Preparation method for growing perovskite single crystal by liquid-phase diffusion separation crystallization at room temperature

A liquid phase diffusion and perovskite technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems affecting human health and environmental protection, high sealing requirements of the reaction system, and slow solvent volatilization speed, etc., to achieve low The effect of carrier recombination rate, non-toxic and non-volatile, and huge application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method is as follows:

[0041] (1) Lead bromide and methylamine hydrobromide (CH 3 NH 3 Br, MABr) was added to dimethylformamide (DMF) solvent at a molar ratio of 1:1, dissolved at room temperature, prepared into a 0.8mol / L solution, and then filtered with a 0.22 micron filter head to obtain a saturated precursor solution;

[0042] (2) Add the precursor solution into the sample bottle, the height of the liquid level is about 3mm, and add 3mL of silicone oil on the upper layer of the precursor solution;

[0043] (3) Place the sample bottle on a heating stage at 35 degrees Celsius, place it for 72 hours, and obtain MAPbBr with a thickness of about 50 microns at the bottom of the solution 3 single crystal.

[0044] figure 1 The entire preparation process is shown. figure 2 a) is the resulting MAPbBr 3 Scanning electron microscope (SEM) image of a perovskite single crystal, inset showing a thickness of about 50 micrometers.

Embodiment 2

[0046] The preparation method is as follows:

[0047] (1) Lead bromide and methylamine hydrobromide (CH 3 NH 3 Br, MABr) was added to the dimethylformamide (DMF) solvent at a molar ratio of 1:1, dissolved at room temperature, prepared into a 1.6mol / L solution, and then filtered with a 0.22 micron filter head to obtain a saturated precursor solution;

[0048] (2) Add the precursor solution to the sample bottle, and add silicone oil (3ml) to the upper layer of the precursor solution;

[0049] (3) Place the sample bottle on a heating stage at 35 degrees Celsius for 72 hours, and obtain about 0.5 cm of MAPbBr at the bottom of the solution 3 single crystal.

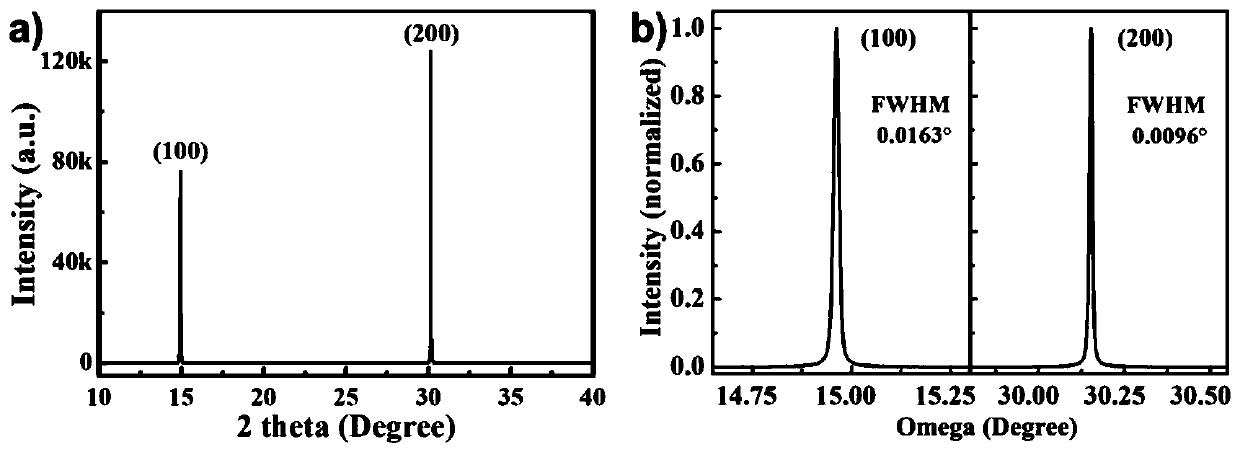

[0050] figure 2 b) is the resulting MAPbBr 3 Optical photograph image of a perovskite single crystal, about 0.5 cm in size. image 3 is the resulting MAPbBr 3 X-ray diffraction pattern of perovskite single crystal, a) is 2θ diffraction curve, b) is MAPbBr 3 The rocking curves of single crystals (100) and (200); the F...

Embodiment 3

[0052] The preparation method is as follows:

[0053] (1) Lead chloride and methylamine hydrochloride (CH 3 NH 3 Cl, MACl) was added to a mixed solvent of dimethylformamide (DMF) and dimethyl sulfoxide at a molar ratio of 1:1, dissolved at room temperature, prepared into a 0.9mol / L solution, and then filtered with 0.22 microns Obtain a saturated precursor solution after head filtration;

[0054] (2) Add the precursor solution to the sample bottle, and add silicone oil (3mL) to the upper layer of the precursor;

[0055] (3) Place the sample bottle on a heating stage at 35 degrees Celsius, place it for 72 hours, and obtain MAPbCl at the bottom of the solution 3 single crystal.

[0056] Figure 5 On the left is MAPbCl 3 Optical photograph of a single crystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Band gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com