Device for producing expandable polystyrene by bulk method

A technology of expanded polystyrene and body, which is applied in transportation and packaging, chemical instruments and methods, chemical/physical/physicochemical processes, etc., and can solve the problems of high energy consumption, poor product stability, and high labor intensity in batch polymerization processes , to achieve the effect of excellent appearance, less oligomer and impurity content, and low residual monomer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

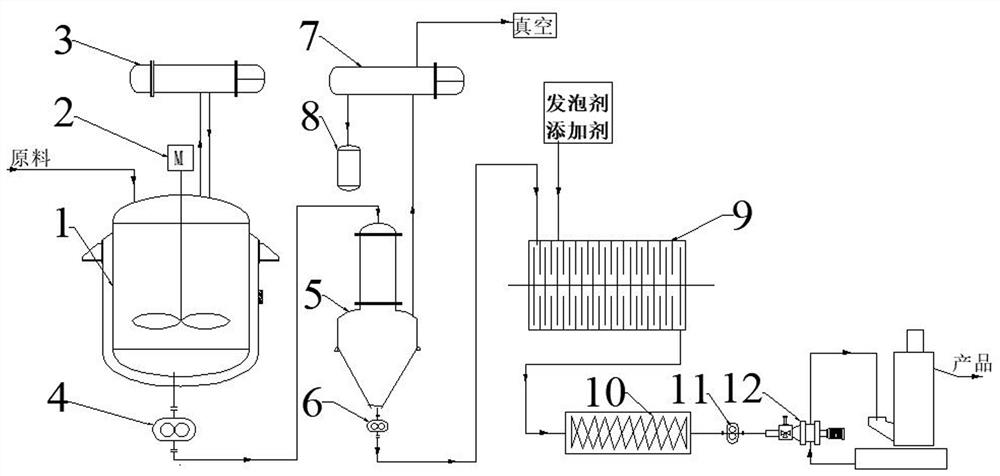

[0028] figure 1 It is the process flow diagram of the production of foamable polystyrene by the ontology method of the patent. The device used for producing the foamable polystyrene in this specific embodiment includes: a polymerization reaction unit (1), a head set on the polymerization reaction unit (1). There is a material inlet, and a reaction stirrer (2) is installed in the middle, which is also connected to the condenser (3). The upper end of the volatilizer (5) is connected with a condenser (7), and the condenser (7) is connected to the vacuum liquid collecting tank (8); the heating devolatilizer (5) is connected to the mixer (9) and the melt through the pump (6) below. The heat exchanger (10) is connected, and the melt heat exchanger (10) is connected with the high-pressure underwater pelletizing system (12) through a pump (11).

[0029] The polymerization reaction unit (1) adopts a reactor. During operation, according to the following weight parts, 92.5 kg of styrene...

Embodiment 2

[0038] In this example, on the basis of Example 1, the polymerization reaction unit (1) adopts two reactors connected in series, and a third fluid, namely the flame retardant polystyrene masterbatch interface, is added at the front inlet of the mixer (9). The third fluid is flame retardant polystyrene masterbatch, which contains 0.7kg of flame retardant. The third stream of fluid flame retardant polystyrene masterbatch is extruded and input to the front inlet of the mixer (9) and the first stream of fluid polystyrene, and the second stream of fluid foaming agent into the dynamic mixer (9) After shearing and mixing evenly, it is cooled down to the material temperature of 205 ℃ by the melt heat exchanger (10), and then input to the high-pressure underwater pelletizing system (12) by the pump (11) to be pelletized and dried to obtain the finished flame-retardant expandable polyphenylene vinyl pellets. After testing, the oxygen index of flame-retardant expandable polystyrene reac...

Embodiment 3

[0046] On the basis of Example 1, the polymerization reaction unit (1) used in this example adopts 5 reactors connected in series, and a third fluid, that is, polyphenylene containing graphite and flame retardant, is added at the front inlet of the mixer (9). Vinyl masterbatch interface, which contains 2.0kg of graphite and 0.3kg of flame retardant. The third stream of fluid flame retardant polystyrene masterbatch is extruded and input to the front inlet of the mixer (9) and the first stream of fluid polystyrene, and the second stream of fluid foaming agent into the dynamic mixer (9) After shearing and mixing evenly, it is cooled down to the material temperature of 205°C by the melt heat exchanger (10), and then input to the high-pressure underwater pelletizing system (12) by the pump (11) for granulation and drying into finished graphite-type expanded polystyrene particles . After testing, the oxygen index of flame-retardant expandable polystyrene reaches 32, which meets the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com