Liquid state coal-saving additive

A technology of coal-saving additive and liquid state is applied in the field of coal-fired additives for boilers, which can solve the problems of pipeline corrosion of boiler water-cooled wall reheater, difficulty in fully mixing coal combustion, and increase environmental pollution, etc., so as to shorten the ignition delay time and achieve stable properties. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

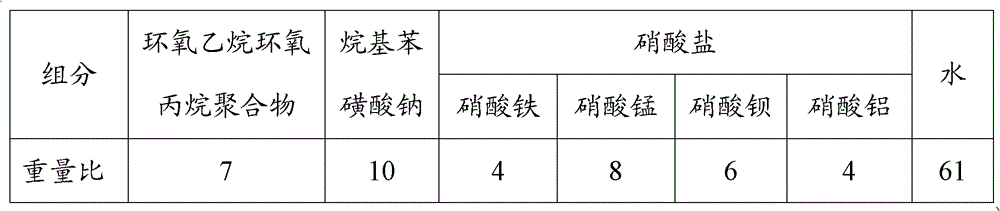

[0020] The components and weight ratios of this embodiment are shown in the following table:

[0021]

[0022] The additive of the above formula is mixed with coal at a ratio of 3 / 10,000, and the thermal efficiency is increased by 7.4% during the combustion process, and the furnace temperature is increased by 140°C.

Embodiment 2

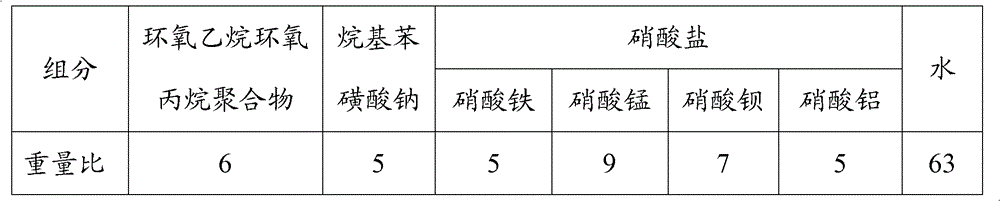

[0024] The components and weight ratios of this embodiment are shown in the following table:

[0025]

[0026] The additive of the above formula is mixed with the coal at a ratio of 3 / 10,000, the thermal efficiency is increased by 6.2% during the combustion process, and the furnace temperature is increased by 145°C.

Embodiment 3

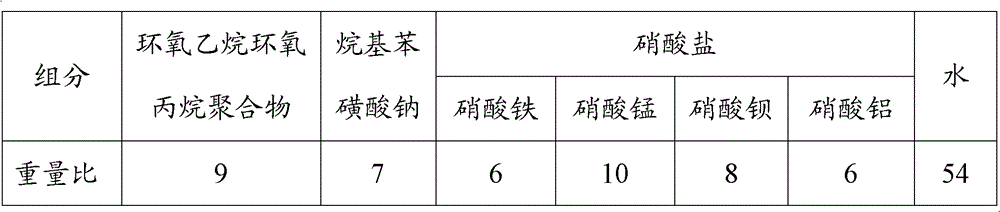

[0028] The components and weight ratios of this embodiment are shown in the following table:

[0029]

[0030] The additive of the above formula is mixed with coal at a ratio of 3 / 10,000, the thermal efficiency is increased by 6.6% during the combustion process, and the furnace temperature is increased by 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com