Method and device for continuous preparation of lithium hexafluorophosphate

A lithium hexafluorophosphate and separation device technology, applied in lithium hexafluorophosphate, chemical instruments and methods, lithium compounds, etc., can solve problems such as high equipment requirements and difficult processes, and achieve large cryogenic loss, eliminate large power consumption, and large particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

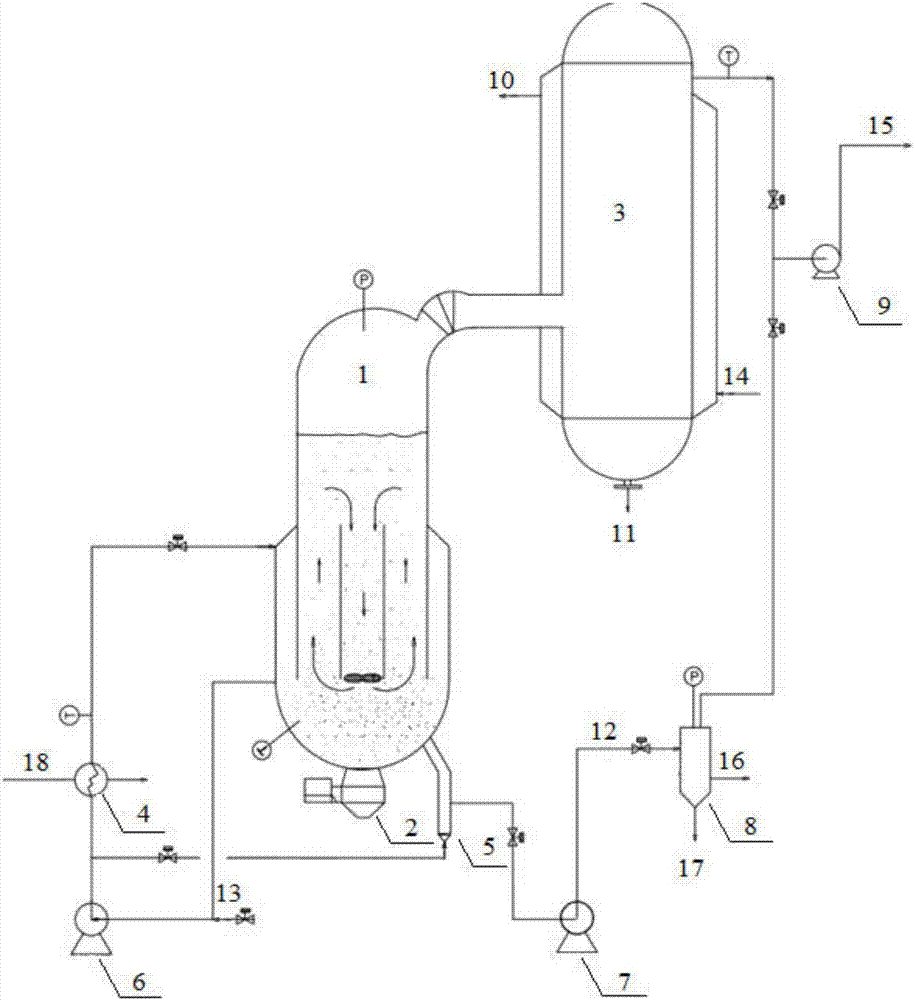

Method used

Image

Examples

Embodiment 1

[0061] A. Synthetic liquid heating up

[0062] Lithium hexafluorophosphate synthetic liquid (6000L / h, temperature 10°C, concentration 20%) from the liquid pump of the synthetic liquid storage tank enters the crystallizer together with the mother liquor (2000L / h, temperature 30°C, concentration 5%) The inlet of the circulation pump is pressurized to 0.15MPa by the external circulation pump and then enters the steam heater, and the mixed solution is heated to 45°C-50°C and enters the crystallizer (concentration is about 16%).

