Method and device for preparing lithium hexafluorophosphate through dynamic crystallization

A technology of lithium hexafluorophosphate and crystallization, which is applied in the directions of lithium hexafluorophosphate, chemical instruments and methods, lithium compounds, etc., can solve the problems of long crystallization time and uneven growth of crystal particles, and achieves simple structure, improved production efficiency and product quality, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

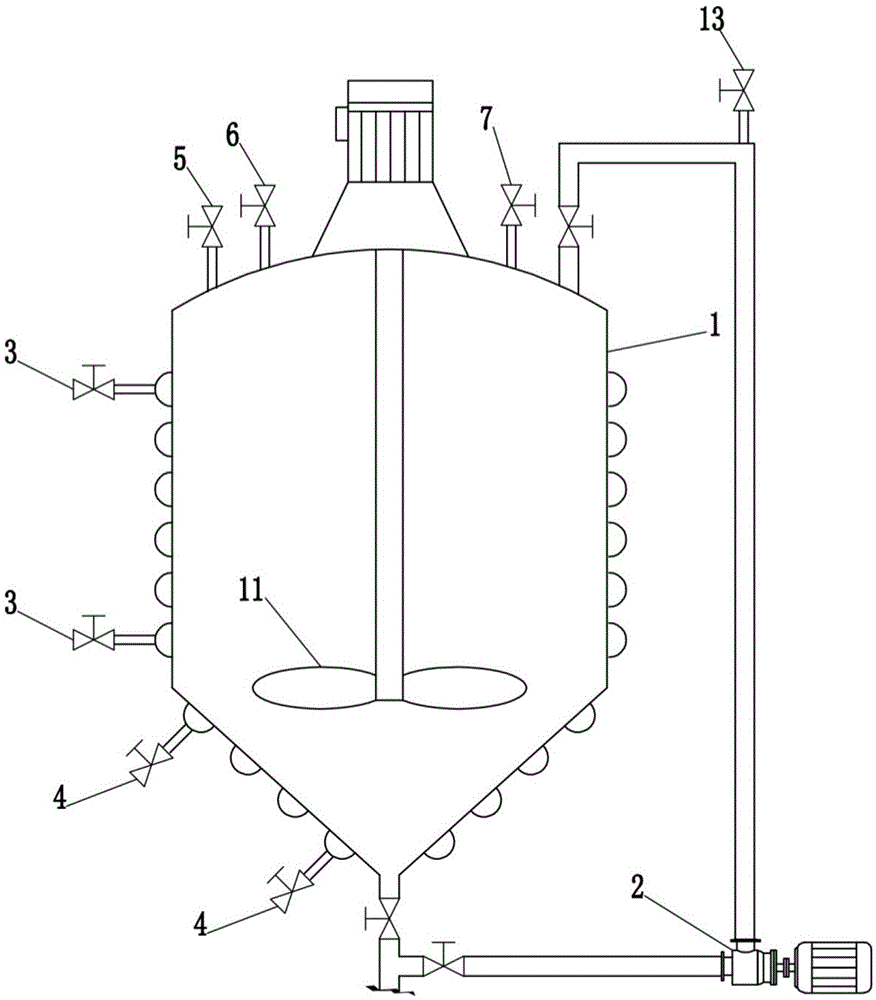

[0038] The dynamic crystallization of the present embodiment prepares the device of lithium hexafluorophosphate, such as figure 1As shown, it includes a crystallization kettle 1 with a stirring device 11, and the outside of the crystallization kettle is provided with an external circulation pipeline 2 connected to the upper and lower parts of the crystallization kettle respectively, so as to realize the circulating flow of materials inside and outside the crystallization kettle. An ultrasonic probe 13 is provided on the outer circulation pipeline to realize ultrasonic-induced nucleation in the initial stage of crystallization, and a circulation pump is also provided; the upper peripheral panel of the crystallization kettle is provided with a refrigerant pipeline 3 for controlling the cooling rate, and the lower peripheral panel is provided with a heat sink. The medium pipe 4 is used to make a little crystal on the inner wall of the kettle come off, and simultaneously make the s...

