Lithium difluorobisoxalate phosphate preparation method, non-aqueous electrolyte and battery

A technology of difluorobis-oxalate lithium phosphate and bis-oxalate lithium phosphate, which is applied to non-aqueous electrolyte batteries, secondary batteries, lithium batteries, etc. , the product is difficult to purify and other problems, to achieve the effect of simple process, small internal resistance and electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

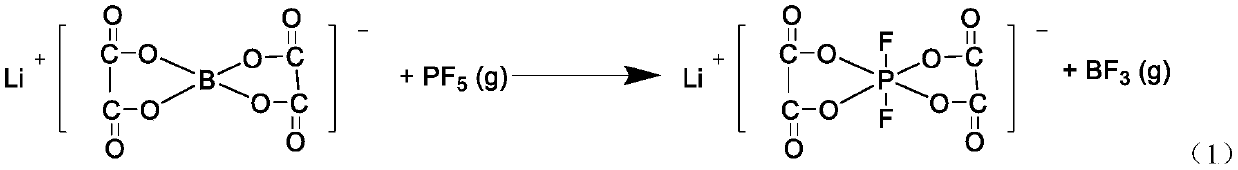

Method used

Image

Examples

Embodiment 1

[0037] In a glove box, take 30 g of synthesized lithium bisoxalate borate with a moisture content below 200 ppm in a 500 mL three-necked flask, and add 309 mL of acetonitrile with a moisture content below 50 ppm dried over molecular sieves. Move it out of the glove box, immerse it in the set 60°C oil bath and stir it well, when the temperature in the flask is 60°C, pass into phosphorus pentafluoride gas (make the mixture of bisoxalate lithium borate and phosphorus pentafluoride The molar ratio is 1:1.05), and the total feeding time is controlled within 2-3 hours. After the gas feeding is completed, continue to stir for 2 hours to react. After the reaction is completed, remove insoluble impurities by filtration to obtain a lithium difluorobisoxalate phosphate solution. After vacuum distillation at 90-110°C, dichloromethane is added to the concentrated solution for crystallization to obtain a crude product of lithium difluorobisoxalate phosphate. Dry in a vacuum drying oven at a...

Embodiment 2

[0039]In the glove box, take 35.8 g of synthesized lithium bisoxalate borate with a moisture content below 200 ppm in a 250 mL three-necked flask, and add 185 ml of acetonitrile with a moisture content below 50 ppm dried with molecular sieves. Move it out of the glove box, immerse it in the set 80°C oil bath and stir it fully. When the temperature in the flask is 80°C, pass in phosphorus pentafluoride gas (make the mixture of bisoxalate lithium borate and phosphorus pentafluoride The molar ratio is 1:2), and the total feeding time is controlled at 2-3 hours. After the gas feeding is completed, continue to stir for 2 hours to react. After the reaction is completed, remove insoluble impurities by filtration to obtain a lithium difluorobisoxalate phosphate solution. After vacuum distillation at 90-110°C, dichloromethane is added to the concentrated solution for crystallization to obtain a crude product of lithium difluorobisoxalate phosphate. Dry in a vacuum drying oven at a temp...

Embodiment 3

[0041] In a glove box, take 36.5 g of synthesized lithium bisoxalate borate with a moisture content below 200 ppm in a 250 mL three-necked flask, and add 125 ml of tetrahydrofuran with a moisture content below 30 ppm dried with molecular sieves. Move it out of the glove box, immerse it in the set 80°C oil bath and stir it fully. When the temperature in the flask is 80°C, pass in phosphorus pentafluoride gas (make the mixture of bisoxalate lithium borate and phosphorus pentafluoride The molar ratio is 1:2.5), and the total feeding time is controlled at 2-3 hours. After the gas feeding is completed, continue to stir for 2 hours to react. After the reaction is completed, remove insoluble impurities by filtration to obtain a lithium difluorobisoxalate phosphate solution. After vacuum distillation at 90-110°C, dichloromethane is added to the concentrated solution for crystallization to obtain a crude product of lithium difluorobisoxalate phosphate. Dry in a vacuum drying oven at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com