Cooling crystallization device

A technology of cooling crystallization and cooling cover, applied in the direction of heat exchange cooling crystallization, solution crystallization, etc., can solve the problems of low crystallization efficiency, many impurities in crystallization products, and poor product stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

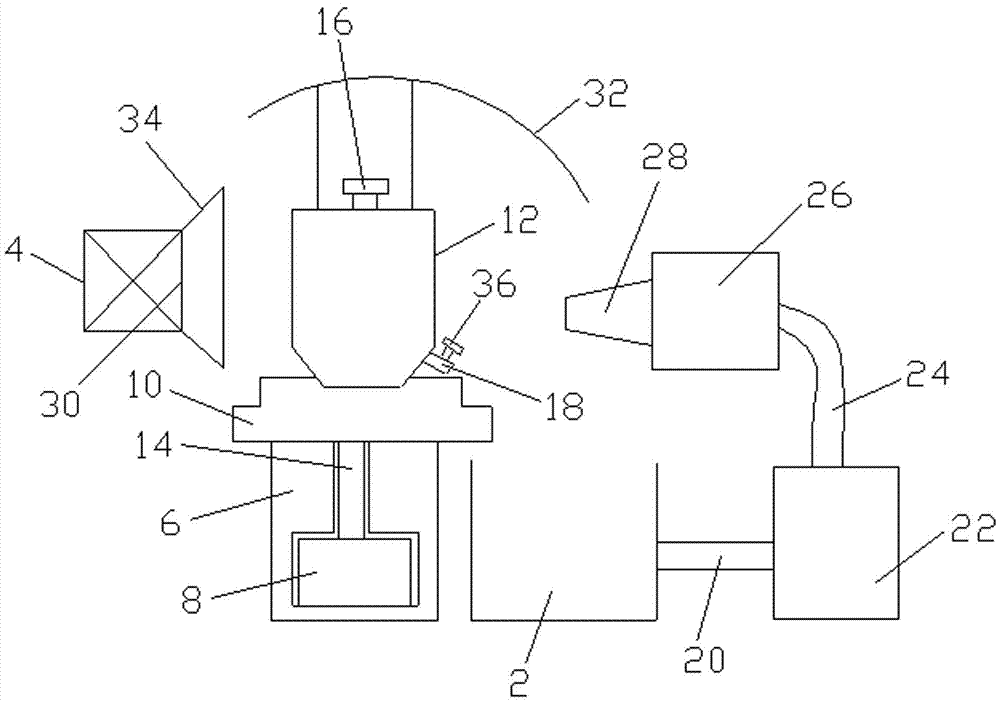

[0013] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0014] Such as figure 1 As shown, a cooling crystallization device includes a liquid storage tank 2, a fan 4, a base 6, a motor 8 installed in the base 6, a bracket 10 positioned on the base 6, and a tank body 12 installed on the bracket 10, the motor 8 The output shaft 14 extends out of the base 6 and is fixed to the bracket 10. The upper and lower ends of the tank body 12 are respectively provided with a feed port 16 and a discharge port 18. The liquid storage tank 2 is connected with a refrigerator 22 through a first branch pipe 20. The refrigerator 22 is connected to the atomizer 26 through the second branch pipe 24, and the atomizing noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com