Embodiment 2

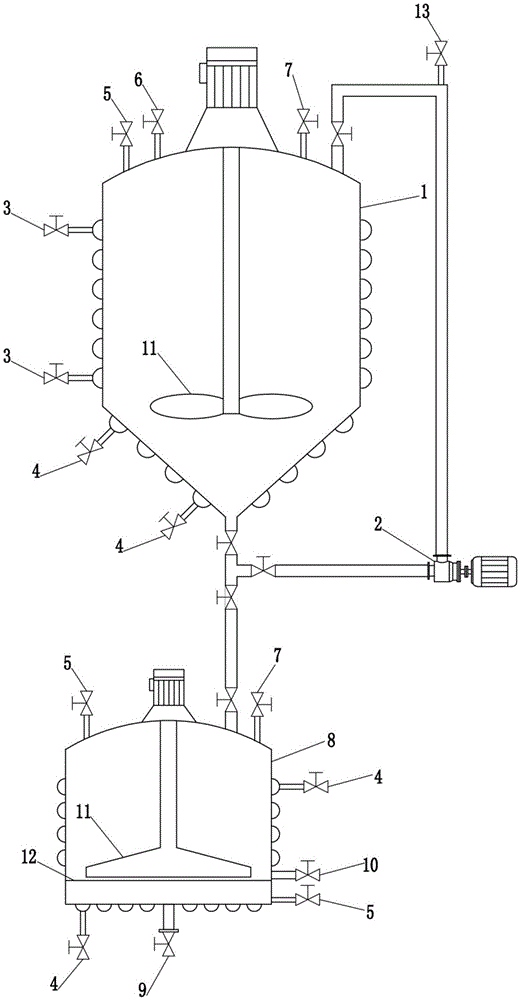

[0041] The dynamic crystallization of the present embodiment prepares the device of lithium hexafluorophosphate, such as figure 2 As shown, the structure of the crystallization kettle is the same as that in Example 1, and also includes a filter drying integrated machine 8, which is used to simultaneously realize filter drying of the lithium hexafluorophosphate suspension obtained after dynamic crystallization; The liquid port is connected. The all-in-one filtering and drying machine includes a shell, and a filter plate 12 is arranged at the bottom of the inside of the shell, and a stirring device 11 located above the filter plate is arranged inside the shell, and a heat medium pipeline 4 is arranged on the outer plate of the shell. An inert gas inlet 5 and a waste gas outlet 7 are provided at the upper end of the filtering and drying integrated machine 8, a filtrate outlet 9 is provided at the lower end, and a finished product outlet 10 is provided at the side, and its height...

Embodiment 3

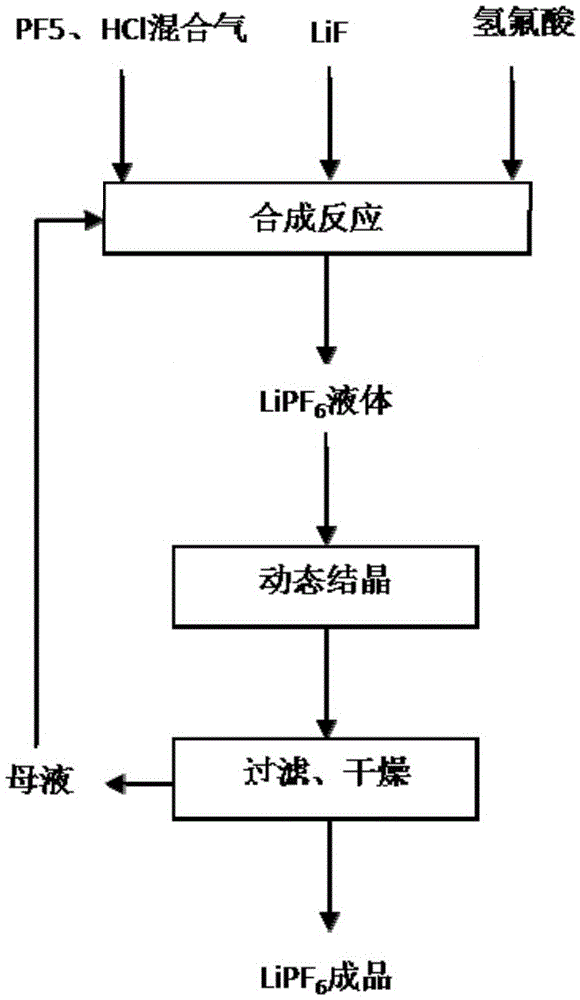

[0044] The method for preparing lithium hexafluorophosphate by dynamic crystallization in this embodiment, the process flow is as follows image 3 As shown, the device used is as figure 2 shown, including the following steps:

[0045] 1) Inject the hydrogen fluoride liquid into the reaction kettle that has been added with 1.2 tons of phosphorus pentachloride, wherein the weight ratio of hydrogen fluoride liquid: phosphorus pentachloride is 1:1, and hydrogen fluoride reacts with phosphorus pentachloride at 80°C and 0.18MPa Produce a mixed gas of phosphorus pentafluoride and hydrogen chloride;

[0046] 2) Pass the mixed gas obtained in step 1) into the reaction kettle that has been added with lithium fluoride and hydrogen fluoride liquid, the dosage of lithium fluoride is 0.126 tons, and react at 10°C and 0.1MPa to obtain A total of 7.776 tons of lithium hexafluorophosphate solution, hydrogen chloride gas is regularly discharged and absorbed by water to produce hydrochloric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com