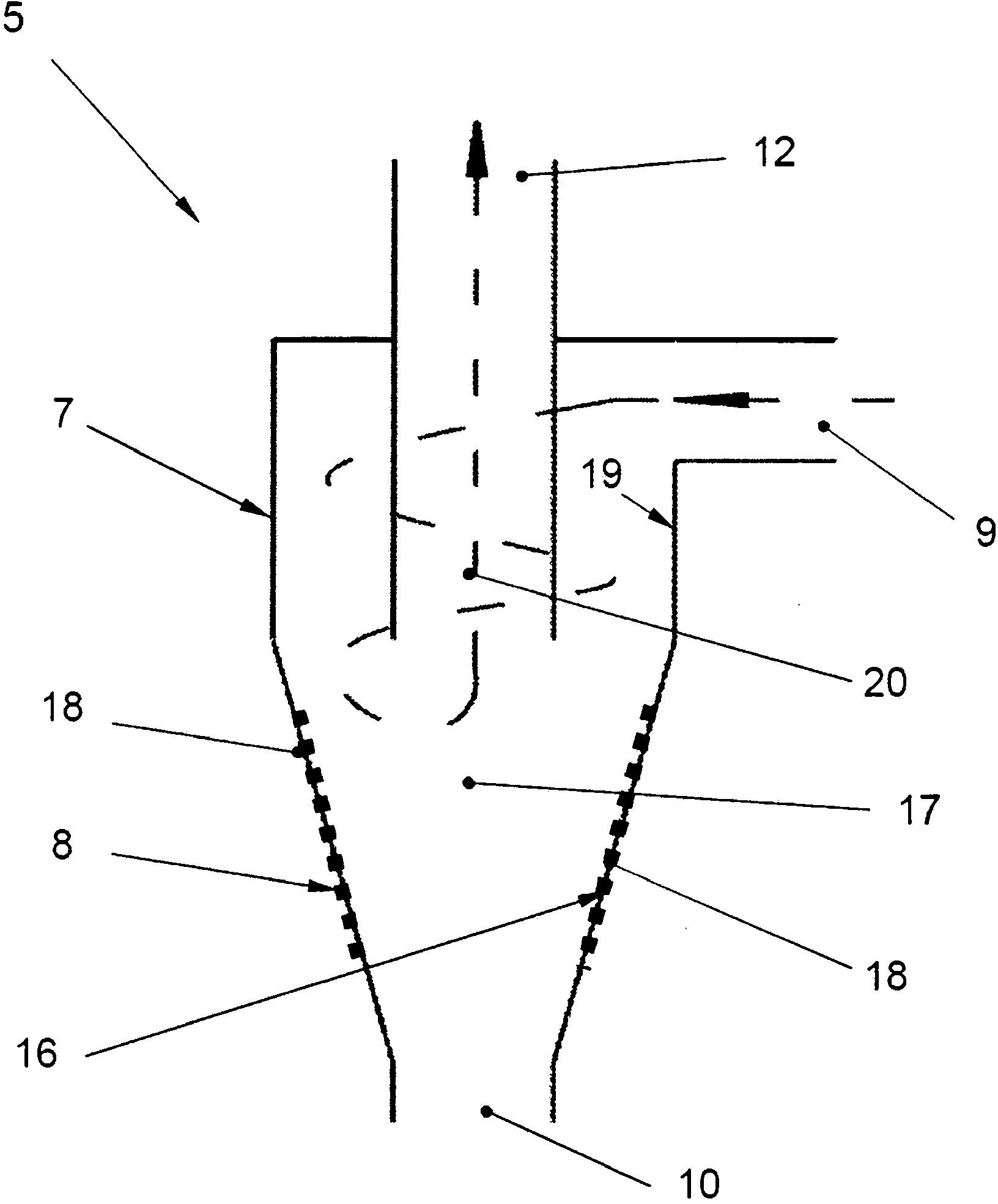

[0053] Activated sludge consisting of a sludge-water mixture is supplied from the activation tank 3 to the hydrocyclone 5 by means of the pump 4 (direction arrow 6 ). The hydrocyclone 5 has a cylindrical section 7 and a conical section 8 . The cylindrical section 7 has a diameter between 50 mm and 250 mm. The hydrocyclone 5 is filled by the pump 4 with a delivery pressure which, depending on the diameter of the cylindrical section 7 of the hydrocyclone 5 , is between 1.1 bar and 2.1 bar. Via a feeder 9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com