High-purity nickel-based high-temperature alloy and preparation method of spherical powder of high-purity nickel-based high-temperature alloy

A technology of nickel-based superalloy and spherical powder, which is applied in the fields of laser cladding, additive manufacturing and high-end repair. It can solve the problems of inability to guarantee high purity, poor welding performance, and insufficient sphericity, and achieve a safe and controllable production process. , good fluidity, high bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A high-purity nickel-based superalloy, the alloy is composed of the following components by weight: 0.005 parts of C, 14.5 parts of Cr, 2.4 parts of Mo, 4 parts of Nb, 0.65 parts of Ti, and 1.4 parts of Al, Fe is 7 parts, Co is 8.5 parts, W is 0.8 parts, P is 0.002 parts, Ni is 50 parts, S is 0.0020 parts, Si is 0.05 parts, Mg is 0.002 parts, Mn is 0.02 parts, Cu is 0.05 parts, O is 0.0009 parts, and N is 0.001 parts.

[0041] The preparation method of the high-purity nickel-based superalloy composed of the above raw materials in parts by weight is as follows:

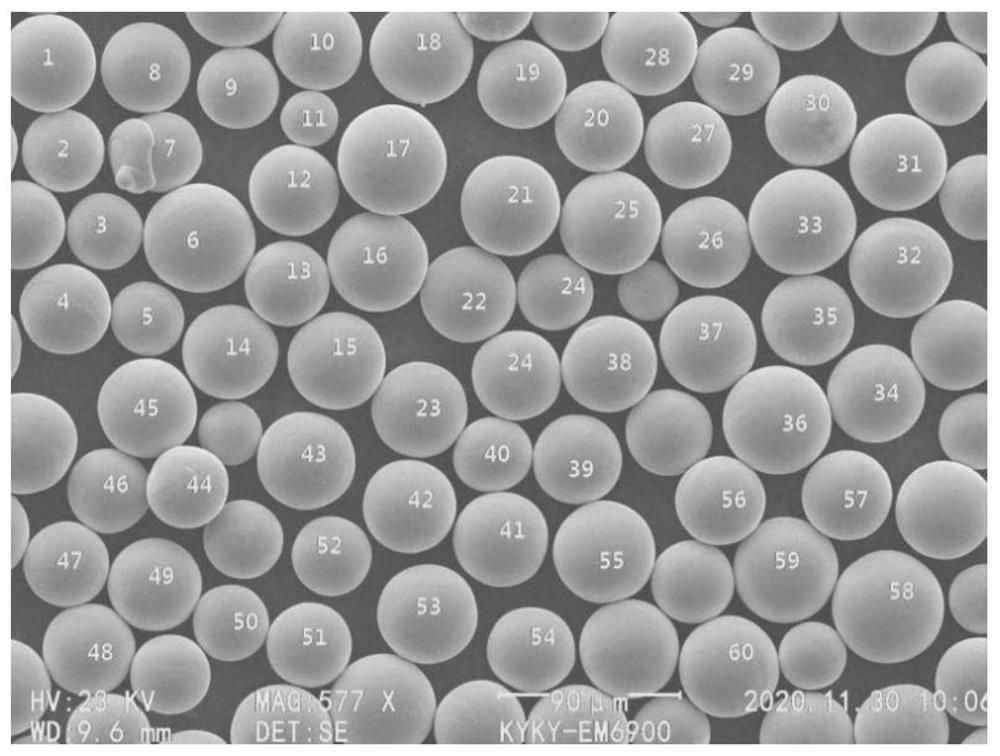

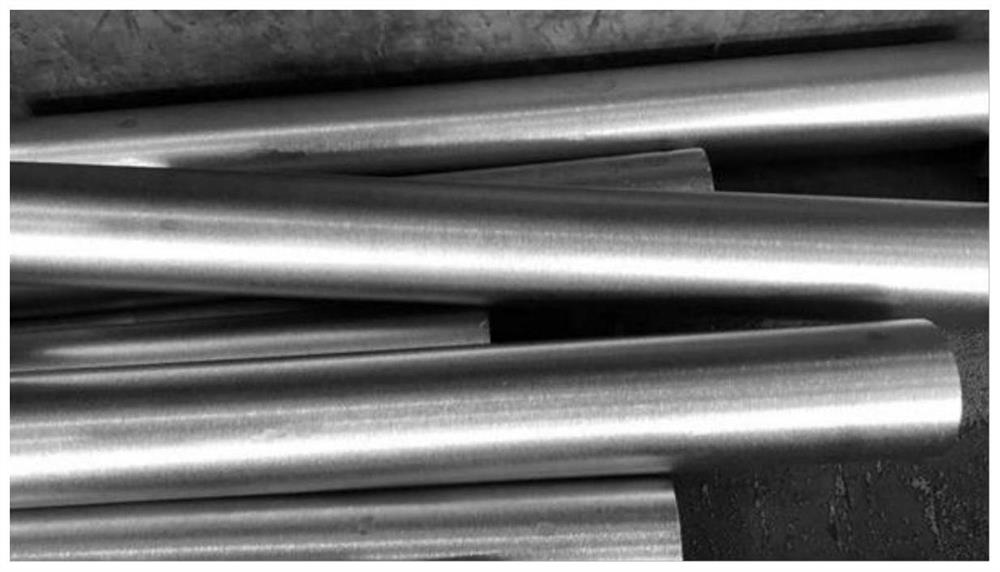

[0042] Step 1, batching, wherein, oxygen and nitrogen are used as interstitial elements, and the content is all ≤ 10ppm; all components are placed in a vacuum induction suspension melting furnace for alloy melting, and after the melting is completed, they are poured into steel ingot mold tubes to make steel ingots, and steel ingot mold tubes The diameter is 40-70mm, the length is 500-800mm, such as figure 1 sh...

Embodiment 2

[0050] According to the steps of Example 1, wherein step 3 adopts step 3', adopts PREP plasma rotating electrode atomization powder making equipment to process and make powder on the bar to obtain metal powder, specifically:

[0051] Step 3-1', start the electrode rotating motor of the PREP plasma rotating electrode atomization powder making equipment, use a plasma gun to melt the rod to form metal droplets; wherein, the speed of the rod is 10000-30000r / min, the speed of the rod Feeding speed 30-120mm / min, plasma arc current intensity 1000-3000A, plasma working gas flow rate 50-100L / min, distance between plasma and rod end 10-30mm;

[0052] Step 3-2', the molten metal droplets condense into spherical powder and fall into the powder collection system;

[0053] During the pulverization process in step 3', the inert protective gas is automatically charged and discharged, so that the interior of the PREP plasma rotating electrode atomization pulverization equipment is always in a ...

Embodiment 3

[0056] A high-purity nickel-based superalloy, the alloy is composed of the following components by weight: 0.015 parts of C, 19 parts of Cr, 2.5 parts of Mo, 5.8 parts of Nb, 0.71 parts of Ti, and 1.5 parts of Al, Fe is 9.8 parts, Co is 9 parts, W is 1 part, P is 0.02 parts, Ni is 61 parts, S is 0.0020 parts, Si is 0.05 parts, Mg is 0.002 parts, Mn is 0.02 parts, Cu is 0.05 parts, O is 0.0009 part, and N is 0.001 part; the preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com