Impact polystyrene with capacity scale of 50,000 tons or above as well as equipment and production process of impact polystyrene

A technology of impact-resistant polystyrene and polystyrene, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as insufficient impact resistance and mechanical properties, and achieve good environmental protection effects , less risk, good apparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

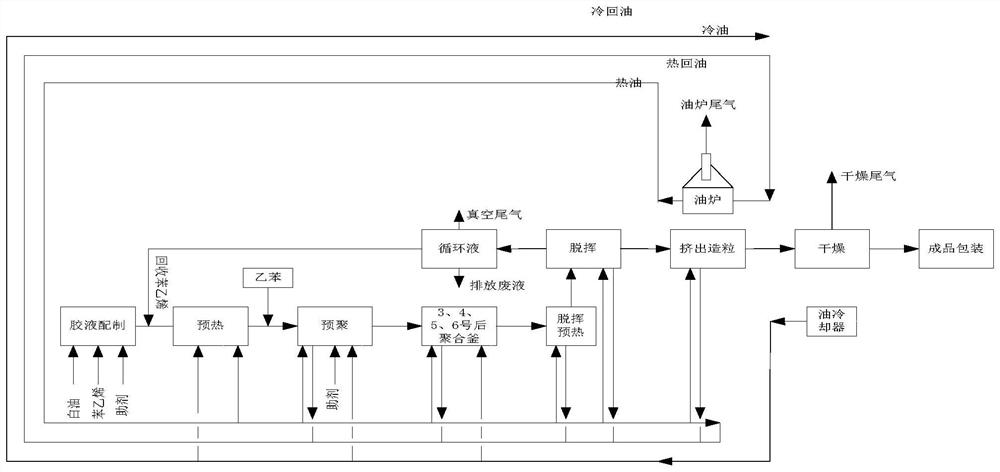

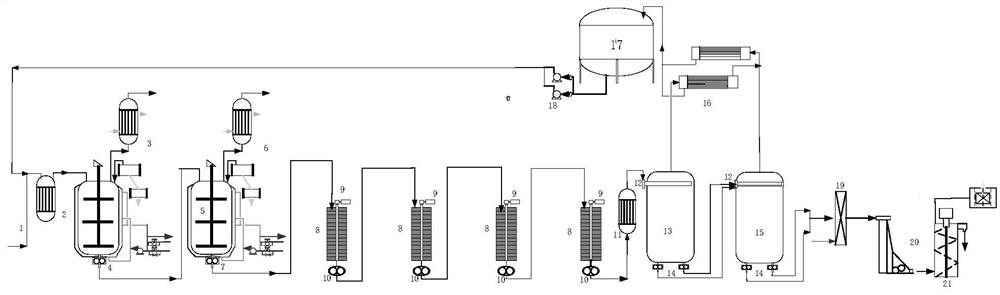

[0031] Below in conjunction with accompanying drawing, the present invention will be further described

[0032] The invention provides a kind of impact polystyrene with a production capacity above 50,000 tons, and the formula of the impact polystyrene includes:

[0033] A. Styrene: purity greater than 99.9%, colorless transparent liquid, dosage 0.960-0.990;

[0034] B. Industrial white oil: a colorless transparent liquid with a flash point greater than 240 degrees, and the dosage is 0.015-0.025;

[0035] C. Internal and external lubricants: paraffin wax, zinc stearate, calcium stearate, stearic acid amide, oleic acid amide, the appearance is white particles or powder, the purity is greater than 99.8%, and it needs to be used in combination of 2-3 kinds. The dosage is 0.001-0.005;

[0036]D. Antioxidant: BHT, Irganox1076, Irganox1010, Irganox1330, use 2 kinds of compounds according to the needs, the dosage is 0.001-0.005;

[0037] E. Polybutadiene rubber: dosage 0.030-0.060;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com