Technique for preparing phosphorus pentafluoride

A preparation process, a technology of phosphorus pentafluoride, applied in the direction of phosphorus halide/oxyhalide, etc., can solve the problems of difficulty in obtaining high-purity target products, enhanced corrosion of equipment, and a large amount of impurities in products, and achieves simple process and equipment structure. , The effect of simple reaction process and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

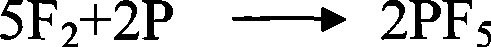

Image

Examples

Embodiment 1

[0035] First add 25 kg of red phosphorus to the horizontal gas-solid reaction device in advance, vacuumize, control the pressure in the kettle to be less than 0.1MPa, and slowly introduce fluorine gas under the condition that the reaction temperature is lower than 300°C, and the pentafluoride produced by the reaction The phosphorus gas passes through the precooler and is cooled to -45°C, then introduces phosphorus pentafluoride gas into the rectification tower at a rate of 10mol / hour, and controls the temperature of the reboiler in the rectification tower to be -35°C. The temperature of the condenser is -75 DEG C, and the total reflux is maintained for 2 hours. After reaching equilibrium, the reflux ratio is controlled to be 5:1, and the product obtained by rectification and separation is sampled and analyzed for the purity of phosphorus pentafluoride to be 99.5%.

Embodiment 2

[0037] First add 15 kg of red phosphorus to the horizontal gas-solid reaction device in advance, vacuumize, control the pressure in the kettle to be less than 0.25MPa, and slowly introduce fluorine gas under the condition that the reaction temperature is lower than 400°C, and the pentafluoride produced by the reaction The phosphorus gas passes through the precooler and is cooled to -55°C, then introduces phosphorus pentafluoride gas into the rectification tower at a rate of 10mol / hour, and controls the temperature of the reboiler in the rectification tower to be -40°C. The temperature of the condenser is -85 DEG C, and the total reflux is maintained for 2 hours. After reaching equilibrium, the reflux ratio is controlled to be 1:1, and the product obtained by rectification separation is sampled and analyzed to have a purity of 99.9% of phosphorus pentafluoride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com