[0063] B. Stirring cycle inside the crystallizer

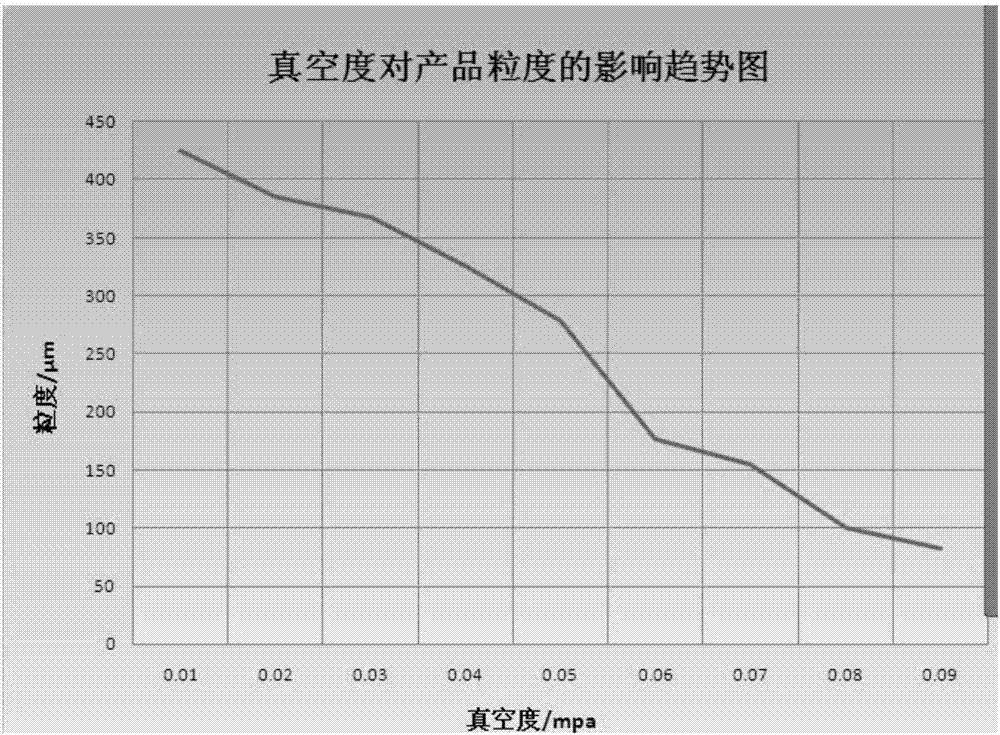

[0064] The mixed liquid entering the crystallizer, under the action of the magnetic stirrer, circulates along the circulation channel formed by the guide tube, and controls the negative pressure in the crystallizer to be between -15kPa~-25kPa, and the boiling liquid level is to produce supersaturation Area, with the help of evaporation, becomes a supersaturated solution and contacts the crystals in the c...

Embodiment 2

[0072] The specific process is the same as in Example 1, except for the following differences:

[0073] The feed temperature of the synthetic liquid in A is 5°C; the heating temperature of the synthetic liquid is 55°C;

[0074] The negative pressure in B is -25kPa;

[0075] The temperature of the refrigerant in C is -5°C; the refrigerant is 60wt% ethylene glycol aqueous solution;

[0076] The vacuum degree during condensation is -50kp;

[0077] The pressure at the time of separation in E is -10kPa.

[0078] The resulting high-quality lithium hexafluorophosphate has moisture ≤ 2.8ppm, acid ≤ 59ppm, insoluble matter ≤ 130ppm, and iron ≤ 2.4ppm.

Embodiment 3

[0080] The specific process is the same as in Example 1, except for the following differences:

[0081] The feed temperature of the synthetic liquid in A is 15°C; the heating temperature of the synthetic liquid is 40°C;

[0082] The negative pressure in B is -50kPa;

[0083] The temperature of the refrigerant in C is -20°C; the refrigerant is 15wt% ethylene glycol aqueous solution;

[0084] The vacuum degree during condensation is -40kPa;

[0085] The pressure at the time of separation in E is 0 kPa.

[0086] The resulting high-quality lithium hexafluorophosphate has moisture ≤ 3.4ppm, acid ≤ 65ppm, insoluble matter ≤ 146ppm, and iron ≤ 2ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com