Preparation and application of a composite nanofiber fresh-keeping film

A composite nanofiber and plastic wrap technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as inability to kill harmful microorganisms, affect children's intellectual development, and inability to prevent spoilage of fruits and vegetables, and achieve a safe and controllable production process. Good water permeability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

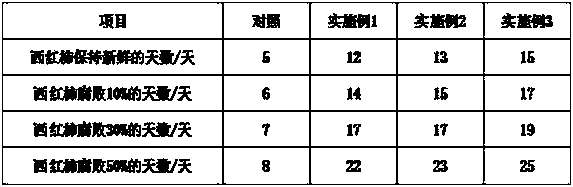

Embodiment 1

[0020] A kind of composite nanofiber preservative film preparation, comprises the following steps:

[0021] 1) Accurately weigh 0.4 parts of chitosan and dissolve it into 20 parts of 10% acetic acid solution, stir until completely dissolved; additionally weigh 0.108 parts of D-(+)-threose and 0.012 parts of D-(-)-threose in In the reaction vessel, add 30 parts of distilled water and slowly add 2.0 parts of 25% glutaraldehyde solution for stirring, place in a microwave reactor, and heat reaction under microwave radiation conditions; add chitosan acetic acid solution, and heat reaction under microwave radiation conditions After natural cooling, add 2 volumes of 3% sodium hydroxide solution to soak for 5 hours and then suction filter, then wash with acetone, ether, ethanol, distilled water until neutral, dry at low temperature to obtain modified chitosan; modified chitosan synthesis The rate is fast, the conversion rate is high, and microwave radiation is helpful for modification...

Embodiment 2

[0023] A preparation and application of a composite nanofiber fresh-keeping film, including: microwave synthesis of modified chitosan, preparation of spinning solution, composite spinning, and application, specifically including the following steps:

[0024] Microwave synthesis of modified chitosan: accurately weigh 0.42 parts of chitosan and dissolve in 25 parts of 12% acetic acid solution, stir until completely dissolved; additionally weigh 0.09 parts of D-(+)-threose, 0.010 parts of D- (-)-threose in a reaction vessel, add 50 parts of distilled water and slowly add 2.2 parts of 35% glutaraldehyde solution for stirring, place in a microwave reactor, 300W microwave radiation power, 42 ℃, 350rmp heating and stirring reaction 30 minutes; add chitosan acetic acid solution, under 300W microwave radiation power, heat and stir at 35°C and 230rmp for 40 minutes, then cool naturally, add 3 volumes of 5% sodium hydroxide solution, soak for 8 hours, and then filter with acetone , ether...

Embodiment 3

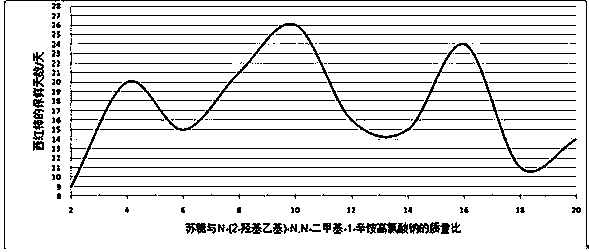

[0028] A kind of composite nanofiber preservative film preparation and its application, on the basis of the used implementation steps and data of embodiment 2, in the microwave synthesis step of modified chitosan, join in the reaction vessel along with chitosan acetic acid solution, At the same time, 0.005 parts of N-(2-hydroxyethyl)-N,N-dimethyl-1-octylammonium sodium perchlorate was added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com