System and method for preparing high-purity phosphorus pentafluoride

A phosphorus pentafluoride, high-purity technology, applied in the direction of phosphorus halide/oxyhalide, etc., can solve the problems of target product performance degradation, PF cannot be completely separated, and water cannot be completely removed, so as to avoid the interference of water and the secondary Secondary pollution, the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

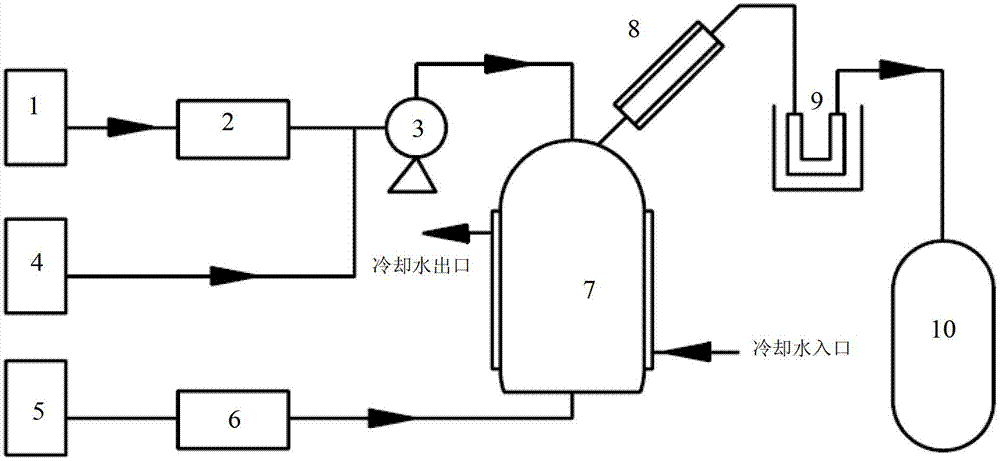

Image

Examples

Embodiment 1

[0045] Example 1: 10mol of PCl 3 After the container is dehydrated by the first dryer, it enters the atomizing pump and is sprayed in a mist form from the top of the reactor. PCl sprayed as mist 3 with Al 2 o 3 Dry 11mol Cl 2 After contact, it reacts quickly to generate PCl 5 , by adjusting the flow of cooling water in the jacket of the reactor, the temperature in the reactor was maintained at 130°C. PCl 5 After the preparation is completed, 50mol anhydrous HF enters the reactor through the atomization pump, and the sprayed HF and the PCl condensed on the reactor wall 5 After contact, react quickly to generate PF 5 ; gaseous reactant HF and reaction products HCl and PF 5 After passing through the primary condenser at -40°C, HF will be condensed and returned to the jacketed reactor to continue the reaction. HCl and PF 5 into the secondary condenser at -80°C, PF 5 It will be condensed and stored in the condenser, and HCl will enter the exhaust gas discharge tower throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com